Presentation on Quality & Texting of Geosynthetics. - Technotex

Presentation on Quality & Texting of Geosynthetics. - Technotex

Presentation on Quality & Texting of Geosynthetics. - Technotex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

QUALITY & TESTING OFGEOSYNTHETICSV.K.PATIL &A.N.DESAIBOMBAY TEXTILE RESEARCH ASSOCIATIONL.B.S.MARG, GHATKOPAR (W),MUMBAI-400086.WEB : btraindia.com e-mail : btra@vsnl.comINTRODUCTIONIn the past 25 years many applicati<strong>on</strong>s <strong>of</strong>geosynthetics have proved their value in civilengineering projects and this new class <strong>of</strong> materialhas added entirely a new dimensi<strong>on</strong> to the world <strong>of</strong>geotechnical engineering. Geosynthetic materials likeGeotextiles, Geogrids, Ge<strong>on</strong>ets, Geocell, andGeomembranes are used in various civil engineeringactivities especially in highway engineering t<strong>of</strong>acilitate c<strong>on</strong>structi<strong>on</strong>, ensure better performance <strong>of</strong>the structure and reduce maintenance.To know the performance <strong>of</strong> these products,performance evaluati<strong>on</strong> is to be d<strong>on</strong>e & to meet therequirements, quality has to be maintained.

* NEED FOR TESTING* NABL Accreditati<strong>on</strong>* GEO-TECHNICAL PRODUCTS* GEO-TEXTILE TESTING* VARIOUS TESTS &TEST STANDARDSNEED FOR TESTINGProducts are tested for the following reas<strong>on</strong>s.* <strong>Quality</strong> assurance and c<strong>on</strong>trol* Setting and maintaining performance standards* Investigati<strong>on</strong> <strong>of</strong> complaints* Product developments and research* Testing can be classified into two categories,1. <strong>Quality</strong> testing 2. Performance assessments1. <strong>Quality</strong> TestingIndividual characteristics are measured against required specificati<strong>on</strong>.se.g.C<strong>on</strong>structi<strong>on</strong>aldetails <strong>of</strong> woven geotextile* Fabric mass, density and thickness* Threads per inch* Type <strong>of</strong> weave* Cloth cover factor* Other physical propertiese.g.C<strong>on</strong>structi<strong>on</strong>aldetails <strong>of</strong> Geogrid* Aperture Size* Density* Melt flow index & other physical properties2. Performance AssessmentsPredicti<strong>on</strong> <strong>of</strong> behaviour <strong>of</strong> Product in use c<strong>on</strong>diti<strong>on</strong>s.

Factors affecting the<strong>Quality</strong> <strong>of</strong> Testing• Variati<strong>on</strong> in the material• Variati<strong>on</strong> caused by the testmethod• Envir<strong>on</strong>ment• Type <strong>of</strong> instrument & itsaccessories• C<strong>on</strong>diti<strong>on</strong>s <strong>of</strong> testing such asspeed, pressure and durati<strong>on</strong>QUALITY ASSURANCE• What is QUALITY ?• <strong>Quality</strong> is a quantifiable attribute based <strong>on</strong> product performance,satisfies the customer and meets the requirements or specificati<strong>on</strong>s.• <strong>Quality</strong> <strong>of</strong> design, c<strong>on</strong>formance, applicati<strong>on</strong> and customer service.• <strong>Quality</strong> c<strong>on</strong>trol is the process <strong>of</strong> maintaining the current standards &product quality by the regular inspecti<strong>on</strong> carried out <strong>on</strong> limited no.<strong>of</strong>items. The results are recorded <strong>on</strong> c<strong>on</strong>trol charts and m<strong>on</strong>itoring thesample means & ranges to give warning <strong>of</strong> the process moving out <strong>of</strong>c<strong>on</strong>trol.• What is <strong>Quality</strong> Assurance ?• The system by which <strong>on</strong>e can give assurance <strong>of</strong> quality <strong>of</strong> products,process, testing, design/development, installati<strong>on</strong> & servicing andassessment. The system c<strong>on</strong>sists <strong>of</strong> guide lines. <strong>Quality</strong>management system ( ISO 9000 ).• ISO 9000 is the guide line for quality c<strong>on</strong>trol i.e totality <strong>of</strong> features andcharacteristics <strong>of</strong> product or service that bear <strong>on</strong> the ability to satisfystated or implied needs.

