Full CoMPleMent wItH needle roller

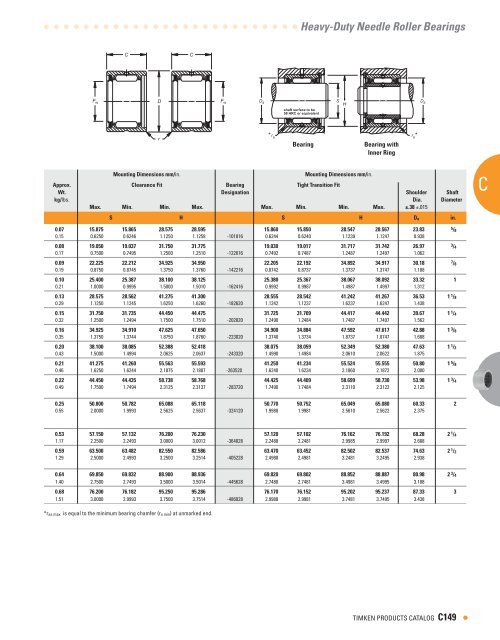

Full CoMPleMent wItH needle roller

Full CoMPleMent wItH needle roller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

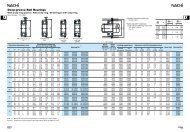

NEEDLE Roller BearingsInner RingsInch Series• Check for availabilty.• Ideal choice where shaft not practical to use as innerraceway.• Provided in inch nominal dimensions for use with inch seriesheavy-duty <strong>needle</strong> <strong>roller</strong> bearings.• Designed to meet established inch tolerances.• Selected size should be wider than matching drawn cupbearing.• Maximum shaft fillet radius (r as max) cannot exceed inner ringbore chamfer (r s min) as shown.• Optional centralized lubrication groove (bore) or through-holeavailable – specify when ordering.• Designed to be axially clamped against shoulder for loosetransition fit on shaft.• After mounting, for tight transition fit (keeping inner ring fromrotating relative to shaft), inner ring O.D. must not exceedraceway diameter on matching bearing.CShaft dimensions mm/in. Inner Ring I inner Ring U used WithDiameter D designation Approx. D designation BearingWt. Loose Transition Fit I interference Fit Designationkg/lbs. mm/in. mm/in.Max. Min. Max. Min.in. d F B r s min s s3 / 8 9.525 15.875 19.05 0.64 IR-061012 0.018 9.520 9.510 IR-061012 9.538 9.530 HJ-1018120.3750 0.6250 0.750 0.025 0.040 0.3748 0.3744 0.3755 0.37521 / 2 12.700 19.050 19.05 1.02 IR-081212 0.023 12.692 12.682 IR-081212 12.715 12.708 HJ-1220120.5000 0.7500 0.750 0.04 0.050 0.4997 0.4993 0.5006 0.500312.700 19.050 25.40 1.02 IR-081216 0.032 12.692 12.682 IR-081216 12.715 12.708 HJ-1220160.5000 0.7500 1.000 0.04 0.070 0.4997 0.4993 0.5006 0.50035 / 8 15.875 22.225 19.05 1.02 IR-101412 0.027 15.867 15.857 IR-101412 15.890 15.883 HJ-1422120.6250 0.8750 0.750 0.04 0.060 0.6247 0.6243 0.6256 0.625315.875 22.225 25.40 1.02 IR-101416 0.036 15.867 15.857 IR-101416 15.890 15.883 HJ-1422160.6250 0.8750 1.000 0.04 0.080 0.6247 0.6243 0.6256 0.625311 / 16 17.463 22.225 19.05 1.02 IR-111412 0.023 17.455 17.445 IR-111412 17.478 17.470 HJ-1422120.6875 0.8750 0.750 0.04 0.050 0.6872 0.6868 0.6881 0.68783 / 4 19.050 25.400 19.05 1.02 IR-121612 0.032 19.042 19.030 IR-121612 19.068 19.058 HJ-1624120.7500 1.0000 0.750 0.04 0.070 0.7497 0.7492 0.7507 0.750319.050 25.400 25.40 1.02 IR-121616 0.041 19.042 19.030 IR-121616 19.068 19.058 HJ-1624160.7500 1.0000 1.000 0.04 0.090 0.7497 0.7492 0.7507 0.750313 / 16 20.638 25.400 25.40 1.02 IR-131616 0.032 20.630 20.617 IR-131616 20.655 20.645 HJ-1624160.8125 1.0000 1.000 0.04 0.070 0.8122 0.8117 0.8132 0.81287 / 8 22.225 28.575 25.40 1.02 IR-141816 0.050 22.217 22.205 IR-141816 22.243 22.233 HJ-1826160.8750 1.1250 1.000 0.04 0.110 0.8747 0.8742 0.8757 0.875322.225 28.575 31.75 1.02 IR-141820 0.059 22.217 22.205 IR-141820 22.243 22.233 HJ-1826200.8750 1.1250 1.250 0.04 0.130 0.8747 0.8742 0.8757 0.875315 / 16 23.813 28.575 25.40 1.02 IR-151816 0.036 23.805 23.792 IR-151816 23.830 23.820 HJ-1826160.9375 1.1250 1.000 0.04 0.080 0.9372 0.9367 0.9382 0.937823.813 28.575 31.75 1.02 IR-151820 0.045 23.805 23.792 IR-151820 23.830 23.820 HJ-1826200.9375 1.1250 1.250 0.04 0.100 0.9372 0.9367 0.9382 0.93781 25.400 31.750 25.40 1.02 IR-162016 0.054 25.392 25.380 IR-162016 25.418 25.408 HJ-2028161.0000 1.2500 1.000 0.04 0.120 0.9997 0.9992 1.0007 1.000325.400 31.750 31.75 1.02 IR-162020 0.068 25.392 25.380 IR-162020 25.418 25.408 HJ-2028201.0000 1.2500 1.250 0.04 0.150 0.9997 0.9992 1.0007 1.00031 1 / 8 28.575 34.925 25.40 1.02 IR-182216 0.059 28.567 28.555 IR-182216 28.593 28.583 HJ-2230161.1250 1.3750 1.000 0.04 0.130 1.1247 1.1242 1.1257 1.125328.575 34.925 31.75 1.02 IR-182220 0.077 28.567 28.555 IR-182220 28.593 28.583 HJ-2230201.1250 1.3750 1.250 0.04 0.170 1.1247 1.1242 1.1257 1.12531 1 / 16 30.163 38.100 31.75 1.52 IR-192420 0.100 30.155 30.142 IR-192420 30.180 30.170 HJ-2433201.1875 1.5000 1.250 0.06 0.220 1.1872 1.1867 1.1882 1.18781 1 / 4 31.750 38.100 25.40 1.52 IR-202416 0.068 31.740 31.725 IR-202416 31.770 31.760 HJ-2433161.2500 1.5000 1.000 0.06 0.150 1.2496 1.2490 1.2508 1.250431.750 38.100 31.75 1.52 IR-202420 0.082 31.740 31.725 IR-202420 31.770 31.760 HJ-2433201.2500 1.5000 1.250 0.06 0.180 1.2496 1.2490 1.2508 1.25041 5 / 16 33.338 41.275 25.40 1.52 IR-212616 0.086 33.327 33.312 IR-212616 33.358 33.348 HJ-2635161.3125 1.6250 1.000 0.06 0.190 1.3121 1.3115 1.3133 1.3129Continued on next page.•C150 TIMKEN PRODUCTS CATALOG

Heavy-Duty Needle Roller BearingsDF WB• See tables for required bearing dimensions racewaydiameter.r a *r• After mounting, if O.D. of inner ring exceeds the requiredraceway diameter for matching bearing, ring should bed F Sground to proper diameter while mounted on shaft.• Unmarked end of inner ring to be assembled against the shaftshoulder to assure clearing the maximum allowable shaftfillet (r as max) as indicated in tables shown.rShaft dimensions mm/in. Inner Ring I inner Ring U used WithFa Diameter D SD Hdesignation a Approx. D designation BearingWt. Loose Transition Fit I interference Fit Designationshaft surface to be58 HRC or equivalentkg/lbs. mm/in. mm/in.Max. Min. Max. Min.in. d F B r s min s sr aF33.338 41.275 31.75 1.52 IR-212620 0.109 33.327 33.312 IR-212620 33.358 33.348 HJ-2635201.3125 1.6250 1.250 0.06 r a 0.240 1.3121 1.3115 S1.3133 1.3129d1 3 / 8 34.925 41.275 31.75 1.52 IR-222620 0.091 34.915 34.900 IR-222620 34.945 34.935 HJ-2635201.3750 1.6250 1.250 0.06 0.200 1.3746 1.3740 1.3758 1.375434.925 44.450 31.75 1.52 IR-222820 0.141 34.915 34.900 IR-222820 34.945 34.935 HJ-2837201.3750 1.7500 1.250 0.06 0.310 1.3746 1.3740 1.3758 1.3754r1 7 / 16 36.513 44.450 25.40 1.52 IR-232816 0.095 36.502 36.487 IR-232816 36.533 36.523 HJ-2837161.4375 re: Service 1.7500 Catalog, 1.000 pages 0.06408, 410, 411, 4120.210 1.4371 1.4365 1.4383 1.437936.513 44.450 31.75rev3 - 8Oct991.52 IR-232820 0.118 36.502 36.487 IR-232820 36.533 36.523 HJ-2837201.4375 1.7500 1.250 0.06 0.260 1.4371 1.4365 1.4383 1.43791 1 / 2 38.100 44.450 25.40 1.52 IR-242816 0.077 38.090 38.075 IR-242816 38.120 38.110 HJ-2837161.5000 1.7500 1.000 0.06 0.170 1.4996 1.4990 1.5008 1.500438.100 44.450 31.75 1.52 IR-242820 0.095 38.090 38.075 IR-242820 38.120 38.110 HJ-283720B 3d1.5000 1.7500 1.250 0.06 0.210 1.4996 1.4990 1.5008 1.500438.100 50.800 31.75 1.52 IR-243220 0.209 38.090 38.075 IR-243220 38.120 38.110 HJ-3241201.5000 2.0000 1.250 0.06 0.460 1.4996 1.4990 1.5008 1.50041 9 / 16 39.688 47.625 31.75 1.52 IR-253020 0.127 39.677 39.662 IR-253020D39.708 d4 39.698 HJ-3039201.5625 1.8750 1.250 0.06 0.280 1.5621 1.5615 1.5633 1.562939.688 50.800 31.75 1.52 IR-253220 0.186 39.677 39.662 IR-253220 39.708 39.698 HJ-3241201.5625 2.0000 1.250 0.06 0.410 1.5621 1.5615 1.5633 1.56291 5 / 8 41.275 50.800 31.75 1.52 IR-263220 0.163 41.265 41.250 IR-263220 41.295 41.285 HJ-3241201.6250 2.0000 1.250 0.06 0.360 1.6246 1.6240 1.6258 1.6254B 21 11 / 16 42.863 50.800 25.40 1.52 IR-273216 0.109 42.852 42.837 IR-273216 42.883 42.873 HJ-3241161.6875 2.0000 1.000 0.06 0.240 1.6871 1.6865 1.6883 1.687942.863 50.800 31.75 1.52 IR-273220 0.136 42.852 42.837 IR-273220 42.883 42.873 HJ-3241201.6875 2.0000 1.250 0.06 0.300 1.6871 1.6865 1.6883 1.6879re: Service Catalog, pages 4131 3 / 4 44.450 57.150 38.10 1.52 IR-283624 0.286 44.440 44.425 IR-283624 44.470 44.460 HJ-364824 rev1 - 20Sept991.7500 2.2500 1.500 0.06 0.630 1.7496 1.7490 1.7508 1.750444.450 57.150 44.45 1.52 IR-283628 0.336 44.440 44.425 IR-283628 44.470 44.460 HJ-3648281.7500 2.2500 1.750 0.06 0.740 1.7496 1.7490 1.7508 1.75041 15 / 16 49.213 63.500 38.10 2.03 IR-314024 0.358 49.202 49.187 IR-314024 49.233 49.223 HJ-4052241.9375 2.5000 1.500 0.08 0.790 1.9371 1.9365 1.9383 1.937949.213 63.500 44.45 2.03 IR-314028 0.417 49.202 49.187 IR-314028 49.233 49.223 HJ-4052281.9375 2.5000 1.750 0.08 0.920 1.9371 1.9365 1.9383 1.93792 50.800 63.500 38.10 2.03 IR-324024 0.322 50.790 50.772 IR-324024 50.823 50.810 HJ-4052242.0000 2.5000 1.500 0.08 0.710 1.9996 1.9989 2.0009 2.000450.800 63.500 44.45 2.03 IR-324028 0.376 50.790 50.772 IR-324028 50.823 50.810 HJ-4052282.0000 2.5000 1.750 0.08 0.830 1.9996 1.9989 2.0009 2.00042 3 / 16 55.563 69.850 44.45 2.03 IR-354428 0.467 55.552 55.535 IR-354428 55.585 55.573 HJ-4456282.1875 2.7500 1.750 0.08 1.030 2.1871 2.1864 2.1884 2.18792 1 / 4 57.150 69.850 38.10 2.03 IR-364424 0.358 57.140 57.122 IR-364424 57.173 57.160 HJ-4456242.2500 2.7500 1.500 0.08 0.790 2.2496 2.2489 2.2509 2.2504* *Continued on next page.ACTIMKEN PRODUCTS CATALOG C151•

