1 Prof. Dr. George Kaptay List of publications ... - Miskolci Egyetem

1 Prof. Dr. George Kaptay List of publications ... - Miskolci Egyetem

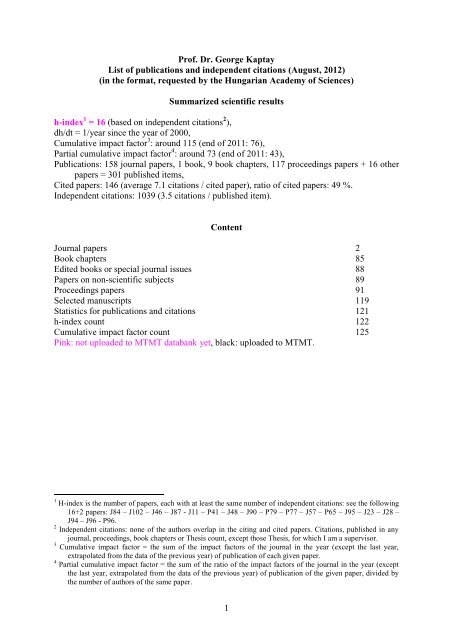

1 Prof. Dr. George Kaptay List of publications ... - Miskolci Egyetem

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

J.145. G. <strong>Kaptay</strong>: On the atomic masses (weights?) <strong>of</strong> the elements, J. Min. Metall. B, 2012,vol.48, pp. 153-159 (2011-IF = 1.317).J144. G.<strong>Kaptay</strong>: Interfacial Forces in Dispersion Science and Technology - Journal <strong>of</strong>Dispersion Science and Technology, 2012, vol.33, pp.130-140 (2011-IF = 0.560).J143. G.<strong>Kaptay</strong>: On the optimum contact angle <strong>of</strong> stability <strong>of</strong> foams by particles – Advancesin Colloid and Interface Science, 2012, vol.170, pp. 87-88 (2011-IF = 8.120).J.142. G.<strong>Kaptay</strong>: The conversion <strong>of</strong> phase diagrams <strong>of</strong> solid solution type intoelectrochemical synthesis diagrams for binary metallic systems on inert cathodes -Electrochimica Acta, 2012, vol.60, pp.401-409. (2011-IF = 3.832)J.141. Y. Tang, Y. Du, L. Zhang, X. Yuan, G.<strong>Kaptay</strong>: Thermodynamic description <strong>of</strong> the Al–Mg–Si system using a new formulation for the excess Gibbs energy – Thermochimica Acta,2012, vol.527, pp.131-142. (2011-IF = 1.805).J.140. G.<strong>Kaptay</strong>: On the tendency <strong>of</strong> solutions to tend toward ideal solutions at hightemperatures – Metall Mater Trans A, 2012, vol.43, pp. 531-543. (2011-IF = 1.545).J.139. G.<strong>Kaptay</strong>: Interfacial phenomena in producing metallic materials. Part 5: Theinterfacial spreading force (in Hungarian). – BKL Kohászat, 2011., vol.144., No.5., pp. 9-13.(IF = 0)J.138. G.<strong>Kaptay</strong>: On the five base quantities <strong>of</strong> nature and SI (The International system <strong>of</strong>Units) – JMM B, 2011, vol47, No.2, pp.241-246. (IF = 1.317).J138-c1. KW Craig: No child left behind: teaching the metric system in US schools – Int J Appl Sci Technol,2012, vol.2, No.4, pp.40-48. – „Although there are seven base units in SI, “it is claimed that five is thesmallest number <strong>of</strong> base quantities that is sufficient to define all derived quantities and allows thedescription <strong>of</strong> all natural phenomena … length, mass, time, temperature and electric charge … The firstfour … coincide with the current list <strong>of</strong> base quantities in SI” (<strong>Kaptay</strong>, 2011, p. 242). There is a proposalto replace electric current with electric charge and to eliminate both the amount <strong>of</strong> substance andluminous intensity.” – p.41.J.137. D.Madarasz, I.Budai, G.<strong>Kaptay</strong>: Fabrication <strong>of</strong> SiC-particles shielded Al-spheres uponrecycling Al/SiC composites – Metal Mater Trans A, 2011, Volume 42, Number 6, 1439-1443 (IF = 1.545).J137-c1. Baumli P.: Fémmátrixú kompozitok előállítása öntészeti módszerekkel – CD-Proc. <strong>of</strong> 26. Int. Sci. Conf.microCAD, 29-30 March, 2012. – „A NaCl-KCl-KF típusú sókeverékkel az alumínium olvadékban lévőSiC szemcsék is eltávolíthatóak [J137].” – 4.o.J136. I.Budai, O.Z.Nagy, G.<strong>Kaptay</strong>: Inversion <strong>of</strong> a liquid Bi/Al metallic emulsion stabilizedby solid SiC particles, Coll Surf A, 2011, vol.377, pp.325-329 (IF = 2.236)J.135. O.Verezub, Z.Kálazi, A.Sytcheva, L.Kuzsella, G.Buza, N.V.Verezub, A.Fedorov,G.<strong>Kaptay</strong>: Performance <strong>of</strong> a cutting tool made <strong>of</strong> steel matrix surface nano-compositeproduced by in-situ laser melt injection technology – J Mater Process Technol., 2011, vol.211,pp.750-758 (IF = 1.783)3

J135-c1. Baumli P.: Fémmátrixú kompozitok előállítása öntészeti módszerekkel – CD-Proc. <strong>of</strong> 26. Int Sci ConfmicroCAD, 29-30 March, 2012. – „Lézer segítségével felületi kompozitok állíthatóak elő. Ebben azesetben a mátrix anyagául szolgáló fém felületét lézerrel megolvasztják, és az így kialakult fémtócsábamegfelelő sebességgel lövik az erősítő fázisnak szánt szemcséket [J135].” – 4.o.J135-c2. C.W.Rejil, I.Dinaharan, S.J.Vijay, N.Murugan: Microstructure and sliding wear behavior <strong>of</strong>AA6360/(TiC+B4C) hybrid surface composite layer synthesized by friction stir processing on aluminumsubstrate. Mater Sci Eng A, 2012, vol.552, pp.336-344. „SCLs (surface composite layers) are fabricatedusing conventional liquid phase processing methods such as high energy laser melt injection [J135], etc…„ – p.336.J134. I.Budai, G.<strong>Kaptay</strong>: Monotectic Al/Cd alloys with homogeneously dispersed Cd-dropletsstabilized by strontium aluminide precipitates – Intermetallics, 2011, vol.19. pp.423-425 (IF =1.649).J.133. <strong>Kaptay</strong> Gy.: Határfelületi jelenségek a fémesanyaggyártásban. 4.rész. A határfelületigradiens erő – BKL Kohászat, 2010., 143. évf., 5. szám, 45-54.o. (IF = 0)J.132. G.<strong>Kaptay</strong>: The Extension <strong>of</strong> the Phase Rule to Nano-Systems and on the QuaternaryPoint in One-Component Nano Phase Diagrams - J. Nanosci. Nanotechnol., 2010, vol.10,pp.8164–8170. (IF = 1.352).J.131. M.Reger, B.Vero, I.Kardos, E.R.Fabian, G.<strong>Kaptay</strong>: Diffusion <strong>of</strong> carbon in thecenterline region <strong>of</strong> continuous cast slabs – Mater Sci Forum, 2010, vol.659, pp.441-446 (IF =0)J.130. <strong>Kaptay</strong> Gy.: Határfelületi jelenségek a fémesanyaggyártásban. 3.rész. A görbületindukálta határfelületi erő – BKL Kohászat, 2010., 143. évf., 3. szám, 33-38. (IF = 0)J.129. P.Baumli, J.Sytchev, G.<strong>Kaptay</strong>: Perfect wettability <strong>of</strong> carbon by liquid aluminumachieved by a multifunctional flux. J Mater Sci, 2010, vol.45, pp.5177-5190. (IF = 1.859).J129-c1. I.N.Orbulov: Infiltration <strong>of</strong> ceramic microballons by liquid metals – research plan for SCIEX-NMS,February, 2011, 12 pp. – „There are many papers in the pr<strong>of</strong>essional literature which are dealing withthe phenomenon <strong>of</strong> infiltartion [J129]” – p.9.J129-c2. Lévai Gábor (tud. vez.: dr. Török Tamás): Acéllemezek színes tűzi horganyzása, 6. doktoriszeminárium, 2011, június 14., 28 oldal. – “<strong>Kaptay</strong> és mtsai több alkalommal publikáltak pozitíveredményeket alumíniumnak K 2 TiF 6 sóval történő ötvözéséről [129]”. – p.19.J129-c3. W.Xi, R.L. Peng, W. Wu, N. Li, S. Wang, S. Johansson: Al2O3 nanoparticle reinforced Fe-based alloyssynthesized by thermite reaction – J Mater Sci, 2012, vol.47, pp.3585-3591 – „Many studiesdemonstrate that a low interfacial energy between ceramic particles and metal matrix is the mostimportant condition for obtaining homogeneous distribution <strong>of</strong> ceramic particles in the metal matrixwhen a metal matrix components is produced by solidification process [J129]” – p.3588.J.128. Á.E. Horváth, F. Járai-Szabó, G.<strong>Kaptay</strong>, R.Vajtai, Z.Néda: Pattern formation andselection in nanotube arrays - Univ Polit Bucharest Sci Bull – Ser A - Appl Math Phys, 2010,vol.72, Iss.1, pp.27-32. (IF = 0.253).J.127. I.Budai, G.<strong>Kaptay</strong>: Wettability <strong>of</strong> SiC and alumina particles by liquid Bi under liquidAl – J. Mater Sci, 2010, vol.45, pp.2090-2098. (IF = 1.859)J127-c1. I.Kaban, M.Köhler, W.Hoyer, L.Ratke: Catalytic efficiency <strong>of</strong> oxide particles on heterogeneousnucleation in aluminium alloy with miscibility gap – Hig Temperatures – High Pressures, 2010, vol.39,pp.347-355. – „In this case, the advancing contact angle is around 10 degrees and the receeding contactangle is around zero, which correlates with the results <strong>of</strong> work [J127] were the perfect wetting <strong>of</strong> aluminaby Bi- and Pb-rich phase has been reported” – p.352.4