The standard is not directly c<strong>on</strong>cerned with the actualproperties or design <strong>of</strong> product but with gaureenting thatthe product is always manufactured in the same way, to thesame specificati<strong>on</strong>s, that no substandard raw material usedin the producti<strong>on</strong> and that any rejects do not find their wayinto the output. The c<strong>on</strong>cerns <strong>of</strong> the standard are really withgood organizati<strong>on</strong>al practice and it involves completedocumentati<strong>on</strong> <strong>of</strong> the whole process together with internaland external checks to ensure that everything is being runaccording to these written instructi<strong>on</strong>s.QUALITY ASSURANCE OFTESTINGSKILLED & EXPERIENCEDTESTING STAFFCALIBRATED EQUIPPMENTSNABL ACCREDITED & ISO17025 CERTIFIED LAB

Testing staff having skill in sample preparati<strong>on</strong>, handling<strong>of</strong> test equipments, knowledge <strong>of</strong> quality system and teststandards. Experience in testing <strong>of</strong> similar products &various tests will have better influence <strong>on</strong> quality <strong>of</strong>testing. The staffs are trained time to time for varioustests, quality c<strong>on</strong>trol systems and interpretati<strong>on</strong> <strong>of</strong>results.Calibrati<strong>on</strong> <strong>of</strong> test equipments is d<strong>on</strong>e periodically( every year ).<strong>Quality</strong> audit is carried out by NABL every year.The Laboratory implements new or revised teststandards.The system c<strong>on</strong>sists <strong>of</strong> following areas.• Enquiries and orders• Purchased material or services• Inspecti<strong>on</strong> & testing• Calibrati<strong>on</strong> <strong>of</strong> test equipment• Organizati<strong>on</strong>al structure• <strong>Quality</strong> audit• Training• M<strong>on</strong>itoring the producti<strong>on</strong>• Assessing the final product• Investigati<strong>on</strong> <strong>of</strong> faulty material• Product development & research

Accreditati<strong>on</strong>Laboratory accreditati<strong>on</strong> is a procedure by which anauthoritative body gives formal recogniti<strong>on</strong> <strong>of</strong> technicalcompetence for specific tests/ measurements, based <strong>on</strong> thirdparty assessment and following nati<strong>on</strong>al /internati<strong>on</strong>alstandardsWTO recognises that n<strong>on</strong> acceptance <strong>of</strong> test results andmeasurement data is a Technical Barrier to Trade.Global sourcing <strong>of</strong> comp<strong>on</strong>ents calls for equivalence <strong>of</strong>measurement, which can be facilitated by a chain <strong>of</strong> accreditedcalibrati<strong>on</strong> laboratories.Accreditati<strong>on</strong> is c<strong>on</strong>sidered as the first essential step forfacilitating mutual acceptance <strong>of</strong> test results and measurementdata.Benefits <strong>of</strong> Accreditati<strong>on</strong>• Increased c<strong>on</strong>fidence in Testing/ Calibrati<strong>on</strong> Reportsissued by the laboratory.Better c<strong>on</strong>trol <strong>of</strong> laboratory operati<strong>on</strong>s and feedback tolaboratories as to whether they have sound <strong>Quality</strong>Assurance System and are technically competent.Users <strong>of</strong> accredited laboratories enjoy greater access fortheir products, in both domestic and internati<strong>on</strong>almarkets.Customers can search and identify the laboratoriesaccredited by NABL for their specific requirementsfrom the NABL.• Savings in terms <strong>of</strong> time and m<strong>on</strong>ey due to reducti<strong>on</strong> oreliminati<strong>on</strong> <strong>of</strong> the need for re-testing <strong>of</strong> products.

GEO-TECHNICAL PRODUCTS:GEOTEXTILESGEONETSGEOGRIDSGEOMEMBRANESGEOCOMPOSITESGeosynthetic Clay Liner ( GCL )Turf Reinforcement Mats (TRM)GEOFOAMSRigid Cellular Polystyrene Ge<strong>of</strong>oamExpanded Polystyrene (EPS) Ge<strong>of</strong>oamDRAINSGeocomposite Pavement Panel DrainsVertical Strip DrainsPrefabricated Vertical Drains ( PVD )Erosi<strong>on</strong> C<strong>on</strong>trol Blankets ( ECB )Alternative Daily Covers (ADC)Prefabricated Bituminous Geomembranes (PBGM)GEO-TECHNICAL PRODUCTS:GEOTEXTILE : A flexible, permeable fabric used with foundati<strong>on</strong>, soil, rock,earth, or other geotechnical engineering related material as an integral part <strong>of</strong> a manmade project, structure, or system.GEONET: A netlike polymeric material formed from intersecting ribs integrallyjoined at the juncti<strong>on</strong>s used for drainage with foundati<strong>on</strong>, soil, rock, earth or anyother geotechnical-related material.GEOGRID: An open grid structure <strong>of</strong> polymeric material used primarily fortensile reinforcement.GEOMEMBRANE : An essentially impermeable membrane.GEOCOMPOSITE : A manufactured material using geotextiles, geogrids and/orgeomembranes in laminated or composite form.GEOCELL: A three-dimensi<strong>on</strong>al structure filled with soil, thereby forming amattress for increased stability when used with loose or compressible sible soils.Geosynthetic Clay Liner : Factory-manufactured hydraulic barriers c<strong>on</strong>sisting <strong>of</strong> alayer <strong>of</strong> bent<strong>on</strong>ite clay or other very low permeability material supported bygeotextiles and/or geomembranes and mechanically held together by needling,stitching or chemical adhesive.