NEEDLE Roller BearingsInner Rings – continuedInch Series• Check for availabilty.• Ideal choice where shaft not practical to use as innerraceway.• Provided in inch nominal dimensions for use with inch seriesheavy-duty <strong>needle</strong> <strong>roller</strong> bearings.• Designed to meet established inch tolerances.• Selected size should be wider than matching drawn cupbearing.• Maximum shaft fillet radius (r as max) cannot exceed inner ringbore chamfer (r s min) as shown.• Optional centralized lubrication groove (bore) or through-holeavailable – specify when ordering.• Designed to be axially clamped against shoulder for loosetransition fit on shaft.• After mounting, for tight transition fit (keeping inner ring fromrotating relative to shaft), inner ring O.D. must not exceedraceway diameter on matching bearing.CShaft dimensions mm/in. Inner Ring I inner Ring U used WithDiameter D designation Approx. D designation BearingWt. Loose Transition Fit I interference Fit Designationkg/lbs. mm/in. mm/in.Max. Min. Max. Min.in. d F B r s min s s57.150 69.850 44.45 2.03 IR-364428 0.417 57.140 57.122 IR-364428 57.173 57.160 HJ-4456282.2500 2.7500 1.750 0.08 0.920 2.2496 2.2489 2.2509 2.25042 3 / 8 60.325 76.200 44.45 2.03 IR-384828 0.562 60.315 60.297 IR-384828 60.348 60.335 HJ-4860282.3750 3.0000 1.750 0.08 1.240 2.3746 2.3739 2.3759 2.37542 1 / 2 63.500 76.200 38.10 2.03 IR-404824 0.395 63.490 63.472 IR-404824 63.523 63.510 HJ-4860242.5000 3.0000 1.500 0.08 0.870 2.4996 2.4989 2.5009 2.500463.500 76.200 44.45 2.03 IR-404828 0.463 63.490 63.472 IR-404828 63.523 63.510 HJ-4860282.5000 3.0000 1.750 0.08 1.020 2.4996 2.4989 2.5009 2.50042 3 / 4 69.850 82.550 44.45 2.03 IR-445228 0.503 69.840 69.822 IR-445228 69.873 69.860 HJ-5268282.7500 3.2500 1.750 0.08 1.110 2.7496 2.7489 2.7509 2.750469.850 82.550 50.80 2.03 IR-445232 0.576 69.840 69.822 IR-445232 69.873 69.860 HJ-5268322.7500 3.2500 2.000 0.08 1.270 2.7496 2.7489 2.7509 2.75042 15 / 16 74.613 88.900 50.80 2.03 IR-475632 0.694 74.602 74.585 IR-475632 74.635 74.623 HJ-5672322.9375 3.5000 2.000 0.08 1.530 2.9371 2.9364 2.9384 2.93793 76.200 88.900 50.80 2.03 IR-485632 0.621 76.190 76.172 IR-485632 76.223 76.210 HJ-5672323.0000 3.5000 2.000 0.08 1.370 2.9996 2.9989 3.0009 3.00043 1 / 8 79.375 95.250 50.80 2.54 IR-506032 0.880 79.365 79.347 IR-506032 79.398 79.385 HJ-6076323.1250 3.7500 2.000 0.1 1.940 3.1246 3.1239 3.1259 3.12543 1 / 4 82.550 95.250 50.80 2.54 IR-526032 0.708 82.537 82.517 IR-526032 82.578 82.563 HJ-6076323.2500 3.7500 2.000 0.1 1.560 3.2495 3.2487 3.2511 3.250582.550 101.600 50.80 2.54 IR-526432 1.089 82.537 82.517 IR-526432 82.578 82.563 HJ-6480323.2500 4.0000 2.000 0.1 2.400 3.2495 3.2487 3.2511 3.25053 3 / 8 85.725 101.600 50.80 2.54 IR-546432 0.930 85.712 85.692 IR-546432 85.753 85.738 HJ-6480323.3750 4.0000 2.000 0.1 2.050 3.3745 3.3737 3.3761 3.37553 1 / 2 88.900 101.600 50.80 2.54 IR-566432 0.757 88.887 88.867 IR-566432 88.928 88.913 HJ-6480323.5000 4.0000 2.000 0.1 1.670 3.4995 3.4987 3.5011 3.500588.900 107.950 50.80 2.54 IR-566832 1.179 88.887 88.867 IR-566832 88.928 88.913 HJ-6884323.5000 4.2500 2.000 0.1 2.600 3.4995 3.4987 3.5011 3.50053 3 / 4 95.250 107.950 50.80 2.54 IR-606832 1.012 95.237 95.217 IR-606832 95.278 95.263 HJ-6884323.7500 4.2500 2.000 0.1 2.230 3.7495 3.7487 3.7511 3.750595.250 114.300 57.15 2.54 IR-607236 1.406 95.237 95.217 IR-607236 95.278 95.263 HJ-7296363.7500 4.5000 2.250 0.1 3.100 3.7495 3.7487 3.7511 3.750595.250 114.300 63.50 2.54 IR-607240 1.565 95.237 95.217 IR-607240 95.278 95.263 HJ-7296403.7500 4.5000 2.500 0.1 3.450 3.7495 3.7487 3.7511 3.75054 101.600 127.000 57.15 2.54 IR-648036 2.046 101.587 101.567 IR-648036 101.628 101.613 HJ-80104364.0000 5.0000 2.250 0.1 4.510 3.9995 3.9987 4.0011 4.0005101.600 127.000 63.50 2.54 IR-648040 2.272 101.587 101.567 IR-648040 101.628 101.613 HJ-80104404.0000 5.0000 2.500 0.1 5.010 3.9995 3.9987 4.0011 4.00054 1 / 4 107.950 127.000 57.15 2.54 IR-688036 1.565 107.937 107.917 IR-688036 107.978 107.963 HJ-80104364.2500 5.0000 2.250 0.1 3.450 4.2495 4.2487 4.2511 4.25054 1 / 2 114.300 139.700 63.50 2.54 IR-728840 2.495 114.287 114.267 IR-728840 114.328 114.313 HJ-88112404.5000 5.5000 2.500 0.1 5.500 4.4995 4.4987 4.5011 4.5005Continued on next page.•C152 TIMKEN PRODUCTS CATALOG

Heavy-Duty Needle Roller BearingsDF WB• See tables for required bearing dimensions racewaydiameter.r a *r• After mounting, if O.D. of inner ring exceeds the requiredraceway diameter for matching bearing, ring should bed F Sground to proper diameter while mounted on shaft.• Unmarked end of inner ring to be assembled against the shaftshoulder to assure clearing the maximum allowable shaftfillet (r as max) as indicated in tables shown.rShaft dimensions mm/in. Inner Ring I inner Ring U used WithFa Diameter D SD Hdesignation a Approx. D designation BearingWt. Loose Transition Fit I interference Fit Designationshaft surface to be58 HRC or equivalentkg/lbs. mm/in. mm/in.Max. Min. Max. Min.in. d F B r s min s sr aF114.300 139.700 76.20 2.54 IR-728848 2.989 114.287 114.267 IR-728848 114.328 114.313 HJ-88112484.5000 5.5000 3.000 0.1 r a 6.590 4.4995 4.4987 S4.5011 4.5005d4 3 / 4 120.650 146.050 76.20 3.05 IR-769248 3.180 120.635 120.612 IR-769248 120.683 120.665 HJ-92116484.7500 5.7500 3.000 0.12 7.010 4.7494 4.7485 4.7513 4.75065 127.000 152.400 63.50 3.05 IR-809640 2.781 126.985 126.962 IR-809640 127.033 127.015 HJ-96120405.0000 6.0000 2.500 0.12 6.130 4.9994 4.9985 5.0013 5.0006r127.000 152.400 76.20 3.05 IR-809648 3.325 126.985 126.962 IR-809648 127.033 127.015 HJ-96120485.0000 re: Service 6.0000 Catalog, 3.000 pages 0.12408, 410, 411, 4127.330 4.9994 4.9985 5.0013 5.00065 1 / 2 139.700 165.100 63.50rev3 - 8Oct993.05 IR-8810440 3.035 139.685 139.662 IR-8810440 139.733 139.715 HJ-104128405.5000 6.5000 2.500 0.12 6.690 5.4994 5.4985 5.5013 5.5006139.700 165.100 76.20 3.05 IR-8810448 3.629 139.685 139.662 IR-8810448 139.733 139.715 HJ-104128485.5000 6.5000 3.000 0.12 8.000 5.4994 5.4985 5.5013 5.50066 152.400 184.150 76.20 3.05 IR-9611648 4.935 152.385 152.362 IR-9611648 152.433 152.415 HJ-11614648B 3d6.0000 7.2500 3.000 0.12 10.880 5.9994 5.9985 6.0013 6.00066 1 / 2 165.100 196.850 76.20 3.05 IR-10412448 5.343 165.085 165.062 IR-10412448 165.133 165.115 HJ-124154486.5000 7.7500 3.000 0.12 11.780 6.4994 6.4985 6.5013 6.50067 177.800 209.550 76.20 3.05 IR-11213248 5.389 177.785 177.762 IR-11213248D177.833 d4 177.815 HJ-132162487.0000 8.2500 3.000 0.12 11.880 6.9994 6.9985 7.0013 7.00067 1 / 2 190.500 222.250 76.20 4.06 IR-12014048 6.110 190.485 190.454 IR-12014048 190.536 190.515 HJ-140170487.5000 8.7500 3.000 0.16 13.470 7.4994 7.4982 7.5014 7.50068 203.200 234.950 76.20 4.06 IR-12814848 6.518 203.185 203.154 IR-12814848 203.236 203.215 HJ-148178488.0000 9.2500 3.000 0.16 14.370 7.9994 7.9982 8.0014 8.0006B 2* *ACre: Service Catalog, pages 413rev1 - 20Sept99TIMKEN PRODUCTS CATALOG C153•

NEEDLE Roller BearingsNOTESC•C154 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track Rollerstrack <strong>roller</strong>sOverview: Track <strong>roller</strong>s (also known as cam followers) are characterized by their thick-walled outerrings that run directly on a track. The thick outer rings permit high load-carrying capability whileminimizing both distortion and bending stresses. Sealed designs with internal thrust washers helpextend service life under conditions of infrequent lubrication.• Sizes: 16 mm - 110 mm ( 1 / 2 in. - 4 in.) bore.• Markets: Ram support <strong>roller</strong>s, material handling and indexing equipment.• Features: Available in two basic designs: with an inner ring for straddle mountingin a yoke or with an integral stud for cantilever mounting.• Benefits: High load-carrying capability with minimized distortion and bending stresses.Extended service life under conditions of infrequent relubrication.CAFPOAFPOTIMKEN PRODUCTS CATALOG C155•

Yoke NEEDLE Type Track Roller Rollers Bearings – Metric Nominal DimensionsBore diameter from 10 mm to 17 mm (for NA22)00 = 10 mm 02 = 15 mm01 = 12 mm 03 = 17 mmBore diameter > 17 mm (for NA22)05 = 25 mmNA22 05 2rsCPrefixNA22 track <strong>roller</strong>, yoke type, profiled outsidediameter with inner ring, sealedRNA22 track <strong>roller</strong>, yoke type, profiled outsidediameter without inner ring, sealedRSTO track <strong>roller</strong>, yoke type, profiled outsidediameter without inner ring, without washersSTO track <strong>roller</strong>, yoke type, profiled outsidediameter with inner ring, without washersNATR track <strong>roller</strong>, yoke type, profiled outsidediameter with inner ring, with washersNUTR track <strong>roller</strong>, yoke type, profiled outsidediameter with inner ring, with washers;two paths of full complement cylindrical <strong>roller</strong>sSuffixTN molded cage of reinforced, engineered polymerDZ cylindrical outside diameterZZ two washers for track <strong>roller</strong>s used for axiallocation.2RS lip contact seal on each side of the bearingZZ.DZ two washers for track <strong>roller</strong>s used for axiallocation; cylindrical outside diameterDZ.TN cylindrical outside diameter; molded cage ofreinforced, engineered polymer.2RS.DZ lip contact seal on each side of bearing;cylindrical outside diameterSTO 25 DZBore diameter for STO, NATR, NUTR:25 = 25 mm45 = 45 mmNUTR 45 100 DZOutside diameter for NUTR100 = 100 mmStud Type Track Rollers – Metric Nominal DimensionsPrefix ModificationE Eccentric studSuffixSK hexagonal wrench socket in stud headDZ.2RS cylindrical outside diameter: lip contactseals on each end of bearing.2RS lip contact seal on each side of the bearingDZ cylindrical outside diameterAKR E 22 .2RSPrefixKR track <strong>roller</strong>, stud type with cage; profiled outside diameterKRV track <strong>roller</strong>, stud type, full complement <strong>needle</strong> <strong>roller</strong>s; profiled outside diameterNUKR track <strong>roller</strong>, stud type, full complement of cylindrical <strong>roller</strong>s (2 rows) profiled outside diameterTrack Rollers ⁄ Cam Followers – Inch Nominal DimensionsOutside diameter22 = 22 mmPrefixCR stud typeYCR yoke typeOutside Diameter8 = 8 ⁄ 16 = 1 ⁄ 2 in.16 = 16 ⁄ 16 = 1 in.CR S B E - 1632 = 32 ⁄ 16 = 2 in.36 = 36 ⁄ 16 = 2 1 ⁄ 4 in.•Design ModificationsS seals with internal thrust washers (CR Type only)B hex wrench socketC crowned O.D.E eccentric stud (CR Type only)C156 TIMKEN PRODUCTS SERVICE CATALOG

