spade drill inserts - carbide(k20) - YG-1

spade drill inserts - carbide(k20) - YG-1

spade drill inserts - carbide(k20) - YG-1

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

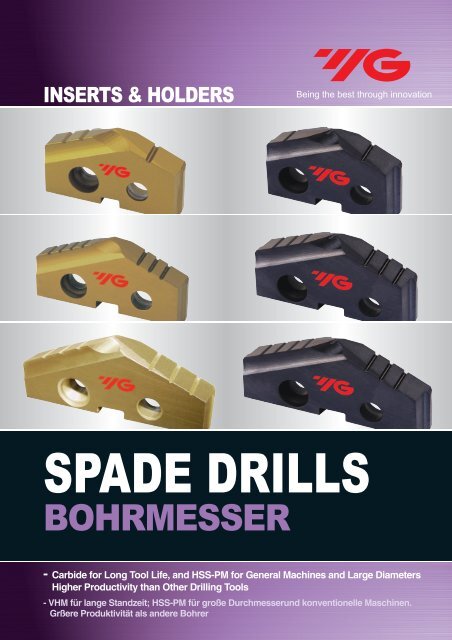

INSERTS & HOLDERSBeing the best through innovationSPADE DRILLSBOHRMESSER- Carbide for Long Tool Life, and HSS-PM for General Machines and Large DiametersHigher Productivity than Other Drilling Tools- VHM für lange Standzeit; HSS-PM für große Durchmesserund konventionelle Maschinen.Grßere Produktivität als andere Bohrer

SELECTION GUIDESPADE DRILL INSERTSITEM MODEL DESCRIPTION PAGESIZEMIN MAXSERIES1~8SPADE DRILL INSERTS - HSS M4EINWEG BOHREINSATZ - HSS M417.86(#1)114.3(#8)216SERIESY,Z,0,1~4SPADE DRILL INSERTS - SUPER HSS T15EINWEG BOHREINSATZ - SUPER HSS T159.5(#Y)65.09(#4)222SERIESY,Z,0,1,2SPADE DRILL INSERTS - PREMIUM HSS M48EINWEG BOHREINSATZ - PREMIUM HSS M489.5(#Y)35(#2)227SERIESY,Z,0,1,2SPADE DRILL INSERTS forCAST IRON - CARBIDE(K10)EINWEG BOHREINSATZ - VOLLHARTMETALL (K10)9.5(#Y)35(#2)230SERIESY,Z,0,1~3SPADE DRILL INSERTS - CARBIDE(K20)EINWEG BOHREINSATZ - VOLLHARTMETALL (K20)9.5(#Y)47.63(#3)233SERIESY,Z,0,1~3SPADE DRILL INSERTS - CARBIDE(P40)EINWEG BOHREINSATZ - VOLLHARTMETALL (P40)9.5(#Y)47.63(#3)237SERIES1~3SM-POINT SPADE DRILL INSERTS - HSS M4SM-POINT EINWEG BOHREINSATZ - HSS M417.86(#1)47.63(#3)242SERIESY,Z,0,1~3SM-POINT SPADE DRILL INSERTS - SUPER HSS T15SM-POINT EINWEG BOHREINSATZ - SUPER HSS T159.5(#Y)47.63(#3)245SERIESY,Z,0,1,2SM-POINT SPADE DRILL INSERTS - PREMIUM HSS M48SM-POINT EINWEG BOHREINSATZ - PREMIUM HSS M489.5(#Y)35(#2)249SERIESY,Z,0,1,2SM-POINT SPADE DRILL INSERTS forCAST IRON - CARBIDE(K10)SM-POINT EINWEG BOHREINSATZ - VOLLHARTMETALL (K10)9.5(#Y)35(#2)252SERIESY,Z,0,1~3SM-POINT SPADE DRILL INSERTS - CARBIDE(K20)SM-POINT EINWEG BOHREINSATZ - VOLLHARTMETALL (K20)9.5(#Y)47.63(#3)255SERIESY,Z,0,1~3SM-POINT SPADE DRILL INSERTS - CARBIDE(P40)SM-POINT EINWEG BOHREINSATZ - VOLLHARTMETALL (P40)9.5(#Y)47.63(#3)259SPADE DRILL HOLDERSTAPERSHANKTAPER SHANK HOLDERS - INCH/METRICHALTER MIT MORSEKEGEL263FLANGEDSHANKFLANGED STRAIGHT SHANK HOLDERS - INCH/METRICHALTER MIT ZYLINDERSCHAFT UND SPANNFLÄCHE271STRAIGHTSHANKSTRAIGHT SHANK HOLDERS - INCHHALTER MIT ZYLINDERSCHAFT278214phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr

SPADE DRILLS215phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.krNonalloyedSteels,FreeMachiningSteelsCarbon Steels Alloy Steels High Alloyed steels Structural Steels Tool SteelsStainlessSteelsCast lron Aluminum CopperAlloys~HRc24(~HB250)~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)~HRc28(~HB275)~HRc19(~HB220)HRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDEHSSSPADE DRILLSSERIES 1,2i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - HSS M4EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATASeriesMin. to Max.(mm/inch)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)117.53(.690)to24.38(.960)224.41(.961)to35.05(1.380)Inch(inch)45/6423/3247/643/449/6425/3251/6413/1627/3255/647/857/6429/3259/6415/1631/3263/6411-1/641-1/321-3/641-1/16DiameterMetric(mm)17.8618.0018.2618.5018.6519.0019.0519.4519.5019.8420.0020.2420.5020.6421.0021.4321.8322.0022.2322.6223.0023.0223.4223.8124.0024.6125.0025.4025.8026.0026.1926.5926.9927.00Decimal(inch).7031.7087.7188.7283.7344.7480.7500.7656.7677.7813.7874.7969.8071.8125.8268.8438.8594.8661.8750.8906.9055.9063.9219.9375.9449.9688.98431.00001.01561.02361.03131.04691.06251.0630Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAIN4.0(5/32)4.8(3/16)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)S1405045S1455180S1405046S1455185S1405047S1455190S1405048S1405049S1455195S1405050S1455200S1405051S1455205S1405052S1455210S1405054S1405055S1455220S1405056S1405057S1455230S1405058S1405059S1405060S1455240S1405062S1405063S1405100S1405101S1455260S1405102S1405103S1405104S1455270HRc13~(HB200~)StainlessSteels~HRc28(~HB275)216phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.krS1410045S1460180S1410046S1460185S1410047S1460190S1410048S1410049S1460195S1410050S1460200S1410051S1460205S1410052S1460210S1410054S1410055S1460220S1410056S1410057S1460230S1410058S1410059S1410060S1460240S1410062S1410063S1410100S1410101S1460260S1410102S1410103S1410104S1460270~HRc19(~HB220)cutting conditions : p.283S1415045S1465180S1415046S1465185S1415047S1465190S1415048S1415049S1465195S1415050S1465200S1415051S1465205S1415052S1465210S1415054S1415055S1465220S1415056S1415057S1465230S1415058S1415059S1415060S1465240S1415062S1415063S1415100S1415101S1465260S1415102S1415103S1415104S1465270 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110

