ELASTOMERIC JOINT COMPOUND NO. 69 ... - Sauereisen

ELASTOMERIC JOINT COMPOUND NO. 69 ... - Sauereisen

ELASTOMERIC JOINT COMPOUND NO. 69 ... - Sauereisen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

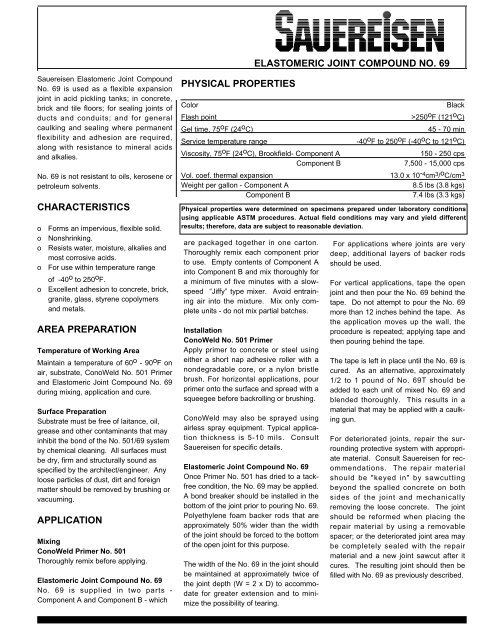

<strong>ELASTOMERIC</strong> <strong>JOINT</strong> <strong>COMPOUND</strong> <strong>NO</strong>. <strong>69</strong><strong>Sauereisen</strong> Elastomeric Joint CompoundNo. <strong>69</strong> is used as a flexible expansionjoint in acid pickling tanks; in concrete,brick and tile floors; for sealing joints ofducts and conduits; and for generalcaulking and sealing where permanentflexibility and adhesion are required,along with resistance to mineral acidsand alkalies.No. <strong>69</strong> is not resistant to oils, kerosene orpetroleum solvents.CHARACTERISTICSo Forms an impervious, flexible solid.o Nonshrinking.o Resists water, moisture, alkalies andmost corrosive acids.o For use within temperature rangeof -40 o to 250 o F.o Excellent adhesion to concrete, brick,granite, glass, styrene copolymersand metals.AREA PREPARATIONTemperature of Working AreaMaintain a temperature of 60 o - 90 o F onair, substrate, ConoWeld No. 501 Primerand Elastomeric Joint Compound No. <strong>69</strong>during mixing, application and cure.Surface PreparationSubstrate must be free of laitance, oil,grease and other contaminants that mayinhibit the bond of the No. 501/<strong>69</strong> systemby chemical cleaning. All surfaces mustbe dry, firm and structurally sound asspecified by the architect/engineer. Anyloose particles of dust, dirt and foreignmatter should be removed by brushing orvacuuming.APPLICATIONMixingConoWeld Primer No. 501Thoroughly remix before applying.Elastomeric Joint Compound No. <strong>69</strong>No. <strong>69</strong> is supplied in two parts -Component A and Component B - whichPHYSICAL PROPERTIESColorBlackFlash point >250 o F (121 o C)Gel time, 75 o F (24 o C)45 - 70 minService temperature range -40 o F to 250 o F (-40 o C to 121 o C)Viscosity, 75 o F (24 o C), Brookfield- Component A150 - 250 cpsComponent B7,500 - 15,000 cpsVol. coef. thermal expansion 13.0 x 10 -4 cm 3 / o C/cm 3Weight per gallon - Component A8.5 lbs (3.8 kgs)Component B7.4 lbs (3.3 kgs)Physical properties were determined on specimens prepared under laboratory conditionsusing applicable ASTM procedures. Actual field conditions may vary and yield differentresults; therefore, data are subject to reasonable deviation.are packaged together in one carton.Thoroughly remix each component priorto use. Empty contents of Component Ainto Component B and mix thoroughly fora minimum of five minutes with a slowspeed“Jiffy” type mixer. Avoid entrainingair into the mixture. Mix only completeunits - do not mix partial batches.InstallationConoWeld No. 501 PrimerApply primer to concrete or steel usingeither a short nap adhesive roller with anondegradable core, or a nylon bristlebrush. For horizontal applications, pourprimer onto the surface and spread with asqueegee before backrolling or brushing.ConoWeld may also be sprayed usingairless spray equipment. Typical applicationthickness is 5-10 mils. Consult<strong>Sauereisen</strong> for specific details.Elastomeric Joint Compound No. <strong>69</strong>Once Primer No. 501 has dried to a tackfreecondition, the No. <strong>69</strong> may be applied.A bond breaker should be installed in thebottom of the joint prior to pouring No. <strong>69</strong>.Polyethylene foam backer rods that areapproximately 50% wider than the widthof the joint should be forced to the bottomof the open joint for this purpose.The width of the No. <strong>69</strong> in the joint shouldbe maintained at approximately twice ofthe joint depth (W = 2 x D) to accommodatefor greater extension and to minimizethe possibility of tearing.For applications where joints are verydeep, additional layers of backer rodsshould be used.For vertical applications, tape the openjoint and then pour the No. <strong>69</strong> behind thetape. Do not attempt to pour the No. <strong>69</strong>more than 12 inches behind the tape. Asthe application moves up the wall, theprocedure is repeated; applying tape andthen pouring behind the tape.The tape is left in place until the No. <strong>69</strong> iscured. As an alternative, approximately1/2 to 1 pound of No. <strong>69</strong>T should beadded to each unit of mixed No. <strong>69</strong> andblended thoroughly. This results in amaterial that may be applied with a caulkinggun.For deteriorated joints, repair the surroundingprotective system with appropriatematerial. Consult <strong>Sauereisen</strong> for recommendations.The repair materialshould be "keyed in" by sawcuttingbeyond the spalled concrete on bothsides of the joint and mechanicallyremoving the loose concrete. The jointshould be reformed when placing therepair material by using a removablespacer; or the deteriorated joint area maybe completely sealed with the repairmaterial and a new joint sawcut after itcures. The resulting joint should then befilled with No. <strong>69</strong> as previously described.