J127-c2. I.Kaban, M.Köhler, L.Ratke, W.Hoyer, N.Mattern, J.Eckert, A.L.Geer: Interfacial tension, wetting andnucleation in Al-Bi and Al-Pb monotectic alloys – Acta mater, 2011, vol.59, pp. 6880-6889 – „Budai and<strong>Kaptay</strong> [J127] found that Al 2 O 3 particles were perfectly wetted by the Bi-rich phase in a solidified Al-Bialloy.” – p.6881.J.126. <strong>Kaptay</strong> Gy.: Határfelületi jelenségek a fémesanyaggyártásban. 2.rész. A határfelületiösszehúzó erő – BKL Kohászat, 2009., 142. évf., 6. szám, 37-46. (IF = 0)J.125. J.Sytchev, G.<strong>Kaptay</strong>: Influence <strong>of</strong> alkali metal on the erosion <strong>of</strong> a graphite cathode andmorphology <strong>of</strong> carbon nanotubes – Electrochim Acta, 2009, vol.54, pp. 6725-6731. (IF =3.325)J125-c1. C.Schwandt, A.T.Dimitrov, D.J.Fray: The preparation <strong>of</strong> nano-structured carbon materials byelectrolysis <strong>of</strong> molten lithium chloride at graphite electrodes – J Electroanal Chem, 2010, vol.647, pp.150-158 – „<strong>Kaptay</strong> and co-workers also investigated the electrolytic preparation method. Carbonaceousproducts were prepared by using various molten salt electrolytes and fundamental studies likewisesuggested alkali metal intercalation into graphite as an essntial step <strong>of</strong> the process [J125]” – p.151J125-c2. A.R.Kamali, D.J.Fray, C.Schwandt: Thermokinetic characterisation <strong>of</strong> lithium chloride – J Therm AnalCalorim, 2011, vol.104, pp.619-626. “More recent investigations have shown that intercalation <strong>of</strong> lithiuminto graphite may also proceed at elevated temperatures as high as 625 to 900 C [J125]” – p.619.J125-c3. AR Kamali, C Schwandt, DJ Fray: Effect <strong>of</strong> graphite electrode material on the characteristics <strong>of</strong> moltensalt electrolitically produced carbon nanomaterials – Mater Charact, 2011, vol.62, pp. 987-994. –„Fundamental investigations have reveasled that the molten salt electrolytic formation <strong>of</strong> carbonnanomaterials commences with the intercalation <strong>of</strong> alkali metal from the molten salt electrolyte into thegraphitic cathode [J125]” – p.987.J125-c4. C.Schwandt, AT Dimitrov, DJ Fray: High yield synthesis <strong>of</strong> multi-walled carbon nanotubes fromgraphite by molten salt electrolysis – Carbon, 2012, vol.50, pp. 1311-1315 – „It is generally accepted thatthe first step <strong>of</strong> the cathodic reduction is the intercalation <strong>of</strong> the alkali metal into the spacings between thegraphitic layers and the formation <strong>of</strong> intercalation compounds, MeC x [J125]” – p.1311.J125-c5. A. Juhasz-Szalai, E. Kiss-Toth-Dojcsak, P. Koska, J. Szebeni, B. Fodor: Characteristic features <strong>of</strong>carbon nanotubes and their application in living systems – Egészségtudományi Közlemények, 2012,vol.2, No.1, pp.105-111 – “Several techniques have been developed for the synthesis <strong>of</strong> CNTs,including …. molten chloride electrolysis [J125]…” – p.106.J125-c6. Hui Huang, Yang Xia, Xinyong Tao, Jun Du, Junwu Fang, Yongping Gan and Wenkui Zhang:Highly efficient electrolytic exfoliation <strong>of</strong> graphite into graphene sheets based on Li ions intercalation–expansion–microexplosion mechanism - J. Mater. Chem., 2012, vol.22, pp. 10452-10456.J125-c7. A.R. Kamali, G. Divitini, C. Schwandt, D.J. Fray, Correlation between microstructure andthermokinetic characteristics <strong>of</strong> electrolytic carbon nanomaterials, Corrosion Science (2012), doi:http://dx.doi.org/ - „…the reaction commences with the diffusion-controlled intercalation <strong>of</strong> Li into thebulk <strong>of</strong> the graphite cathode, and it has also been considered that Li is simply deposited onto the surface<strong>of</strong> the graphite cathode in case the rate <strong>of</strong> Li generation is faster than that <strong>of</strong> Li inward diffusion[J125].”J.124. O. Verezub, Z. Kálazi, G. Buza, N. V. Verezub, G. <strong>Kaptay</strong>: Classification <strong>of</strong> laserbeam induced surface engineering technologies and in situ synthesis <strong>of</strong> steel matrix surfacenanocomposites - Surface Engineering, 2011, vol.27, No.6, pp. 428-435 (2010-IF = 0.633)J.123. <strong>Kaptay</strong> György: Határfelületi jelenségek a fémesanyaggyártásban. 1. rész. Ahatárfelületi erők osztályozása. BKL Kohászat, 2009., 142. évf., 3. szám, 39-46.o.Helyreigazítás: 2009., 142. évf., 5. szám, 43. o.J.122. O. Verezub, Z. Kálazi, G. Buza, N.V. Verezub, G. <strong>Kaptay</strong>: In-situ synthesis <strong>of</strong> acarbide reinforced steel matrix surface nanocomposite by laser melt injection technology andsubsequent heat treatment, Surface & Coatings Technology, 2009, vol. 203, pp.3049-3057.(IF = 1.793)5

J122-c1. E.Laszlo, A.Sytcheva, J.Szucs: <strong>Dr</strong>illing <strong>of</strong> aluminium alloys and composites – Diáktudomány, A<strong>Miskolci</strong> <strong>Egyetem</strong> tudományos diákköri munkáiból, 2010, Miskolc, pp.87-98, ISBN 978-963-661-932-9 –“A kompozitok és nano-kompozitok fejlesztése az egyik fontos mérnöki feladat anyagtudomány ésgépgyártástechnológia határterületén [J122]”.J122-c2. M.J.Hamedi, M.J.Torkamany, J.Sabbaghzadeh: Effect <strong>of</strong> pulsed laser parameters on in-situ TiCsynthesis in laser surface treatment – Opt Lasers Eng, 2011, vol.49, pp.557-563. – “Recently, theapplications <strong>of</strong> the titanium carbide (TiC) composites have been increased … [J122]..” – p.557.J122-c3. B.S. Yilbas, S.S. Akhtar, A. Matthews, C. Karatas: Laser treatment <strong>of</strong> carbon film coated steel surface,Surface Eng, 2012, vol.28, No.1, pp.57-67.J122-c4. Baumli P.: Fémmátrixú kompozitok előállítása öntészeti módszerekkel – CD-Proc. <strong>of</strong> 26. Int Sci ConfmicroCAD, 29-30 March, 2012. – „Lézer segítségével felületi kompozitok állíthatóak elő. Ebben azesetben a mátrix anyagául szolgáló fém felületét lézerrel megolvasztják, és az így kialakult fémtócsábamegfelelő sebességgel lövik az erősítő fázisnak szánt szemcséket [J122].” – 4.o.J122-c5. A.P.I. Popoola, B.A. Obadele, O.M. Popoola: Effects <strong>of</strong> TiC-particulate distribution in AISI 304Lstainless steel matrix - Digest Journal <strong>of</strong> Nanomaterials and Biostructures, 2012, vol. 7, No. 3, pp. 1245 –1252. „In the present investigations, TiC particulate reinforced austenitic stainless steel has beenfabricated using laser processing. Lately, the applications <strong>of</strong> carbides especially titanium carbide (TiC)composites have increased. This is as a result <strong>of</strong> the new and promising materials for wearresistant partsand high temperature engineering structural components [J122], high specific strength, low density andhigh elastic modulus.” – p.1246.J.121. I.Budai, G.<strong>Kaptay</strong>: A new class <strong>of</strong> engineering materials: particles stabilized metallicemulsions and monotectic alloys, Metall. Mater Trans A, 2009, vol.40A, pp.1524-1528. (IF =1.564)J121-c1. S.E.Friberg: Foams from Non-aqueous systems – Curr Opinion Coll Interface Sci, 2010, vol.15,pp.359-364 – “The analysis <strong>of</strong> stability and general properties <strong>of</strong> solid foams, on the other hand, hasgained a separate place in the scientific literature against the fact that their properties are as muchdependent on details <strong>of</strong> their preparation and manufacturing as on basic collid phenomena and the latterhave first been adequately examined [J121].” – p.359, “In the area <strong>of</strong> metallic foams truly significantprogress was made by <strong>Kaptay</strong> and collaborators [121]….” – p. 362.J121-c2. I.Kaban, M.Köhler, W.Hoyer, L.Ratke: Catalytic efficiency <strong>of</strong> oxide particles on heterogeneousnucleation in aluminium alloy with miscibility gap – Hig Temperatures – High Pressures, 2010, vol.39,pp.347-355. – “Unfortunately, there are practically no data on the wetting <strong>of</strong> solids at the liquid-liquidinterfaces in metallic monotectic alloys (a short view <strong>of</strong> the state <strong>of</strong> the art can be found in the recent work<strong>of</strong> Budai and <strong>Kaptay</strong> [J121])” – p.348. „In this case, the advancing contact angle is around 10 degrees andthe receeding contact angle is around zero, which correlates with the results <strong>of</strong> work [J121] were theperfect wetting <strong>of</strong> alumina by Bi- and Pb-rich phase has been reported” – p.352.J121-c3. I.Kaban, M.Köhler, L.Ratke, W.Hoyer, N.Mattern, J.Eckert, A.L.Geer: Interfacial tension, wetting andnucleation in Al-Bi and Al-Pb monotectic alloys – Acta mater, 2011, vol.59, pp.6880-6889 – „Budai and<strong>Kaptay</strong> [J121] found that Al 2 O 3 particles were perfectly wetted by the Bi-rich phase in a solidified Al-Bialloy. On the other hand, the contact angle with SiC particles at the interface between two solid phases inan Al-Bi-Si alloy was about 90 o [J121]” – p.6881.J121-c4. T.Frolov, KA Darling, LJ Kecskes, Y.Mishin: Stabilization and strengthening <strong>of</strong> nanocrystalline copperby alloying with tantalum – Acta Mater, 2010, vol.60, pp. 2158-2168 – “Alloying with immiscibleelemenets is a promising approach to the design <strong>of</strong> materials with extraordinary structural stability andmechanical strength at high temperatures [J121]” – p.2158.J.120. T.Gábor, F.H.Kármán, J.Sytchev, E.Kálmán, G.<strong>Kaptay</strong>: The separation <strong>of</strong> carbonnanotubes from chlorides – Carbon, 2009, vol.47, pp.1195-1198. (IF = 4.504)J120-c1. C.Schwandt, A.T.Dimitrov, D.J.Fray: The preparation <strong>of</strong> nano-structured carbon materials byelectrolysis <strong>of</strong> molten lithium chloride at graphite electrodes – J Electroanal Chem, 2010, vol.647, pp.150-158 – „The separation <strong>of</strong> the nano-structured components from residual salt and unreacted graphite needsto be optimized. In this context, the suitability <strong>of</strong> a recently developed extraction technique using ethilacetate [J120] will be ascertained” – p.158J120-c2. Graham KA, Kulawiec M, Owens KM, Li XR, Desouki MM, Chandra D, Singh KK: NADPH oxidase4 is an oncoprotein localized to mitochondria, CANCER BIOLOGY & THERAPY 10: (3) Paper 12207.(2010)J120-c3. A. Juhasz-Szalai, E. Kiss-Toth-Dojcsak, P. Koska, J. Szebeni, B. Fodor: Characteristic features <strong>of</strong>carbon nanotubes and their application in living systems – Egészségtudományi Közlemények, 2012,6

