Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

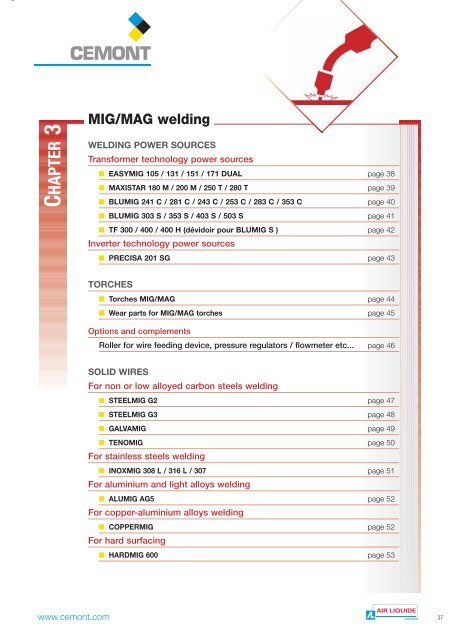

Compact installations (integrated wire feeder) for MIG-MAGsemi-automatic <strong>welding</strong>. Transformer technology.Single-phase or three-phase input voltage.MIG/MAGPOWER SOURCESBLUMIG 241 C / 281 C - (single-phase)243 C / 253 C / 283 C / 353 C - (three-phase)The BLUMIG are semi-automatic MIG/MAG <strong>welding</strong>installations. Robust and <strong>power</strong>ful, they providethe best performances on the market and willanswer all your needs.The Advantages:■ Input voltage: 230 V single-phase and 230 – 400 V three-phase.■■■■■■Mode: 2 T / 4T / Point.Wire feeder device: 4 rollers plate.BUILT IN WIRE FEEDERINTENSIVE USESimple: adjustment of the intensity with switch and regulationof the wire speed with potentiometer.Digital display: included on the BLUMIG 353 and inBLUMIG 241 Coption for other ones.Cat. nr : W 000 261 955Versatile: all kind of gas.BLUMIG 281 CPowerful: copper cooled transformer.Cat. nr : W 000 261 9621ClassificationEN 60974.1EN 60974.102467538 9TECHNICAL DATA:123456789Selection 2T / 4T / point.Point adjustment.Displays.Stick-out adjustment.Wire speed.Starting speed regulation.Power switch.Switch on/off.European connection for torch.BLUMIG BLUMIG BLUMIG BLUMIG 283 C BLUMIG241 C 281 C 243 C 253 ALU 353 CInput voltage 50 Hz 230 V single-phase 230 V - 400 V three-phasePrimary consumption* - 38 A 54 A 19 - 11 A 23 - 19 A 33 - 19 APower* 8.2 kVA 10 kVA 6.5 kVA 9 kVA 11.5 kVAEffective consumption 14 A 29 A 10.5 - 6 A 19.5 - 11.5 A 19 - 11 AAdjustments positions 10 14 7 10 14Welding voltage 18 - 35 V 20 - 53 V 18 - 35 V 18 - 40 V 18 - 45 VWelding current 40 - 200 A 30 - 250 A 35 - 200 A 35 - 250 A 35 - 350 ASteel wire diameter 0.6 - 1.0 mm 0.6 - 1.0 mm** 0.6 - 1.0 mm 0.6 - 1.0 mm** 0.6 - 1.2 mmDuty cycle at 30 % 200 A (25%) 250 A 200 A 250 A 300 A (35%)at 40 °Cat 60 % 130 A 175 A 140 A 170 A 230 Aat 100 % 100 A 140 A 110 A 140 A 180 AProtection class IP 23Dimensions (mm) 500 X 870 X 490 620 x 940 x 1000Weight 52 kg 86 kg 71 kg 80 kg 96 kg* at maximum <strong>welding</strong> intensity ** 1.2 mm possible* version speciallydesigned for aluminiumapplications with apush-pull torch.BLUMIG 243 CCat. nr : W 000 261 728BLUMIG 253 C ALU*Cat. nr : W 000 262 179BLUMIG 283 CCat. nr : W 000 263 729BLUMIG 353 CCat. nr : W 000 264 208• Torches see page 44• Rollers see page 46Delivered equipped with:■ electric cable,■ equipped earh cable,■ rollers 0.8- 1.0 mm,■ safety instruction for useand maintenance manual.40 www.cemont.com