CARBIDESPADE DRILLSSERIES 2,3HSSSPADE DRILL INSERTS - HSS M4EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXSeriesMin. to Max.(mm/inch)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)224.41(.961)to35.05(1.380)334.37(1.353)to47.80(1.882)Inch(inch)1-3/321-7/641-1/81-5/321-3/161-7/321-1/41-9/321-5/161-11/321-3/81-13/321-7/161-15/321-1/21-17/321-9/161-19/321-5/8DiameterMetric(mm)27.7828.0028.1828.5829.0029.3730.0030.1630.9631.0031.7532.0032.5433.0033.3434.0034.1334.9335.0035.7236.0036.5137.0037.3138.0038.1038.8939.0039.6940.0040.4841.0041.2842.00Decimal(inch)1.09381.10241.10941.12501.14171.15631.18111.18751.21881.22051.25001.25981.28131.29921.31251.33861.34381.37501.37801.40631.41731.43751.45671.46881.49611.50001.53131.53541.56251.57481.59381.61421.62501.65354.8(3/16)6.4(1/4)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAINHRc24~(HB250~)~HRc13(~HB200)S1405106S1455280S1405107S1405108S1455290S1405110S1455300S1405112S1405114S1455310S1405116S1455320S1405118S1455330S1405120S1455340S1405122S1405124S1455350S1405126S1455360S1405128S1455370S1405130S1455380S1405132S1405134S1455390S1405136S1455400S1405138S1455410S1405140S1455420HRc13~(HB200~)StainlessSteels~HRc28(~HB275)S1410106S1460280S1410107S1410108S1460290S1410110S1460300S1410112S1410114S1460310S1410116S1460320S1410118S1460330S1410120S1460340S1410122S1410124S1460350S1410126S1460360S1410128S1460370S1410130S1460380S1410132S1410134S1460390S1410136S1460400S1410138S1460410S1410140S1460420~HRc19(~HB220)cutting conditions : p.283S1415106S1465280S1415107S1415108S1465290S1415110S1465300S1415112S1415114S1465310S1415116S1465320S1415118S1465330S1415120S1465340S1415122S1415124S1465350S1415126S1465360S1415128S1465370S1415130S1465380S1415132S1415134S1465390S1415136S1465400S1415138S1465410S1415140S1465420 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr217DREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 3,4i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - HSS M4EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATASeriesMin. to Max.(mm/inch)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)334.37(1.353)to47.80(1.882)446.99(1.850)to65.28(2.570)Inch(inch)1-21/321-11/161-23/321-3/41-25/321-13/161-27/321-7/81-29/321-15/161-31/3222-1/322-3/642-1/162-3/322-1/82-5/322-3/162-7/32DiameterMetric(mm)42.0742.8643.0043.6644.0044.4545.0045.2446.0046.0446.8347.0047.6348.0048.4249.0049.2150.0050.0150.8051.0051.5952.0052.3953.0053.1853.9854.0054.7955.0055.5656.0056.3657.00Decimal(inch)1.65631.68751.69291.71881.73231.75001.77171.78131.81101.81251.84381.85041.87501.88981.90631.92911.93751.96851.96882.00002.00792.03132.04722.06252.08662.09382.12502.12602.15632.16542.18752.20472.21882.2441Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAIN6.4(1/4)7.9(5/16)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)S1405142S1405144S1455430S1405146S1455440S1405148S1455450S1405150S1455460S1405152S1405154S1455470S1405156S1455480S1405158S1455490S1405160S1455500S1405162S1405200S1455510S1405202S1405203S1405204S1455530S1405206S1405208S1455540S1405210S1455550S1405212S1455560S1405214S1455570HRc13~(HB200~)StainlessSteels~HRc28(~HB275)218phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.krS1410142S1410144S1460430S1410146S1460440S1410148S1460450S1410150S1460460S1410152S1410154S1460470S1410156S1460480S1410158S1460490S1410160S1460500S1410162S1410200S1460510S1410202S1410203S1410204S1460530S1410206S1410208S1460540S1410210S1460550S1410212S1460560S1410214S1460570~HRc19(~HB220)cutting conditions : p.283S1415142S1415144S1465430S1415146S1465440S1415148S1465450S1415150S1465460S1415152S1415154S1465470S1415156S1465480S1415158S1465490S1415160S1465500S1415162S1415200S1465510S1415202S1415203S1415204S1465530S1415206S1415208S1465540S1415210S1465550S1415212S1465560S1415214S1465570 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110

CARBIDESPADE DRILLSSERIES 4,5HSSSPADE DRILL INSERTS - HSS M4EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXSeriesMin. to Max.(mm/inch)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)446.99(1.850)to65.28(2.570)562.38(2.456)to76.20(3.000)Inch(inch)2-1/42-9/322-5/162-11/322-3/82-13/322-7/162-15/322-1/22-17/322-9/162-1/22-17/322-9/162-19/322-5/82-21/322-11/162-23/322-3/42-25/322-13/16DiameterMetric(mm)57.1557.9458.0058.7459.0059.5360.0060.3361.0061.1261.9162.0062.7163.0063.5064.0064.2965.0065.0963.5064.0064.2965.0965.8866.0066.6867.4768.0068.2669.0569.8570.0070.6471.44Decimal(inch)2.25002.28132.28352.31252.32282.34382.36222.37502.40162.40632.43752.44092.46882.48032.50002.51972.53132.55912.56252.50002.51972.53132.56252.59382.59842.62502.65632.67722.68752.71882.75002.75592.78132.81257.9(5/16)11.1(7/16)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAINHRc24~(HB250~)~HRc13(~HB200)S1405216S1405218S1455580S1405220S1455590S1405222S1455600S1405224S1455610S1405226S1405228S1455620S1405230S1455630S1405232S1455640S1405234S1455650S1405236S14052D2S145564AS14052D4S14052D6S1405238S1455660S1405240S1405242S1455680S1405244S1405246S1405248S1455700S1405250S1405252HRc13~(HB200~)StainlessSteels~HRc28(~HB275)S1410216S1410218S1460580S1410220S1460590S1410222S1460600S1410224S1460610S1410226S1410228S1460620S1410230S1460630S1410232S1460640S1410234S1460650S1410236S14102D2S146064AS14102D4S14102D6S1410238S1460660S1410240S1410242S1460680S1410244S1410246S1410248S1460700S1410250S1410252~HRc19(~HB220)cutting conditions : p.283S1415216S1415218S1465580S1415220S1465590S1415222S1465600S1415224S1465610S1415226S1415228S1465620S1415230S1465630S1415232S1465640S1415234S1465650S1415236S14152D2S146564AS14152D4S14152D6S1415238S1465660S1415240S1415242S1465680S1415244S1415246S1415248S1465700S1415250S1415252 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr219DREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 5,6,7i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - HSS M4EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATASeriesMin. to Max.(mm/inch)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)562.38(2.456)to76.20(3.000)676.23(3.001)to89.08(3.507)7Inch(inch)2-27/322-7/82-29/322-15/162-31/3233-1/323-1/163-3/323-1/83-5/323-3/163-7/323-1/43-9/323-5/163-11/323-3/83-13/323-7/163-15/323-1/23-17/323-9/16DiameterMetric(mm)72.0072.2373.0373.8274.0074.6175.4176.0076.2076.9977.7978.0078.5879.3880.0080.1780.9681.7682.0082.5583.3484.0084.1484.9385.7386.0086.5287.3188.0088.1188.9089.6990.0090.49Decimal(inch)2.83462.84382.87502.90632.91342.93752.96882.99213.00003.03133.06253.07093.09383.12503.14963.15633.18753.21883.22833.25003.28133.30713.31253.34383.37503.38583.40633.43753.46463.46883.50003.53133.54333.5625Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAIN11.1(7/16)11.1(7/16)11.1(7/16)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)S1455720S1405254S1405256S1405258S1455740S1405260S1405262S1455760S1405300S1405302S1405304S1455780S1405306S1405308S1455800S1405310S1405312S1405314S1455820S1405316S1405318S1455840S1405320S1405322S1405324S1455860S1405326S1405328S1455880S1405330S1405332S1405334S1455900S1405336HRc13~(HB200~)StainlessSteels~HRc28(~HB275)220phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.krS1460720S1410254S1410256S1410258S1460740S1410260S1410262S1460760S1410300S1410302S1410304S1460780S1410306S1410308S1460800S1410310S1410312S1410314S1460820S1410316S1410318S1460840S1410320S1410322S1410324S1460860S1410326S1410328S1460880S1410330S1410332S1410334S1460900S1410336~HRc19(~HB220)cutting conditions : p.283S1465720S1415254S1415256S1415258S1465740S1415260S1415262S1465760S1415300S1415302S1415304S1465780S1415306S1415308S1465800S1415310S1415312S1415314S1465820S1415316S1415318S1465840S1415320S1415322S1415324S1465860S1415326S1415328S1465880S1415330S1415332S1415334S1465900S1415336 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110

CARBIDESPADE DRILLSSERIES 7,8HSSSPADE DRILL INSERTS - HSS M4EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXSeriesMin. to Max.(mm/inch)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)787.76(3.455)to101.60(4.000)8101.63(4.001)to114.48(4.507)Inch(inch)3-19/323-5/83-21/323-11/163-23/323-3/43-25/323-13/163-27/323-7/83-29/323-15/163-31/3244-1/644-1/164-3/324-1/84-3/164-1/44-5/164-3/84-7/164-1/2DiameterMetric(mm)91.2892.0092.0892.8793.6694.0094.4695.2596.0096.0496.8497.6398.0098.4399.22100.00100.01100.81101.60102.00103.19104.00104.78106.00106.36107.95108.00109.54110.00111.13112.00112.71114.00114.30Decimal(inch)3.59383.62213.62503.65633.68753.70083.71883.75003.77953.78133.81253.84383.85833.87503.90633.93703.93753.96884.00004.01574.06254.09454.12504.17324.18754.25004.25204.31254.33074.37504.40944.43754.48824.500011.1(7/16)11.1(7/16)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAINHRc24~(HB250~)~HRc13(~HB200)S1405338S1455920S1405340S1405342S1405344S1455940S1405346S1405348S1455960S1405350S1405352S1405354S1455980S1405356S1405358S1455A00S1405360S1405362S1405400S1405401S1405404S1405406S1405408S1455A60S1405412S1405416S1455A80S1405420S1455B00S1405424S1455B20S1405428S1455B40S1405432HRc13~(HB200~)StainlessSteels~HRc28(~HB275)S1410338S1460920S1410340S1410342S1410344S1460940S1410346S1410348S1460960S1410350S1410352S1410354S1460980S1410356S1410358S1460A00S1410360S1410362S1410400S1410401S1410404S1410406S1410408S1460A60S1410412S1410416S1460A80S1410420S1460B00S1410424S1460B20S1410428S1460B40S1410432~HRc19(~HB220)cutting conditions : p.283S1415338S1465920S1415340S1415342S1415344S1465940S1415346S1415348S1465960S1415350S1415352S1415354S1465980S1415356S1415358S1465A00S1415360S1415362S1415400S1415401S1415404S1415406S1415408S1465A60S1415412S1415416S1465A80S1415420S1465B00S1415424S1465B20S1415428S1465B40S1415432 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr221DREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES Y,Z,0i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - SUPER HSS T15EINWEG BOHREINSATZ - SUPER HSS T15 For use in high nickel alloys and materials over 280 Brinell. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung bei legierten Stählen mit hohem Nickelanteilund Werkstoffen über 280 Brinell Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATASeriesMin. to Max.(mm/inch)Y9.50(.374)to11.07(.436)Z11.11(.437)to12.95(.510)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)012.98(.511)to17.65(.695)Inch(inch)3/825/6413/3227/647/1629/6415/3231/641/233/6417/3235/649/1637/6419/3239/645/8DiameterMetric(mm)9.509.539.809.9210.0010.2010.3210.5010.7210.8011.0011.1111.5011.5111.9112.0012.3012.5012.7013.0013.1013.4913.5013.8914.0014.2914.5014.6815.0015.0815.4815.5015.8816.00Decimal(inch).3740.3750.3860.3906.3937.4016.4063.4134.4219.4252.4331.4375.4528.4531.4688.4724.4844.4921.5000.5118.5156.5313.5315.5469.5512.5625.5709.5781.5906.5938.6094.6102.6250.6299Thick EDP No.Metric SUPER HSS (T15)(mm/inch) TiN TiCN TiAIN2.4(3/32)2.4(3/32)3.2(1/8)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)S1155095S1105024S1155098S1105025S1155100S1155102S1105026S1155105S1105027S1155108S1155110S1105028S1155115S1105029S1105030S1155120S1105031S1155125S1105032S1155130S1105033S1105034S1155135S1105035S1155140S1105036S1155145S1105037S1155150S1105038S1105039S1155155S1105040S1155160HRc13~(HB200~)StainlessSteels~HRc28(~HB275)222phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.krS1160095S1110024S1160098S1110025S1160100S1160102S1110026S1160105S1110027S1160108S1160110S1110028S1160115S1110029S1110030S1160120S1110031S1160125S1110032S1160130S1110033S1110034S1160135S1110035S1160140S1110036S1160145S1110037S1160150S1110038S1110039S1160155S1110040S1160160~HRc19(~HB220)cutting conditions : p.283S1165095S1115024S1165098S1115025S1165100S1165102S1115026S1165105S1115027S1165108S1165110S1115028S1165115S1115029S1115030S1165120S1115031S1165125S1115032S1165130S1115033S1115034S1165135S1115035S1165140S1115036S1165145S1115037S1165150S1115038S1115039S1165155S1115040S1165160 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110