<strong>Full</strong> Complement Yoke Type Track Rollers - Metric Nominal DimensionsPrefixNUTR track <strong>roller</strong>, yoke type, profiled outside diameterwith inner ring and washers (two paths of cylindrical <strong>roller</strong>s)FG track <strong>roller</strong>, yoke type, profiled outside diameter standard seriesFGU track <strong>roller</strong>, yoke type, profiled outside diameter light seriesFGU track <strong>roller</strong>, yoke type, profiled outside diameter heavy series(larger O.D. than light series of same bore size)FP track <strong>roller</strong>, yoke type, profiled outside diameter small seriesRNA track <strong>roller</strong>, yoke type, profiled outside diameter 11000 Series(without seals)NUTR 45 100 .DZBore diameter45 = 45 mmOutside diameter100 = 100 mm(see tables fordimensions)RNA 110 12 B6Suffix.DZ cylindrical outside diameter (NUTR styles only)EE 2 polymer shields (FG styles only)EEM 2 metal shields (FG styles only)MM 2 metal shields (FGU styles only)CCAFG L 6 19 EEMPrefix ModificationL cylindrical outside diameter<strong>Full</strong> Complement Stud Type Track Rollers - Metric Nominal DimensionsPrefixNUKR track <strong>roller</strong>, stud type, profiled outside diameter(two paths of cylindrical <strong>roller</strong>s)KRV track <strong>roller</strong>, stud type, profiled outside diameterwith full complement of <strong>needle</strong> <strong>roller</strong>sGC track <strong>roller</strong>, stud type, profiled outside diametersmall series (up to 15 mm O.D.), standard seriesGCU track <strong>roller</strong>, stud type, profiled outside diameterlight seriesOutside diameter16 = 16 mmKRV 16 .DZNUKR 62 .2SKGC L 6 19 EEMAPrefix ModificationL cylindrical outside diameterR eccentric collarBore diameter45 = 45 mmSuffix.DZ cylindrical outside diameter (KRV styles only).2SK hexagonal socket in stud head (NUKR styles only)EE 2 polymer shields (GC, GCR styles only)EEM 2 metal shields (GC, GCR styles only)MM 2 metal shields (GCU, GCUR styles only)TIMKEN PRODUCTS SERVICE CATALOG C157TIMKEN SERVICE CATALOG C157• • •

CCA•C158 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke TypeTrack RollersSTUD TYPE AND YOKE TYPE TRACK ROLLERSMETRIC SERIESPageIntroduction.............................................................................. C160STUD TYPE Metric SeriesNeedle Roller and Cage Assemblies (KR Series)................... C168Needle Roller and Cage Assemblies, Sealed(KR….2S Series)................................................................. C170<strong>Full</strong> Complement with Needle Rollers (KRV Series) orCylindrical Rollers (NUKR Series).................................... C172<strong>Full</strong> Complement, Small Series, Unsealed (GC Series)........ C174<strong>Full</strong> Complement, Standard Series, with orwithout Seals (GC Series)................................................ C176<strong>Full</strong> Complement, with Metal Seals (GCU…..MM Series).... C178<strong>Full</strong> Complement, Eccentric (GCR Series).............................. C180<strong>Full</strong> Complement Eccentric, with Metal Seals(GCUR…..MM Series)........................................................ C184YOKE TYPE METRIC SERIESCaged, without Inner Ring, No End Washers(RSTO Series)..................................................................... C186Caged, with Inner Ring, No End Washers (STO Series)....... C188Caged, without Inner Ring, No End Washers,Sealed (RNA22 Series)...................................................... C190Caged, with Inner Ring, No End Washers,Sealed (NA22 Series)........................................................ C192Caged, with Inner Ring, With End Washers(NATR, STO.ZZ Series)...................................................... C194<strong>Full</strong> Complement, with Inner Ring, with End Washers,Cylindrical Rollers (NUTR Series).................................... C196....................................................................................................... Page<strong>Full</strong> Complement, Non-Separable, Small Series,Unsealed (FP Series)......................................................... C198<strong>Full</strong> Complement, Non-Separable, Sealed or Unsealed(FG Series).......................................................................... C199<strong>Full</strong> Complement, Non-Separable, Light Series,with Metal Seals (FGU…..MM Series)............................. C202<strong>Full</strong> Complement, Non-Separable, Heavy Series,with Metal Seals (FGU…..MM Series)............................. C203<strong>Full</strong> Complement, without Inner Ring, Unsealed(RNA…..B6, RNAB, RNAL Series)..................................... C205Separate Inner Rings for RNA…..B6, RNAB,RNAL Series (BIC Series).................................................. C205STUD TYPE AND YOKE TYPE TRACK ROLLERS ....................................INCH SERIESIntroduction.............................................................................. C206Stud Type Track Rollers CR, CRS Series................................ C212Stud Type Track Rollers CRSB Series..................................... C216Yoke Type Track Rollers YCR, YCRS Series........................... C220CAATIMKEN PRODUCTS CATALOG C159•

NEEDLE Roller BearingsCStud Type And Yoke Type Track Rollers –Metric SeriesTimken track <strong>roller</strong>s listed in this catalog have been designedwith outer rings of a large radial cross section to withstand heavyrolling and shock loads on track type or cam-controlled equipment.The outside diameters of the outer rings are either profiled orcylindrical. Profiled track <strong>roller</strong>s are designed to alleviate unevenbearing loading resulting from deflection, bending or misalignmentin mounting.Stud type track <strong>roller</strong>s are available in various open designs,as well as with lip contact seals or metal shields.Yoke type track <strong>roller</strong>s are designed for straddle mounting.The various metric series designs are grouped and organized asillustrated below.Reference standards are:• ISO 6278 – Needle <strong>roller</strong> bearings – Track <strong>roller</strong>s –Boundary dimensions• ISO 492 – Radial bearings – Tolerances• DIN 620 – Tolerances of Ball and Roller Bearings• ISO 281 – Rolling bearings – Dynamic load ratingsand rating lifeASuffixes – Stud Type, Metric Series (except GC types).2RStwo sealsDZcylindrical outside diameterDZ.2RS cylindrical outside diameter • two sealsSKhexagonal socket in flange end2SKhexagonal socket in both flange and stud endsSuffixes – Yoke Type, Metric Series (except FP or FG types)DZ.TNcylindrical outside diameter • molded cage of reinforced engineered polymerTNmolded cage of reinforced engineered polymerDZcylindrical outside diameterZZtwo end washers for the outer ringZZ.DZtwo end washers for the outer ring • cylindrical outside diameter.2RStwo seals.2RS.DZ two seals • cylindrical outside diameterSuffixes – Yoke Type (FP, FG) and Stud Type (GC)EEpolymer sealsEEMmetal shieldsMMmetal shields•C160 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track RollersKRStud Type Metric series Track Roller TypesKR.BKR.CKR.DZKR.B.DZKR.C.DZStud type track <strong>roller</strong>s, caged <strong>needle</strong> <strong>roller</strong>sKRKR.BKR.Ckr kr.DZ KR.2RS KR.DZ.2RSKR.DZKR.B.DZKR.C.DZKR.B.2RSKR.C.2RSKR.B.DZ.2RSKR.C.DZ.2RSCAStud type track <strong>roller</strong>s, full complement <strong>needle</strong> <strong>roller</strong>sPage 131-1rev1.26Jan99KR.B.2RSKR.C.2RSKR.B.DZ.2RSKR.C.DZ.2RSKRVkrVKRV.DZkrV.DZPage 131-1rev1.26Jan99GC/GCL GC/GCL GCR/GCRLKRVKRV.DZNUKR.AANUKR.AA.DZAGC...series:Stud type track <strong>roller</strong>s, GC...EE series: withoutfull with plasticsealscomplement sealscylindrical <strong>roller</strong>sGC...EEM series: with metal sealsPage 131-2rev4.25Feb99NUKR.AANUKR.AA.DZnukr NUKR.DZ GCU/GCUL GCUR/GCURLPage 131-2rev4.25Feb99TIMKEN PRODUCTS CATALOG C161•

NEEDLE Roller BearingsTypes of Metric Series Yoke Type Track RollersYoke type track <strong>roller</strong>s without end washersCrsto rsto.DZ sto sto.DZRSTO RSTO.DZ STORSTO.DZ RSTO.DZ RSTO.DZ STO.DZSTO.DZRSTO RSTO.DZ STORSTO.DZ RSTO.DZ RSTO.DZ STO.DZSTO.DZSealed yoke type track <strong>roller</strong>s without end washers.RNA22.2RSRNA22.2RS.DRNA22.2RS.DNA22.2RS.DZRNA22.2RS.DNA22.2RS.DZRNA22.2RS.DNA22.2RS.DZNA22.2RS.DZZZZZRNA22.2rs rna22.2RS.DZ na22.2rs na22.2RS.DZRNA22.2RSRNA22.2RS.DRNA22.2RS.DNA22.2RS.DZRNA22.2RS.DRNA22.2RS.DNA22.2RS.DZNA22.2RS.DZNA22.2RS.DZZZZZPage 109-1Page 109-1 rev0.Nov98 Page 109-1Yoke type track <strong>roller</strong>s Page 109-1 with end Page washers109-1 rev0.Nov98 Page 109-1rev0.Nov98 Page 109-1 rev0.Nov98rev0.Nov98Yoke type track <strong>roller</strong>s with fullcomplement of cylindrical <strong>roller</strong>srev0.Nov98 Page 109-1rev0.Nov98rev0.Nov98Anatr natr.DZ sto.ZZ sto.ZZ.DZNATR NATR NATR NATR NATR.DZ NATR.DZ NATR.DZ NATR.DZ ST0.ZZ ST0.ZZ ST0.ZZ ST0.ZZ STO.ZZ.DZ STO.ZZ.DZ STO.ZZ.DZ STO.ZZ.DZFGU/FGUL LightFGU/FGUL HeavyNATR NATR NATR.DZ NATR.DZ ST0.ZZ ST0.ZZ STO.ZZ.DZ STO.ZZYoke type track <strong>roller</strong>s with end washers, full complement of <strong>needle</strong> <strong>roller</strong>sNUTR NUTR NUTR NUTRNUTR.DZ NUTR.DZ NUTR.DZ NUTR.DZFP/FPL FG/FGl rna1100 NUTRnutr NUTR NUTR.DZ NUTR.DZ nutr.DZPage Page 109-2 Page 109-2 Page 109-2 109-2rev0.Nov98rev0.Nov98RNA...B6•C162 TIMKEN PRODUCTS CATALOGPage 109-2 Page 109-2rev0.Nov98

ConstructionStud Type Track RollersThe metric series stud type track <strong>roller</strong> is a non-separableunit, consisting of a large radial cross-section outer ring, <strong>needle</strong><strong>roller</strong> and cage radial assembly or a full complement of <strong>needle</strong> orcylindrical <strong>roller</strong>s, a stud and a retaining washer securely fastenedto the stud.The seals on the sealed stud type track <strong>roller</strong>s are located in thecounterbores of the outer ring and seal against the stud flange and theretaining washer, providing good retention of lubricant and exclusionof foreign material. The seals are thermally stable in a temperaturerange between -30˚ C and 110˚ C.A screwdriver slot (standard) or a hexagonal wrench socket(customer requested) in the head of the stud facilitates mounting.Wrench sizes are listed on the dimensional tables where found amongcertain GC Series sizes on pages later in this section. Other metricseries hexagonal socket sizes are listed in Table 1.Stud Type and Yoke Type Track RollersSome applications may require more secure positioning thanprovided by the tightened stud nut. If so, it is recommended thatthe mounting hole and the eccentric bushing be drilled at the timeof installation to accept a locating dowel pin.B ee De SW80 90 30 35 29 1.5tTable 1 –Hexagonal Socket – Metric SeriesTable 2 –Eccentric Bushing Dimensions –Stud Type Track RollerdimensionsMetric Series (except GCR, GCUR series)Outside DiameterStud Type Track Roller> ≤ sw tOutside Diameter mm dimensionsmm> ≤16 3 2.5d e D e B e e19 26 4 2.516 6 9 7 0.530 35 6 419 19 8 11 9 0.540 52 8 522 26 10 13 10 0.562 72 12 730 32 12 15 11 0.580 90 17 1035 35 16 20 14 1.040 40 18 22 16 1.047 52 20 24 18 1.0B eSWCAd ee DePage 132Table 2A -Eccentric Bushing DimensionsMetric Series GCR, GCurEccentric Studs For Stud Type Track RollersTo provide radial adjustment of the outer ring toward the track orcam surface at the time of installation, some metric series stud typetrack <strong>roller</strong>s are available with eccentric studs which are specifiedby adding the letter “E” to the designation letters: KRE and NUKRE.The GCR and GCUR Series include an eccentric bushing added tothe track <strong>roller</strong> stud. Appropriate dimensions of the eccentric studbushing are listed in Table 2 and 2A.Since a track <strong>roller</strong> with an eccentric stud is usually adjustedupon installation by turning the stud in the mounting hole, a closeclearance fit between the outside diameter of the bushing andthe mounting hole is necessary. For turning the stud, a hexagonalwrench is generally more convenient than a screwdriver, thus,the option of a hexagonal wrench socket in the head of the studshould be considered.tover incl. de De Bw emm- 19 6 9 7.5 0.519 28 10 14 10.5 1.028 32 12 16 11.5 1.032 35 16 21 15.1 1.535 40 18 24 17.1 1.540 52 20 27 19.1 2.052 72 24 36 24.1 3.072 90 30 42 30.7 3.090 110 36 48 36.5 3.0110 - 42 54 43.5 3.0ATIMKEN PRODUCTS CATALOG C163•