Separated wire feeder installationsfor semi-automatic MIG/MAG <strong>welding</strong>.Transformer technology. Three-phase input voltage.BLUMIG 303 S / 353 SBLUMIG 403 S / 503 SThe BLUMIG are semi-automatic MIG/MAG <strong>welding</strong> installations.Robust and <strong>power</strong>ful, they provide the best performanceson the market and will answer all your needs.The Advantages:■ Input voltage: 230 V – 400 V three-phase.■■■■■■Mode: 22 T / 4T / Point.Wire feeder device: 4 rollers plate.Perfect starting: possibility to adjust the starting speed.Stick-out: adjustable with potentiometer.Simple: adjustment of the intensity with switch and regulationof the wire speed with potentiometer.Digital display: precise adjustment and optimalreading (353/403).12456 73■■Versatile: for all kind of solid or flux cored wires<strong>welding</strong>.Powerful: air cooled transformer.■ Safety: protection class IP 23.■Comfortable in use: due to its pivoting wire feedunit support.SEPARATED WIRE FEEDERINTENSIVE USEBLUMIG 303 SCat. nr: W 000 263 730(<strong>power</strong> source only)BLUMIG 353 SCat. nr: W 000 263 731(<strong>power</strong> source only)BLUMIG 403 SCat. nr: W 000 263 732(<strong>power</strong> source only)ClassificationEN 60974.1EN 60974.10MIG/MAGPOWER SOURCESMIG/MAG WELDING POWER SOURCES81 Selection 2T / 4T / point.2 Point adjustment.63 Wire speed.9 4 Stick-out adjustment.5 Starting speed regulation.TECHNICAL DATA:6789Digital displays.European connection for torchPower and on/off switch.Power switch (preciseadjustment).BLUMIG 503 SCat. nr: W 000 263 733(<strong>power</strong> source only)BLUMIG 303 S BLUMIG 353 S BLUMIG 403 S BLUMIG S / SHCompatible wire feeders TF 300 - TF 400 TF 400 - TF 400HInput voltage 50 Hz230 V - 400 V three-phasePrimary consumption* - 27 - 15 A 33 - 19 A 42 - 24 A 60 - 34 APower* 9 kVA 11.5 kVA 15 kVA 23 kVAEffective consumption 15 - 8.5 A 20 - 11 A 25 - 14 A 35 - 20 AAdjustments positions 12 14 30 30Welding voltage 18 - 40 V 18 - 45 V 18 - 46 V 19 - 54 VWelding current 35 - 250 A 40 - 300 A 35 - 350 A 50 - 450 ASteel wire diameter 0.8 - 1.0 mm** 0.8 - 1.2 mm 0.8 - 1.2 mm 0.8 - 1.6 mmDuty cycle at 35 % 250 A (30 %) 300 A 350 A 450 Aat 40 °C at 60 % 170 A 230 A 270 A 345 Aat 100 % 140 A 180 A 210 A 270 AProtection class IP 23Dimensions (mm) 500 x 1180 x 950 600 x 1250 x 1050Weight 102 kg 118 kg 133 kg 165 kg* at maximum <strong>welding</strong> intensity ** 1.2 mm possible (1) version prepared for cooling unitBLUMIG 503 SH (1)Cat. nr: W 000 263 734(<strong>power</strong> source only)See:• Wire feeder page 42• Torches page 44• Rollers page 46Delivered equipped with:■ electric cable,■ equipped earh cable,■ safety instruction for useand maintenance manual.www.cemont.com41