GEOTEXTILE IN USE FOR ROADGEONET

GEOGRIDGEOMAT

• GEOFOAM• GEOCOMPOSITE• GEOSYNTHETICCLAY LINER• PREFABRICATEDVERTICAL DRAIN

• TURFREINFORCEMENTMAT• EROSION CONTROLBLANKET• GEOCELL• ALTERNATE DAILYCOVERS

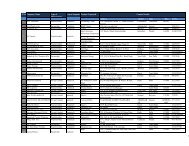

T E S T I N G S E R V I C E S AT BTRAGeomembranesGeogrids• Peel and Shear• Thickness• Density• Melt Flow Index• Carb<strong>on</strong> Black C<strong>on</strong>tent• Tear & Puncture Resistance• Tensile PropertiesGe<strong>on</strong>ets and Geocomposites• Aperture Size• Density• Melt Flow Index• Carb<strong>on</strong> Black C<strong>on</strong>tent & Dispersi<strong>on</strong>• Rib & Juncti<strong>on</strong> Strength• Wide WidthGeosynthetic Clay Liners• Mass per Unit Area• Thickness• Density• Melt Flow Index• Carb<strong>on</strong> Black C<strong>on</strong>tent• Transmissivity• Compressi<strong>on</strong> Behavior• CBR PunctureGeotextiles• Bent<strong>on</strong>ite Mass per Unit Area• Swell Index & Fluid Loss• Internal Shear• Index Flux or PermeabilityInterface Fricti<strong>on</strong> by Direct Shear• Mass per Unit Area• Thickness• Grab Strength• Trapezoidal Tear• Puncture Resistance• Permittivity• Apparent Opening Size (AOS)• CBR Puncture• Geosynthetic to Geosynthetic• Geosynthetic to Soils• Geosynthetic to GCL's• SoilComm<strong>on</strong> Tests <strong>of</strong> Geotxtile• Mass : gms per meter square• Thickness at specified pressure• Tensile strength : Strip / Grab / Wide Width• Tear Strength : Trapezoid• Water Permeability : Vertical / Horiz<strong>on</strong>tal• Apparent Opening Size : Sieving method• Puncture Resistance : CBR / Index / C<strong>on</strong>e

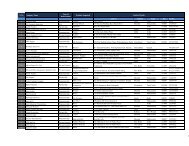

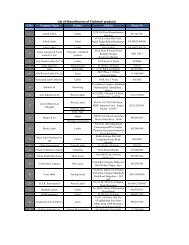

STANDARD TEST METHODS FOR GEOTEXTILES / GEOSYNTHETICSSr.No.TEST PARAMETERSASTMISO1 Apparent Opening Size D 4751 129562 Mass per unit area D 5261 98643 CBR Puncture Resistance D 6241 122364 Index Puncture Resistance D 48335 Grab breaking load & el<strong>on</strong>gati<strong>on</strong> D 4632 139346 Trapezoid Tearing Strength D 4533 134347 Tensile Properties <strong>of</strong> Geotextiles bythe Wide-Width Width Strip MethodD 4595 103198 Nominal Thickness <strong>of</strong> <strong>Geosynthetics</strong> D 5199 9863-19 Water Permeability by Permittivity D 4491 1105810 Hydraulic Transmissivity <strong>of</strong> aGeosynthetic Using a C<strong>on</strong>stant HeadD 4716 12958STANDARD TEST METHODS FOR GEOTEXTILES / GEOSYNTHETICSSr.No.TEST PARAMETERSASTMISO11 Dynamic perorati<strong>on</strong> by C<strong>on</strong>e Drop 1343312 Biological Clogging <strong>of</strong> Geotextiles D 198713 Bursting Strength-HydraulicD 388614 ,, ,, - Ball D 388715Tensile Properties <strong>of</strong> Geogrids bythe Single or Multi-RibTensileMethod16 Strength <strong>of</strong> Sewn or ThermallyB<strong>on</strong>ded Seams <strong>of</strong> Geotextiles17 Deteriorati<strong>on</strong> <strong>of</strong> Geotextile byExposure to Light, Moisture & HeatD 6637 13426D 4884 1032113426D 435518 Microbiological degradati<strong>on</strong> 12961