CANEEDLE Roller BearingsYoke Type Track RollersMetric Series Yoke Type Track RollersWithout End WashersThese yoke type track <strong>roller</strong>s are available with a profiled or acylindrical outside diameter of the outer ring, and with or without aseparable inner ring. Since they are supplied without end washers,their outer rings must be guided by the adjacent end locatingsurfaces. Tolerance class F6 is the normal specification for thebore of the metric series <strong>needle</strong> <strong>roller</strong> and cage radial assembliesused with these yoke type track <strong>roller</strong>s.Yoke Type Track Rollers – Series RSTO & STOSeries STO have a separable inner ring and when the innerring is removed they become series RSTO. They run directly on ahardened and ground inner raceway. Quality requirements for innerraceways are given in the engineering section of this catalog.Sealed Yoke Type Track Rollers Without EndWashers – Series RNA 22.2RS & NA22.2RSThese yoke type track <strong>roller</strong>s have the same bore diameter andoutside diameter as most of the other metric series yoke type track<strong>roller</strong>s listed in this catalog. The thick section outer ring is madeof one-piece channel-shaped bearing quality steel, heat treated toyield maximum load carrying capability. The integral end flangesprovide axial guidance for the large diameter <strong>needle</strong> <strong>roller</strong>s, anda cage supplies their inward retention. These track <strong>roller</strong>s havetwo integral lip contact seals designated by .2RS. The seals arethermally stable in a temperature range between -30° C and 110° C.Care should be exercised when mounting track <strong>roller</strong>s withoutinner rings onto inner raceways to avoid damage to the seals.Inner raceway quality requirements are given in the engineeringsection of this catalog.Metric Series Yoke Type Track Rollers WithEnd WashersThese yoke type track <strong>roller</strong>s are available with a crowned ora cylindrical outside diameter of the outer ring. Metric series yoketype track <strong>roller</strong>s with end washers, depending on the internalconstruction, may be end guided, either through the end washersor between the end faces of the <strong>roller</strong>s and the inside faces of theouter ring flanges.Yoke Type Track Rollers – Series NATR & STO.ZZThe series NATR yoke type track <strong>roller</strong>s are of non-separabledesign consisting of a crowned or a cylindrical outer ring, caged<strong>needle</strong> <strong>roller</strong>s, an inner ring and two retaining end washers securelyfastened to the inner ring. The series STO.ZZ yoke type track <strong>roller</strong>sare of separable design with two loose end washers. These endwashers placed in the counter bores of the outer ring form veryeffective labyrinth type shields, providing good retention of lubricantand exclusion of foreign material. A lubrication hole in the innerring enables relubrication when a cross-drilled bolt or shaft, whichcan be serviced from the end, is used.Yoke Type Track Rollers – Series NUTRThe series NUTR yoke type track <strong>roller</strong>s are of non-separabledesign consisting of a profiled or cylindrical outer ring, two rows offull complements of cylindrical <strong>roller</strong>s, an inner ring, two retainingend washers and two shields. The outer ring is located axiallythrough the cylindrical <strong>roller</strong>s.A lubricating hole in the inner ring enables relubrication whena cross-drilled bolt or shaft, which can be serviced from the end,is used.The smallest track <strong>roller</strong> of this series has an outside diameterof 35 mm. NUTR yoke type track <strong>roller</strong>s are well suited to carryhigh loads and designs with a thicker outer ring are particularlysuitable for high shock loads. Designs with thicker outer ring havea larger outside diameter which can be identified by the bearingdesignation (e.g., NUTR 1542).Yoke type track <strong>roller</strong>s – series FP and FGThe FP and FG non-separable inner ring designs are available inprofiled or cylindrical outer rings. Both employ a full complementof <strong>needle</strong> <strong>roller</strong>s and require relubrication via a pathway throughthe shaft. The FP Series is the smallest series available and is notoffered with seals.Yoke type track <strong>roller</strong>s – series FGU(Light and Heavy types)The FGU non-separable inner ring desings are availablein profiled or cylindrical outer rings. All FGU Series use a fullcomplement of cylindrical <strong>roller</strong>s between the inner and outer ringsand require relubrication via a pathway through the shaft. The FGUHeavy series uses a thicker outer ring section and are capable ofhigher loads.Both FGU Series are only available with a metal shield for a<strong>roller</strong> sealing option.Yoke type track <strong>roller</strong>s – series RNA, RNAB,RNALThe RNA and RNAB Series design use a full complement of<strong>needle</strong> <strong>roller</strong>s retained with a pair of end washers. A separate,matching inner ring is listed in the tables of part numbers. TheRNAL Series use a cylindrical outer ring and is only offered inlimited sizes.•C164 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track RollersDimensional AccuracyThe tolerances of the basic metric series caged <strong>roller</strong> and NUKRstud type and yoke type track <strong>roller</strong>s whose outer rings have acylindrical outside diameter, correspond to tolerances specifiedin ISO-492 Radial bearings - Tolerances. The outer ring tolerancesgiven in Table 4 apply to the outer rings used in the caged <strong>roller</strong> andNUKR stud type and caged <strong>roller</strong> and NUTR yoke type, metric series,track <strong>roller</strong>s. Metric series track <strong>roller</strong>s with a crowned outsidediameter are the exception: their outside diameter tolerances is 0-0.05 for all caged <strong>roller</strong> sizes and NUTR, NUKR types. The remainingtypes have h9 tolerance on profiled outer diameters and h7 forstraight diameters. Stud diameter and stud length tolerances areTable 3 –Tolerances For Stud Diameter And Stud Length– Metric SeriesStud Diameter mmStud Length mmµm> ≤ high low high lowd 1 ∆d 1S B 2 ∆B 23 6 0 -126 10 0 -15 all10 18 0 -18 lengths 0 -118 30 0 -2130 50 0 -2550 80 0 -3080 100 0 -35given in Table 3. The inner ring tolerances given in Table 5 apply toinner rings used in metric series caged <strong>roller</strong>, NUKR Series yoketype track <strong>roller</strong>s.Mounting Stud Type Track RollersWhen the stud shank of a metric series stud type track <strong>roller</strong> ismounted in a hole of tolerance H7, the installation force should beapplied only to the center portion of the flanged end of the stud,preferably with an arbor press. The surface of the hole in themachine element which supports the stud must not deform underthe expected load, and the support should be sufficiently rigid toresist bending loads. Deformation and bending will cause unevenloading of the outer ring.In mounting the stud type track <strong>roller</strong>, the retaining washer mustbe firmly backed up by a flat shoulder which is square with the studcenter line. The shoulder diameter must be no smaller than theminimum clamping diameter, d a listed in the tabular data.The maximum inherent strength of the stud is obtained whenthe track <strong>roller</strong> is supported as close as possible to the retainingwasher, which minimizes the bending moment. For this reason theedge of the housing which supports the stud shank should be keptas sharp as practical, but free from burrs.The clamping nut should not be tightened with a torque valuehigher than the maximum listed. A screwdriver slot or hexagonalwrench socket in the flanged end of the stud is provided for a toolto prevent the stud from turning when the nut is being tightened.Hexagonal nuts are supplied with all metric series stud type track<strong>roller</strong>s.CATable 4 –Outer Ring – Metric Series (Caged <strong>roller</strong> and nukr, nutr types)Tolerances in mm (0.001 mm)mm> ≤ cylindrical crownedhigh low high low high low max.D ∆ Dmp ∆ Cs k ea10 18 0 -8 0 -50 0 -120 1518 30 0 -9 0 -50 0 -120 1530 50 0 -11 0 -50 0 -120 2050 80 0 -13 0 -50 0 -120 2580 120 0 -15 0 -50 0 -120 35120 150 0 -18 0 -50 0 -120 40150 180 0 -25 0 -50 0 -150 45180 240 0 -30 0 -50 0 -200 50ATable 5 – Inner Ring – Metric Series (Caged <strong>roller</strong> and nutr types)Tolerances in mm (0.001 mm)mm> ≤ high low high lowd ∆ dmp ∆ Bs2.5 18 0 -8 0 -18018 30 0 -10 0 -21030 50 0 -12 0 -25050 80 0 -15 0 -30080 120 0 -20 0 -350TIMKEN PRODUCTS CATALOG C165•

NEEDLE Roller BearingsCYoke Type Track RollersThe machine element with the holes in which the mountingbolt or shaft is supported must be sufficiently rigid to resist localcrushing under the applied load, and to resist bending which cancause uneven loading of the <strong>needle</strong> <strong>roller</strong>s.When applied loads are high, the h6 or j6 tolerance should beused in conjunction with a high strength shaft or bolt for mountingmetric series yoke type track <strong>roller</strong>s. When loads are moderate,a g6 tolerance may be used with a high strength shaft or bolt. Forlight loads, the loose transition fit with the f6 tolerance may be usedwith an unhardened shaft or bolt.The yoke type track <strong>roller</strong>s with inner rings, also those withend washers as well as inner rings, should be clamped endwisebetween parallel faces perpendicular to the axis to prevent theretaining washers from coming off under load. The dimensions ofmachine parts adjoining the metric series yoke type track <strong>roller</strong>sshould be based on the minimum clamping diameter d a to ensurethat the washers are adequately supported. If the track <strong>roller</strong>cannot be end clamped, a close axial fit in the yoke is required.Care should be taken that the lubricating hole is located in theunloaded zone of the raceway.The metric series yoke type track <strong>roller</strong>s without inner ringsrequire a hardened and ground shaft or bolt with a k5 tolerance.Inner raceway quality requirements are given in the engineeringsection of this catalog.ALoad RatingsDynamic Loading As A Track RollerWhen the outer ring of a stud type or yoke type track <strong>roller</strong>runs on a track, the contact, under a radial load, causes elastic(oval) deformation of the outer ring. As a result, a smaller zone ofthe raceway is loaded and the load is distributed on fewer <strong>needle</strong><strong>roller</strong>s. This in turn affects the dynamic and static load ratings ofthe track <strong>roller</strong>s. Also, this deformation generates bending stressin the outer ring which must not exceed the maximum permitted forthe material of the outer ring. The maximum permissible dynamic(F r perm) radial load condition is determined by this requirement.The rating life of stud type or yoke type track <strong>roller</strong>s should becalculated using the dynamic load ratings C w shown in the tables.The tables also show the maximum permissible radial load, F r permthat can be dynamically applied on stud type or yoke type track<strong>roller</strong>s. However, to calculate the L 10 life of a track <strong>roller</strong>, theapplied radial load must not be greater than C w/2 based on idealoperating conditions of alignment, lubrication, temperature, speed,and accelerations.Static Rating As A Track RollerIn addition to the basic static load rating C 0, the tables also listthe maximum permissible static radial load F 0r perm that may beapplied to a stud type or yoke type metric series track <strong>roller</strong>. Thevalues of F 0r perm result in a calculated minimum static factor f s of 0.7for the worst condition of internal load distribution in metric seriestrack <strong>roller</strong> operation. The F 0r perm values must not be exceeded. Thestatic factor f s can be calculated using the following formula:f s ≥F0.7 • 0r permwhereF 0r permP 0rF 0rf s= Maximum permissible static radial load (kN)= Equivalent static load (kN)P 0r = F 0r for metric series track <strong>roller</strong>s= Static radial load (kN)= Static factor whose values should not besmaller than those suggested in Table 6.Table 6 –suggested Values For Static Factors f s For Metric SeriesTrack RollersRequirements For Yoketype Track Rollers And Studtype Track RollersP 0rsuggested f s ValuesHigh shock-type loadsQuiet running 1.5...2.5Normal loadingNormal quietness ofrunning 1...1.5Minor impact loads androtary motion particularlyquiet running not required 0.7...1•C166 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track RollersLubrication Of Stud TypeTrack RollersTimken metric series stud type track <strong>roller</strong>s are supplied with alithium soap based, general purpose grease. When the caged KRSeries track <strong>roller</strong>s are operated at low speeds, with light loadsand in clean environments, there often is no need to relubricatethe track <strong>roller</strong>. In other applications, periodic relubrication maybe necessary to obtain optimum performance. The full complementseries of track <strong>roller</strong>s have less internal volume available forgrease storage, therefore, they may require more frequentlubrication than caged type track <strong>roller</strong>s. Stud type track <strong>roller</strong>s,with a screwdriver slot in the flanged end of the stud, haveprovisions for relubrication through the flanged end of the stud.Metric series stud type track <strong>roller</strong>s with hexagonal sockets cannot be relubricated from the flanged end of the stud. Both types ofmetric series stud type track <strong>roller</strong>s, with outside diameters largerthan 22 mm (28 mm for all GC variations), allow for relubricationthrough the threaded end of the stud. In addition, caged <strong>roller</strong> andNUKR Series stud type track <strong>roller</strong>s with 30 mm and larger outsidediameters allow for relubrication through a cross-drilled hole in thestud shank. The ends of the axial holes are counterbored to acceptpress-fit grease fittings of series VENN. The grease fittings aresupplied with metric series stud type track <strong>roller</strong>s. Hole diameters(d 4) for these grease fittings are listed in the tables of dimensionson pages later in this chapter as it applies. Note that the GC smallseries has no axial hole.One or more plugs are supplied with every metric series studtype track <strong>roller</strong> to close off unused holes. At the flanged end,the plug must not be pushed in too deeply as it may cover thecross-drilled lubricating hole. The plug should be pressed in usingan installation tool whose dimensions are given in Table 8. If thecross-drilled hole in the stud shank is not used, it will be coveredwhen the track <strong>roller</strong> is properly installed.t 1-0,1d D-0,1 d 4-0,1d E-0,1t +0,2During installation of the track <strong>roller</strong> it will be desirable to ensurethat the cross drilled hole is positioned in the unloaded zone of thetrack <strong>roller</strong> raceway. The location of the cross-drilled hole can bebest recognized by its alignment with the manufacturer's stampor parallel to the screwdriver slot, in certain cases.Lubrication Of Yoke TypeTrack RollersYoke type track <strong>roller</strong>s are produced with a lubricating hole inthe inner ring so they can be relubricated through a cross-drilledhole in the supporting shaft or bolt. When mounting yoke type track<strong>roller</strong>s, care should be taken that the lubrication hole is located inthe unloaded raceway zone.Oil is the preferred lubricant for yoke type track <strong>roller</strong>s.Continuous oil lubrication or frequent grease lubrication should beused for steady rotating conditions. Applications involving slow,intermittent oscillations are not as critical, and longer intervalsbetween relubrication are permitted. Sealed yoke type track<strong>roller</strong>s are normally supplied with an initial charge of a mediumtemperature grease. Caged yoke type track <strong>roller</strong>s have maximumgrease storage capacity and, consequently, longer pregreased lifethan full complement types.CAd 4H 1D kHATable 7 – Metric Series Grease Fittings, Series VENNDesignation Dimensions mm wt. gapprox.d 4 D K H H 1VENN 4 4 6 6 1.5 0.4VENN 6 6 8 7 2 1.6VENN 8 8 10 12 3 4.7Table 8 – Installation Tool For Metric Series PlugStud Typedimensionstrack Rolleroutsidediameter mm> ≤ d 4 d D d E t t 116 26 3.9 10 2.7 3.7 4.530 40 5.9 12 4.7 4.7 747 90 7.9 15 6.7 6.7 10TIMKEN PRODUCTS CATALOG C167•