CARBIDESPADE DRILLSSERIES 0,1HSSSPADE DRILL INSERTS - SUPER HSS T15EINWEG BOHREINSATZ - SUPER HSS T15 For use in high nickel alloys and materials over 280 Brinell. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung bei legierten Stählen mit hohem Nickelanteilund Werkstoffen über 280 Brinell Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXcutting conditions : p.283DREAMDRILLS-MQL TYPESeriesMin. to Max.(mm/inch)012.98(.511)to17.65(.695)117.53(.690)to24.38(.960)Inch(inch)41/6421/3243/6411/1645/6423/3247/643/449/6425/3251/6413/1627/3255/647/857/6429/3259/6415/16DiameterMetric(mm)16.2716.5016.6717.0017.0717.4617.5017.8618.0018.2618.5018.6519.0019.0519.4519.5019.8420.0020.2420.5020.6421.0021.4321.8322.0022.2322.6223.0023.0223.4223.8124.00Decimal(inch).6406.6496.6563.6693.6719.6875.6890.7031.7087.7188.7283.7344.7480.7500.7656.7677.7813.7874.7969.8071.8125.8268.8438.8594.8661.8750.8906.9055.9063.9219.9375.9449Thick EDP No.Metric SUPER HSS (T15)(mm/inch) TiN TiCN TiAIN3.2(1/8)4.0(5/32)S1105041S1155165S1105042S1155170S1105043S1105044S1155175S1105045S1155180S1105046S1155185S1105047S1155190S1105048S1105049S1155195S1105050S1155200S1105051S1155205S1105052S1155210S1105054S1105055S1155220S1105056S1105057S1155230S1105058S1105059S1105060S1155240S1110041S1160165S1110042S1160170S1110043S1110044S1160175S1110045S1160180S1110046S1160185S1110047S1160190S1110048S1110049S1160195S1110050S1160200S1110051S1160205S1110052S1160210S1110054S1110055S1160220S1110056S1110057S1160230S1110058S1110059S1110060S1160240S1115041S1165165S1115042S1165170S1115043S1115044S1165175S1115045S1165180S1115046S1165185S1115047S1165190S1115048S1115049S1165195S1115050S1165200S1115051S1165205S1115052S1165210S1115054S1115055S1165220S1115056S1115057S1165230S1115058S1115059S1115060S1165240DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSNonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275)~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr223CENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 2,3i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - SUPER HSS T15EINWEG BOHREINSATZ - SUPER HSS T15 For use in high nickel alloys and materials over 280 Brinell. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung bei legierten Stählen mit hohem Nickelanteilund Werkstoffen über 280 Brinell Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATASeriesMin. to Max.(mm/inch)224.41(.961)to35.05(1.380)334.37(1.353)to47.80(1.882)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Inch(inch)31/3263/6411-1/641-1/321-3/641-1/161-3/321-7/641-1/81-5/321-3/161-7/321-1/41-9/321-5/161-11/321-3/81-13/321-7/161-15/32DiameterMetric(mm)24.6125.0025.4025.8026.0026.1926.5926.9927.0027.7828.0028.1828.5829.0029.3730.0030.1630.9631.0031.7532.0032.5433.0033.3434.0034.1334.9335.0035.7236.0036.5137.0037.3138.00Decimal(inch).9688.98431.00001.01561.02361.03131.04691.06251.06301.09381.10241.10941.12501.14171.15631.18111.18751.21881.22051.25001.25981.28131.29921.31251.33861.34381.37501.37801.40631.41731.43751.45671.46881.4961Thick EDP No.Metric SUPER HSS (T15)(mm/inch) TiN TiCN TiAIN4.8(3/16)6.4(1/4)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)S1105062S1105063S1105100S1105101S1155260S1105102S1105103S1105104S1155270S1105106S1155280S1105107S1105108S1155290S1105110S1155300S1105112S1105114S1155310S1105116S1155320S1105118S1155330S1105120S1155340S1105122S1105124S1155350S1105126S1155360S1105128S1155370S1105130S1155380HRc13~(HB200~)StainlessSteels~HRc28(~HB275)224phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.krS1110062S1110063S1110100S1110101S1160260S1110102S1110103S1110104S1160270S1110106S1160280S1110107S1110108S1160290S1110110S1160300S1110112S1110114S1160310S1110116S1160320S1110118S1160330S1110120S1160340S1110122S1110124S1160350S1110126S1160360S1110128S1160370S1110130S1160380~HRc19(~HB220)cutting conditions : p.283S1115062S1115063S1115100S1115101S1165260S1115102S1115103S1115104S1165270S1115106S1165280S1115107S1115108S1165290S1115110S1165300S1115112S1115114S1165310S1115116S1165320S1115118S1165330S1115120S1165340S1115122S1115124S1165350S1115126S1165360S1115128S1165370S1115130S1165380 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110

