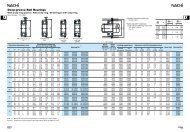

Full CoMPleMent wItH needle roller

Full CoMPleMent wItH needle roller

Full CoMPleMent wItH needle roller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

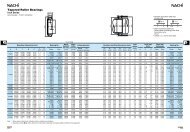

Needle Roller Thrust Bearings, Assemblies, WashersThe rolling elements of the AX Series thrust bearings areretained and guided in radial pockets within the cage. The cageis retained in relation to the thrust washer by means of a retainingcap. The design of a one-piece steel cage employs a specialcurvature that guides the rolling elements by their ends alongtheir centerlines.In addition, this special curvature gives the steel cage greatrigidity while providing maximum lubricant space. This unitizedassembly of components facilitates installation and provides a highaxial load capacity while occupying only minimal space. Note thatthe AX Series is not interchangeable with the AXK Series or FNTSeries <strong>needle</strong> <strong>roller</strong> and cage thrust assemblies.Standard AX Series <strong>needle</strong> thrust bearings combined with athick washer provide rotational accuracy and axial run-out to Class6 levels according to ISO Standard 199 for ball thrust bearings.They can be supplied in High Precision “HP” quality, providing aprecision grade above Class 5. AX Series <strong>needle</strong> thrust bearingswith a thin washer are of minimal thickness and provide excellenteconomy. They should be considered whenever the degree ofsupport and rotational accuracy requirement allow.Thrust WashersIdeally, a thrust washer should be stationary with respect to,and piloted by, its supporting or backing member, whether or notthis is an integral part of the shaft or housing. There should be norubbing action between the thrust washer and any other machinemember. Some thrust washers are designed for bore piloting othersmay be piloted by their outside diameter.Thin Thrust Washers (AS)The metric series thin thrust washers are made of hardenedspring steel. They may be out of flat due to heat treatment, but willflatten under load. Thin washers are used when the supporting orbacking members cannot be adequately prepared as racewaysfor the <strong>needle</strong> <strong>roller</strong>s. These washers are only 1 mm (0.04 in.)thick (dimensions) and provide a very compact and cost-effectivebearing arrangement. Although they are usually guided on the shaft,they may be housing-guided when required by application.Heavy Thrust Washers (LS)These metric series thrust washers are made of bearingquality steel, hardened and precision ground on the flat racewaysurfaces. Their bores and outside diameters are not ground butprovide satisfactory surfaces for shaft piloting or housing pilotingarrangements.Shaft Piloted Washers (WS.811) AndHousing Piloted Washers (GS.811)These shaft piloted and housing piloted metric series thrustwashers are primarily for use with metric series cylindrical <strong>roller</strong>thrust bearings of Series 811. They are made of bearing qualitysteel with, hardened and precision ground and lapped flat racewaysurfaces. The tolerances of the thrust bearing bore and outsidediameter shown in the engineering section apply to shaft andhousing piloted washers.Thin (CP) and thick (CPR) thrust washersThe washer incorporated in the AX Series thrust bearing is madefrom hardened bearing steel and forms one of the reaceways forthe rolling elements. The opposing raceway is generally providedby a separate thrust washer of similar design supplied by Timken.When the AX Series thrust bearing is piloted by the revolving part,the thrust washer must be piloted by the stationary part and viceversa. If the revolving part and the stationary part are noticeablyeccentric to each other, the thrust bearing with integral washermust, without exception, be piloted by the revolving part.The second raceway for the rolling elements may also be formedby the face of a shoulder or an inserted washer, provided thesehave the correct hardness and geometric dimensions.CAATIMKEN PRODUCTS CATALOG C229•