NEEDLE Roller BearingsD d a d 4 d 1 d 4 GG 1B 2KRKR.BKR.CNeedle Roller and Cage Assemblies,Stud type (KR Series)Metric SeriesrCrCC 1B 1B 3d 3R500B 3d 3D d a d 4 d 1 d 4 GG 1B 2KRD KR.B d a d 4 d 1d 4KR.CGKR.DZKR.B.DZKR.C.DZCAC 1B 1KRL 2 C B 3rd ard 3R500Outer D dimensions mm/in.Dia.KR.DZThreadD D a d 1 d h d 1D KR.B.DZ d a d 4 d 1d 4mm d 1 h 7 C r s min B 1 B 2 B 3 G 1 KR.C.DZd 4 d 3 G C 116 6 16 11 0.3 28.2 16 8 4 M6x1 0.60.2362 0.6299 0.433 0.012 1.110 0.630 0.315 0.157 0.0246 16 11 0.3 28.2 16 8 4 C M6x1 10.6 G 10.2362 0.6299 0.433 0.012 C 1.110 0.630 0.315 0.157 0.024sB 219 8 19 11 0.3 32.2L20 10 4 M8x1.25 0.6B0.3150 0.7480 0.433 0.012 1.268 1L0.787 0.394 0.157 0.02428 19 11 0.3 32.2 20 10 4 M8x1.25 0.6r0.3150 0.7480 0.433 0.012 1.268d0.787 a0.394 0.157 0.02422 10 22 12 R500 0.3 36.0 23 12 4 M10x1 0.60.3937 0.8661 0.472 0.012 1.417 0.906 0.472 0.157 0.024KR.B.2RS10 22 12 D D a d0.3 36.2 1 d h23 d 1 G 12 4 M10x1 0.6KR.C.2RS0.3937 0.8661 0.472 0.012 1.425 0.906 0.472 0.157 0.024300.3937 1.0236 0.472 0.012 1.425 0.906 0.472 0.157 0.024CLs112 30 14 0.6 40.0 25 6 13 Page 136/138 6 3 M12x1.5 0.6Lrev3.26Jan990.4724 1.1811 0.551 0.024 1.575 0.984 0.236 0.512 0.236 0.118 0.02410 26 12 0.3 36.2 23 L 3 12 4 M10x1 0.626 10 26 12 0.3 36.0 23 12 4 M10x1 0.60.3937 1.0236 0.472 0.012 1.417 0.906 0.472 0.157 0.024L 1L 3GC 1B 1KR.DZB 2G 112 30 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.1811 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.02432 12 32 14 0.6 40.0 25 6 13 6 3 M12x1.5 0.60.4724 1.2598 0.551 0.024 1.575 0.984 0.236 0.512 0.236 0.118 0.02412 32 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.2598 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.024GKR.B.2RKR.C.2RPage 136/138•C168 TIMKEN PRODUCTS CATALOG

Dd a d 4 d 1 d 4G 1B 2GKR.DZKR.B.DZKR.C.DZStud Type and Yoke Type Track RollersC 1B 1DC B 3rd 3R500d a d 4 d 1d 4GKR.B.2RSKR.C.2RSC 1KR.2RSB 2G 1Page 136/138B 1Load Ratings kN/lbf. tightening Limitingrev4.25Feb99CABearing as a Track Roller torque Speed wt.designation Dynamic Static Dynamic static Nm/in.-lbs. Grease kg/lbs.d a C C o C w F r perm F Or perm RPM11 KR16 3.60 3.58 2.97 2.85 3.58 7 17000 0.0190.433 810 800 670 640 800 62.0 0.04211 KR16.DZ 3.60 3.58 2.97 2.85 3.58 7 17000 0.0190.433 810 800 670 640 800 62.0 0.04213 KR19 4.18 4.65 3.28 3.29 4.22 16 13000 0.0310.512 940 1050 740 740 950 142 0.06813 KR19.DZ 4.18 4.65 3.28 3.29 4.22 16 13000 0.0310.512 940 1050 740 740 950 142 0.06815 KR22 5.35 6.79 3.94 4.04 5.45 28 10000 0.0460.591 1200 1530 890 910 1230 248 0.10115 KR22.DZ 5.35 6.79 3.94 4.04 5.45 28 10000 0.0460.591 1200 1530 890 910 1230 248 0.10115 KR26 5.35 6.79 4.55 6.78 7.24 28 10000 0.0590.591 1200 1530 1020 1520 1630 248 0.13015 KR26.DZ 5.35 6.79 4.55 6.78 7.24 28 10000 0.0590.591 1200 1530 1020 1520 1630 248 0.13021 KR30 7.89 9.79 6.32 7.74 9.31 45 8200 0.0870.827 1770 2200 1420 1740 2090 398 0.19221 KR30.DZ 7.89 9.79 6.32 7.74 9.31 45 8200 0.0870.827 1770 2200 1420 1740 2090 398 0.19221 KR32 7.89 9.79 6.65 9.62 10.3 45 8200 0.0950.827 1770 2200 1490 2160 2320 398 0.20921 KR32.DZ 7.89 9.79 6.65 9.62 10.3 45 8200 0.0980.827 1770 2200 1490 2160 2320 398 0.216ATIMKEN PRODUCTS CATALOG C169•

NEEDLE Roller BearingsD d a d 4 d 1 d 4 GG 1B 2KRKR.BKR.CNeedle Roller and Cage Assemblies, Sealed,Stud type (KR...2S Series)Metric SeriesrR500CrCC 1B 1B 3d 3B 3d 3D d a d 4 d 1 d 4 GG 1B 2KRD KR.B d a d 4 d 1d 4KR.CGKR.DZKR.B.DZKR.C.DZCAC 1B 1KRL 2 C B 3rd ard 3R500Outer D dimensions mm/in.dia.KR.DZThreadD D a d 1 d h d 1D KR.B.DZ d a d 4 d 1d 4mm d 1 h 7 C r s min B 1 B 2 B 3 G 1 KR.C.DZd 4 d 3 G C 116 6 16 11 0.3 28.2 16 8 4 M6x1 0.60.2362 0.6299 0.433 0.012 1.110 0.630 0.315 0.157 0.0246 16 11 0.3 28.2 16 8 4CM6x1G0.6110.2362 0.6299 0.433 0.012C1.110 0.630 0.315 0.157 0.024sB 219 8 19 11 0.3 32.2 20 10 4 M8x1.25 0.6L0.3150 0.7480 0.433 0.012 1.268 0.787 0.394 0.157 B 10.024L 28 19 11 0.3 32.2 20 10 4 M8x1.25 0.60.3150 0.7480 0.433 0.012 r 1.268 0.787 d a0.394 0.157 0.02422 10 22 12 R500 0.3 36.2 23 12 4 M10x1 0.60.3937 0.8661 0.472 0.012 1.425 0.906 0.472 0.157 0.02410 22 12 KR.B.2RSD D0.3 a d36.2 1 d 23 h d12 4 M10x1 0.61 GKR.C.2RS0.3937 0.8661 0.472 0.012 1.425 0.906 0.472 0.157 0.024300.3937 1.0236 0.472 0.012 1.425 0.906 0.472 0.157 0.024CLs112 30 14 0.6 40.2 25 6 13 Page 136/138 6 3 M12x1.5 0.6Lrev3.26Jan990.4724 1.1811 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.02410 26 12 0.3 36.2 23 L 3 12 4 M10x1 0.626 10 26 12 0.3 36.2 23 12 4 M10x1 0.60.3937 1.0236 0.472 0.012 1.425 0.906 0.472 0.157 0.024L 1L 3GC 1B 1KR.DZB 2G 112 30 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.1811 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.02432 12 32 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.2598 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.02412 32 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.2598 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.024GKR.B.2RKR.C.2RPage 136/138•C170 TIMKEN PRODUCTS CATALOG

Dd a d 4 d 1 d 4G 1B 2GKR.DZKR.B.DZKR.C.DZStud Type and Yoke Type Track RollersC 1B 1DC B 3rd 3R500d a d 4 d 1d 4GKR.B.2RSKR.C.2RSC 1B 1KR.2RSB 2G 1Page 136/138rev4.25Feb99CALoad Ratings kN/lbf. tightening LimitingBearing as a Track Roller torque Speed wt.designation Dynamic Static Dynamic static Nm/in.-lbs. Grease kg/lbs.d a C C o C w F r perm F Or perm RPM11 KR16.2RS 3.60 3.58 2.97 2.85 3.58 7.0 17000 0.0190.433 810 800 670 640 800 61.96 0.04211 KR16.DZ.2RS 3.60 3.58 2.97 2.85 3.58 7.0 17000 0.010.433 810 800 670 640 800 61.96 0.04213 KR19.2RS 4.18 4.65 3.28 3.29 4.22 16 13000 0.0310.512 940 1050 740 740 950 141.61 0.06813 KR19.DZ.2RS 4.18 4.65 3.28 3.29 4.22 16 13000 0.0310.512 940 1050 740 740 950 141.61 0.06815 KR22.2RS 5.35 6.79 3.94 4.04 5.45 28 10000 0.0460.591 1200 1530 890 910 1230 247.82 0.10115 KR22.DZ.2RS 5.35 6.79 3.94 4.04 5.45 28 10000 0.0460.591 1200 1530 890 910 1230 247.82 0.10115 KR26.2RS 5.35 6.79 4.55 6.78 7.24 28 10000 0.0590.591 1200 1530 1020 1520 1630 247.82 0.13015 KR26.DZ.2RS 5.35 6.79 4.55 6.78 7.24 28 10000 0.0590.591 1200 1530 1020 1520 1630 247.82 0.13021 KR30.2RS 7.89 9.79 6.32 7.74 9.31 45 8200 0.0870.827 1770 2200 1420 1740 2090 398.28 0.19221 KR30.DZ.2RS 7.89 9.79 6.32 7.74 9.31 45 8200 0.0870.827 1770 2200 1420 1740 2090 398.28 0.19221 KR32.2RS 7.89 9.79 6.65 9.62 10.3 45 8200 0.0980.827 1770 2200 1490 2160 2320 398.28 0.21621 KR32.DZ.2RS 7 .89 9.79 6.65 9.62 10.3 45 8200 0.0980.827 1770 2200 1490 2160 2320 398.28 0.216ATIMKEN PRODUCTS CATALOG C171•