CARBIDESPADE DRILLSSERIES 3,4HSSSPADE DRILL INSERTS - SUPER HSS T15EINWEG BOHREINSATZ - SUPER HSS T15 For use in high nickel alloys and materials over 280 Brinell. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung bei legierten Stählen mit hohem Nickelanteilund Werkstoffen über 280 Brinell Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXSeriesMin. to Max.(mm/inch)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)334.37(1.353)to47.80(1.882)446.99(1.850)to65.28(2.570)Inch(inch)1-1/21-17/321-9/161-19/321-5/81-21/321-11/161-23/321-3/41-25/321-13/161-27/321-7/81-29/321-15/161-31/3222-1/322-3/642-1/16DiameterMetric(mm)38.1038.8939.0039.6940.0040.4841.0041.2842.0042.0742.8643.0043.6644.0044.4545.0045.2446.0046.0446.8347.0047.6348.0048.4249.0049.2150.0050.0150.8051.0051.5952.0052.3953.00Decimal(inch)1.50001.53131.53541.56251.57481.59381.61421.62501.65351.65631.68751.69291.71881.73231.75001.77171.78131.81101.81251.84381.85041.87501.88981.90631.92911.93751.96851.96882.00002.00792.03132.04722.06252.08666.4(1/4)7.9(5/16)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)Thick EDP No.Metric SUPER HSS (T15)(mm/inch) TiN TiCN TiAINHRc24~(HB250~)~HRc13(~HB200)S1105132S1105134S1155390S1105136S1155400S1105138S1155410S1105140S1155420S1105142S1105144S1155430S1105146S1155440S1105148S1155450S1105150S1155460S1105152S1105154S1155470S1105156S1155480S1105158S1155490S1105160S1155500S1105162S1105200S1155510S1105202S1105203S1105204S1155530HRc13~(HB200~)StainlessSteels~HRc28(~HB275)S1110132S1110134S1160390S1110136S1160400S1110138S1160410S1110140S1160420S1110142S1110144S1160430S1110146S1160440S1110148S1160450S1110150S1160460S1110152S1110154S1160470S1110156S1160480S1110158S1160490S1110160S1160500S1110162S1110200S1160510S1110202S1110203S1110204S1160530~HRc19(~HB220)cutting conditions : p.283S1115132S1115134S1165390S1115136S1165400S1115138S1165410S1115140S1165420S1115142S1115144S1165430S1115146S1165440S1115148S1165450S1115150S1165460S1115152S1115154S1165470S1115156S1165480S1115158S1165490S1115160S1165500S1115162S1115200S1165510S1115202S1115203S1115204S1165530 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr225DREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 4i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - SUPER HSS T15EINWEG BOHREINSATZ - SUPER HSS T15 For use in high nickel alloys and materials over 280 Brinell. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung bei legierten Stählen mit hohem Nickelanteilund Werkstoffen über 280 Brinell Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.283DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSSeriesMin. to Max.(mm/inch)446.99(1.850)to65.28(2.570)Inch(inch)2-3/322-1/82-5/322-3/162-7/322-1/42-9/322-5/162-11/322-3/82-13/322-7/162-15/322-1/22-17/322-9/16DiameterMetric(mm)53.1853.9854.0054.7955.0055.5656.0056.3657.0057.1557.9458.0058.7459.0059.5360.0060.3361.0061.1261.9162.0062.7163.0063.5064.0064.2965.0065.09Decimal(inch)2.09382.12502.12602.15632.16542.18752.20472.21882.24412.25002.28132.28352.31252.32282.34382.36222.37502.40162.40632.43752.44092.46882.48032.50002.51972.53132.55912.5625Thick EDP No.Metric SUPER HSS (T15)(mm/inch) TiN TiCN TiAIN7.9(5/16)S1105206S1105208S1155540S1105210S1155550S1105212S1155560S1105214S1155570S1105216S1105218S1155580S1105220S1155590S1105222S1155600S1105224S1155610S1105226S1105228S1155620S1105230S1155630S1105232S1155640S1105234S1155650S1105236S1110206S1110208S1160540S1110210S1160550S1110212S1160560S1110214S1160570S1110216S1110218S1160580S1110220S1160590S1110222S1160600S1110224S1160610S1110226S1110228S1160620S1110230S1160630S1110232S1160640S1110234S1160650S1110236S1115206S1115208S1165540S1115210S1165550S1115212S1165560S1115214S1165570S1115216S1115218S1165580S1115220S1165590S1115222S1165600S1115224S1165610S1115226S1115228S1165620S1115230S1165630S1115232S1165640S1115234S1165650S1115236NC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275) 226phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES Y,Z,0HSSSPADE DRILL INSERTS - PREMIUM HSS M48EINWEG BOHREINSATZ - PREMIUM HSS M48 For use in high temperature alloys and materials with 350~500 Brinell. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung bei hitzebeständigen Legierungenund Werkstoffen mit 350 - 500 Brinell Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXSeriesMin. to Max.(mm/inch)Y9.50(.374)to11.07(.436)Z11.11(.437)to12.95(.510)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)012.98(.511)to17.65(.695)Inch(inch)3/825/6413/3227/647/1629/6415/3231/641/233/6417/3235/649/1637/6419/3239/645/8DiameterMetric(mm)9.509.539.809.9210.0010.2010.3210.5010.7210.8011.0011.1111.5011.5111.9112.0012.3012.5012.7013.0013.1013.4913.5013.8914.0014.2914.5014.6815.0015.0815.4815.5015.8816.00Decimal(inch).3740.3750.3860.3906.3937.4016.4063.4134.4219.4252.4331.4375.4528.4531.4688.4724.4844.4921.5000.5118.5156.5313.5315.5469.5512.5625.5709.5781.5906.5938.6094.6102.6250.62992.4(3/32)2.4(3/32)3.2(1/8)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)Thick EDP No.Metric PREMIUM HSS (M48)(mm/inch) TiN TiCN TiAINHRc24~(HB250~)~HRc13(~HB200)S1555095S1505024S1555098S1505025S1555100S1555102S1505026S1555105S1505027S1555108S1555110S1505028S1555115S1505029S1505030S1555120S1505031S1555125S1505032S1555130S1505033S1505034S1555135S1505035S1555140S1505036S1555145S1505037S1555150S1505038S1505039S1555155S1505040S1555160HRc13~(HB200~)StainlessSteels~HRc28(~HB275)S1560095S1510024S1560098S1510025S1560100S1560102S1510026S1560105S1510027S1560108S1560110S1510028S1560115S1510029S1510030S1560120S1510031S1560125S1510032S1560130S1510033S1510034S1560135S1510035S1560140S1510036S1560145S1510037S1560150S1510038S1510039S1560155S1510040S1560160~HRc19(~HB220)cutting conditions : p.283S1565095S1515024S1565098S1515025S1565100S1565102S1515026S1565105S1515027S1565108S1565110S1515028S1565115S1515029S1515030S1565120S1515031S1565125S1515032S1565130S1515033S1515034S1565135S1515035S1565140S1515036S1565145S1515037S1565150S1515038S1515039S1565155S1515040S1565160 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr227DREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 0,1i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - PREMIUM HSS M48EINWEG BOHREINSATZ - PREMIUM HSS M48 For use in high temperature alloys and materials with 350~500 Brinell. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung bei hitzebeständigen Legierungenund Werkstoffen mit 350 - 500 Brinell Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.283DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSSeriesMin. to Max.(mm/inch)012.98(.511)to17.65(.695)117.53(.690)to24.38(.960)Inch(inch)41/6421/3243/6411/1645/6423/3247/643/449/6425/3251/6413/1627/3255/647/857/6429/3259/6415/16DiameterMetric(mm)16.2716.5016.6717.0017.0717.4617.5017.8618.0018.2618.5018.6519.0019.0519.4519.5019.8420.0020.2420.5020.6421.0021.4321.8322.0022.2322.6223.0023.0223.4223.8124.00Decimal(inch).6406.6496.6563.6693.6719.6875.6890.7031.7087.7188.7283.7344.7480.7500.7656.7677.7813.7874.7969.8071.8125.8268.8438.8594.8661.8750.8906.9055.9063.9219.9375.9449Thick EDP No.Metric PREMIUM HSS (M48)(mm/inch) TiN TiCN TiAIN3.2(1/8)4.0(5/32)S1505041S1555165S1505042S1555170S1505043S1505044S1555175S1505045S1555180S1505046S1555185S1505047S1555190S1505048S1505049S1555195S1505050S1555200S1505051S1555205S1505052S1555210S1505054S1505055S1555220S1505056S1505057S1555230S1505058S1505059S1505060S1555240S1510041S1560165S1510042S1560170S1510043S1510044S1560175S1510045S1560180S1510046S1560185S1510047S1560190S1510048S1510049S1560195S1510050S1560200S1510051S1560205S1510052S1560210S1510054S1510055S1560220S1510056S1510057S1560230S1510058S1510059S1510060S1560240S1515041S1565165S1515042S1565170S1515043S1515044S1565175S1515045S1565180S1515046S1565185S1515047S1565190S1515048S1515049S1565195S1515050S1565200S1515051S1565205S1515052S1565210S1515054S1515055S1565220S1515056S1515057S1565230S1515058S1515059S1515060S1565240CENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275) 228phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES 2HSSSPADE DRILL INSERTS - PREMIUM HSS M48EINWEG BOHREINSATZ - PREMIUM HSS M48 For use in high temperature alloys and materials with 350~500 Brinell. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung bei hitzebeständigen Legierungenund Werkstoffen mit 350 - 500 Brinell Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXcutting conditions : p.283DREAMDRILLS-MQL TYPESeriesMin. to Max.(mm/inch)224.41(.961)to35.05(1.380)Inch(inch)31/3263/6411-1/641-1/321-3/641-1/16”1-3/321-7/641-1/81-5/321-3/161-7/321-1/41-9/321-5/161-11/321-3/8DiameterMetric(mm)24.6125.0025.4025.8026.0026.1926.5926.9927.0027.7828.0028.1828.5829.0029.3730.0030.1630.9631.0031.7532.0032.5433.0033.3434.0034.1334.9335.00Decimal(inch).9688.98431.00001.01561.02361.03131.04691.06251.06301.09381.10241.10941.12501.14171.15631.18111.18751.21881.22051.25001.25981.28131.29921.31251.33861.34381.37501.3780Thick EDP No.Metric PREMIUM HSS (M48)(mm/inch) TiN TiCN TiAIN4.8(3/16)S1505062S1505063S1505100S1505101S1555260S1505102S1505103S1505104S1555270S1505106S1555280S1505107S1505108S1555290S1505110S1555300S1505112S1505114S1555310S1505116S1555320S1505118S1555330S1505120S1555340S1505122S1505124S1555350S1510062S1510063S1510100S1510101S1560260S1510102S1510103S1510104S1560270S1510106S1560280S1510107S1510108S1560290S1510110S1560300S1510112S1510114S1560310S1510116S1560320S1510118S1560330S1510120S1560340S1510122S1510124S1560350S1515062S1515063S1515100S1515101S1565260S1515102S1515103S1515104S1565270S1515106S1565280S1515107S1515108S1565290S1515110S1565300S1515112S1515114S1565310S1515116S1565320S1515118S1565330S1515120S1565340S1515122S1515124S1565350DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSNonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275)~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr229CENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES Y,Z,0i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS FOR CAST IRON - CARBIDE(K10)EINWEG BOHREINSATZ - VOLLHARTMETALL(K10) High performance on Gray cast iron over 220 Brinell, malleablecast iron with short chips, silicon aluminum and copper alloys. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Beste Leistung in Grauguss über 220 Brinell, kurzspanendem Kugelgraphitguss,Si-Aluminium und Kupferlegierungen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATASeriesMin. to Max.(mm/inch)Y9.50(.374)to11.07(.436)Z11.11(.437)to12.95(.510)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)012.98(.511)to17.65(.695)Inch(inch)3/825/6413/3227/647/1629/6415/3231/641/233/6417/3235/649/1637/6419/3239/645/8DiameterMetric(mm)9.509.539.809.9210.0010.2010.3210.5010.7210.8011.0011.1111.5011.5111.9112.0012.3012.5012.7013.0013.1013.4913.5013.8914.0014.2914.5014.6815.0015.0815.4815.5015.8816.00Decimal(inch).3740.3750.3860.3906.3937.4016.4063.4134.4219.4252.4331.4375.4528.4531.4688.4724.4844.4921.5000.5118.5156.5313.5315.5469.5512.5625.5709.5781.5906.5938.6094.6102.6250.6299Thick EDP No.Metric CARBIDE (K10)(mm/inch) TiN TiCN TiAIN2.4(3/32)2.4(3/32)3.2(1/8)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)S1655095S1605024S1655098S1605025S1655100S1655102S1605026S1655105S1605027S1655108S1655110S1605028S1655115S1605029S1605030S1655120S1605031S1655125S1605032S1655130S1605033S1605034S1655135S1605035S1655140S1605036S1655145S1605037S1655150S1605038S1605039S1655155S1605040S1655160HRc13~(HB200~)StainlessSteels~HRc28(~HB275)230phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.krS1660095S1610024S1660098S1610025S1660100S1660102S1610026S1660105S1610027S1660108S1660110S1610028S1660115S1610029S1610030S1660120S1610031S1660125S1610032S1660130S1610033S1610034S1660135S1610035S1660140S1610036S1660145S1610037S1660150S1610038S1610039S1660155S1610040S1660160~HRc19(~HB220)cutting conditions : p.284S1665095S1615024S1665098S1615025S1665100S1665102S1615026S1665105S1615027S1665108S1665110S1615028S1665115S1615029S1615030S1665120S1615031S1665125S1615032S1665130S1615033S1615034S1665135S1615035S1665140S1615036S1665145S1615037S1665150S1615038S1615039S1665155S1615040S1665160 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES 0,1HSSSPADE DRILL INSERTS FOR CAST IRON - CARBIDE(K10)EINWEG BOHREINSATZ - VOLLHARTMETALL(K10) High performance on Gray cast iron over 220 Brinell, malleablecast iron with short chips, silicon aluminum and copper alloys. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Beste Leistung in Grauguss über 220 Brinell, kurzspanendem Kugelgraphitguss,Si-Aluminium und Kupferlegierungen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXcutting conditions : p.284DREAMDRILLS-MQL TYPESeriesMin. to Max.(mm/inch)012.98(.511)to17.65(.695)117.53(.690)to24.38(.960)Inch(inch)41/6421/3243/6411/1645/6423/3247/643/449/6425/3251/6413/1627/3255/647/857/6429/3259/6415/16DiameterMetric(mm)16.2716.5016.6717.0017.0717.4617.5017.8618.0018.2618.5018.6519.0019.0519.4519.5019.8420.0020.2420.5020.6421.0021.4321.8322.0022.2322.6223.0023.0223.4223.8124.00Decimal(inch).6406.6496.6563.6693.6719.6875.6890.7031.7087.7188.7283.7344.7480.7500.7656.7677.7813.7874.7969.8071.8125.8268.8438.8594.8661.8750.8906.9055.9063.9219.9375.9449Thick EDP No.Metric CARBIDE (K10)(mm/inch) TiN TiCN TiAIN3.2(1/8)4.0(5/32)S1605041S1655165S1605042S1655170S1605043S1605044S1655175S1605045S1655180S1605046S1655185S1605047S1655190S1605048S1605049S1655195S1605050S1655200S1605051S1655205S1605052S1655210S1605054S1605055S1655220S1605056S1605057S1655230S1605058S1605059S1605060S1655240S1610041S1660165S1610042S1660170S1610043S1610044S1660175S1610045S1660180S1610046S1660185S1610047S1660190S1610048S1610049S1660195S1610050S1660200S1610051S1660205S1610052S1660210S1610054S1610055S1660220S1610056S1610057S1660230S1610058S1610059S1610060S1660240S1615041S1665165S1615042S1665170S1615043S1615044S1665175S1615045S1665180S1615046S1665185S1615047S1665190S1615048S1615049S1665195S1615050S1665200S1615051S1665205S1615052S1665210S1615054S1615055S1665220S1615056S1615057S1665230S1615058S1615059S1615060S1665240DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSNonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275)~HRc19(~HB220)phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr231 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110CENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 2i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS FOR CAST IRON - CARBIDE(K10)EINWEG BOHREINSATZ - VOLLHARTMETALL(K10) High performance on Gray cast iron over 220 Brinell, malleablecast iron with short chips, silicon aluminum and copper alloys. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Beste Leistung in Grauguss über 220 Brinell, kurzspanendem Kugelgraphitguss,Si-Aluminium und Kupferlegierungen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.284DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSSeriesMin. to Max.(mm/inch)224.41(.961)to35.05(1.380)Inch(inch)31/3263/6411-1/641-1/321-3/641-1/161-3/321-7/641-1/81-5/321-3/161-7/321-1/41-9/321-5/161-11/321-3/8DiameterMetric(mm)24.6125.0025.4025.8026.0026.1926.5926.9927.0027.7828.0028.1828.5829.0029.3730.0030.1630.9631.0031.7532.0032.5433.0033.3434.0034.1334.9335.00Decimal(inch).9688.98431.00001.01561.02361.03131.04691.06251.06301.09381.10241.10941.12501.14171.15631.18111.18751.21881.22051.25001.25981.28131.29921.31251.33861.34381.37501.3780Thick EDP No.Metric CARBIDE (K10)(mm/inch) TiN TiCN TiAIN4.8(3/16)S1605062S1605063S1605100S1605101S1655260S1605102S1605103S1605104S1655270S1605106S1655280S1605107S1605108S1655290S1605110S1655300S1605112S1605114S1655310S1605116S1655320S1605118S1655330S1605120S1655340S1605122S1605124S1655350S1610062S1610063S1610100S1610101S1660260S1610102S1610103S1610104S1660270S1610106S1660280S1610107S1610108S1660290S1610110S1660300S1610112S1610114S1660310S1610116S1660320S1610118S1660330S1610120S1660340S1610122S1610124S1660350S1615062S1615063S1615100S1615101S1665260S1615102S1615103S1615104S1665270S1615106S1665280S1615107S1615108S1665290S1615110S1665300S1615112S1615114S1665310S1615116S1665320S1615118S1665330S1615120S1665340S1615122S1615124S1665350NC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275)232phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES Y,Z,0HSSSPADE DRILL INSERTS - CARBIDE(K20)EINWEG BOHREINSATZ - VOLLHARTMETALL(K20) For use in Gray cast iron up to 220 Brinell, nonferrous metals,copper, brass and aluminum. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung in Grauguss bis 220 Brinell, Nichteisen - Metallen,Kupfer, Messing und Aluminium Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXSeriesMin. to Max.(mm/inch)Y9.50(.374)to11.07(.436)Z11.11(.437)to12.95(.510)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)012.98(.511)to17.65(.695)Inch(inch)3/825/6413/3227/647/1629/6415/3231/641/233/6417/3235/649/1637/6419/3239/645/8DiameterMetric(mm)9.509.539.809.9210.0010.2010.3210.5010.7210.8011.0011.1111.5011.5111.9112.0012.3012.5012.7013.0013.1013.4913.5013.8914.0014.2914.5014.6815.0015.0815.4815.5015.8816.00Decimal(inch).3740.3750.3860.3906.3937.4016.4063.4134.4219.4252.4331.4375.4528.4531.4688.4724.4844.4921.5000.5118.5156.5313.5315.5469.5512.5625.5709.5781.5906.5938.6094.6102.6250.62992.4(3/32)2.4(3/32)3.2(1/8)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)Thick EDP No.Metric CARBIDE (K20)(mm/inch) TiN TiCN TiAINHRc24~(HB250~)~HRc13(~HB200)S1755095S1705024S1755098S1705025S1755100S1755102S1705026S1755105S1705027S1755108S1755110S1705028S1755115S1705029S1705030S1755120S1705031S1755125S1705032S1755130S1705033S1705034S1755135S1705035S1755140S1705036S1755145S1705037S1755150S1705038S1705039S1755155S1705040S1755160HRc13~(HB200~)StainlessSteels~HRc28(~HB275)S1760095S1710024S1760098S1710025S1760100S1760102S1710026S1760105S1710027S1760108S1760110S1710028S1760115S1710029S1710030S1760120S1710031S1760125S1710032S1760130S1710033S1710034S1760135S1710035S1760140S1710036S1760145S1710037S1760150S1710038S1710039S1760155S1710040S1760160~HRc19(~HB220)cutting conditions : p.284S1765095S1715024S1765098S1715025S1765100S1765102S1715026S1765105S1715027S1765108S1765110S1715028S1765115S1715029S1715030S1765120S1715031S1765125S1715032S1765130S1715033S1715034S1765135S1715035S1765140S1715036S1765145S1715037S1765150S1715038S1715039S1765155S1715040S1765160 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr233DREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 0,1i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - CARBIDE(K20)EINWEG BOHREINSATZ - VOLLHARTMETALL(K20) For use in Gray cast iron up to 220 Brinell, nonferrous metals,copper, brass and aluminum. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung in Grauguss bis 220 Brinell, Nichteisen - Metallen,Kupfer, Messing und Aluminium Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.284DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSSeriesMin. to Max.(mm/inch)012.98(.511)to17.65(.695)117.53(.690)to24.38(.960)Inch(inch)41/6421/3243/6411/1645/6423/3247/643/449/6425/3251/6413/1627/3255/647/857/6429/3259/6415/16DiameterMetric(mm)16.2716.5016.6717.0017.0717.4617.5017.8618.0018.2618.5018.6519.0019.0519.4519.5019.8420.0020.2420.5020.6421.0021.4321.8322.0022.2322.6223.0023.0223.4223.8124.00Decimal(inch).6406.6496.6563.6693.6719.6875.6890.7031.7087.7188.7283.7344.7480.7500.7656.7677.7813.7874.7969.8071.8125.8268.8438.8594.8661.8750.8906.9055.9063.9219.9375.9449Thick EDP No.Metric CARBIDE (K20)(mm/inch) TiN TiCN TiAIN3.2(1/8)4.0(5/32)S1705041S1755165S1705042S1755170S1705043S1705044S1755175S1705045S1755180S1705046S1755185S1705047S1755190S1705048S1705049S1755195S1705050S1755200S1705051S1755205S1705052S1755210S1705054S1705055S1755220S1705056S1705057S1755230S1705058S1705059S1705060S1755240S1710041S1760165S1710042S1760170S1710043S1710044S1760175S1710045S1760180S1710046S1760185S1710047S1760190S1710048S1710049S1760195S1710050S1760200S1710051S1760205S1710052S1760210S1710054S1710055S1760220S1710056S1710057S1760230S1710058S1710059S1710060S1760240S1715041S1765165S1715042S1765170S1715043S1715044S1765175S1715045S1765180S1715046S1765185S1715047S1765190S1715048S1715049S1765195S1715050S1765200S1715051S1765205S1715052S1765210S1715054S1715055S1765220S1715056S1715057S1765230S1715058S1715059S1715060S1765240CENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275) 234phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES 2HSSSPADE DRILL INSERTS - CARBIDE(K20)EINWEG BOHREINSATZ - VOLLHARTMETALL(K20) For use in Gray cast iron up to 220 Brinell, nonferrous metals,copper, brass and aluminum. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung in Grauguss bis 220 Brinell, Nichteisen - Metallen,Kupfer, Messing und Aluminium Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXcutting conditions : p.284DREAMDRILLS-MQL TYPESeriesMin. to Max.(mm/inch)224.41(.961)to35.05(1.380)Inch(inch)31/3263/6411-1/641-1/321-3/641-1/161-3/321-7/641-1/81-5/321-3/161-7/321-1/41-9/321-5/161-11/321-3/8DiameterMetric(mm)24.6125.0025.4025.8026.0026.1926.5926.9927.0027.7828.0028.1828.5829.0029.3730.0030.1630.9631.0031.7532.0032.5433.0033.3434.0034.1334.9335.00Decimal(inch).9688.98431.00001.01561.02361.03131.04691.06251.06301.09381.10241.10941.12501.14171.15631.18111.18751.21881.22051.25001.25981.28131.29921.31251.33861.34381.37501.3780Thick EDP No.Metric CARBIDE (K20)(mm/inch) TiN TiCN TiAIN4.8(3/16)S1705062S1705063S1705100S1705101S1755260S1705102S1705103S1705104S1755270S1705106S1755280S1705107S1705108S1755290S1705110S1755300S1705112S1705114S1755310S1705116S1755320S1705118S1755330S1705120S1755340S1705122S1705124S1755350S1710062S1710063S1710100S1710101S1760260S1710102S1710103S1710104S1760270S1710106S1760280S1710107S1710108S1760290S1710110S1760300S1710112S1710114S1760310S1710116S1760320S1710118S1760330S1710120S1760340S1710122S1710124S1760350S1715062S1715063S1715100S1715101S1765260S1715102S1715103S1715104S1765270S1715106S1765280S1715107S1715108S1765290S1715110S1765300S1715112S1715114S1765310S1715116S1765320S1715118S1765330S1715120S1765340S1715122S1715124S1765350DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSNonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275)~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr235CENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 3i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - CARBIDE(K20)EINWEG BOHREINSATZ - VOLLHARTMETALL(K20) For use in Gray cast iron up to 220 Brinell, nonferrous metals,copper, brass and aluminum. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Zur Anwendung in Grauguss bis 220 Brinell, Nichteisen - Metallen,Kupfer, Messing und Aluminium Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.284DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSSeriesMin. to Max.(mm/inch)334.37(1.353)to47.80(1.882)Inch(inch)1-13/321-7/161-15/321-1/21-17/321-9/161-19/321-5/81-21/321-11/161-23/321-3/41-25/321-13/161-27/321-7/8DiameterMetric(mm)35.7236.0036.5137.0037.3138.0038.1038.8939.0039.6940.0040.4841.0041.2842.0042.0742.8643.0043.6644.0044.4545.0045.2446.0046.0446.8347.0047.63Decimal(inch)1.40631.41731.43751.45671.46881.49611.50001.53131.53541.56251.57481.59381.61421.62501.65351.65631.68751.69291.71881.73231.75001.77171.78131.81101.81251.84381.85041.8750Thick EDP No.Metric CARBIDE (K20)(mm/inch) TiN TiCN TiAIN6.4(1/4)S1705126S1755360S1705128S1755370S1705130S1755380S1705132S1705134S1755390S1705136S1755400S1705138S1755410S1705140S1755420S1705142S1705144S1755430S1705146S1755440S1705148S1755450S1705150S1755460S1705152S1705154S1755470S1705156S1710126S1760360S1710128S1760370S1710130S1760380S1710132S1710134S1760390S1710136S1760400S1710138S1760410S1710140S1760420S1710142S1710144S1760430S1710146S1760440S1710148S1760450S1710150S1760460S1710152S1710154S1760470S1710156S1715126S1765360S1715128S1765370S1715130S1765380S1715132S1715134S1765390S1715136S1765400S1715138S1765410S1715140S1765420S1715142S1715144S1765430S1715146S1765440S1715148S1765450S1715150S1765460S1715152S1715154S1765470S1715156NC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275) 236phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES Y,Z,0HSSSPADE DRILL INSERTS - CARBIDE(P40)EINWEG BOHREINSATZ - VOLLHARTMETALL(P40) For general use in carbon steels and alloy steels. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Kohlenstoffstählen und legierten Stählen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXSeriesMin. to Max.(mm/inch)Y9.50(.374)to11.07(.436)Z11.11(.437)to12.95(.510)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)012.98(.511)to17.65(.695)Inch(inch)3/825/6413/3227/647/1629/6415/3231/641/233/6417/3235/649/1637/6419/3239/645/8DiameterMetric(mm)9.509.539.809.9210.0010.2010.3210.5010.7210.8011.0011.1111.5011.5111.9112.0012.3012.5012.7013.0013.1013.4913.5013.8914.0014.2914.5014.6815.0015.0815.4815.5015.8816.00Decimal(inch).3740.3750.3860.3906.3937.4016.4063.4134.4219.4252.4331.4375.4528.4531.4688.4724.4844.4921.5000.5118.5156.5313.5315.5469.5512.5625.5709.5781.5906.5938.6094.6102.6250.62992.4(3/32)2.4(3/32)3.2(1/8)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)Thick EDP No.Metric CARBIDE (P40)(mm/inch) TiN TiCN TiAINHRc24~(HB250~)~HRc13(~HB200)S1855095S1805024S1855098S1805025S1855100S1855102S1805026S1855105S1805027S1855108S1855110S1805028S1855115S1805029S1805030S1855120S1805031S1855125S1805032S1855130S1805033S1805034S1855135S1805035S1855140S1805036S1855145S1805037S1855150S1805038S1805039S1855155S1805040S1855160HRc13~(HB200~)StainlessSteels~HRc28(~HB275)S1860095S1810024S1860098S1810025S1860100S1860102S1810026S1860105S1810027S1860108S1860110S1810028S1860115S1810029S1810030S1860120S1810031S1860125S1810032S1860130S1810033S1810034S1860135S1810035S1860140S1810036S1860145S1810037S1860150S1810038S1810039S1860155S1810040S1860160~HRc19(~HB220)cutting conditions : p.284S1865095S1815024S1865098S1815025S1865100S1865102S1815026S1865105S1815027S1865108S1865110S1815028S1865115S1815029S1815030S1865120S1815031S1865125S1815032S1865130S1815033S1815034S1865135S1815035S1865140S1815036S1865145S1815037S1865150S1815038S1815039S1865155S1815040S1865160 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr237DREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 0,1i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - CARBIDE(P40)EINWEG BOHREINSATZ - VOLLHARTMETALL(P40) For general use in carbon steels and alloy steels. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Kohlenstoffstählen und legierten Stählen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.284DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSSeriesMin. to Max.(mm/inch)012.98(.511)to17.65(.695)117.53(.690)to24.38(.960)Inch(inch)41/6421/3243/6411/1645/6423/3247/643/449/6425/3251/6413/1627/3255/647/857/6429/3259/6415/16DiameterMetric(mm)16.2716.5016.6717.0017.0717.4617.5017.8618.0018.2618.5018.6519.0019.0519.4519.5019.8420.0020.2420.5020.6421.0021.4321.8322.0022.2322.6223.0023.0223.4223.8124.00Decimal(inch).6406.6496.6563.6693.6719.6875.6890.7031.7087.7188.7283.7344.7480.7500.7656.7677.7813.7874.7969.8071.8125.8268.8438.8594.8661.8750.8906.9055.9063.9219.9375.9449Thick EDP No.Metric CARBIDE (P40)(mm/inch) TiN TiCN TiAIN3.2(1/8)4.0(5/32)S1805041S1855165S1805042S1855170S1805043S1805044S1855175S1805045S1855180S1805046S1855185S1805047S1855190S1805048S1805049S1855195S1805050S1855200S1805051S1855205S1805052S1855210S1805054S1805055S1855220S1805056S1805057S1855230S1805058S1805059S1805060S1855240S1810041S1860165S1810042S1860170S1810043S1810044S1860175S1810045S1860180S1810046S1860185S1810047S1860190S1810048S1810049S1860195S1810050S1860200S1810051S1860205S1810052S1860210S1810054S1810055S1860220S1810056S1810057S1860230S1810058S1810059S1810060S1860240S1815041S1865165S1815042S1865170S1815043S1815044S1865175S1815045S1865180S1815046S1865185S1815047S1865190S1815048S1815049S1865195S1815050S1865200S1815051S1865205S1815052S1865210S1815054S1815055S1865220S1815056S1815057S1865230S1815058S1815059S1815060S1865240CENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275) 238phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES 2HSSSPADE DRILL INSERTS - CARBIDE(P40)EINWEG BOHREINSATZ - VOLLHARTMETALL(P40) For general use in carbon steels and alloy steels. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Kohlenstoffstählen und legierten Stählen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXcutting conditions : p.284DREAMDRILLS-MQL TYPESeriesMin. to Max.(mm/inch)224.41(.961)to35.05(1.380)Inch(inch)31/3263/6411-1/641-1/321-3/641-1/161-3/321-7/641-1/81-5/321-3/161-7/321-1/41-9/321-5/161-11/321-3/8DiameterMetric(mm)24.6125.0025.4025.8026.0026.1926.5926.9927.0027.7828.0028.1828.5829.0029.3730.0030.1630.9631.0031.7532.0032.5433.0033.3434.0034.1334.9335.00Decimal(inch).9688.98431.00001.01561.02361.03131.04691.06251.06301.09381.10241.10941.12501.14171.15631.18111.18751.21881.22051.25001.25981.28131.29921.31251.33861.34381.37501.3780Thick EDP No.Metric CARBIDE (P40)(mm/inch) TiN TiCN TiAIN4.8(3/16)S1805062S1805063S1805100S1805101S1855260S1805102S1805103S1805104S1855270S1805106S1855280S1805107S1805108S1855290S1805110S1855300S1805112S1805114S1855310S1805116S1855320S1805118S1855330S1805120S1855340S1805122S1805124S1855350S1810062S1810063S1810100S1810101S1860260S1810102S1810103S1810104S1860270S1810106S1860280S1810107S1810108S1860290S1810110S1860300S1810112S1810114S1860310S1810116S1860320S1810118S1860330S1810120S1860340S1810122S1810124S1860350S1815062S1815063S1815100S1815101S1865260S1815102S1815103S1815104S1865270S1815106S1865280S1815107S1815108S1865290S1815110S1865300S1815112S1815114S1865310S1815116S1865320S1815118S1865330S1815120S1865340S1815122S1815124S1865350DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSNonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275)~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr239CENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 3i-DREAMDRILLSDREAMDRILLS-GENERALSPADE DRILL INSERTS - CARBIDE(P40)EINWEG BOHREINSATZ - VOLLHARTMETALL(P40) For general use in carbon steels and alloy steels. Set up time can be reduced due to changing <strong>inserts</strong> easily on themachine. Any non-standard size available. Für allgemeine Anwendung in Kohlenstoffstählen und legierten Stählen Reduzierte Rüstzeiten, einfacher Einsatzwechsel auf der Maschine Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.284DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSSeriesMin. to Max.(mm/inch)334.37(1.353)to47.80(1.882)Inch(inch)1-13/321-7/161-15/321-1/21-17/321-9/161-19/321-5/81-21/321-11/161-23/321-3/41-25/321-13/161-27/321-7/8DiameterMetric(mm)35.7236.0036.5137.0037.3138.0038.1038.8939.0039.6940.0040.4841.0041.2842.0042.0742.8643.0043.6644.0044.4545.0045.2446.0046.0446.8347.0047.63Decimal(inch)1.40631.41731.43751.45671.46881.49611.50001.53131.53541.56251.57481.59381.61421.62501.65351.65631.68751.69291.71881.73231.75001.77171.78131.81101.81251.84381.85041.8750Thick EDP No.Metric CARBIDE (P40)(mm/inch) TiN TiCN TiAIN6.4(1/4)S1805126S1855360S1805128S1855370S1805130S1855380S1805132S1805134S1855390S1805136S1855400S1805138S1855410S1805140S1855420S1805142S1805144S1855430S1805146S1855440S1805148S1855450S1805150S1855460S1805152S1805154S1855470S1805156S1810126S1860360S1810128S1860370S1810130S1860380S1810132S1810134S1860390S1810136S1860400S1810138S1860410S1810140S1860420S1810142S1810144S1860430S1810146S1860440S1810148S1860450S1810150S1860460S1810152S1810154S1860470S1810156S1815126S1865360S1815128S1865370S1815130S1865380S1815132S1815134S1865390S1815136S1865400S1815138S1865410S1815140S1865420S1815142S1815144S1865430S1815146S1865440S1815148S1865450S1815150S1865460S1815152S1815154S1865470S1815156NC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275) 240phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