vol.2, No.1, pp.105-111 – “Several techniques have been developed for the synthesis <strong>of</strong> CNTs,including …. molten chloride electrolysis [J120]…” – p.106.J.119. O.N.Verezub, G.<strong>Kaptay</strong>, G.Buza, N.V.Verezub: The modification <strong>of</strong> surface layers <strong>of</strong>materials by laser alloying method. Part II. Laser melt injection technology <strong>of</strong> instrumentalcarbon steels - Journal <strong>of</strong> Functional Materials, 2008, vol.2, No.4, pp.137-143. (in Russian).(IF = 0)J.118. O.N.Verezub, G.<strong>Kaptay</strong>, G.Buza, N.V.Verezub: The modification <strong>of</strong> surface layers <strong>of</strong>materials by laser alloying method. Part I. Journal <strong>of</strong> Functional Materials, 2008, vol.2, No.3,pp.82-91. (in Russian). (IF = 0)J.117. P.Baumli, G.<strong>Kaptay</strong>: Wettability <strong>of</strong> carbon surfaces by pure molten alkali chlorides andtheir penetration into a porous graphite substrate – Mater Sci Eng A, 2008, vol.495, pp.192-196. (IF = 1.860)J117-c1. J.F.Cooper J.R.Selman: Electrochemical Oxidation <strong>of</strong> Carbon for Electric Power Generation: A Review– Abstract Book <strong>of</strong> the 214th Meeting <strong>of</strong> the Electrochemical Society, October 2008http://ecsmeet7.peerxpress.org/ms_files/ecsmeet7/2008/12/15/00001942/00/1942_0_art_0_kbxyy3.pdf -„A recent study <strong>of</strong> graphite wetting in molten chlorides indicates strong dependence on cationiccomposition and temperature [J117]”J117-c2. N.Esutathopoulos, B.<strong>Dr</strong>evet, S.Brandon, A.Virozub: Basic principles <strong>of</strong> capillarity in relation to crystalgrowth – Chapter 1 in: Crystal Growth Processes Based on Capillarity: Czochralski, Floating Zone,Shaping and Crucible Techniques, ed. by T.Duffar, 2010, John Wiley and Sons Ltd. – „Thethermodynamic adhesion <strong>of</strong> molten halides on carbon is weak, as ensured solely by physical interactions[J117]. From modeling molten halide / graphite interactions, it was shown that for the same type <strong>of</strong>halides (for instance chlorides), when the surface tension decreases, the work <strong>of</strong> adhesion increasesrapidly. According to the Young-Dupré equation, this implies a strong decrease in the contact angle(Table 1.8). Table 1.8 Reprinted with permission from [J117], copyright 2008 Elsevier Ltd.” – p.27.J117-c3. X. Liu, Z. Wang, S. Zhang: Molten Salt Synthesis and Characterization <strong>of</strong> Titanium Carbide-CoatedGraphite Flakes for Refractory Castable Applications – Int J Appl Ceram Technol, 2011, vol. 8, pp.911-919 – „Among the three molten salts, NaCl has the highest viscosity and wets graphite poorly [J117];therefore, the transport <strong>of</strong> Ti to the surface <strong>of</strong> graphite will be hindered considerably. Although LiCl hasthe lowest viscosity it does not wet graphite [J117] and consequently the delivery <strong>of</strong> Ti to the reactionsites on the graphite surface becomes difficult. Differently from these two molten salts, KCl wets graphitewell [J117] and has a low viscosity which facilitates the diffusion <strong>of</strong> Ti species in it and thus the rapid TiCcoating formation. Thanks to the useful properties <strong>of</strong> KCl salt mentioned above, the KCl–LiCl eutecticsalt was also effective in the MSS <strong>of</strong> TiC coatings”. p.914.J117-c4. I.N.Orbulov, I.Kientzl, J.T.Blücher, Á.Németh, J.Dobránszky, J.Ginsztler: Production and investigation<strong>of</strong> a metal matrix composite pipe – in: Proc <strong>of</strong> 14th European Conf on Composite Materials, Paper ID:262-ECCM14, 8 pp. – „Efforst have been done to reduce the contact angle either by coating <strong>of</strong> the fibersor by using three component reinforcement – salt – matrix systems [J117]” – p.2.J117-c5. Kientzl I.: Alumíniummátrixú kompozithuzalok és kettős kompozit-szerkezetek – PhD értekezés, BME(tud. vez.: dr.Dobránszky János), 2010, 112.o. – „.. ha a porózus test egyforma, szorosan pakoltgömbökből van kirakva, akkor a kritikus peremszög 50,7 o [], amire az első kísérleti bizonyítékBaumlitől származik [J117]” – 20.o.J117-c6. I.N.Orbulov, Á.Németh: Infiltration characteristics <strong>of</strong> carbon fiber reinforced MMCs – Mater SciForum, 2010, vol.659, pp.229-234. – „Effort have been done to reduce the contact angle either by coatingfibers or by using three component reinforcement – salt – matrix system [J117]” – p. 230.J117-c7. Youliang Cheng, Tiehu Liy, Xianliang Hou, Deqi Jing, Qiang Zhuang, Tingkai Zhao: Effects <strong>of</strong> AlCl 3 -NaCl Content on the Formation <strong>of</strong> Mesocarbon Microbeads – Int J Chem Reactor Eng, 2010, vol.8, NoteS7, pp. 1-12 – „Moreover, due to the low wettability <strong>of</strong> carbon and molten salt [J117], the morphology <strong>of</strong>obtained mesophase spheres gets more regular.” – p.5.J117-c8. Korenko M, Simko F: Measurement <strong>of</strong> Interfacial Tension in Liquid-Liquid High-Temperature Systems– J Chem Eng Data, 2010, vol.55, issue 11, pp. 4561-4573. „Baumli and <strong>Kaptay</strong> [J117] used contact anglemeasurements for the evaluation <strong>of</strong> surface tension and wettability <strong>of</strong> several chlorides (KCl, NaCl, RbCl,CsCl) on graphite and glassy carbon substrates” – p.4570.7

J117-c9. I.N.Orbulov: Infiltration <strong>of</strong> ceramic microballons by liquid metals – research plan for SCIEX-NMS,February, 2011, 12 pp. – „There are many papers int he pr<strong>of</strong>essional literature which are dealing withthe phenomenon <strong>of</strong> infiltartion [J117]” – p.9.J117-c10. Z.Tao, Q.Guo, X.Gao, L.Liu: The wettability and interface thermal resitance <strong>of</strong> copper/graphitesystem with addition <strong>of</strong> chromium – Mater Chem, 2011, vol.128, pp.228-232 – „.. there exists a criticalcontact angle for spontaneous filling the surface pores <strong>of</strong> graphite material. This value is around 50 degwhich has been demonstrated both by theory and experiment [J117]”J.116. C.Mekler, G.<strong>Kaptay</strong>: Calculation <strong>of</strong> surface tension and surface phase transition line inbinary Ga-Tl system – Mater Sci Eng A, 2008, vol.495, pp.65-69. (IF = 1.860)J116-c1. Zoltai László (+Dúl Jenő): Grafitcsírák keletkezési lehetőségének elméleti vizsglata – 3.kutatószemináriumi dolgozat, <strong>Miskolci</strong> <strong>Egyetem</strong>, 2009. február, 48 oldal – „A paraméter a felületirétegben meglévő kötések hányada, ami 1-nél ksiebb pozitív szám, értéke 0,83 [J116]” – 31.o.J116-c2. S.H.Sheng, R.F.Zhang, S.Veprek: Phase stabilities and decomposition mechanism in the Zr-Si-Nsystem studied by combined ab initio DFT and thermodynamic calculation – Acta Mater, 2011, vol.59,pp.297-307 – “The so-called surface phase transition, which has been theoretically predicted by Cahn andrecently elaborated in more detail by <strong>Kaptay</strong> et al [J116], essentially states that the system will decreasethe high surface energy <strong>of</strong> the ionic transition metal nitride by wetting it with covalent Si3N4” – p.305.J116-c3. A.Aqra, A.Ayyad, F.Takrori: Model calculation <strong>of</strong> the surface tension <strong>of</strong> liquid Ga-Bi alloy – Appl SurfSci, 2011, vol.257, pp.3577-3580 – “It should be noted that the surface tension <strong>of</strong> liquid solders may becalculated by means <strong>of</strong> various methods such as Butler method [J116] – p.3578.J116-c4. F.Aqra, A.Ayyad: Theoretical calculations <strong>of</strong> the surface tension <strong>of</strong> Ag-Cu liquid alloys – J AlloysCompounds, 2011, vol.509, pp.5736-5739 – “Many attempts have been made to predict the surfacetension <strong>of</strong> liquid metals and alloys, such as computer simulation with Monte Carlo or molecular dynamicsmethods and models based on Butler's concept [J116]” – p.5736.J116-c5. L.E.Gonzalez, D.J.Gonzalez: Orbital free ab initio simulation <strong>of</strong> surface freezing in a dilute Ga-Tl alloy– Eur. Phys. J. Special Topics, 2011, vol. 196, pp.15-26. – “A theoretical thermodynamic calculation <strong>of</strong>the surface phase transition line, separating the regions where the segregation <strong>of</strong> a Tl-rich nanolayer takesplace or does not take place, has been pursued by Mekler and <strong>Kaptay</strong> [J116]. They obtained goodagreement with the adsorpőtion measurements <strong>of</strong> Shim et al.” - pp.17-18.J.115. G.<strong>Kaptay</strong>: A unified model for the cohesive enthalpy, critical temperature, surfacetension and volume thermal expansion coefficient <strong>of</strong> liquid metals <strong>of</strong> bcc, fcc and hcp crystals– Mater Sci Eng A, 2008, vol.495, pp.19-26. (corrigendum: see Mater Sci Eng A, 2009,vol.501, p.255.) (IF = 1.860)J115-c1. Zoltai László (+Dúl Jenő): Grafitcsírák keletkezési lehetőségének elméleti vizsglata – 3.kutatószemináriumi dolgozat, <strong>Miskolci</strong> <strong>Egyetem</strong>, 2009. február, 48 oldal – „Az irodalmi érték: Fe-g = 2470– 0.32T mJ/, 2 [J115]” – 30.o.J115-c2. A.G.Cherevko: Nukleacionno-fluktuacionnii podhod k opredeleniiu temperaturnoi zavisimostipoverhnostnogo natiazheniia metallov – Kolloidnii zhurnal, 2009, vol.71, No.6, pp.852-859 (Nucleationfluctuationapproach to determining the temperature dependence <strong>of</strong> the surface tension <strong>of</strong> metals – ColloidJournal, 2009, vol.71, No. 6, pp. 869-876) – V rabotach [J115] bili naideni korreliacii poverhnostnogonatiazheniia vblizi temperaturi plavleniia s teplotoi plavleniia i moliarnim obiomom” – p.852.J115-c3. V.Morel, A.Bultel, B.G.Cheron: The critical temperature <strong>of</strong> aluminum – Int J Thermophys, 2009,vol.30, pp.1853-1863 – „Recently, <strong>Kaptay</strong> [J115] has given a unified model linking the cohesive enthalpy <strong>of</strong>a liquid with the melting point <strong>of</strong> alkali metals. This model also yields fairly good results for other metals.The cohesive enthalpy is defined as the energy existing in the liquid resulting from the mutual atomicattractions, which vanishes when the critical temperature is reached… (2 equations)”- p.1858. “Table 4.New estimates <strong>of</strong> the critical temperature for aluminium. Method: cohesive enthalpy, Tc = 6548 K.” –p.1861. “Finally, the recommended critical temperature <strong>of</strong> aluminium, obtained as the average <strong>of</strong> our ownresults and the latter, is 6700 800 K” – p.1862.J115-c4. F.Aqra, A.Ayyad: Theoretical calculations <strong>of</strong> the surface tension <strong>of</strong> liquid transition metals – MetalMater Trans B, 2011, vol.42B, pp.5-8 – “Few published models [J115]… ” – p.7.J115-c5. F.Aqra, A.Ayyad: Surface tension <strong>of</strong> pure liquid bismuth and its temperature dependence: Theoreticalcalculations, Mater Letters, 2011, vol.65, pp.760-762 – “few established models [J115]…” – p.760.J115-c6. F.Aqra, A.Ayyad: Surface energies <strong>of</strong> metals in both liquid and solid states – Appl Surf Sci, 2011,vol.257, pp.6372-6379. – “The surface tension <strong>of</strong> liquids is defined as the ratio <strong>of</strong> the excess surface Gibbs8