R500NEEDLE Roller BearingsCfull complement with <strong>needle</strong>1 G<strong>roller</strong>1(KRV Series)B B 2or Cylindrical Rollers,Stud typeCr(NUKR Series)Metric SeriesDd a d 4 d 1R500B 1d 4B 3d 3 D d a d 4 d 1 d 4GGKR.B.DZ.2RSKR.C.DZ.2RSD d a d 4 d 1 d 4KRVDrCC 1B 1B 2G 1d a d 4 d 1B 3d 3d 4GGKRVKRV.DZCAC 1B 1B 2G 1L 2KRVkrV.DZrd aOuter D dimensions mm/in.KRV.DZDia. T threadD D a d 1 dDh d 1mm d 1 D, h 7 C r s min B 1 B 2 B 3 G 1 d 4 d 3 G C 116 6 16 11 0.3 28.2 16 8 4 M6x1 0.60.2362 0.6299 0.433 0.012 1.110 0.630 0.315 0.157 0.0246 16 11 0.3 C 28.2 16 8 4 M6x1 0.60.2362 0.6299 0.433 0.012 s 1.110 0.630 Page 0.315 137 0.157 rev4.26Jan990.024L19 8 19 11 0.3 32.2 20 10 4 M8x1.25 0.60.3150 0.7480 0.433 0.012 1.268 0.787 0.394 0.157 0.024GL 3 L 1C 1B 1B 2G 18 19 11 0.3 32.2 20 10 4 M8x1.25 0.60.3150 0.7480 0.433 0.012 1.268 0.787 0.394 0.157 0.02422 10 22 12 0.3 36.2 23 12 4 M10x1 0.60.3937 0.8661 0.472 0.012 1.425 0.906 0.472 0.157 0.02410 22 12 0.3 36.2 23 12 4 M10x1 0.60.3937 0.8661 0.472 0.012 1.425 0.906 0.472 0.157 0.02426 10 26 12 0.3 36.2 23 12 4 M10x1 0.60.3937 1.0236 0.472 0.012 1.425 0.906 0.472 0.157 0.02410 26 12 0.3 36.2 23 12 4 M10x1 0.60.3937 1.0236 0.472 0.012 1.425 0.906 0.472 0.157 0.02430 12 30 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.1811 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.02412 30 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.1811 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.02432 12 32 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.2598 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.02412 32 14 0.6 40.2 25 6 13 6 3 M12x1.5 0.60.4724 1.2598 0.551 0.024 1.583 0.984 0.236 0.512 0.236 0.118 0.02435 16 35 18 0.6 52 32.5 8 17 6 3 M16x1.5 0.80.6299 1.3780 0.709 0.024 2.047 1.280 0.315 0.669 0.236 0.118 0.03140 18 40 20 1 58 36.5 8 19 6 3 M18x1.5 0.80.7087 1.5748 0.787 0.039 2.283 1.437 0.315 0.748 0.236 0.118 0.03147 20 47 24 1 66 40.5 9 21 6 4 M20x1.5 0.80.7874 1.8504 0.945 0.039 2.598 1.594 0.354 0.827 0.236 0.157 0.03152 20 52 24 1 66 40.5 9 21 6 4 M20x1.5 0.80.7874 2.0472 0.945 0.039 2.598 1.594 0.354 0.827 0.236 0.157 0.03162 24 62 29 1 80 49.5 11 25 8 4 M24x1.5 0.80.9449 2.4409 1.142 0.039 3.150 1.949 0.433 0.984 0.315 0.157 0.03172 24 72 29 1.1 80 49.5 11 25 8 4 M24x1.5 0.80.9449 2.8346 1.142 0.043 3.150 1.949 0.433 0.984 0.315 0.157 0.03180 30 80 35 1.1 100 63 15 32 8 4 M30x1.5 1.01.1811 3.1496 1.378 0.043 3.937 2.480 0.591 1.260 0.315 0.157 0.03990 30 90 35 1.1 100 63 15 32 8 4 M30x1.5 1.01.1811 3.5433 1.378 0.043 3.937 2.480 0.591 1.260 0.315 0.157 0.039Page 137•C172 TIMKEN PRODUCTS CATALOG

Dd a d 4 d1G 1B 2B 1GNUKRStud Type and Yoke Type Track RollersC 1d 4rCB 3d 3rCB 3d 3R500NUKR.DZDd a d 4 d1G 1B 2B 1NUKRC 1d 4GNUKRDd a d 4 d 1d 4NUKR.DZC 1 G 1B 2B 1CB 3rd 3Load Ratings kN/lbf. tightening LimitingBearing NUKR.DZas a Track Roller Page 139 torque Speed rev4.27Jan99 Wt.designation Dynamic Static dynamic static Nm/in.-lbs. Grease kg/lbs.d aD d a d 4 d 1Cd 4C 0GC w F r perm F 0r perm RPM11 KRV16 6.90 8.40 5.11 3.49 6.28 7 5700 0.0190.433 1550 1890 1150 780 1410 62.0 0.04211 KRV16.DZ 6.90 8.40 5.11 3.49 6.28 7 5700 0.0190.433 1550 1890 1150 780 1410 62.0 0.04213 KRV19 C 1 8.08 G 1 11.0 5.66 4.13 7.43 16 4300 0.03113 KRV19.DZ B 18.08 11.0 5.66 4.13 7.43 16 4300 0.0310.512 1820 B 22470 1270 930 1670 142 0.0680.512 1820 2470 1270 930 1670 142 0.06815 KRV22 9.45 14.3 6.32 5.04 9.07 28 3400 0.0460.591 2120 3210 1420 1130 2040 248 0.10115 KRV22.DZ 9.45 14.3 6.32 5.04 9.07 28 3400 0.0460.591 2120 3210 1420Page 139rev4.27Jan991130 2040 248 0.10115 KRV26 9.45 14.3 7.30 8.60 12.7 28 3400 0.0590.591 2120 3210 1640 1930 2860 248 0.13015 KRV26.DZ 9.45 14.3 7.30 8.60 12.7 28 3400 0.0590.591 2120 3210 1640 1930 2860 248 0.13021 KRV30 13.4 19.8 9.85 9.20 15.7 45 2800 0.0870.827 3010 4450 2210 2070 3530 398 0.19221 KRV30.DZ 13.4 19.8 9.85 9.20 15.7 45 2800 0.0870.827 3010 4450 2210 2070 3530 398 0.19221 KRV32 13.4 19.8 10.4 11.3 17.4 45 2800 0.0980.827 3010 4450 2340 2540 3910 398 0.21621 KRV32.DZ 13.4 19.8 10.4 11.3 17.4 45 2800 0.0980.827 3010 4450 2340 2540 3910 398 0.21625 NUKR35.2SK 24.7 29.4 16.2 10.1 16.1 53.2 6100 0.1700.984 5550 6610 3640 2270 3620 471 0.37527 NUKR40.2SK 26.6 33.3 18.7 15.0 23.9 77.5 5300 0.2501.063 5980 7490 4200 3370 5370 686 0.55133 NUKR47.2SK 41.4 53.2 28.1 20.5 32.7 109 4500 0.3801.299 9310 12000 6320 4610 7350 965 0.83837 NUKR52.2SK 45.8 63.1 29.6 22.2 35.4 109 3700 0.4611.457 10300 14200 6650 4990 7960 965 1.01645 NUKR62.2SK 62.7 83.1 40.9 29.6 47.2 193 3200 0.7901.772 14100 18700 9190 6650 10600 1 708 1.74251 NUKR72.2SK 68.9 97.8 46.1 39.6 63.1 193 2600 1.0402.008 15500 22000 10400 8900 14200 1 708 2.29352 NUKR80.2SK 95.4 130 69.7 63.2 101 390 2900 1.5502.047 21400 29200 15700 14200 22700 3 452 3.41752 NUKR90.2SK 95.4 130 77.8 97.8 128 390 2900 2.0202.047 21400 29200 17500 22000 28800 3 452 4.453GCAATIMKEN PRODUCTS CATALOG C173•

NEEDLE Roller Bearingsfull complement, Small Series,Unsealed,Stud type (GC Series)Metric SeriesGC: convex outer ringGCL: cylindrical outer ringDCC 1G 1d 1B 1CGC series:without sealsGC SeriesOuter D dimensions mm/in. ProfiledDia. D designationTmm d d 1 C C 1 r s min B 1 G 110 10 4 8 0.25 0.2 19.5 6 GC 100.3937 0.1575 0.315 0.010 0.008 0.768 0.23611 11 4 8 0.25 0.2 19.5 6 GC 110.4331 0.1575 0.315 0.010 0.008 0.768 0.23612 12 5 9 0.25 0.2 22.5 7 GC 120.4724 0.1969 0.354 0.010 0.008 0.886 0.27613 13 5 9 0.25 0.2 22.5 7 GC 130.5118 0.1969 0.354 0.010 0.008 0.886 0.27614 14 6 9.5 0.25 0.3 26 8 GC 140.5512 0.2362 0.374 0.010 0.012 1.024 0.31515 15 6 9.5 0.25 0.3 26 8 GC 150.5906 0.2362 0.374 0.010 0.012 1.024 0.315A•C174 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track RollersCylindricalLimiting Speeddesignation tightening load Ratings kN/lbf. wt.torque Nm/in.-lbs. dynamic static Grease kg/lbs.C 1 F r perm F 0 RPMCAGCL 10 0.9 2.13 0.52 0.96 14000 0.0067.97 479 117 216 0.014GCL 11 0.9 2.48 0.52 0.96 14000 0.0077.97 558 117 216 0.016GCL 12 1.8 2.98 0.90 1.68 11000 0.01115.93 670 202 378 0.024GCL 13 1.8 3.35 0.90 1.68 11000 0.01115.93 753 202 378 0.024GCL 14 3.0 3.5 1.48 2.75 10000 0.01626.55 787 333 618 0.035GCL 15 3.0 3.75 1.48 2.75 10000 0.01826.55 843 333 618 0.039ATIMKEN PRODUCTS CATALOG C175•

NEEDLE Roller Bearingsfull complement,Standard series,with or without seals,Stud type (GC Series)DrCd 4GC/GCL GC...EE, GC...EMd 4 d 1Metric SeriesCGC: convex outer ringGCL: cylindrical outer ringGC...series: without sealsGC...EE series: with plastic sealsGC...EEM series: with metal sealsOuter Dimensions mm/in. ProfiledDia. D designationC 1B 1G 1mm d d 1 C C 1 r s min B 1 G 1A16 16 6 11 0.60 0.3 28.3 8 GC 160.6299 0.2362 0.433 0.024 0.012 1.114 0.31519 19 8 11 0.60 0.3 32.3 10 GC 190.748 0.315 0.433 0.024 0.012 1.272 0.39422 22 10 12 0.60 0.3 36.3 12 GC 220.8661 0.3937 0.472 0.024 0.012 1.429 0.47224 24 10 12 0.60 0.3 36.3 12 GC 240.9449 0.3937 0.472 0.024 0.012 1.429 0.47226 26 10 12 0.60 0.3 36.3 12 GC 26 (4)1.0236 0.3937 0.472 0.024 0.012 1.429 0.47228 28 10 12 0.60 0.3 36.3 12 GC 281.1024 0.3937 0.472 0.024 0.012 1.429 0.47230 30 12 14 0.60 0.6 40.3 13 GC 301.1811 0.4724 0.51 0.024 0.024 1.587 0.51232 32 12 14 0.60 0.6 40.3 13 GC 321.2598 0.4724 0.51 0.024 0.024 1.587 0.51235 35 16 18 0.80 0.6 52.3 17 GC 351.378 0.6299 0.709 0.031 0.024 2.059 0.66947 47 20 24 0.80 1 66.3 21 GC 471.8504 0.7874 0.45 0.031 0.039 2.61 0.82752 52 20 24 0.80 1 66.3 21 GC 522.0472 0.7874 0.45 0.031 0.039 2.61 0.82762 62 24 29 0.80 1 80.3 25 GC 622.4409 0.9449 1.142 0.031 0.039 3.161 0.98472 72 24 29 0.80 1 80.3 25 GC 722.8346 0.9449 1.142 0.031 0.039 3.161 0.98480 80 30 35 1.00 1 100.3 32 GC 803.1496 1.1811 1.378 0.039 0.039 3.949 1.2685 85 30 35 1.00 1 100.3 32 GCL 85 EE3.3465 1.1811 1.378 0.039 0.039 3.949 1.2685 30 35 1.00 1 100.3 32 GCL 85 EEM3.3465 1.1811 1.378 0.039 0.039 3.949 1.2690 90 30 35 1.00 1 100.3 32 GC 903.5433 1.1811 1.378 0.039 0.039 3.949 1.26•C176 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track RollersTightening Load Ratings kN/lbf. Limiting Speedtorque mm wt.nm/in.-lbs. dynamic static Grease wrench mm/in. kg/lbs.C F r perm F 0 RPM3 5.05 1.18 2.2 9300 n/A 4 0.02126.6 1140 265 495 0.157 0.0468 5.75 2.83 5.2 7600 n/A 4 0.03470.8 1290 636 1170 0.157 0.07520 6.3 4.9 8.1 6300 n/A 4 0.058177 1420 1100 1820 0.157 0.12820 6.9 5.2 9.2 6300 n/A 4 0.067177 1550 1170 2070 0.157 0.14820 8.9 5.2 9.6 5500 n/A 4 0.072177 2000 1170 2160 0.157 0.15920 9.6 5.2 9.6 5500 n/A 4 0.08177 2160 1170 2160 0.157 0.17626 12.9 7.7 14.3 4800 8 4 0.115230 2900 1730 3210 0.157 0.25426 13.8 7.7 14.3 4800 8 4 0.12230 3100 1730 3210 0.157 0.26564 19.2 11.4 24 3850 10 6 0.208566 4320 2560 5400 0.236 0.459120 28.3 21.4 40 2700 14 6 0.4771060 6360 4810 8990 0.236 1.052120 34 21.4 40 2700 14 6 0.5421060 7640 4810 8990 0.236 1.195220 42 31 57.5 2330 12 6 0.9441950 9440 6970 12900 0.236 2.081220 44 31 57.5 2330 12 6 1.1651950 9890 6970 12900 0.236 2.568450 60 50 93 1700 14 8 1.9153980 13500 11200 20900 0.315 4.222450 64 50 93 1700 14 8 2.0963980 14400 11200 20900 0.315 4.621450 64 50 93 1700 14 8 2.0963980 14400 11200 20900 0.315 4.621450 65 50 93 1700 14 8 2.2873980 14600 11200 20900 0.315 5.042CAATIMKEN PRODUCTS CATALOG C177•