STANDARD TEST METHODS FOR GEOTEXTILES / GEOSYNTHETICSSr.No.TEST PARAMETERS19 Interface Fricti<strong>on</strong> between Soil &Geotextile by Direct Shear Method20 B<strong>on</strong>d Strength (Ply Adhesi<strong>on</strong>) <strong>of</strong>Geocomposites21 Oxidative Inducti<strong>on</strong> Time <strong>of</strong>Polyolefin <strong>Geosynthetics</strong> by HighPressure Differential Scanning Calorimetry22 Effect <strong>of</strong> Temperature <strong>on</strong> stability<strong>of</strong> GeotextileASTMISOD 5321 12957D 7005D 5885 11357D 459423 Permittivity <strong>of</strong> Geotextiles Under Load D 549324 Ply Adhesi<strong>on</strong> Strength <strong>of</strong> ReinforcedGeomembranesD 6636STANDARD TEST METHODS FOR GEOTEXTILES / GEOSYNTHETICSSr.NoTEST PARAMETERS25 Filtering Efficiency and Flow Rate<strong>of</strong> a Geotextile for Silt FenceApplicati<strong>on</strong> Using Site-Specific Specific Soil26 Pyramid Puncture Resistance <strong>of</strong>Unprotected and Protected Geomembranes27 Soil-Geotextile System CloggingPotential by the Gradient Ratio28 Determinati<strong>on</strong> <strong>of</strong> tensile creep andcreep rupture behaviour29ASTMD 5141D 5494D 5101ISOD 5262 13431Determining the resistance to Oxidati<strong>on</strong> 1343830 Chemical Resistance <strong>of</strong><strong>Geosynthetics</strong> / Geotextile to Liquids31 Strip Tensile Properties <strong>of</strong>Reinforced GeomembranesD 5322D 6389D 7003

STANDARD TEST METHODS FOR GEOTEXTILES / GEOSYNTHETICSSr.No.TEST PARAMETERS32 Microscopic Evaluati<strong>on</strong> <strong>of</strong> theDispersi<strong>on</strong> <strong>of</strong> Carb<strong>on</strong> Black inPolyolefin <strong>Geosynthetics</strong>33 Hydraulic Transmissivity <strong>of</strong> aGeosynthetic by Radial Flow34 Pore Size Characteristics <strong>of</strong>Geotextiles by Capillary Flow Test35 Grab Tensile Properties <strong>of</strong>Reinforced GeomembranesASTMISOD 5596 11420D 6574D 6767D 700436 Determining Ge<strong>on</strong>et Breaking Force D 717937 Abrasi<strong>on</strong> Resistance <strong>of</strong> Geotextiles(Sand Paper/Sliding Block Method)38 Tensile Creep & Creep rupture behaviour<strong>of</strong> geo-textileD 4886 1342713431Wide Width Tensile StrengthASTM D 4595

Index Puncture Resistance( ASTM D 4833 ):CBR ( static ) puncture resistanceASTM D 6241 / ISO 12236

Trapezoid Tear StrengthOf Geotextile( ASTM D 4533 )CREEP & RUPTUREBEHAVIOUR Of GeotextileASTM D 5262

C<strong>on</strong>e Drop Test( EN 918, ISO 13433 )SEAM STRENGTHOf GeotextileASTM D 4884

Water permeability bypermittivity method( ASTM D 4491 )In-plane Permeability( Hydraulic Transmissivity ):Of GeotextileASTM D 4716DIscharge CapacityLoadHead Lossgeotextile

Bursting Strength( Mullen / Hydraulic )ASTM D 3786Where to test• In Accredited LaboratoriesLike BTRA• Benefits <strong>of</strong> testing in accredited Labs :• User is c<strong>on</strong>fident about the test report issued byaccredited laboratory & sure that the same resultswill be obtained if tested in any other accreditedlaboratory within specified limits.• Users <strong>of</strong> accredited laboratory enjoy greater accessfor their products in both domestic as well asinternati<strong>on</strong>al market.• Savings in terms <strong>of</strong> time & m<strong>on</strong>ey due to reducti<strong>on</strong>or eliminati<strong>on</strong> <strong>of</strong> the need for re-testing <strong>of</strong> products

NON-WOVEN PLANT- NEEDLE PUNCHING WITH HOT AIR BONDINGAND THERMAL CALENDERING