Technical Data Sheet - Devcon

Technical Data Sheet - Devcon

Technical Data Sheet - Devcon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

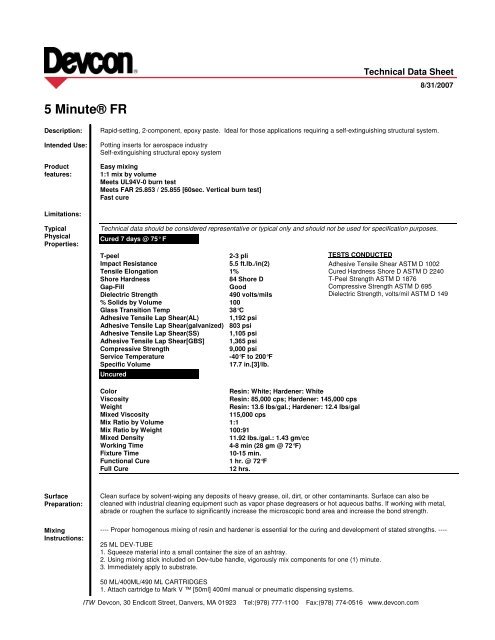

<strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>8/31/20075 Minute® FRDescription:Intended Use:Productfeatures:Rapid-setting, 2-component, epoxy paste. Ideal for those applications requiring a self-extinguishing structural system.Potting inserts for aerospace industrySelf-extinguishing structural epoxy systemEasy mixing1:1 mix by volumeMeets UL94V-0 burn testMeets FAR 25.853 / 25.855 [60sec. Vertical burn test]Fast cureLimitations:TypicalPhysicalProperties:<strong>Technical</strong> data should be considered representative or typical only and should not be used for specification purposes.Cured 7 days @ 75° FT-peelImpact ResistanceTensile ElongationShore HardnessGap-FillDielectric Strength% Solids by VolumeGlass Transition TempAdhesive Tensile Lap Shear(AL)Adhesive Tensile Lap Shear(galvanized)Adhesive Tensile Lap Shear(SS)Adhesive Tensile Lap Shear[GBS]Compressive StrengthService TemperatureSpecific VolumeUncured2-3 pli5.5 ft.lb./in(2)1%84 Shore DGood490 volts/mils10038°C1,192 psi803 psi1,105 psi1,365 psi9,000 psi-40°F to 200°F17.7 in.[3]/lb.TESTS CONDUCTEDAdhesive Tensile Shear ASTM D 1002Cured Hardness Shore D ASTM D 2240T-Peel Strength ASTM D 1876Compressive Strength ASTM D 695Dielectric Strength, volts/mil ASTM D 149ColorViscosityWeightMixed ViscosityMix Ratio by VolumeMix Ratio by WeightMixed DensityWorking TimeFixture TimeFunctional CureFull CureResin: White; Hardener: WhiteResin: 85,000 cps; Hardener: 145,000 cpsResin: 13.6 lbs/gal.; Hardener: 12.4 lbs/gal115,000 cps1:1100:9111.92 lbs./gal.: 1.43 gm/cc4-8 min (28 gm @ 72°F)10-15 min.1 hr. @ 72°F12 hrs.SurfacePreparation:Clean surface by solvent-wiping any deposits of heavy grease, oil, dirt, or other contaminants. Surface can also becleaned with industrial cleaning equipment such as vapor phase degreasers or hot aqueous baths. If working with metal,abrade or roughen the surface to significantly increase the microscopic bond area and increase the bond strength.MixingInstructions:---- Proper homogenous mixing of resin and hardener is essential for the curing and development of stated strengths. ----25 ML DEV-TUBE1. Squeeze material into a small container the size of an ashtray.2. Using mixing stick included on Dev-tube handle, vigorously mix components for one (1) minute.3. Immediately apply to substrate.50 ML/400ML/490 ML CARTRIDGES1. Attach cartridge to Mark V [50ml] 400ml manual or pneumatic dispensing systems.ITW <strong>Devcon</strong>, 30 Endicott Street, Danvers, MA 01923 Tel:(978) 777-1100 Fax:(978) 774-0516 www.devcon.com

2. Open tip.3. Burp cartridge by squeezing out some material until both sides are uniform (ensures no air bubbles are present duringmixing).4. Attach mix nozzle to end of cartridge.5. Apply to substrate.ApplicationInstructions:1. Apply mixed epoxy directly to one surface in an even film or as a bead.2. Assemble with mating part within reccommended working time.3. Apply firm pressure between mating parts to minimize any gap and ensure good contact (a small fillet of epoxy shouldflow out of the edges to display adequate gap fill.)For very large gaps:1. Apply epoxy to both surfaces.2. Spread to cover entire area OR make a bead pattern to allow flow throughout the joint.Let bonded assemblies stand for recommended functional cure time prior to handling.BONDLINE GUIDELINES:All metal bonds were MEK wiped abraded (80 grit sandpaper) and MEK wiped again. Bondline thickness was a 0.010".Storage:CAPABILITIES:Can withstand processing forcesDo not drop, shock load, or heavily loadStore at room temperature.Compliances: FAR 25.853 / 25.855 [Vertical burn test] Meets Underwriters Laboratory UL 94-V0ChemicalResistance:Precautions:Warranty:Disclaimer:OrderInformation:Chemical resistance is calculated with a 7 day, room temp. cure (30 days immersion) @ 75°F)Acetic (Dilute) 10% PoorAcetone PoorAmmonia FairCorn Oil ExcellentCutting Oil ExcellentEthanol PoorGasoline (Unleaded) ExcellentGlycols/Antifreeze FairPlease refer to the appropriate material safety data sheet (MSDS) prior to using this product.For technical assistance, please call 1-800-933-8266FOR INDUSTRIAL USE ONLY<strong>Devcon</strong> will replace any material found to be defective. Because the storage, handling and application of this material isbeyond our control, we can accept no liability for the results obtained.All information on this data sheet is based on laboratory testing and is not intended for design purposes. ITW <strong>Devcon</strong>makes no representations or warranties of any kind concerning this data.14271 50 ml Dev-PakIsopropanol FairKerosene ExcellentMethyl Ethyl Ketone PoorMineral Spirits ExcellentMotor Oil ExcellentSodium Hydroxide 10% FairSulfuric 10% PoorITW <strong>Devcon</strong>, 30 Endicott Street, Danvers, MA 01923 Tel:(978) 777-1100 Fax:(978) 774-0516 www.devcon.com