energy (expressed through excess surface enthalpy and excess surface entropy) divided by the molar surfacearea: Eq.(17-18) where f is a geometrical constant (approximately = 1.0) [J115]” – p.6375.J115-c7. F.Aqra, A.Ayyad: Surface tension <strong>of</strong> liquid alkali, alkaline, and main group metals: theoreticaltreatment and relationship investigations – Metall Mater Trans A, 2011, vol.42A, pp.2680-2684 –„Establishing an accurate, successful, and universal theoretical model for calculating the surface tension <strong>of</strong>liquid metals is necessary [J115]” – p.2680J115-c8. F.Aqra, A.Ayyad: Theoretical estimation <strong>of</strong> temperature-dependent surface tension <strong>of</strong> liquid antimony,boron and sulfur – Metall Mater Trans A, 2011, vol.42, pp.437-440 – „Few established models are universal[J115], but the agreement with experiment is not satisfactory” – p. 437.J115-c9. F.Aqra, A.Ayyad: Theoretical temperature-dependence surface tension <strong>of</strong> pure liquid gold - MaterLetters, 2011, vol.65, pp.2124-2126 – „… it is still difficult to identify successfull model for which bothaccuracy and universality apply. Although few established models are universal [J115], but the agreementwith experiment is not very satisfactory” – p. 2124.J115-c10. F.Aqra, A.Ayyad: Surface tension, surface energy and crystal-melt interfacial energy <strong>of</strong> metals –Current Applied Phys, 2012, vol.12, pp.31-35 – „… it is still difficult to identify successfull model forwhich both accuracy and universality apply. Although few established models are universal [J115], but theagreement with experiment is not very satisfactory” – p. 34.J115-c11. F.Aqra, A.Ayyad: Surface tension <strong>of</strong> pure liquid lanthanide and early actinide metals – Phys ChemLiquids, 2012, vol.50, pp. 336-345.J.114. P.Baumli, G.<strong>Kaptay</strong>: Wettability <strong>of</strong> carbon surfaces by molten alkali chloride mixtures– Mater Sci Forum, 2008, vol.589, pp.355-359. (IF = 0)J.113. G. Buza, V. Janó, M. Svéda, O. Verezub, Z. Kálazi, G. <strong>Kaptay</strong>, A. Roósz: On thepossible mechanisms <strong>of</strong> porosity formation during laser melt injection (LMI) technology –Mater Sci Forum, 2008, vol.589, pp.79-84. (IF = 0)J.112. G.<strong>Kaptay</strong>: A CALPHAD-compatible method to calculate liquid/liquid interfacialenergies in immiscible metallic systems – Calphad, 2008, vol.32, pp.338-352. (IF = 1.530)J112-c1. J.Lee, S.Min, J.Park: Effect <strong>of</strong> Ce and La on surface property <strong>of</strong> Bi-Cu-Sn alloys – PPT file <strong>of</strong> TOFA2008, June 22-27, Krakow, Poland, 23 slides – „new equation and 2 graphs are taken from paper [J112]” –slide 18.J112-c2. J.Park, S.Min, J.Lee: Effect <strong>of</strong> REM addition on the surface tension and the critical temperature <strong>of</strong> theimmiscible liquid phase separation <strong>of</strong> the 60%Bi-24%Cu-16%Sn alloy – Korean J Mater Res, 2009, vol.19,pp. 111-114. – “Recently, <strong>Kaptay</strong> [J112] suggested a semiempirical equation to predict the interfacialtension between two immiscible liquids based on the models <strong>of</strong> Chatain et al. and Hoyer et al. Simply, theinterfacial tension can be expressed as Eq.(2) … This equation successfully described the interfcial tension<strong>of</strong> the Ga-Pb and Al-Bi systems [J112]” – p.113. “Fig. Cacilated by Eq.(2)” – p.114.J112-c3. J.Li, B.Ma, S.Min, J.Lee, Z.Yuan, L.Zang: Effect <strong>of</strong> Ce addition on macroscopic core-shell structure <strong>of</strong>Cu-Sn-Bi immiscible alloy – Mater Letteres, 2010, vol.64, pp.814-816 – “<strong>Kaptay</strong> [J112] suggested that theinterfacial tension between two immiscible liquids could be expressed by the equation: …{Eq.2}… “ – p.2.Fig.4. Temperature dependence <strong>of</strong> interfacial tension <strong>of</strong> the 24Cu – 16Sn – 60 Bi alloy with 0.05 wt % Ceaddition, calculated using Eq.(2)” – p.815.J112-c4. Mende T.: Az ESTPHAD módszer fejlesztése és alkalmazása kettő-, három- és négyalkotós rendszereklikvidusz hőmérsékletének közelítésére, PhD értekezés, (tud. vez.: Roósz A.), 2010, Miskolc, 129 o. – “A4.33 ábrán a szakirodalomból származó [J112] és a 31. egyenlettel számított szétválási görbe látható. 4.18.táblázat [J112]” – 65.o, „A reguláris elegymodellből levezethetően a szétválási hőmértésklet koncentrációfüggésérea következő egyenlet írható fel [J112]: (34) egyenlet.” – 67.o.J112-c5. Mende T., Roósz A.: Egyensúlyi fázisdiagramok nonvariáns pontjainak nagy pontossággú számításaEstphad módszerrel – BKL Kohászat, 2011, vol.144, No.3, pp.47-50.J112-c6. L.Zhao, J. Zhao: Microstructure formation in a gas-atomized drop <strong>of</strong> Al-Pb Immiscible alloy – MetallMater Trans A, 2012, doi: 10.1007/s11660-012-1313-3. – “”The critical temperature for a ternaryimmiscible alloy is determined by the alloy composition [J112]” -9