NEEDLE Roller Bearingsfull complement,with metal seals,Stud type (GCU...MM series)CB 3C 1B 2Metric SeriesDPd 1MCGCU: convex outer ringGCUL: cylindrical outer ringGCU...MM series:with metal sealsOutside dimensions mm/in. Profiled CylindricalDia. designation Designationrd 4G 1B 1GCU, GCULmm d d 1 C C 1 B 1 G 1 r sminA35 35 16 18 0.85 52.3 17 0.6 GCU 35 MM GCUL 35 MM1.3780 0.6299 0.709 0.033 2.059 0.669 0.02440 40 18 20 0.85 58.3 19 1.0 GCU 401.5748 0.7087 0.787 0.033 2.295 0.748 0.03940 18 20 0.85 58.3 19 1.0 GCU 40 MM GCUL 40 MM1.5748 0.7087 0.787 0.033 2.295 0.748 0.03947 47 20 24 0.85 66.3 21 1.0 GCU 47 MM GCUL 47 MM1.8504 0.7874 0.945 0.033 2.610 0.827 0.03952 52 20 24 0.85 66.3 21 1.0 GCUL 522.0472 0.7874 0.945 0.033 2.610 0.827 0.03952 20 24 0.85 66.3 21 1.0 GCU 52 MM GCUL 52 MM2.0472 0.7874 0.945 0.033 2.610 0.827 0.03962 62 24 29 0.85 80.3 25 1.0 GCU 62 MM2.4409 0.9449 1.142 0.033 3.161 0.984 0.03972 72 24 29 0.85 80.3 25 1.1 GCUL 72 MM2.8346 0.9449 1.142 0.033 3.161 0.984 0.04380 80 30 35 1.10 100.3 32 1.1 GCU 80 MM3.1496 1.1811 1.378 0.043 3.949 1.260 0.04390 90 30 35 1.10 100.3 32 1.1 GCUL 903.5433 1.1811 1.378 0.043 3.949 1.260 0.04390 30 35 1.10 100.3 32 1.1 GCU 90 MM3.5433 1.1811 1.378 0.043 3.949 1.260 0.043100 100 36 40 1.10 117.3 38 2.0 GCU 1003.9370 1.4173 1.575 0.043 4.618 1.496 0.079100 36 40 1.10 117.3 38 2.0 GCU 100 MM3.9370 1.4173 1.575 0.043 4.618 1.496 0.079110 110 36 40 1.10 117.3 38 2.0 GCU 110 MM GCUL 110 MM4.3307 1.4173 1.575 0.043 4.618 1.496 0.079120 120 42 46 1.10 136.3 44 2.0 GCU 120 MM4.7244 1.6535 1.811 0.043 5.366 1.732 0.079130 130 42 46 1.10 136.3 44 2.0 GCUL 1305.1181 1.6535 1.811 0.043 5.366 1.732 0.079130 42 46 1.10 136.3 44 2.0 GCU 130 MM5.1181 1.6535 1.811 0.043 5.366 1.732 0.079•C178 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track Rollerstightening load Ratings kN/lbf. limiting Speedtorque mm wt.Nm/in.-lbs. Dynamic static Grease wrench mm/in. kg/lbs.CAC F r perm F 01 RPM B 3 d 464 17.0 7.80 17.2 5700 10 8 6 0.200566 3820 1750 3870 0.315 0.236 0.44190 20.0 11.5 22.0 5200 12 8 6 0.289797 4500 2590 4950 0.315 0.236 0.63790 20.0 11.5 22.0 5200 12 8 6 0.289797 4500 2590 4950 0.315 0.236 0.637120 29.5 15.5 33.0 4400 14 9 6 0.4501060 6630 3480 7420 0.354 0.236 0.992120 36.5 21.5 40.0 4400 14 9 6 0.5201060 8210 4830 8990 0.354 0.236 1.146120 36.5 21.5 40.0 4400 14 9 6 0.5201060 8210 4830 8990 0.354 0.236 1.146220 52.0 31.0 58.0 3700 12 11 6 0.9101950 11700 6970 13000 0.433 0.236 2.006220 63.0 31.0 58.0 3700 12 11 6 1.1401950 14200 6970 13000 0.433 0.236 2.513450 76.0 48.0 93.0 2700 14 15 8 1.8703980 17100 10800 20900 0.591 0.315 4.123450 94.0 50.0 93.0 2700 14 15 8 2.2303980 21100 11200 20900 0.591 0.315 4.916450 94.0 50.0 93.0 2700 14 15 8 2.2303980 21100 11200 20900 0.591 0.315 4.914740 115 76.0 142 2300 17 20 8 3.2906550 25900 17100 31900 0.787 0.315 7.253740 115 76.0 142 2300 17 20 8 3.2906550 25900 17100 31900 0.787 0.315 7.253740 129 76.0 142 2300 17 20 8 3.8006550 29000 17100 31900 0.787 0.315 8.3781 200 150 120 200 2000 19 24 8 5.42210620 33700 27000 45000 0.945 0.315 1.9531 200 163 121 223 2000 19 24 8 5.78010620 36600 27200 50100 0.945 0.315 12.7431 200 163 121 223 2000 19 24 8 5.78010620 36600 27200 50100 0.945 0.315 12.743ATIMKEN PRODUCTS CATALOG C179•

NEEDLE Roller Bearingsfull complement,eccentric, stud type(GCR series)DrCd4d14Metric SeriesGCR: convex outer ringGCRL: cylindrical outer ringGCR 16 - 52C 1B 1G 1d 4GCR 16-52 GCR 62-90GCR 62 - 90CAOuter Dimensions mm/in. Profiled CylindricalDia. designation Designationmm d d 1 C C 1 B 1 G 1 r a min16 16 6 11 0.60 28.3 8 0.3 GCR 160.6299 0.2362 0.433 0.024 1.114 0.315 0.01216 6 11 0.60 28.3 8 0.3 GCR 16 EE GCRL 16 EE0.6299 0.2362 0.433 0.024 1.114 0.315 0.01216 6 11 0.60 28.3 8 0.3 GCR 16 EEM GCRL 16 EEM0.6299 0.2362 0.433 0.024 1.114 0.315 0.01219 19 8 11 0.60 32.3 10 0.3 GCR 190.748 0.315 0.433 0.024 1.272 0.394 0.01219 8 11 0.60 32.3 10 0.3 GCR 19 EE GCRL 19 EE0.748 0.315 0.433 0.024 1.272 0.394 0.01219 8 11 0.60 32.3 10 0.3 GCR 19 EEM0.748 0.315 0.433 0.024 1.272 0.394 0.01222 22 10 12 0.60 36.3 12 0.3 GCR 22 EE GCRL 22 EE0.8661 0.3937 0.472 0.024 1.429 0.472 0.01222 10 12 0.60 36.3 12 0.3 GCR 22 EEM GCRL 22 EEM0.8661 0.3937 0.472 0.024 1.429 0.472 0.01224 24 10 12 0.60 36.3 12 0.3 GCR 240.9449 0.3937 0.472 0.024 1.429 0.472 0.01224 10 12 0.60 36.3 12 0.3 GCR 24 EE GCRL 24 EE0.9449 0.3937 0.472 0.024 1.429 0.472 0.01224 10 12 0.60 36.3 12 0.3 GCR 24 EEM GCRL 24 EEM0.9449 0.3937 0.472 0.024 1.429 0.472 0.01226 26 10 12 0.60 36.3 12 0.3 GCR 261.0236 0.3937 0.472 0.024 1.429 0.472 0.01226 10 12 0.60 36.3 12 0.3 GCR 26 EE GCRL 26 EE1.0236 0.3937 0.472 0.024 1.429 0.472 0.01228 28 10 12 0.60 36.3 12 0.3 GCR 28 ee1.1024 0.3937 0.472 0.024 1.429 0.472 0.01228 10 12 0.60 36.3 12 0.3 GCR 28 EEM GCRL 28 EEM1.1024 0.3937 0.472 0.024 1.429 0.472 0.01230 30 12 14 0.60 40.3 13 0.6 GCR 30 EE GCRL 30 EE1.1811 0.4724 0.551 0.024 1.587 0.512 0.02430 12 14 0.60 40.3 13 0.6 GCR 30 EEM GCRL 30 EEM1.1811 0.4724 0.551 0.024 1.587 0.512 0.02432 32 12 14 0.60 40.3 13 0.6 GCR 321.2598 0.4724 0.551 0.024 1.587 0.512 0.02432 12 14 0.60 40.3 13 0.6 GCR 32 EE GCRL 32 EE1.2598 0.4724 0.551 0.024 1.587 0.512 0.02432 12 14 0.60 40.3 13 0.6 GCR 32 EEM1.2598 0.4724 0.551 0.024 1.587 0.512 0.02435 35 16 18 0.80 52.3 17 0.6 GCR 351.378 0.6299 0.709 0.031 2.059 0.669 0.02435 16 18 0.80 52.3 17 0.6 GCR 35 EE GCRL 35 EE1.378 0.6299 0.709 0.031 2.059 0.669 0.02435 16 18 0.80 52.3 17 0.6 GCR 35 EEM GCRL 35 EEM1.378 0.6299 0.709 0.031 2.059 0.669 0.024•C180 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track Rollerstightening Load Ratings kN/lbf. Limiting Speedtorquewt.nm/in.-lbs. dynamic static Grease mm/in. kg/lbs.C 0 F r perm F 0 RPM d42 5.05 1.18 2.20 9300 4 0.02417.7 1140 265 495 0.157 0.0532 5.05 1.18 2.20 9300 4 0.02417.7 1140 265 495 0.157 0.0532 5.05 1.18 2.20 9300 4 0.02417.7 1140 265 495 0.157 0.0535 5.75 2.83 4.50 7600 4 0.03944.3 1290 636 1010 0.157 0.0865 5.75 2.83 4.50 7600 4 0.03944.3 1290 636 1010 0.157 0.0865 5.75 2.83 4.50 7600 4 0.03944.3 1290 636 1010 0.157 0.08616 6.30 4.90 5.60 6300 4 0.057142 1420 1100 1260 0.157 0.12616 6.30 4.90 5.60 6300 4 0.057142 1420 1100 1260 0.157 0.12616 6.90 5.20 5.60 6300 4 0.072142 1550 1170 1260 0.157 0.15916 6.90 5.20 5.60 6300 4 0.072142 1550 1170 1260 0.157 0.15916 6.90 5.20 5.60 6300 4 0.072142 1550 1170 1260 0.157 0.15916 8.90 5.20 6.10 5500 4 0.080142 2000 1170 1370 0.157 0.17616 8.90 5.20 6.10 5500 4 0.080142 2000 1170 1370 0.157 0.17616 9.60 5.20 6.10 5500 4 0.088142 2160 1170 1370 0.157 0.19416 9.60 5.20 6.10 5500 4 0.088142 2160 1170 1370 0.157 0.19422 12.9 7.70 10.4 4800 4 0.118195 2900 1730 2340 0.157 0.26022 12.9 7.70 10.4 4800 4 0.118195 2900 1730 2340 0.157 0.26022 13.8 7.70 10.4 4800 4 0.126195 3100 1730 2340 0.157 0.27822 13.8 7.70 10.4 4800 4 0.126195 3100 1730 2340 0.157 0.27822 13.8 7.70 10.4 4800 4 0.126195 3100 1730 2340 0.157 0.27855 19.2 11.4 11.0 3850 6 0.220487 4320 2560 2470 0.236 0.48555 19.2 11.4 11.0 3850 6 0.220487 4320 2560 2470 0.236 0.48555 19.2 11.4 11.0 3850 6 0.220487 4320 2560 2470 0.236 0.485CAAContinued on next page.TIMKEN PRODUCTS CATALOG C181•

