Dry-Ice Cleaning on SRF-Cavities A. Brinkmann, J. Iversen, D ... - Desy

Dry-Ice Cleaning on SRF-Cavities A. Brinkmann, J. Iversen, D ... - Desy

Dry-Ice Cleaning on SRF-Cavities A. Brinkmann, J. Iversen, D ... - Desy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

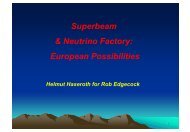

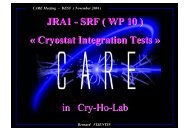

not efficient enough, more heater power was needed. Acompany made IR-heater system with 8 shortwave twintube heaters and a maximum power of 5.6 KW is installednow (Fig.:3 and 4) The wavelength is 1.0 μm – 1.4μm.With this heating power and wavelength the cavity is notfrosted <strong>on</strong> the outer surface during the cleaning process.The temperature is measured with a IR-Temp.Sensor.The exhaust system ensures a harmless CO 2 –c<strong>on</strong>centrati<strong>on</strong> in the cleanroom and keeps particles awayfrom the cavity.CO 2 and O 2 c<strong>on</strong>centrati<strong>on</strong> in the cleanroom atmosphere,cleanroom fans and exhaust are c<strong>on</strong>trolled by aninterlock-system, which automatically stops the gassupplyif <strong>on</strong>e of these comp<strong>on</strong>ents or c<strong>on</strong>centrati<strong>on</strong>s failsor gets too high.1,00E+11Qo1,00E+101,00E+09RF-TEST RESULTSQo/Eacc1DE7 BD1DE4 FE1DE7 FE1DE7 PWR1AC4 BD1,00E+081,00E+070 5 10 15 20 25 30 35 40 45Eacc [MV/m]Figure 2: horiz<strong>on</strong>tal orientati<strong>on</strong> of nozzleFigure 3: IR-heaterFigure 5: Test resultsFig.5 shows some RF-test results of several 1-cellcavities. No previous cleaning steps were applied to thecavities before dry ice cleaning. The cavities were storedunder cleanroom-air or kept under vacuum and ventedwith particle-filtered N 2 . In all tests maximum gradientsabove or at 30 MV/m were achieved. The tests showedtypical Q-values above 10 10 at 2 K for superc<strong>on</strong>ductingcavities at 1.3 GHz. High Q-values indicate that DIC notc<strong>on</strong>taminates the inner cavity surface. An optimizedcleaning and handling procedure led to a RF-test with agradient up to 38 MV/m limited by breakdown. Fieldemissi<strong>on</strong> is still a limiting factor, but most likely causedby particle c<strong>on</strong>taminati<strong>on</strong> during assembly of the cavities.Figure 4: IR-heaterSUMMARYIt was shown that no previous cleaning steps like highpressure water rinsing applied to cavites is necessary toobtain high performance in RF-tests. The new IR-heaterwith optimal wavelength and countoured alignment of thetube heaters provides a high thermal gradient betweenCO 2 -jet and Cavity-surface. A safety interlock is build toc<strong>on</strong>trol gas c<strong>on</strong>centrati<strong>on</strong>s. Field emissi<strong>on</strong> is a limitingfactor, but surely caused by particle c<strong>on</strong>taminati<strong>on</strong> duringfinal assembly of the cavity. Particle c<strong>on</strong>taminati<strong>on</strong>during the cleaning procedure is almostnegligible,nevertheless particles must be m<strong>on</strong>itored. Insome cases the particle counter showed a very high rate ofparticles, but this occurred due to a defect in the exhaustsystem.