J111. G.<strong>Kaptay</strong>: Link between the semi-empirical Andrade and Shytil equations and thestatictical-mechanical Born-Green equation for viscosity and surface tension <strong>of</strong> pure liquidmetals – Metall Mater Trans B, 2008, vol.39B, pp.387-389. (IF = 0.798)J110. G.<strong>Kaptay</strong>: A new theoretical equation for temperature dependent self-diffusioncoefficient <strong>of</strong> pure liquid metals – Int J. Mater Res. (formerly Z. Metallkunde), 2008, vol.99,pp.14-17. (IF = 0.819)J110-c1. S.Yang, X.Su, J.Wang, F.Yin, Z.Li, S.Chen, C.Liu: Temperature-evolution <strong>of</strong> structure and diffusionproperties <strong>of</strong> liquid transition metals – J Non-Crystalline Solids, 2010, vol.356, pp.1061-1069 – „… arecently derived predictive equation for temperature dependence <strong>of</strong> self-diffusion coefficients <strong>of</strong> liquidmetals [J110] has been applied to give theoretical prediction. The new equation was derived combining aunified equation on the viscosity <strong>of</strong> pure liquid metals with the well known Sutherland-Einstein equationwithout any adjustable parameters. The perfect agreement <strong>of</strong> the prediction <strong>of</strong> this new equation with theexperimental values measured under micro-gravity conditions confirms its applicability. The equation hasbeen derived as: {Eq.4}… + 10 lines. The performance <strong>of</strong> the present MD study was evaluated bydetermining relative difference between the calculated and theoretical prediction values. .... The values arelisted in Table 1. Table 1. Simulated self-diffusion coefficients <strong>of</strong> liquid transition metal – 1 coloumn iscalculated by Eq.(4) [J110]”.J110-c2. DL Beke: On the composition and pressure dependence <strong>of</strong> the self-diffusion coefficient in liquid metals– Int J Mater Res, 2010, vol.101, 353-355. - „In a very recent paper <strong>Kaptay</strong> [J110] presented a unifiedequation for the temperature dependence <strong>of</strong> the self-diffusioin coefficient, D, in liquid metals. It ismentioned in [J110] that the result is also a prepequisite for modeling <strong>of</strong> the composition and pressuredependence <strong>of</strong> D.” – p.353. “.. fortunately this data collection and trial to get a relation expressing at leastthe non-reduced values <strong>of</strong> D as the function <strong>of</strong> T was already done in [J110]. Thus it is worth to comparerelation (5) with the results <strong>of</strong> [J110]: {2 equations, 9 lines copied from [J110]}. – p.354. “The use <strong>of</strong> the socalled“corrected” melting point for semi metals is a good trial in [J110]: indeed for these elements themelting point is not a good measure <strong>of</strong> the bonding strength because during melting there are changes in theelectronic structure” – p.354.J110-c3. Beke DL.: Composition and Pressure Dependence <strong>of</strong> the Diffusion Coefficients in Binary LiquidAlloys – Defect and Diffusion Forum, 2010, vol.297-301, pp.1371-1376. – „Data collection and trial to get arelation expressing at least the non-reduced values <strong>of</strong> D as the function <strong>of</strong> T* has already been done [J110].… Furthermore it was shown in [J110] that in fact the logarithm <strong>of</strong> F2*(T*) is a good linear function <strong>of</strong>Tm/T (see Figs 1-2 in [J110].” – p.1373.J110-c4. AA Simonova: Obespechenie neobhodimogo kachestva poverhnostnogo sloia obiomnichnanokristallicheskich metallov posle mechanicheskoi obrabotki – Naukovi Notatki (Inzhenerna mechanika),No.24, 2009, Luck, pp.500-506 – „Nabliudeniia, predstavlennie v rabote [J110] pokazali, shto….” – p.503.J109. G.<strong>Kaptay</strong>: The threshold pressure <strong>of</strong> infiltration into fibrous preforms normal to thefiber’s axes – Composites Science and Technology, 2008, vol.68, pp.228-237. (IF = 2.533)J109-c1. I.Kientzl, J.Dobránszky: Production and behaviuour <strong>of</strong> aluminium matrix double composite structures –Mater Sci Forum, 2008, vol.589, pp.105-110 – “<strong>Kaptay</strong>’s equation describes the threshold pressure asfunction <strong>of</strong> the contact angle and smallest separation <strong>of</strong> the fibers divided by the fibre diameter. Thethreshold pressure <strong>of</strong> non-wetting liquids is found to be inversely proportional to the smallest distancebetween the fibers although it is commonly beleived to be inversely proportional to the diameter <strong>of</strong> thefibres. Four different cases were distuinguished based on the wettability <strong>of</strong> fibres and the sapce between thefibres and the equations <strong>of</strong> thrshold pressures were worked out for all these cases [J109]” – p.105-106.„Based on <strong>Kaptay</strong>’s method the threshold pressure was calculated and plotted as function <strong>of</strong> the contactangle and relative distance between the fibers (Fig.2).” – p.107.J109-c2. Orbulov I, Németh Á, Dobránszky J: Manufacturing <strong>of</strong> Composites by Pressure infiltration, Structureand Mechanical Properties. In: Penninger A, Váradi K, Vörös G (eds.), Gépészet 2008, Proceedings <strong>of</strong> SixthConference on Mechanical Engineering, BUTE Faculty <strong>of</strong> Mechanical Engineering – “This thresholdpressure can be calculated by theoretical approaches for various systems [J109]” – p.1/9.J109-c3. Orbulov IN, Németh Á, Dobránszky J: XRD and EDS Investigations <strong>of</strong> Metal Matrix Composites andSyntactic Foams. 13th European Conference on X-Ray Spectrometry, Cavtat, Croatia, 16-20 June 2008, In:EXRS 2008 Proceedings – “The main parameter in this case is the infiltration pressure, which can beapproximated numerical calculations and is influenced by wetting” – p. 2/10.J109-c4. Kientzl I.: Alumínium mátrixú kompozithuzalok és kettőskompozit szerkezetek – PhD értekezés, 2010.,BME (tud. vezető: Dobránszky János). – „G. <strong>Kaptay</strong> azonban pontosan egy ilyen számítási módszertmutatott be cikkében határfelületi megfontolásokra alapozva munkáját [J109]. Az ebben a cikkben10

emutatott számítási eljárást ismertetem a következőkben (+ 1 oldal, 2 ábra és 16 egyenlet a cikkből)” – 21-22. o., „… a szálak olvális keresztmetszetűek, hosszirányban 12 μm, keresztirányban 7 μm, így a <strong>Kaptay</strong>által adott módszer, ami kör keresztmetszetű szálakra lett kidolgozva, csak közelítő számításokra alkalmasebben az esetben – 42. ábra” – 44.o.J109-c5. I.N.Orbulov, I.Kientzl, J.T.Blücher, Á.Németh, J.Dobránszky, J.Ginsztler: Production and investigation<strong>of</strong> a metal matrix composite pipe – in: Proc <strong>of</strong> 14th European Conf on Composite Materials, Paper ID:262-ECCM14, 8 pp. – „This threshold pressure can be estimated by theoretical approaches for variouswetting or non-wetting systems [J109]” – p.2.J109-c6. Qi LH, Xu R, Su LZ, Zhou JM, Guan JT: Dynamic measurement on infiltration process and formationmechanism <strong>of</strong> infiltration front – Trans. Nonferr Metals Soc China, 2010, vol.20, pp.980-986 – „As anindispensable step int he fabrication technologies <strong>of</strong> metal matrix composites (MMC), the liquid metalinfitration process in porous preform, such as squeeze casting, vacuum infiltration, variable pressureinfiltration and liquid infiltration-extrusion, have attracted research interest due to the significantlyeffective improvement int he properties <strong>of</strong> composite products [J109]” – p.980.J109-c7. Kientzl I.: Alumíniummátrixú kompozithuzalok és kettős kompozit-szerkezetek – PhD értekezés, BME(tud. vez.: dr.Dobránszky János), 2010, 112.o. – „.. <strong>Kaptay</strong> a hengeres szálak közé való infiltrálástvizsgálta [J109]. Az eredmények szerint a szálakkal párhuzamosan a kritikus peremszög 90 o , míg azokramerőlegesen sokkal kisebb 90 o -nál. A konkrét peremszög értéke függ a szálak térkitöltésétől…” – 20.o.„<strong>Kaptay</strong> egy új számítási módszert mutatott be határfelületi megfontolásokra alapozva munkáját [J109] +2 oldal + 14 egyenlet + 2 ábra idézet” – 21-23. o. „A <strong>Kaptay</strong> modell. 1,5 oldal elemzés… A <strong>Kaptay</strong>modell a folyamatos infiltrációhoz szükséges küszöbnyomást 0,20 – 0,77 MPa értékre becsüli. Ez atartomány a kísérleti eredményekből származó 0,62-0,83 MPa intervallummal átfedésben van, tehát ez amodell magyarázatot ad a folyamatos infiltráció nyomás-szükségletére… Összefoglalva megállapítható,hogy a White-Mortensen és a <strong>Kaptay</strong> modellek közül csak a <strong>Kaptay</strong>-modell mutatott átfedést a mérésieredményeimmel” – 60-64. oldalak. „A <strong>Kaptay</strong>-model által adott küszöbnyomásfüggvény alapján a szálakritkább elrendeződése esetén, még nagy peremszögek mellett sem nő jelentős mértékben a folyamatosinfiltrációhoz szükséges küszöbnyomások értéke” – 83.o. „2.tézis. A küszöbnyomás 0,62-0,83 MPa-osintervallumát összevetettem két elméleti modellel… .. tehát a kísérleti eredményeim matematikaiközelítésére a <strong>Kaptay</strong> modell alkalmas” – 84.o.J109-c8. I.N.Orbulov, Á.Németh: Infiltration characteristics <strong>of</strong> carbon fiber reinforced MMCs – Mater SciForum, 2010, vol.659, pp.229-234. – The threshold pressure can be estimated by theoretical approachesfor various wetting or non-wetting systems [J109]” – p. 230.J109-c9. I Kientzl, J Dobránszky, Á Németh: Effect <strong>of</strong> the Infiltration Pressure on the Properties <strong>of</strong> CompositeWires- Materials Science Forum, 2010, vol. 659, pp.177-182. – „<strong>Kaptay</strong>'s equations describe the thresholdpressure as a function <strong>of</strong> the contact angle and smallest separation <strong>of</strong> the fibres divided by the fibre diameter[J109]. The threshold pressure <strong>of</strong> non-wetting liquids is found to be inversely proportional to the smallestdistance between the fibers … „ p.177J109-c10. L.H.Qi, L.Z.Su, J.M.Zhou, J.T.Guan, X.H.Hou, H.J.Li: Infiltration characteristics <strong>of</strong> liquid AZ91Dalloy into short carbon fiber preform – J Alloys Compds, 2012, vol.527, pp.10-15. – „… much researchwork had also been conducted on the calculation <strong>of</strong> the threshold pressure for initiation <strong>of</strong> infiltration[J109]” – p.10.J109-c11. Seung-Wook Han, Nak-Sam Choi and Min-Soo Lee: Analysis <strong>of</strong> glass fabric impregnation using aresin drop method - J Mechan Sci Technol, 2012, vol. 26, pp. 1477-1482 – “The interplay between thesurface tension <strong>of</strong> the infiltrating liquid, the wettability <strong>of</strong> the fibers by the surrounding liquid and themorphological details <strong>of</strong> the preform fabric directly affects the integrity <strong>of</strong> the manufactured composites[J109]” – p.1477.J109-c12. MA You-ping, LI Xiu-lan, WANG Cheng-hui, LU Lu: Microstructure and Impact Wear Resistance <strong>of</strong>TiN Reinforced High Manganese Steel Matrix – J Iron Steel Res Int. 2012, vol. 19, No. 7, pp. 60-65 – „Themost common surface treatment route is the liquid metal infiltration …. Infiltration technique has beensuccessfully applied in wear parts [J109]” – p.60.J108. K.Wasai, G.<strong>Kaptay</strong>, K.Mukai, N.Shinozaki: Modified classical homogeneous nucleation theroyand a new minimum in free energy change 2. Behavior <strong>of</strong> free energy change with a minimumcalculated for various systems - Fluid Phase Equilibria, 2007, vol.255, pp.55-61. (IF = 1.506)11