Wire feeder with cablesfor BLUMIG S <strong>power</strong> sources.TF 300 / 400 / 400HMIG/MAGPOWER SOURCESThe TF wire feeders are compatible with all the BLUMIG S <strong>power</strong> sources range.They are delivered as standard with a sheathed cable.The Advantages:■ Sealed structure: protection of the wire feeding system.■ Digital display: A/V included on TF 400 and TF 400H.■■■■■Comfortable: adjustment on the front panel, and pivotingwire feed unit support which makes easier the storageand the orientation of the wire feeder.Efficient wire feeding: 4 rollers plate.Safety: perfect locking of the wire feeding compartment.Quick: bi-stripped cable.Robust: sheathed cable.3456212Digital display A/V.Wire speed.734Mode 2T / 4T / point.Point adjustment.156Starting speed.Stick-out adjustment.98789Test / Purge gas / Wire advance.Torch connection.Water inlet / outlet on TF 400H type.Rollers see page 46TECHNICAL DATA:TF 300 - TF 400 - TF 400 HTF 300 AIR TF 400 AIR TF 400 WATERDigital display A/V - ✔ ✔Wheels ✔ ✔ ✔Equipped for water cooled torch - - ✔Rollers0.8 - 1.0 mm / 1.0 - 1.2 mm for steelCat. no. TF 300 TF 400 TF 400 HCable length 5 m W 000 263 745 W 000 263 747 W 000 263 749Cable length 10 m W 000 263 746 W 000 263 781 W 000 263 750Cable length 20 m - W 000 263 748 W 000 263 75142 www.cemont.com

PRECISA 201 SGThe MX 201 SG / PRECISA 201 SG is a multi-processinverter technology installation. Its weight, <strong>power</strong>and primary single-phase input voltage, make the PRECISA201 the specialist for quick interventions.The Advantages:■ Input voltage: 230 V single-phase.■ Display: digital A / V.■■■■Multi-processes: MIG / MMA / TIG DC.Wire feeder device: 2 rollers.Professional: robust structure with handle for transportation.Programmable: 9 programs available 11 programs memorized.■ Polarity inversion: for <strong>welding</strong> applications with gasless fluxcored wire.■ Wire spool: D 200.■Torch MIG: with European connectors or Spool Gun.84 5397126123456789Multi-process semi-automatic <strong>welding</strong><strong>power</strong> source. Portable with inverter technology.Single-phase input voltage.Digital display.Program mode buttons.Potentiometer.MIG / MMA / TIG DC selection.Selection 2T / 4T / point.European connector for torch.Spool Gun connection control.Adjustment of the <strong>welding</strong> <strong>power</strong>.Wire speed regulation.PORTABLEMULTI-PROCESSESCat. nr : W 000 263 772MIG/MAGPOWER SOURCESClassificationEN 60974.1EN 60974.10MIG/MAG WELDING POWER SOURCESTECHNICAL DATA:PRECISA 201Input voltage 50/60 Hz230 V single-phasePrimary consumption* -Power*35 A / 4.8 kVAEffective consumption21 AWelding voltage12 - 24 VWelding current30 - 200 ADuty cycle at 35 % 200 A60 % 165 A100 % 145 AWire diameter0.6 to 1.0 mmProtection class IP 23Dimensions235 x 470 x 570 mmWeight29 kg* at maximum <strong>welding</strong> intensityDelivered equipped with:■ electric cable,• Torches see page 44• Rollers see page 46■ equipped earth cable,■ rollers for wire 0.8 / 1.0 mm,■ safety instruction for use and maintenancemanual.www.cemont.com43

MIG/MAG torches.MIG/MAGTORCHESA complete range of torches forMIG MAG <strong>welding</strong>, designedto answer the needs insemi-automatic <strong>welding</strong>.MIG/MAGTORCHESClassificationEN 60974.1EN 60974.7• WMT 15 A :for car bodies due to its compactness.• WMT 25 A :for metal iron works andmaintenance jobs.• WMT 36 A :for boiler making, mechano<strong>welding</strong>and metal frames manufacturing.• WMT 500 W :for intensive works needinga water cooling of the torch.The Advantages:■■■■■■Great handiness.Ergonomic handle for a perfect catch.Flexibility due to its back knee joint.Wear parts according to Europeanstandard.European connector.Resting hook.TECHNICAL DATA:TORCH WMT 15 A WMT 25 A WMT 36 A WMT 500 WCooling air air air waterDuty cycle at 60%CO 2 180 A 230 A 360 A 500 AAr +CO 2 150 A 200 A 330 A 450 AVoltage class L 113 - 1Suitable wiresSteel 0.6 à 1.0 mm Steel 0.8 à 1.2 mm Steel 0.8 à 1.6 mm Steel 0.8 à 2.4 mm- Alum. 1.0 à 1.2 mm Alum. 1.0 à 1.6 mm Alum. 1.0 à 2.4 mmGas flow 10 à 18 l/min 10 à 18 l/min 10 à 18 l/min 10 à 25 l/minDelivered equipped withContact tip Steel 0.8 mm Steel 1.0 mm Steel 1.2 mm Steel 1.2 mmNozzle (diameter) 12.5 mm 14.0 mm 16.0 mm 16.5 mmSheathFor steel wire For steel wire For steel wire For steel wire0.6 - 0.8 mm 1.0 - 1.2 mm 1.0 - 1.2 mm 1.0 - 1.2 mmCat. nr WMT 15 A WMT 25 A WMT 36 A WMT 500 WLength 3 m W 000 010 600 W 000 010 602 W 000 010 605 W 000 010 608Length 4 m W 000 010 601 W 000 010 603 W 000 010 606 W 000 010 609Length 5 m - W 000 010 604 W 000 010 607 W 000 010 61044 www.cemont.com