Special features ofSM-Point Spade DrillThis new “Hybrid Point” combines the strength of the standard pointwith additional “Web Thinning”.This new point increases stability, reduces thrust, improvescentering and allows increased speeds and feeds.Multiple thinning form at the bottom ofthe large thinning. The optimum thinning for thedifference from the cutting speed,the cutting quantity and the cuttingload according to the distance fromthe <strong>drill</strong> point to the cutting edge.Radius back face Wide chip spaceMultiple web thinning with the cuttingedge of small web thinning. Good self-centering Less tool lead off Reduction in bell mouthing, thrust Increased stabilityFour-facet point Self-centering Less thrust force

CARBIDEHSSSPADE DRILLSSERIES 1i-DREAMDRILLSDREAMDRILLS-GENERALSM-POINT SPADE DRILL INSERTS - HSS M4SM-POINT EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Improved stability and hole straightness by newly developedthinning design. Less thrust force and excellent self-centering. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Erhöhte Stabilität und Fluchtgenauigkeit durch neuentwickelteQuerschneidengeometrie Verminderte Bohrkraft und ausgezeichnete Selbstzentrierung Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.283DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSSeriesMin. to Max.(mm/inch)117.53(.690)to24.38(.960)Inch(inch)45/6423/3247/643/449/6425/3251/6413/1627/3255/647/857/6429/3259/6415/16DiameterMetric(mm)17.8618.0018.2618.5018.6519.0019.0519.4519.5019.8420.0020.2420.5020.6421.0021.4321.8322.0022.2322.6223.0023.0223.4223.8124.00Decimal(inch).7031".7087".7188".7283".7344".7480".7500".7656".7677".7812".7874".7969".8071".8125".8268".8438".8594".8661".8750".8906".9055".9062".9219".9375".9449"Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAIN4.0(5/32)SM405045SM455180SM405046SM455185SM405047SM455190SM405048SM405049SM455195SM405050SM455200SM405051SM455205SM405052SM455210SM405054SM405055SM455220SM405056SM405057SM455230SM405058SM405059SM405060SM455240SM410045SM460180SM410046SM460185SM410047SM460190SM410048SM410049SM460195SM410050SM460200SM410051SM460205SM410052SM460210SM410054SM410055SM460220SM410056SM410057SM460230SM410058SM410059SM410060SM460240SM415045SM465180SM415046SM465185SM415047SM465190SM415048SM415049SM465195SM415050SM465200SM415051SM465205SM415052SM465210SM415054SM415055SM465220SM415056SM415057SM465230SM415058SM415059SM415060SM465240TAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275) 242phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES 2HSSSM-POINT SPADE DRILL INSERTS - HSS M4SM-POINT EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Improved stability and hole straightness by newly developedthinning design. Less thrust force and excellent self-centering. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Erhöhte Stabilität und Fluchtgenauigkeit durch neuentwickelteQuerschneidengeometrie Verminderte Bohrkraft und ausgezeichnete Selbstzentrierung Jede Abmessung außerhalb des Kataloges lieferbari-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXcutting conditions : p.283DREAMDRILLS-MQL TYPESeriesMin. to Max.(mm/inch)224.41(.961)to35.05(1.380)Inch(inch)31/3263/6411-1/641-1/321-3/641-1/161-3/321-7/641-1/81-5/321-3/161-7/321-1/41-9/321-5/161-11/321-3/8DiameterMetric(mm)24.6125.0025.4025.8026.0026.1926.5926.9927.0027.7828.0028.1828.5829.0029.3730.0030.1630.9631.0031.7532.0032.5433.0033.3434.0034.1334.9335.00Decimal(inch).9688".9843"1.0000"1.0156"1.0236"1.0312"1.0469"1.0625"1.0630"1.0938"1.1024"1.1094"1.1250"1.1417"1.1562"1.1811"1.1875"1.2188"1.2205"1.2500"1.2598"1.2812"1.2992"1.3125"1.3386"1.3438"1.3750"1.3780"Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAIN4.8(3/16)SM405062SM405063SM405100SM405101SM455260SM405102SM405103SM405104SM455270SM405106SM455280SM405107SM405108SM455290SM405110SM455300SM405112SM405114SM455310SM405116SM455320SM405118SM455330SM405120SM455340SM405122SM405124SM455350SM410062SM410063SM410100SM410101SM460260SM410102SM410103SM410104SM460270SM410106SM460280SM410107SM410108SM460290SM410110SM460300SM410112SM410114SM460310SM410116SM460320SM410118SM460330SM410120SM460340SM410122SM410124SM460350SM415062SM415063SM415100SM415101SM465260SM415102SM415103SM415104SM465270SM415106SM465280SM415107SM415108SM465290SM415110SM465300SM415112SM415114SM465310SM415116SM465320SM415118SM465330SM415120SM465340SM415122SM415124SM465350DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSNonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275)~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr243CENTERDRILLSSPADEDRILLSTECHNICALDATA