J108-c1. S.Min, J.Park, J.Lee: Surface tension <strong>of</strong> the 60%Bi-24%Cu-16%Sn alloy and the critical temperature <strong>of</strong>the immiscible liquid phase separation – Mater Lett, 2008, vol.62, pp.4464-4466 – „In order to control thestructure <strong>of</strong> the core-shell lead-free solder ball, the surface tension and the interfacial tension between twoimmiscible liquid alloys are required [J108]” – p.4464.J108-c2. Verezub O.: Lézeresen felületkezelt szerszámacél köszörülése – Gyártóeszközök, szerszámok,szerszámgépek, 2008, No.1, pp.65-68. – „A nanométer tartományba tartozó szemcsék kiválásánakfelételeiről lásd [J108]” – p.66.J108-c3. Zoltai László (+Dúl Jenő): Grafitcsírák keletkezési lehetőségének elméleti vizsglata – 3.kutatószemináriumi dolgozat, <strong>Miskolci</strong> <strong>Egyetem</strong>, 2009. február, 48 oldal – „Mivel a SiC képződése során azolvadék Si- és C-tartalma csökken, a nano méretű SiC csírák stabiliázlása elméletileg lehetséges [J108]” –2.o. „Wasai, <strong>Kaptay</strong>, Mukai és Shinozaki ismerték fel először [J108], hogy csíraképződés során azolvadékfázis Gibbs energiája változásának figyelmen kívül hagyása oda vezet, hogy a csíraképződési görbeegyébként létező minimum pontja nem jelenik meg… A levezetés [J108] a nemrég publikált cikkekegyszerűsített változata – 2 oldal egyenletek” – 40. o.J.107. Gábor T., Kármánné H.F., J.Sytchev, <strong>Kaptay</strong> Gy., Kálmán E.: Sóolvadékok elektrolízise soránkialakult szén nanocsövek kinyerése és minősítése – BKL Kohászat, 2007, vol.140., No.2, pp. 43-50.(IF = 0)J106. K.Wasai, G.<strong>Kaptay</strong>, K.Mukai, N.Shinozaki: Modified classical homogeneousnucleation theroy and a new minimum in free energy change 1. A new minimum and Kelvinequation – Fluid Phase Equilibria, 2007, vol.254, pp.67-74. (IF = 1.506)J106-c1. Verezub O.: Lézeresen felületkezelt szerszámacél köszörülése – Gyártóeszközök, szerszámok,szerszámgépek, 2008, No.1, pp.65-68. – „A nanométer tartományba tartozó szemcsék kiválásánakfelételeiről lásd [J106]” – p.66.J106-c2. Zoltai László (+Dúl Jenő): Grafitcsírák keletkezési lehetőségének elméleti vizsglata – 3.kutatószemináriumi dolgozat, <strong>Miskolci</strong> <strong>Egyetem</strong>, 2009. február, 48 oldal – „Mivel a SiC képződése során azolvadék Si- és C-tartalma csökken, a nano méretű SiC csírák stabiliázlása elméletileg lehetséges [J106]” –2.o. „Wasai, <strong>Kaptay</strong>, Mukai és Shinozaki ismerték fel először [J106], hogy csíraképződés során azolvadékfázis Gibbs energiája változásának figyelmen kívül hagyása oda vezet, hogy a csíraképződési görbeegyébként létező minimum pontja nem jelenik meg… A levezetés [J106] a nemrég publikált cikkekegyszerűsített változata – 2 oldal egyenletek” – 40. o.J106-c3. Carreon-Calderon B., Soria A., Romero-Martinez A.: <strong>Dr</strong>iving Force in First-Order Phase Transitionsand Its Application to Gas Hydrate Nucleation from a Single Phase - AICHE Journal, 2009, vol.55, pp.2433-2447. – „.. authors consider the nucleation work as a maximum <strong>of</strong> the free energy surface” – p.2434.J106-c4. Teychene S., Biscans B.: Micr<strong>of</strong>luidic Device for the Crystallization <strong>of</strong> Organic Molecules in OrganicSolvents – Crystal growth & Design, 2011, vol.11, pp.4810-4818. -J105. G.<strong>Kaptay</strong>: On the wettability, encapsulation and surface phase transition in monotecticliquid metallic systems – Materials Science Forum, 2007, vol.537-538, pp.527-532 (IF = 0)J105-c1. Svéda Mária: Monotektikus felületi rétegek létrehozása lézersugaras felületkezeléssel c. PhDértekezéséhez (tudományos vezető: dr. Roósz András) – 2007. – „A nagyobb sűrűségű Pb olvadéknak azötvözett zóna felszínén való elhelyezkedése a határfelületi jelenségekkel magyarázható [J105]” – p.87.J104. I.Budai, M.Z.Benkő, G.<strong>Kaptay</strong>: Comparison <strong>of</strong> different theoretical models toexperimental data on viscosity <strong>of</strong> binary liquid alloys – Materials Science Forum, 2007,vols.537-538, pp.489-496. (IF = 0)J104-c1. D.Zivkovic: Application <strong>of</strong> the <strong>Kaptay</strong> model in calculation <strong>of</strong> ternary liquid alloys viscosities – Int JMat Res, 2008, vol.99, pp.748-750 – „<strong>Kaptay</strong>’s approach to estimate the viscosity <strong>of</strong> liquid metallic alloysfrom viscosities <strong>of</strong> pure liquid metals and thermodynamic properties <strong>of</strong> the liquid alloy has been tested fordifferent types <strong>of</strong> binary systems [J104], including those with considerable deviations from ideality” –pp.748-749.J104-c2. D.Zivkovic: A new approach to estimate the viscosity <strong>of</strong> the ternary liquid alloys using the Budai-Benko-<strong>Kaptay</strong> equation – Metall Mater Trans B, 2008, vol.39, pp.395-398 – „The new Budai-benko-<strong>Kaptay</strong> (BBK) equation has been recently derived for estimation <strong>of</strong> the viscisity <strong>of</strong> liquid alloys and testedon numerous binary systems, showing a good agreement with experimentally obtained data. Equations….… The presented new BBK equation for estimation <strong>of</strong> the viscosity <strong>of</strong> liquid metallic alloys has been12

already tested for different types <strong>of</strong> binary systems [J104], showing good compliance with experimentaldata in most cases. IN this article, the applicability <strong>of</strong> a new equation to ternary systems will be tested inexamples <strong>of</strong> Au-Ag-Cu alloys. „ – p.395, „There is an agreement between the results <strong>of</strong> the BBK equationapplication, presented in this work and the experimental literature data… the ability to predict theviscosity, even if the viscosities <strong>of</strong> the pure componnets are not known, should be underlined int heapplication <strong>of</strong> the new BBK equation and taken as an advantage among other models int he case whenthese data are not known” – p.396. „The greatest advantage <strong>of</strong> the presented BBK equation is to beaccetuated – such estimation <strong>of</strong> the viscosities <strong>of</strong> multicomponent liquid alloys demands just a fewstarting data for the calculation compared to the other known models, which makes it simple and easy toapply in different cases” – p.397.J104-c3. V.Skliarchuk, A.Iakimovich, M.Dufanec: Rozrahunok viazkosti rozplaviv sistemi Al-Cu –Vseukrainska konferencia molodich vchonich “Suchasne materialoznavstvo: materiali ta technologiiSMMT-2008. (PPT file <strong>of</strong> a conference talk) – “Modifikovane rivnannia Budai-Benko-<strong>Kaptay</strong> [J104] ….“ – p. 4, “Rozrahovani znacheniia viazkosti zgidno modeli Chabra i modifikovanogo rivnannia Budai-Benko-<strong>Kaptay</strong> dobre uzgodzhuiutsia z literaturnimi dannimi“ – p.9.J104-c4. Sklyarchuk VM, Yakimovich AS, Dufanets' MV: Calculation on Viscosity <strong>of</strong> Al-Cu Liquid Alloys –Metall<strong>of</strong>izika i noveishie technologii, 2008, vol.30, pp., 315-321.J104-c5. P.Terzieff: The viscosity <strong>of</strong> liquid alloys <strong>of</strong> polyvalent metals with Cu, Ag and Au: Theoreticaltreatments based on the enthalpy <strong>of</strong> mixing – Physica B, 2009, vol.404, pp. 2039-2044 – „The majority <strong>of</strong>the currently used viscosity models are <strong>of</strong> semi-empirical nature focused on thermodynamic quantitiessuch as enthalpy <strong>of</strong> mixing [J104]” – 2039, “The extension toi the case <strong>of</strong> multi-component systemsinvolves the volume <strong>of</strong> mixing and the enthalpy <strong>of</strong> mixing as additional input parameters [J104]: Eq.(3)” –p.2040, “Fig-s 1-10: “unified model”” – pp.2041-2033, “The least strenuous way to calculate viscosities isgiven by the unified equation <strong>of</strong> <strong>Kaptay</strong> and coworkers [J104]. Except for the Ag-Sb and some extent toCu-Sb, the excess viscosities are in reasonable numerical agreement with the experimental values (Table1). Apart from the model’s obvious overestimation <strong>of</strong> the viscosity <strong>of</strong> pure liquid Cu in Cu-BI, Cu-Pb andCu-Sn (Figs 2, 3 and 5) or the disagreement in the values <strong>of</strong> undercooled Au in Au-Sn (Fig.10) the shapes<strong>of</strong> the viscosity isotherms are found to be adequately reproduced (curves b). However, it has to be alsonoted that the experimental values reported for liquid Cu differ from one author to the other by more than1 mPaseven at the same temperature (Figs 3. and 4.). The additional isotherms (curves b’) shown for Cu-Bi, Cu-Sb, Ag-Ge and Ag-Sb were obtained by using the corrected melting temperatures for Ge (450 K),Sb (650 K) and Bi (450 K) as recommended by <strong>Kaptay</strong> [J104]. As compared to the isotherms obtainedwith the uncorrected melting temperatures (curves b) the improvemenets are extremely large for Ag-Ge(Fig.6), less pronounced for Cu-Sb and Ag-Sb (Figs 4, 8) and small for Cu-Bi (Fig.2).” – p.2043.J104-c6. P.Terzieff: Some physico-chemical properties <strong>of</strong> liquid Ag-Sn-Zn – Physica B, Condensed Matter,2010, vol.405, pp.2668-2672 – From a previous analysis it has been concluded that the semi-empiricalapprach based on <strong>Kaptay</strong>’s unified equation [J104] is one <strong>of</strong> the most convenient methods to gain a firstidea <strong>of</strong> the viscosity <strong>of</strong> muticomponent systems, even if the viscosities <strong>of</strong> the pure liquids are unknown.The application requires the melting temperatures <strong>of</strong> the components, their molar masses, and their molarvolumes. The only requirements for alloy is the knowledge <strong>of</strong> the excess volume and the enthalpy <strong>of</strong>mixing : (Eq.10)” – p.2674.J104-c7. Gasior W, Moser Z, Debski A: New data to the SURDAT-database <strong>of</strong> modeled and experimentalphysical properties <strong>of</strong> lead-free solder alloys – Arch Metall Mater, 2009, vol.54, pp. 1253-1259 –„..SURDAT database … experimental … and the viscosity calculated from the dependences proposed by… <strong>Kaptay</strong> [J104] : Eq.(6)” – p.1256. “Fig.4. Experimental (symbols) and calculated (lines) viscosity (Eq-s(1, 2, 5, 6, 7) <strong>of</strong> Ag-Sn (Fig.4a) and Sn-Zn (Fig.4b) alloys” – p.1257.J104-c8. Knott S., Terzieff P.: Calculation <strong>of</strong> the viscosity <strong>of</strong> the liquid ternary Ag-Au-Sn system – Int. J. Mater.Res., 2010, vol.101, pp.834-838. – „Several viscosity models based on thermodynamic data exist, some <strong>of</strong>them apply adjustable parameters, while others make use <strong>of</strong> universal parameters [J104] which a reconsidered to be applicable to a large class <strong>of</strong> alloy systems” – p.834, “The expression for the viscosity,given by Budai et al. [J104] is based on <strong>Kaptay</strong>-s unified equation for pure liquid metals: Eq.(3)” – p.835.Fig-s 2, 4 and Table 2 are calculated by the model [J104] – pp.836-837. “…the unified equation yields amuch better agreement for Ag-Au system” – p.836. “Conclusions: .. in case <strong>of</strong> missing experimentalevidence the unified equation might give a first reasonable estimate <strong>of</strong> the viscosity in liquidmulticomponent systems” – p.838.J104-c9. Wunderlich RK; Fecht H-J: Surface tension and viscosity <strong>of</strong> NiAl catalytic precursor alloys frommicrogravity experiments – Int J Mater Res, 2011, vol.102, pp.1164-1173. „The <strong>Kaptay</strong> model was shownto provide better agreement with observed viscosities <strong>of</strong> binary alloys [J104] than the Moelwyn-Hughesmodel. In the <strong>Kaptay</strong> model the viscosity is given by: Eq-s.(15-16), Fig.11, Table 2.” – p.1170-1171.13