Wear parts for MIG/MAG torches.MIG/MAGTORCHES1. Nozzle2. Contact tip3. Clamp4. DiffuserWEAR PARTS :PU TYPES Ø Cat. nr WMT 15 A WMT 25 A WMT 36 A WMT 500 W0.6 AC W 000 010 820 ✔M6 x 25 steel 0.8 AC W 000 010 821 ✔1.0 AC W 000 010 822 ✔0.8 AC W 000 010 826 ✔M6 x 28 steel 1.0 AC W 000 010 827 ✔M6 x 28 alu1 2 3 41.2 AC W 000 010 828 ✔1.0 Al W 000 010 850 ✔CONTACT 1.2 Al W 000 010 851 ✔TIP 0.8 AC W 000 010 834 ✔ ✔M8 x 30 steel1.0 AC W 000 010 835 ✔ ✔1.2 AC W 000 010 836 ✔ ✔1.6 AC W 000 010 837 ✔ ✔1.0 Al W 000 010 853 ✔ ✔M8 x 30 alu 1.2 Al W 000 010 854 ✔ ✔1.6 Al W 000 010 855 ✔ ✔M6 x 35 - W 000 010 720 ✔CLAMP M6 x 28 - W 000 010 722 ✔M8 x 25 - W 000 010 724 ✔classical - W 000 010 780 ✔high temp. - W 000 010 781 ✔DIFFUSERceramics - W 000 010 782 ✔classical - W 000 010 783 ✔high temp. - W 000 010 784 ✔ceramics - W 000 010 785 ✔10.0 mm W 000 010 787 ✔12.5 mm W 000 010 786 ✔14.0 mm W 000 010 790 ✔12.0 mm W 000 010 792 ✔NOZZLE conical 14.0 mm W 000 010 794 ✔17.0 mm W 000 010 792 ✔16.0 mm W 000 010 794 ✔20.0 mm W 000 010 796 ✔16.5 mm W 000 010 797 ✔steel - length 3 m 0.6 - 0,8 W 000 010 730 ✔ ✔ ✔steel - length 4 m 1.0 - 1.2 W 000 010 731 ✔ ✔ ✔SHEATHalu - length 3 m 0.6 - 0,8 W 000 010 733 ✔ ✔ ✔alu - length 4 m 1.0 - 1.2 W 000 010 734 ✔ ✔ ✔alu - length 3 m 1.0 - 1.2 W 000 010 736 ✔ ✔ ✔WEAR PARTS FOR MIG/MAG TORCHESwww.cemont.com45