CARBIDEHSSSPADE DRILLSSERIES 3i-DREAMDRILLSDREAMDRILLS-GENERALSM-POINT SPADE DRILL INSERTS - HSS M4SM-POINT EINWEG BOHREINSATZ - HSS M4 For general use in steels and cast irons. Improved stability and hole straightness by newly developedthinning design. Less thrust force and excellent self-centering. Any non-standard size available. Für allgemeine Anwendung in Stahl und Gusseisen Erhöhte Stabilität und Fluchtgenauigkeit durch neuentwickelteQuerschneidengeometrie Verminderte Bohrkraft und ausgezeichnete Selbstzentrierung Jede Abmessung außerhalb des Kataloges lieferbarDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEcutting conditions : p.283DREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSSeriesMin. to Max.(mm/inch)334.37(1.353)to47.80(1.882)Inch(inch)1-13/321-7/161-15/321-1/21-17/321-9/161-19/321-5/81-21/321-11/161-23/321-3/41-25/321-13/161-27/321-7/8DiameterMetric(mm)35.7236.0036.5137.0037.3138.0038.1038.8939.0039.6940.0040.4841.0041.2842.0042.0742.8643.0043.6644.0044.4545.0045.2446.0046.0446.8347.0047.63Decimal(inch)1.4062"1.4173"1.4375"1.4567"1.4688"1.4961"1.5000"1.5312"1.5354"1.5625"1.5748"1.5938"1.6142"1.6250"1.6535"1.6562"1.6875"1.6929"1.7188"1.7323"1.7500"1.7717"1.7812"1.8110"1.8125"1.8438"1.8504"1.8750"Thick EDP No.Metric HSS (M4)(mm/inch) TiN TiCN TiAIN6.4(1/4)SM405126SM455360SM405128SM455370SM405130SM455380SM405132SM405134SM455390SM405136SM455400SM405138SM455410SM405140SM455420SM405142SM405144SM455430SM405146SM455440SM405148SM455450SM405150SM455460SM405152SM405154SM455470SM405156SM410126SM460360SM410128SM460370SM410130SM460380SM410132SM410134SM460390SM410136SM460400SM410138SM460410SM410140SM460420SM410142SM410144SM460430SM410146SM460440SM410148SM460450SM410150SM460460SM410152SM410154SM460470SM410156SM415126SM465360SM415128SM465370SM415130SM465380SM415132SM415134SM465390SM415136SM465400SM415138SM465410SM415140SM465420SM415142SM415144SM465430SM415146SM465440SM415148SM465450SM415150SM465460SM415152SM415154SM465470SM415156NC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATANonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)~HRc28(~HB275)HRc28~(HB275~)~HRc37(~HB350)HRc37~(HB350~)~HRc24(~HB250)HRc24~(HB250~)~HRc13(~HB200)HRc13~(HB200~)StainlessSteels~HRc28(~HB275) 244phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr~HRc19(~HB220) Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180)~HB110