J104-c10. R.N.Singh, F.Sommer: Viscosity <strong>of</strong> liquid alloys: generalization <strong>of</strong> the Andrade’s equation – MonatshChem, 2012, vol.143, pp.1235-1242. – „Results obtained from these relations have been compared withnew or given [J104] experimental viscosity data as a function <strong>of</strong> composition and temperature.” – p.1235.“A comparison <strong>of</strong> available semi-empirical models with experimental data <strong>of</strong> the viscosity <strong>of</strong> liquid alloyshas been given recently [J104]” – p.1241.J103. Baumli P., Sytchev J., <strong>Kaptay</strong> Gy.: SiC és Al 2 O 3 kerámia szemcsék felületkezelése sóolvadékban, kompozitok fejlesztése céljából – BKL Kohászat, 2006., 139. évf., 3.szám, 47-50. (IF = 0)J103-c1. Orbulov I., Kientzl I., Németh Á.: Fémhabok és kompozitok előállítása infiltrálásos eljárással – BKLKohászat, 2007, vol.140, No.5, pp.41-46. – „Nagyon fontos, hogy a fémmátrixú kompozitanyagokesetében is csak akkor kapunk megfelelő műszaki tulajdonságokat, ha megfelelő a kapcsolat azerősítőanyag és a mátrixanyag határfelületén [J103]” – p.41.J103-c2. Orbulov I.: Szintaktikus fémhabok keménységmérése – Anyagvizsgálók lapja, 2009, No.1, pp.9-15. –„… vizsgálatok tárgyát képezték az erősítőanyagra felvihető különböző bevonatok is [J103].” – p.9.J102. G.<strong>Kaptay</strong>: On the equation <strong>of</strong> the maximum capillary pressure induced by solidparticles to stabilize emulsions and foams and on the emulsion stability diagram - Colloidsand Surfaces A: Physicochem. Eng. Aspects, 2006, vol.282-283, pp.387-401. (IF = 1.611)J102-c1. Gonzenbach UT, Studart AR, Tervoort E, Gauckler LJ: Tailoring the microstructure <strong>of</strong> particlestabilizedwet foams - LANGMUIR 23 (3): 1025-1032 JAN 30 2007 - „These results suggest that thepreparation <strong>of</strong> wet foams that are stable against bubble coarsening and drainage requires particle sizesnot larger than a few micrometers in diameter. Theoretical calculations based ont he adsoroption energy<strong>of</strong> particles at gas – liquid interface and the maximum capillary pressure developed at the interfaceshowed that particles larger than about 3 microns are not able to stabilize foams for long period <strong>of</strong> time[J102]. These results are in the same order <strong>of</strong> magnitude as our experimental findings” – p.1029.J102-c2. C.Körner: Integral Foam Molding <strong>of</strong> Light Metals – Physical and Technological Principles –Habilitation Thesis, Erlangen, 2007 (Ref. No.132) – “<strong>Kaptay</strong> was the first who realized that stabilizationfor these kind <strong>of</strong> particles is based on the development <strong>of</strong> 3D network structures which transfer forcesfrom one interface to the other [J102].” – p.108.J102-c3. Torres LG, Iturbe R, Snowden MJ, Chowdhry BZ, Leharne SA: Preparation <strong>of</strong> o/w emulsions stabilizedby solid particles and their characterization by oscillatory rheology - COLLOIDS AND SURFACES A-PHYSICOCHEMICAL AND ENGINEERING ASPECTS 302 (1-3): 439-448 JUL 20 2007 – “Themagnitude <strong>of</strong> the free energy required to remove a particle from the interface between two immisciblefluids does not provide an insight into the stability <strong>of</strong> the emulsions [J102]…. It is reported that the waterfil between two drops <strong>of</strong> the discontinuous oil phase resists rupture if the contact angle <strong>of</strong> the stabilisingparticle is in the range <strong>of</strong> 15 – 90 degrees [J102]” – p.440.J102-c4. Studart AR, Gonzenbach UT, Akartuna I, Tervoort E, Gauckler LJ: Materials from foams andemulsions stabilized by colloidal particles - JOURNAL OF MATERIALS CHEMISTRY 17 (31): 3283-3289 2007 – “… stabilization is achieved for intermediate contact angles ranging from 20 to 86 deg foroil-in-water emulsions and foams, and from 94 to 160 deg for water-in-oil emulsions and mists [J102]” –p.3285, “Besides the high energy <strong>of</strong> adsorption <strong>of</strong> particles at the interface, the remarkable resistance <strong>of</strong>particle-stabilized foams and emulsions against coalescence has also been attributed to the development <strong>of</strong>capillary forces that impede thinning down the liquid film between bubbles/droplets, as well as to theformation <strong>of</strong> an attractive network <strong>of</strong> particles throghout the continouos liquid phase [J102]” – p.3286.J102-c5. SE Friberg, AA Bawab, AA Abdoh: Surface active inverse micelles – Colloid Polym Sci, 2007,vol.285, pp.1625-1630 (Ref. No.17) – “Finally <strong>Pr<strong>of</strong></strong>essor <strong>Kaptay</strong> [J102] has published a completetreatment on the influence <strong>of</strong> solid particles on the capillary pressure in their stabilization <strong>of</strong> emulsionsand foams” – p.1628.J102-c6. Orbulov I., Kientzl I., Németh Á.: Fémhabok és kompozitok előállítása infiltrálásos eljárással – BKLKohászat, 2007, vol.140, No.5, pp.41-46. – „A másik csoportba sorolhatjuk azokat az anyagokat, amelyeklétrehozásánál vagy csak a tömegcsökkentés, vagy valamilyen más különleges követelmény dominál.Ezek a porózus szerkezeti anyagok [J102]” – p.41.J102-c7. L.Torres, R.Iturbe, MJ Snowden, B. Chowdhry, S.Lehrane: Can Pickering emulsion formation aid theremoval <strong>of</strong> creosote DNAPL from porous media? – Cemosphere, 2008, vol.71, pp.123-132 – “There are,however, problems with the model that undepints the development <strong>of</strong> Eq.(1) (<strong>of</strong> Binks). For example themodel does not explain experimental observation that particle stabilised emulsions are maximallystabilised when the particles display a contact angle less than 90 o [J102]…. The role <strong>of</strong> the particles in14