Solid wires for non or lowalloyed carbon steels <strong>welding</strong>.STEELMIG G3General characteristics:Solid wire suitable for general use.Very good striking quality.Excellent fusion.High level of elongation.MIG/MAGWELDING WIRESMain applications:■■■■■■Transportation vehiclesTerrestrial vehiclesMechanical constructionsSmall metal fitting worksSmall agricultural reparation worksMechano-welded worksMECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1597-1):Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)(MPa) (MPa) (%) - 30 °CWith CO2 500 - 640 ≥ 490 ≥ 25 ≥ 47With Ar/CO2 550 - 630 ≥ 460 ≥ 24 ≥ 47EXCELLENTFUSIONPROPERTIESORDERING INFORMATION:STEEL TYPES TO BE WELDED:SPOOLDiam(mm) Diam (mm) Material Wounds Weight (kg)0.60.81.01.2Cat. nr200 plastic precision layer 5 W 000 282 561200 plastic layer 5 W 000 282 562300 plastic precision layer 15 W 000 282 563300 plastic layer 15 W 000 282 564300 steel with hub precision layer 16 W 000 282 565300 steel with hub layer 16 W 000 282 566200 plastic precision layer 5 W 000 282 567200 plastic layer 5 W 000 282 568300 plastic precision layer 15 W 000 282 569300 plastic layer 15 W 000 282 570300 steel with hub precision layer 16 W 000 282 571300 steel with hub layer 16 W 000 282 572300 plastic precision layer 15 W 000 282 573300 plastic layer 15 W 000 282 574300 steel with hub precision layer 16 W 000 282 575300 steel with hub layer 16 W 000 282 576300 plastic precision layer 15 W 000 282 577300 plastic layer 15 W 000 282 578300 steel with hub precision layer 16 W 000 282 579300 steel with hub layer 16 W 000 282 580AFNORA 33 - A 34 - A 37 - 42 - 48 (CP AP)E 24 - E 26 - E 28 - E 30 - E 36 (4)DINSt 331.1 - Ust 37.2St 44 (2.3) - HI - HIIASTMA 283 (B.C.D)A 442 (55 - 60)ClassificationEN 440 : G 42 2 M G 3 Si 1AWS A 5.18 : ER 70 S-648 www.cemont.com

Solid wires for galvanized steels <strong>welding</strong>.GALVAMIGGeneral characteristics:Solid wire suitable for galvanized steels.It can also be used for the electro-zinc sheets <strong>welding</strong>.Excellent for thin sheets <strong>welding</strong>.General use <strong>welding</strong>.Main applications:■ Small metal fitting works■ Industrial car bodies fabrication■ Automobile repair■ Agricultural maintenance worksClassificationEN 440 : G 2 TiMECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1597-1):Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)(MPa) (MPa) (%) 0 °CWith Ar/CO2 460 - 550 > 420 ≥ 22 ≥ 90EXCELLENTFUSIONPROPERTIESMIG/MAGWELDING WIRESSOLID WIRES FOR GALVANIZED STEELS WELDINGORDERING INFORMATION:STEEL TYPES TO BE WELDED:Diam(mm)0.60.81.0SPOOLCat. nrDiam (mm) Material Wounds Weight (kg)200 plastic precision layer 5 W 000 282 836200 plastic layer 5 W 000 282 837200 plastic precision layer 5 W 000 282 838200 plastic layer 5 W 000 282 839300 plastic precision layer 15 W 000 282 840300 plastic layer 15 W 000 282 841300 steel with hub precision layer 16 W 000 282 842300 steel with hub layer 16 W 000 282 843300 plastic precision layer 15 W 000 282 844300 plastic layer 15 W 000 282 845300 steel with hub precision layer 16 W 000 282 846300 steel with hub layer 16 W 000 282 847AFNORA 33 - A 34 - A 37 - 42 - 48 (CP AP)E 24 - E 26 - E 28 - E 30 - E 36DINSt 331.1 - Ust 37.2St 37.3 U - St 44 (2.3) - HI - HIIASTMA 283 (B.C.D)A 442 (55 - 60)www.cemont.com49