COVERAGEEstimating Table for No. <strong>69</strong>(Linear feet per mixed gallon)JointWidthJoint Depth(Inches) 1/4" 3/8" 1/2"1/4 2553/8 170 1221/2 127 84 645/8 102 68 503/4 84 56 427/8 73 48 361 64 42 31SETTING/CURINGNo. <strong>69</strong> will gel in approximately one (1)hour at 75 o F. The compound shall bepermitted to cure a minimum of 24 hoursat 60 o -90 o F before being placed into service.Minimum cure temperature is 50 o F.In the 50 o -60 o F range, the No. <strong>69</strong>requires a 48-hour cure period beforebeing placed into service.PACKAGINGNo. 5011 gallon unitPart A HardenerPart B Liquid3 gallon unitPart A HardenerPart B Liquid1 gallon can1 gallon can2 gallon pail3 1 /2 gallon pailContainers are filled by weight, not volume.Container size does not indicate volume ofcontents.No. <strong>69</strong>Part A 1/2 pound in a F-style 1/2 pintcontainerPart B 7.4 pounds in one Imperial gal.containerNo. <strong>69</strong>T Approximately 1 pound ina 1-gallon canCLEAN-UPAll equipment should be cleaned withacetone, xylene; monochlorotoluene, orMEK before No. <strong>69</strong> cures. If removal isrequired after cure, consult <strong>Sauereisen</strong>for recommendations.SHELF LIFEPrimer No. 501 has a shelf life of (1) yearwhen stored in unopened, tightly sealedcontainers in a dry location at 70 o F. Ifthere is a doubt as to the quality of thematerials, consult a <strong>Sauereisen</strong> representativeWARRANTYWe warrant that our goods will conform tothe description contained in the order, andthat we have good title to all goods sold.WE GIVE <strong>NO</strong> WARRANTY, WHETHER OFMERCHANTABILITY, FITNESS FOR PUR-POSE OR OTHERWISE, EXPRESS ORIMPLIED, OTHER THAN AS EXPRESSLYSET FORTH HEREIN. We are glad to offersuggestions or to refer you to customersusing <strong>Sauereisen</strong> cements and compoundsfor a similar application. Users shall determinethe suitability of the product for intendedapplication before using, and usersassume all risk and liability whatsoever inconnection therewith regardless of any suggestionsas to application or construction.In no event shall we be liable hereunder orotherwise for incidental or consequentialdamages. Our liability and your exclusiveremedy hereunder or otherwise, in law or inequity, shall be expressly limited to ourreplacement of nonconforming goods atour factory or, at our sole option, to repaymentof the purchase price of nonconforminggoods.o Distributors and agents in major citiesthroughout the world. Consult manufacturerfor locations.o Information concerning governmentsafety regulations available uponrequest.o <strong>Sauereisen</strong> also produces inorganiccompounds for assembling, sealing,electrically insulating and grouting.Elastomeric Joint Compound No. <strong>69</strong> havea shelf life of six (6) months when storedin unopened, tightly sealed containers ina dry location at 70 o F. If there is a doubtas to the quality of the materials, consulta <strong>Sauereisen</strong> representative.CAUTIONConsult Material Safety Data Sheets andcontainer label Caution Statements forhazards in handling these materials....since 1899160 Gamma DrivePittsburgh, PA 15238-2989 USAPhone 412.963.0303 Fax 412.963.7620www.sauereisen.comMarch 2010© 1985 <strong>Sauereisen</strong> Cements Co.Printed in U.S.A.