CARBIDESPADE DRILLSSERIES Y,Z,0HSSSM-POINT SPADE DRILL INSERTS - SUPER HSS T15SM-POINT EINWEG BOHREINSATZ - SUPER HSS T15 For use in high nickel alloys and materials over 280 Brinell. Improved stability and hole straightness by newly developedthinning design. Less thrust force and excellent self-centering. Any non-standard size available.SeriesMin. to Max.(mm/inch)Y9.50(.374)to11.07(.436)Z11.11(.437)to12.95(.510)NonalloyedSteels,FreeMachiningSteels~HRc24(~HB250)012.98(.511)to17.65(.695)3/825/6413/3227/647/1629/6415/3231/641/233/6417/3235/649/1637/6419/3239/645/89.509.539.809.9210.0010.2010.3210.5010.7210.8011.0011.1111.5011.5111.9112.0012.3012.5012.7013.0013.1013.4913.5013.8914.0014.2914.5014.6815.0015.0815.4815.5015.8816.00.3740".3750".3858".3906".3937".4016".4062".4134".4219".4252".4331".4375".4528".4531".4688".4724".4844".4921".5000".5118".5156".5312".5315".5469".5512".5625".5709".5781".5906".5938".6094".6102".6250".6299"2.4(3/32)2.4(3/32)3.2(1/8)Carbon Steels Alloy Steels High Alloyed steels Structural Steels Tool Steels~HRc28(~HB275)HRc28~(HB275~)Inch(inch)~HRc28(~HB275)HRc28~(HB275~)DiameterMetric(mm)~HRc37(~HB350)Decimal(inch)HRc37~(HB350~)~HRc24(~HB250) Zur Anwendung bei legierten Stählen mit hohem Nickelanteil undWerkstoffen über 280 Brinell Erhöhte Stabilität und Fluchtgenauigkeit durch neuentwickelteQuerschneidengeometrie Verminderte Bohrkraft und ausgezeichnete Selbstzentrierung Jede Abmessung außerhalb des Kataloges lieferbarHRc24~(HB250~)~HRc13(~HB200)SM155095SM105024SM155098SM105025SM155100SM155102SM105026SM155105SM105027SM155108SM155110SM105028SM155115SM105029SM105030SM155120SM105031SM155125SM105032SM155130SM105033SM105034SM155135SM105035SM155140SM105036SM155145SM105037SM155150SM105038SM105039SM155155SM105040SM155160HRc13~(HB200~)StainlessSteels~HRc28(~HB275)SM160095SM110024SM160098SM110025SM160100SM160102SM110026SM160105SM110027SM160108SM160110SM110028SM160115SM110029SM110030SM160120SM110031SM160125SM110032SM160130SM110033SM110034SM160135SM110035SM160140SM110036SM160145SM110037SM160150SM110038SM110039SM160155SM110040SM160160~HRc19(~HB220)cutting conditions : p.283Thick EDP No.Metric SUPER HSS (T15)(mm/inch) TiN TiCN TiAINSM165095SM115024SM165098SM115025SM165100SM165102SM115026SM165105SM115027SM165108SM165110SM115028SM165115SM115029SM115030SM165120SM115031SM165125SM115032SM165130SM115033SM115034SM165135SM115035SM165140SM115036SM165145SM115037SM165150SM115038SM115039SM165155SM115040SM165160 Cast lron Aluminum CopperAlloysHRc19~(HB220~)~HRc8(~HB180) ~HB110phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:yg1@yg1.kr245i-DREAMDRILLSDREAMDRILLS-GENERALDREAMDRILLS-INOXDREAMDRILLS-MQL TYPEDREAMDRILLSfor HARDENEDSTEELSGENERALCARBIDEDRILLSNC-SPOTTINGDRILLSMULTI-1DRILLSHPD DRILLSGOLD-PDRILLSWORMPATTERNDRILLSSTRAIGHTSHANKDRILLSTAPERSHANKDRILLSNC-SPOTTINGDRILLSCENTERDRILLSSPADEDRILLSTECHNICALDATA