Solid wire for <strong>welding</strong>high yield strength steels.TENOMIGGeneral characteristics:Solid wire suitable for high security works.High level of mechanical properties(high yield strength).MIG/MAGWELDING WIRESMain applications:■■Heavy boiler worksTransport and lifting enginesClassificationEN 440 : G 2 MoEN 12070 : ~_ G Mo SiAWS A 5.28 : ER 80 S-GMECHANICAL PROPERTIES OF THE ADDED METAL (according to EN 1597-1):Tensile Strength Yield Strength Elongation A 5 Impact energy V (J)(MPa) (MPa) (%) - 20 °CWith Ar/CO2 480 - 560 ≥ 380 ≥ 22 > 47ORDERING INFORMATION:STEEL TYPES TO BE WELDED:AFNOR15 D 3 - 18 MD 4.0516 D 3 - 18 MD 4.05DIN15 Mo 3 - 16 Mo 516 Mo 3 - 16 Mo 5Diam(mm)0.81.01.2SPOOLCat. nrDiam (mm) Material Wounds Weight (kg)300 plastic precision layer 15 W 000 282 935300 plastic layer 15 W 000 282 936300 steel with hub precision layer 16 W 000 282 937300 steel with hub layer 16 W 000 282 938300 plastic precision layer 15 W 000 282 939300 plastic layer 15 W 000 282 940300 steel with hub precision layer 16 W 000 282 941300 steel with hub layer 16 W 000 282 942300 plastic precision layer 15 W 000 282 943300 plastic layer 15 W 000 282 944300 steel with hub precision layer 16 W 000 282 945300 steel with hub layer 16 W 000 282 94550 www.cemont.com

Solid wires for stainless steels <strong>welding</strong>.INOXMIG 308General characteristics: Solid wire suitable for standardstainless steels "not for alimentary purpose".Main applications:■ Chemical industries■ Pharmaceutical industries■ Stainless steel boiler workClassificationEN 12072 : G 19 9 L SiAWS A 5.9 : ER 308 L SiINOXMIG 316General characteristics: Solid wire suitable for stainless steels<strong>welding</strong> requiring 316L. Widely usable for alimentary purpose.Main applications:■ Food industries ■ Milk industries ■ Pharmaceutical industriesINOXMIG 307General characteristics: Solid wire suitable for application requiring an under lay to avoid risksof cracking. Excellent for dissimilar <strong>welding</strong> (stainless steel with low or non alloyed steel).Used for buffer layers.Main applications:■ Automobile repair ■ Army machinery■ Agricultural works ■ Large thickness assemblyClassificationEN 12072 : G 19 12 3 L SiAWS A 5.9 : ER 316 L SiClassificationEN 12072 : G 18 8 MnAWS A 5.9 : ER 307MIG/MAGWELDING WIRESSOLID WIRES FOR STAINLESS STEELS WELDINGSTEEL TYPES TO BE WELDED:INOXMIG 308AFNOR DIN ASTMZ 2 CN 18.10 - Z 2 CN 18.10 N X 2 Cr 19.11 - X 2 Cr Ni N 18.10 (TP) 304 L - TP 304 LNZ 6 CNT 18.10 X 6 Cr NiTi 18.10 - X 5 Cr Ni Nb 18 (TP) 321 (N) - CF 86, CPF 8 CINOXMIG 316 Z 2 à 6 CND 17.12 à 19.4INOXMIG 307X 2 Cr 17.13.2 - X 2 Cr Ni Mo 17.13.3X 6 Cr Ni Mo Ti 17.12.210 à 60 NC 6 à 17 - Z 35 M 18201-Z 120 M 12 - Z 10 CNT 18.9 307MECHANICAL PROPERTIES OF THE ADDED METAL (according to NFA 81-314):(TP) 316 L - TP 316 LN - C (P) F 8 M Ti316 Ti - CF 8 C, CPF 8 CTensile Strength Yield Strength Elongation A 5 Impact energy V (J)(MPa) (MPa) (%) + 20 °CINOXMIG 308 with gas M 11 (Ar + O2) > 520 > 350 > 35 ≥ 47INOXMIG 316 with gas M 11 (Ar + O2) > 510 > 350 ≥ 30 ≥ 47INOXMIG 307 with gas M 11 (Ar + O2) > 590 > 400 ≥ 30 ≥ 47ORDERING INFORMATION:DiamSPOOLCat. nr(mm) Diam (mm) Material Wounds Weight (kg) INOXMIG 308 L INOXMIG 316 L INOXMIG 3070.8 300 steel layer 15 W 000 282 993 W 000 283 051 W 000 283 1051.0 300 steel layer 15 W 000 282 994 W 000 283 052 W 000 283 1061.2 300 steel layer 15 W 000 282 995 W 000 283 053 W 000 283 1071.6 300 steel layer 15 W 000 282 997 W 000 283 054 W 000 283 108www.cemont.com51