film stabilisation can be incorporated into a model which then predicts that the film between two drops <strong>of</strong>the discontinuous oil phase resists rupture if the contact angle <strong>of</strong> the stabilising particlesis in the rangebetween 15 and 90 deg [J102]” – p.125.J.102-c8. TN Hunter, RJ Pugh, GV Franks, GJ Jameson: The role <strong>of</strong> particles in stabilizing foams and emulsions– Adv. Colloid Interface Sci., 2008, vol.137. pp.57-81 – “A recent review by <strong>Kaptay</strong> [J102] has broughtthis mechanism back into focus, and it will be briefly surmised here. <strong>Kaptay</strong> [J102] derived …. 61 lines +Figures 4-5 + Equation (2) ” – pp.62-63.J102-c9. T.S. Horozov: Foams and foam films stabilised by solid particles - Curr Opinion in Colloid InterfaceSci, 2008, vol.13, pp.134-140. – „Several recent works [J102, etc.] treat the problem <strong>of</strong> liquid filmstability by solid particles theoretically, assuming either a bridging monolayer or a bilayer <strong>of</strong> hexagonallyclose-packed particles.” – p.137. „A recent review on this subject by <strong>Kaptay</strong> [J102] is worth to consider.There, previous and more recent theoretical results are analysed and semi-empirical equations for thedependence <strong>of</strong>maxP on the particle contact angle are obtained with the toroidal pore model. Resultsccalculated by these equations are compared in Fig.3….. description <strong>of</strong> Fig.3 (19 lines + 7 lines <strong>of</strong> figurecaption [J102])…” – p.138, „Another mechanism <strong>of</strong> foam film stabilisation by a network <strong>of</strong> particleaggregates (gel) inside the film has also been discussed in [J102] (Fig.2.c). … description (7 lines)…” –p.138, „Link between the stability <strong>of</strong> particle stabilised aqueous films and that <strong>of</strong> particle-stabilised foamsor oil-in-water (o/w) emulsions has also been discussed [J102] … description (15 lines)… .Semiquantitative arguments have been used to estimate the optimum contact angles for the highest foam(o/w emulsion) stability [J102]…decription (3 lines)…” – pp.138-139, „Smaller particles should stabilisethe film better but their attachment to the liquid surface is weaker and vica versa [J102].” – p.139. „Agood review <strong>of</strong> theoretical studies on liquid films stabilised by solid particles. Useful approximatedequations for the dependence <strong>of</strong> critical capillary pressure for film rupture on the particle contact angle areobtained. Mechanism <strong>of</strong> liquid film stabilisation by solid particles are discussed” – p.140.J102-c10. S Ata: Coalescence <strong>of</strong> bubbles covered by particles – Langmuir, 2008, vol.24, pp.6085-6091. – „Themechanism <strong>of</strong> film stabilisation has been explained by the capillary pressure between bubbles, given by{equation}. The theory was first proposed by Ivanov and co-workers and developed further by others[J102]” – p.6086-6087.J102-c11. I.Akartuna, AR Studart, E.Tervoort, UT Gozenbach, LJ Gauckler: Stabilization <strong>of</strong> oil-in-wateremulsions by colloid particles modified with short amphiphiles – Langmuir, 2008, vol.24, pp.7161-7168.– „The adsoroption energy increases monotonically with increasing contact angle reachin a maximum at90 degrees. Besides a strong adsorption at the interafce, the stabilization <strong>of</strong> emulsions also requires thatthe adsorbed particles impede thinning <strong>of</strong> the liquid film between droplets. In contract to the adsorptionenergy, earlier studies have shown that the highest resistance against film thinning is achieved forparticles forming contact angles approaching 0 and 180 degrees [J102]. COnsidering these oppositetrends, optimum contact angles between 70 and 86 degrees and between 94 and 110 degrees have beensuggested for the stabilization <strong>of</strong> oil-in-water and water-in-oil emuslions, respectively, using interfacialadsorbed particles [J102]. Under such conditions, particles should be able to sterically hinder thecoalescence <strong>of</strong> droplets over long periods <strong>of</strong> time, which has been experimentally confirmed in a number<strong>of</strong> recent studies” – p.7161.J102-c12. H.A.Wege, S.Kim, V.N.Paunov, Q.X.Zhong, O.D.Velev: Long-term stabilization <strong>of</strong> foams andemulsions with in-situ formed microparticles from hydrophobic cellulose – Langmuir, 2008, vol.24,pp.9245-9253. „Removing such particles from interface requires the expense <strong>of</strong> a significant transfereneregz, whose magnitude can be estimated by [J102]: (Eq.1).” – p.9245.J102-c13. C.Körner: Foam formation mechanism in particle suspensions applied to metallic foams – Mater SciEng A, 2008, vol.495, pp.227-235 – “Further progress to explain foam stability was made by <strong>Kaptay</strong>[J102] who uses a model <strong>of</strong> a three-dimensional network <strong>of</strong> solid, spherical particles to explain forcetransfer between two interfaces and in this way stability” – p.228.J102-c14. A.J.Klinter, G. Mendoza-Suarez, R.A.L.<strong>Dr</strong>ew: Wetting <strong>of</strong> pure aluminum and selected alloys onpolycrystalline alumina and sapphire – Mater Sci Eng A, 2008, vol.495, pp.147-152. – “Recently it hasbeen derived that the most favorable ciontact angle range for a liquid foam to be stabilized by particlesis between 70 and 86 degrees [J102]. An experimental simulation conducted by Sun et al employingethanol/water mixture and polymeric particles supports this finding showing that the most stable foamswere obtained when the liquid wetted the particles in a range <strong>of</strong> 70-85 degrees. Therefore, it is assumedthat in order to produce stable aluminum foams, the aluminum alloy melt needs to wet the addedceramic particles in this optimum contact angle range <strong>of</strong> 70-86 degrees over the temperature spanbetween that <strong>of</strong> the melt bath in the direct foaming method (typically around 750 – 800 Centigrades)and the solidification <strong>of</strong> the alloy” – p.148.J102-c15. A.J.Klinter, R.A.L.<strong>Dr</strong>ew: Evaluation <strong>of</strong> the wetting behaviour <strong>of</strong> Al-7Cu and Al-11.5Si on SiC andsapphire in terms <strong>of</strong> Al-foam stability. In: METFOAM-2007, ed. by L.P.Lefebre, J.Banhart, D.C.Dunand,15

DEStech Publ. Inc, 2008, pp.23-26. – „During the early stages <strong>of</strong> Al-foam rersearch, it was found thatalumina or SiC particles are essential in order to obtain stable aluminium foams. Originally it wasbelieved that the stabilizing effect <strong>of</strong> these ceramic particles have on Al-foams was caused by an increasein bulk viscosity <strong>of</strong> the Al melt due to ceramic particles additions. In a very theoreticla approach,KAPTAY [P41, J84] later developed models suggesting that the improved foam stability was due tocapillary effects between the melt and the particles, preventing the two liquid gas interfaces <strong>of</strong> a foam cellwall from touching, and the two adjacent cells from coalescencing….. KAPTAY concluded recently in acomplex and theoretical study [J102] that the optimum contact angle for foam stabilization by a single ora closely packed double layer <strong>of</strong> particles is between 70 and 86 degrees” – p.23. „Fig-s 5 show that Al-11.5Si wets the substrate better than Al-Cu, however neither alloy reaches the optimum contact anglerange for foam stabilization [J102]” – p.25. „Conclusions. … A number <strong>of</strong> researchers have shown thatmetal foams can be produced using a verity <strong>of</strong> aluminum alloy – ceramic particle combinations (includingAl2O3, SiC and TiB2). Nevertheless, it is believed that foams with narrower pore size distribution andmore homogeneous properties can be produced if alloy-particle combinations are chosen with wettingproperties int he optimum contact angle range for foam stabilization by particles <strong>of</strong> 70 to 86 degreesderived by KAPTAY [J102]” – p.26.J102-c16. C.Koerner: Integral Foam Molding <strong>of</strong> Light Metals – Springer, 2008, 224 pp. – „ <strong>Kaptay</strong> [J102] wasthe first who realized, that stabilization for this kind <strong>of</strong> particles is based on the development <strong>of</strong> 3Dnetwork structures which transfer forces from one interface to the other” – p. 100.J102-c17. Hunter, T.N., Wanless, E.J., Jameson, G.J.: Effect <strong>of</strong> esterically bonded agents on the monolayerstructure and foamability <strong>of</strong> nano-silica - Colloids and Surfaces A: Physicochemical and EngineeringAspects, 2009, vol. 334, pp. 181 – 190. – „<strong>Kaptay</strong> [J102] has theoretically weighted the effects <strong>of</strong> weaklyand strongly hydrophobic particles and estimated that particles wit ha contact angle 70 o would beststabilize foam films with a single layer <strong>of</strong> particles. For a bi-layer <strong>of</strong> particles, the contact angle formaximum stability changes to 85 o [J102] (more in line with emulsions) suggesting concentration andconformation may affect the extent in which particles <strong>of</strong> different hydrophobicity stabilize a system” –p.181, “The weak stabilization <strong>of</strong> the SiO-dodecane dispersions highlights that the bubbles in the dynamicfoams are likely not fully loaded, and as drainage continues, bubbles interact with only a single bridginglayer <strong>of</strong> particles (giving theoretical maximum stability with particles near 70 o [J102]).” – p.186,“Following on from <strong>Kaptay</strong> [J102] and the work tabled in a pre4vious review [], it appears dynamicfoams are stabilised by species <strong>of</strong> intermediate hydrophobicity, where there is a balance <strong>of</strong> inter-bubbleand steric stabilisation forces.” – p.188.J102-c18. Hunter TN, Jameson GJ, Wanless EJ, Dupin D, Armes SP: Adsorption <strong>of</strong> Submicrometer-SizedCationic Sterically Stabilized Polystyrene Latex at the Air-Water Interface: Contact Angle Determinationby Ellipsometry - Langmuir, 2009, vol. 25, pp. 3440-3449. – „Less hydrphobic particles can alsodynamically stabilize bubbles by altering threshold capillary pressure [J102]” – p.3441.J102-c19. Fournier CO, Fradette L, Tanguy PA: Effect <strong>of</strong> dispersed phase viscosity on solid-stabilized emulsions– Chemical Engineering Research & Design, 2009, vol. 87, pp. 499-506. – „As a general rule, ahydrophobic particle favors a water-in-oil emulsion while a hydroplhilic particle generates an oil-in-wateremulsion. However, this rule may be broken depending on the number <strong>of</strong> layers the solid particles willform at the oil-water interface. Based on the energy and maximum capillary pressure considerations,<strong>Kaptay</strong> (2006) showed that for an emulsion stabilized by a single layer <strong>of</strong> particles, the contact angle foro/w emulsions must be between 15 and 90 degrees and for w/o emulsions, the contact angle must bebetween 90 and 165 degrees. For emulsions stabilized by a double layer <strong>of</strong> particles, o/w emulsions arestable for contact angle values between 15 and 129.3 degrees and w/o emulsions are stable for contactangle values between 50.7 and 165 degrees. Furthermore, the interval <strong>of</strong> optimum contact angle, for bothsingle and double particles layer appears to be between 70 and 86 degrees for o/w emulsions and between94 and 110 degrees for w/o emulsions” – pp.499-500.J102-c20. J.Frelichowska: Emulsions stabilisees par des particules solides: etudes physico-chmiques etevaluation pour l’application cutanee, PhD, L’Universite Claude Bernard Lyon 1, 2009 Jan – “La stabilitedu film de phase continue entre les gouttelettes peut aussi empecher la coalescence. Le film peut etrestabilise par des forces capillaires et/ou les proprietes theologiques de l’intergace elle-meme [J102] –p.59.J102-c21. A.J.Klinter, C.A.Leon-Patino, R.A.L. <strong>Dr</strong>ew: The optimum contact angle range for metal foamstabilization: an experimental evaluation <strong>of</strong> theory – Abstract book <strong>of</strong> 6th HTC conference, 6-9 May,2009, Athens, Greece, p.75 – „From the measured values, contact angle vs. Temperature curves weregenerated, some <strong>of</strong> which satisfy the contact angle requirement between liquid metal and ceramic particlesfor optimum metal foam stabilization proposed by <strong>Kaptay</strong> (70 to 86 degrees) [J102]. …. Comparing theexperimentally observed liquid foam stability and the resulting foam morphology with the obtained16