NEEDLE Roller Bearingsfull complement,eccentric, stud type(GCR series) – continuedDrCd4d14Metric SeriesGCR: convex outer ringGCRL: cylindrical outer ringGCR 16 - 52C 1B 1G 1d 4GCR 16-52 GCR 62-90GCR 62 - 90CAOuter Dimensions mm/in. Profiled CylindricalDia. designation Designationmm d d 1 C C 1 B 1 G 1 r a min40 40 18 20 0.80 58.3 19 1 GCR 40 GCRL 401.5748 0.7087 0.787 0.709 2.295 0.748 0.03940 18 20 0.80 58.3 19 1 GCR 40 EE GCRL 40 EE1.5748 0.7087 0.787 0.709 2.295 0.748 0.03940 18 20 0.80 58.3 19 1 GCR 40 EEM GCRL 40 EEM1.5748 0.7087 0.787 0.709 2.295 0.748 0.03947 47 20 24 0.80 66.3 21 1 GCR 47 ee1.8504 0.7874 0.945 0.709 2.61 0.827 0.03947 20 24 0.80 66.3 21 1 GCR 47 EEM GCRL 47 EEM1.8504 0.7874 0.945 0.709 2.61 0.827 0.03952 52 20 24 0.80 66.3 21 1 GCR 522.0472 0.7874 0.945 0.709 2.61 0.827 0.03952 20 24 0.80 66.3 21 1 GCR 52 EE GCRL 52 EE2.0472 0.7874 0.945 0.709 2.61 0.827 0.03952 20 24 0.80 66.3 21 1 GCR 52 EEM GCRL 52 EEM2.0472 0.7874 0.945 0.709 2.61 0.827 0.03962 62 24 29 0.80 80.3 25 1 GCR 622.4409 0.9449 1.142 0.709 3.161 0.984 0.03962 24 29 0.80 80.3 25 1 GCR 62 ee2.4409 0.9449 1.142 0.709 3.161 0.984 0.03962 24 29 0.80 80.3 25 1 GCR 62 EEM GCRL 62 EEM2.4409 0.9449 1.142 0.709 3.161 0.984 0.03972 72 24 29 0.80 80.3 25 1 GCR 72 EE GCRL 72 EE2.8346 0.9449 1.142 0.709 3.161 0.984 0.03972 24 29 0.80 80.3 25 1 GCRL 72 EEM2.8346 0.9449 1.142 0.709 3.161 0.984 0.03980 80 30 35 1.00 100.3 32 1 GCR 803.1496 1.1811 1.378 0.039 3.949 1.26 0.03980 30 35 1.00 100.3 32 1 GCR 80 EE GCRL 80 EE3.1496 1.1811 1.378 0.039 3.949 1.26 0.03980 30 35 1.00 100.3 32 1 GCR 80 EEM GCRL 80 EEM3.1496 1.1811 1.378 0.039 3.949 1.26 0.03990 90 30 35 1.00 100.3 32 1 GCR 90 GCRL 903.5433 1.1811 1.378 0.039 3.949 1.26 0.03990 30 35 1.00 100.3 32 1 GCR 90 ee3.5433 1.1811 1.378 0.039 3.949 1.26 0.03990 30 35 1.00 100.3 32 1 GCR 90 EEM3.5433 1.1811 1.378 0.039 3.949 1.26 0.039•C182 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track Rollerstightening Load Ratings kN/lbf. Limiting Speedtorquewt.nm/in.-lbs. dynamic static Grease mm/in. kg/lbs.C 0 F r perm F 0 RPM d475 20.0 14.2 12.3 3150 6 0.321664 4500 3190 2770 0.236 0.70875 20.0 14.2 12.3 3150 6 0.321664 4500 3190 2770 0.236 0.70875 20.0 14.2 12.3 3150 6 0.321664 4500 3190 2770 0.236 0.708100 28.3 21.4 23.7 2700 6 0.500885 6360 4810 5330 0.236 1.102100 28.3 21.4 23.7 2700 6 0.500885 6360 4810 5330 0.236 1.102100 34.0 21.4 23.7 2700 6 0.568885 7640 4810 5330 0.236 1.252100 34.0 21.4 23.7 2700 6 0.568885 7640 4810 5330 0.236 1.252100 34.0 21.4 23.7 2700 6 0.568885 7640 4810 5330 0.236 1.252180 42.0 31.0 28.8 2330 8 1.0351590 9440 6970 6470 0.315 2.282180 42.0 31.0 28.8 2330 8 1.0351590 9440 6970 6470 0.315 2.282180 42.0 31.0 28.8 2330 8 1.0351590 9440 6970 6470 0.315 2.282180 44.0 31.0 28.8 2330 8 1.2781590 9890 6970 6470 0.315 2.818180 44.0 31.0 28.8 2330 8 1.2781590 9890 6970 6470 0.315 2.818370 60.0 50.0 54.0 1700 8 2.0743270 13500 11200 12100 0.315 4.572370 60.0 50.0 54.0 1700 8 2.0743270 13500 11200 12100 0.315 4.572370 60.0 50.0 54.0 1700 8 2.0743270 13500 11200 12100 0.315 4.572370 65.0 50.0 54.0 1700 8 2.4353270 14600 11200 12100 0.315 5.368370 65.0 50.0 54.0 1700 8 2.4353270 14600 11200 12100 0.315 5.368370 65.0 50.0 54.0 1700 8 2.4353270 14600 11200 12100 0.315 5.368CAATIMKEN PRODUCTS CATALOG C183•

NEEDLE Roller BearingsCfull complementeccentric, withmetal seals,Stud type(GCUR...MM series)Metric SeriesGCUR: convex outer ringGCURL: cylindrical outer ringDrCGCUR 35 - 524d 4 d 1C 1 G 1B 1GCUR 62 - 130GCUR 35-52 GCUR 62-130Outside dimensions mm/in. Profiled CylindricalDia. designation Designationmm d d 1 C C 1 B 1 G 1 r sminA35 35 16 18 0.85 52.3 17 0.6 GCUR 351.3780 0.6299 0.709 0.033 2.059 0.669 0.02440 40 18 20 0.85 58.3 19 1.0 GCUR 401.5748 0.7087 0.787 0.033 2.295 0.748 0.03940 18 20 0.85 58.3 19 1.0 GCURL 40 MM1.5748 0.7087 0.787 0.033 2.295 0.748 0.03952 52 20 24 0.85 66.3 21 1.0 GCUR 52 MM2.0472 0.7874 0.945 0.033 2.610 0.827 0.03962 62 24 29 0.85 80.3 25 1.0 GCUR 622.4409 0.9449 1.142 0.033 3.161 0.984 0.03962 24 29 0.85 80.3 25 1.0 GCUR 62 MM2.4409 0.9449 1.142 0.033 3.161 0.984 0.03972 72 24 29 0.85 80.3 25 1.1 GCUR 722.8346 0.9449 1.142 0.033 3.161 0.984 0.04372 24 29 0.85 80.3 25 1.1 GCUR 72 MM2.8346 0.9449 1.142 0.033 3.161 0.984 0.04380 80 30 35 1.10 100.3 32 1.1 GCUR 803.1496 1.1811 1.378 0.014 3.949 1.260 0.04380 30 35 1.10 100.3 32 1.1 GCUR 80 MM3.1496 1.1811 1.378 0.043 3.949 1.260 0.04390 90 30 35 1.10 100.3 32 1.1 GCUR 903.5433 1.1811 1.378 0.043 3.949 1.260 0.043100 100 36 40 1.10 117.3 38 2.0 GCUR 1003.9370 1.4173 1.575 0.043 4.618 1.496 0.079100 36 40 1.10 117.3 38 2.0 GCUR 100 MM3.9370 1.4173 1.575 0.043 4.618 1.496 0.079110 110 36 40 1.10 117.3 38 2.0 GCUR 110 MM4.3307 1.4173 1.575 0.043 4.618 1.496 0.079120 120 42 46 1.10 136.3 44 2.0 GCUR 120 MM4.7244 1.6535 1.811 0.043 5.366 1.732 0.079130 130 42 46 1.10 136.3 44 2.0 GCUR 1305.1181 1.6535 1.811 0.043 5.366 1.732 0.079130 42 46 1.10 136.3 44 2.0 GCUR 130 MM5.1181 1.6535 1.811 0.043 5.366 1.732 0.079•C184 TIMKEN PRODUCTS CATALOG

Stud Type and Yoke Type Track Rollerstightening load Ratings kN/lbf. limiting Speedtorque mm wt.Nm/in.-lbs. Dynamic static Grease wrench mm/in. kg/lbs.CAC F r perm F 01 RPM d 455 17.0 7.8 10.0 5700 10 6 0.215487 3820 1750 2250 0.236 0.47475 20.0 10.9 10.9 5200 12 6 0.313664 4500 2450 2450 0.236 0.69075 20.0 10.9 10.9 5200 12 6 0.313664 4500 2450 2450 0.236 0.690100 36.5 21.3 21.3 4400 14 6 0.555885 8210 4790 4790 0.236 1.224180 52.0 28.8 28.8 3700 12 6 1.0221593 11690 6470 6470 0.236 2.253180 52.0 28.8 28.8 3700 12 6 1.0221593 11690 6470 6470 0.236 2.253180 63.0 28.8 28.8 3700 12 6 0.1131593 14160 6470 6470 0.236 0.249180 63.0 28.8 28.8 3700 12 6 0.1131593 14160 6470 6470 0.236 0.249370 76.0 48.0 54.0 2700 14 8 0.1823275 17090 10790 12140 0.315 0.401370 76.0 48.0 54.0 2700 14 8 0.1823275 17090 10790 12140 0.315 0.401370 94.0 50.0 54.0 2700 14 8 0.1823275 21130 11240 12140 0.315 0.402610 115 76.0 83.0 2300 17 8 0.2445399 25850 17090 18660 0.315 0.539610 115 76.0 83.0 2300 17 8 0.2445399 25850 17090 18660 0.315 0.539610 129 76.0 83.0 2300 17 8 0.2455399 29000 17090 18660 0.315 0.5401000 150 120 130 2000 19 8 0.3288851 33720 26980 29230 0.315 0.7241000 150 121 130 2000 19 8 0.3298851 33720 27200 29230 0.315 0.7251000 150 121 130 2000 19 8 0.3298851 33720 27200 29230 0.315 0.725ATIMKEN PRODUCTS CATALOG C185•

NEEDLE Roller BearingsCaged, without inner ring,no end washers,yoke type (RSTO Series)Cr rR500 R500CrrCCMetric SeriesF wF wE wEDwDF wF wE wEDwDCArstoRSTO RSTOrsto.DZRSTO.DZ RSTO.DZr rr rDimensions Load Ratings kN/lbf. limitingOuter Bearing R500 as R500 a Bearing as a Track Roller speed Wt.Dia. designation Dynamic Static r 1 r 1Dynamic static r 1Grease r 1kg/lbs.mm D B C F w E w r S C C o C w F r perm F Or perm RPM16 16 8 7.8 7 10 0.3 RSTO5A.TNF w Fd2.74 w d2.44E w 2.49EDw D F w 2.97Fdw d2.44 19000E w EDw D0.0090.6299 0.315 0.307 0.2756 0.394 0.012 616 549 560 668 549 0.02016 8 7.8 7 10 0.3 RSTO5ADZ.TN 2.74 2.44 2.49 2.97 2.44 19000 0.0090.6299 0.315 0.307 0.2756 0.394 0.012 616 549 560 668 549 0.02019 19 10 9.8 10 13 0.3 RSTO6 5.40 6.43 4.15 4.04 5.63 13000 0.0140.7480 0.394 0.386 0.3937 0.512 0.012 1210 1450 933 908 1270 0.03119 10 9.8 10 13 0.3 RSTO6DZ 5.40 6.43 B B 4.15 4.04 5.63 B B 13000 0.0140.7480 0.394 0.386 0.3937 0.512 0.012 1210 1450 933 908 1270 0.03119 10 9.8 10 13 0.3 RSTO6TN 5.40 STO 6.43 STO 4.15 4.04 STO.DZ 5.63 STO.DZ 13000 0.0140.7480 0.394 0.386 0.3937 0.512 0.012 1210 1450 933 908 1270 0.03124 24 10 9.8 12 15 0.3 RSTO8 5.85 7.51 4.79 6.67 7.44 10000 0.0230.9449 0.394 0.386 0.4724 0.591 0.012 1320 1690 1080 Page Page 114/116 114/116 1500 1670 rev2.30Nov98 rev2.30Nov980.05124 10 9.8 12 15 0.3 RSTO8DZ 5.85 7.51 4.79 6.67 7.44 10000 0.0230.9449 0.394 0.386 0.4724 0.591 0.012 1320 1690 1080 1500 1670 0.05130 30 12 11.8 14 20 0.3 RSTO10 10.40 10.6 8.62 7.69 10.6 9400 0.0441.1811 0.472 0.465 0.5512 0.787 0.012 2340 2380 1940 1730 2380 0.09730 12 11.8 14 20 0.3 RSTO10DZ 10.40 10.6 8.62 7.69 10.6 9400 0.0441.1811 0.472 0.465 0.5512 0.787 0.012 2340 2380 1940 1730 2380 0.09732 32 12 11.8 16 22 0.3 RSTO12 11.20 11.9 8.80 7.65 10.9 8100 0.0491.2598 0.472 0.465 0.6299 0.866 0.012 2520 2680 1980 1720 2450 0.10832 12 11.8 16 22 0.3 RSTO12DZ 11.20 11.9 8.80 7.65 10.9 8100 0.0491.2598 0.472 0.465 0.6299 0.866 0.012 2520 2680 1980 1720 2450 0.10835 35 12 11.8 20 26 0.3 RSTO15 12.90 15.3 9.13 6.95 11.2 6300 0.0521.3780 0.472 0.465 0.7874 1.024 0.012 2900 3440 2050 1560 2520 0.11535 12 11.8 20 26 0.3 RSTO15DZ 12.90 15.3 9.13 6.95 11.2 6300 0.0521.3780 0.472 0.465 0.7874 1.024 0.012 2900 3440 2050 1560 2520 0.115CCCCContinued on next page.•C186 TIMKEN PRODUCTS CATALOG