concrete repair / corrosion control - Parchem

concrete repair / corrosion control - Parchem

concrete repair / corrosion control - Parchem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

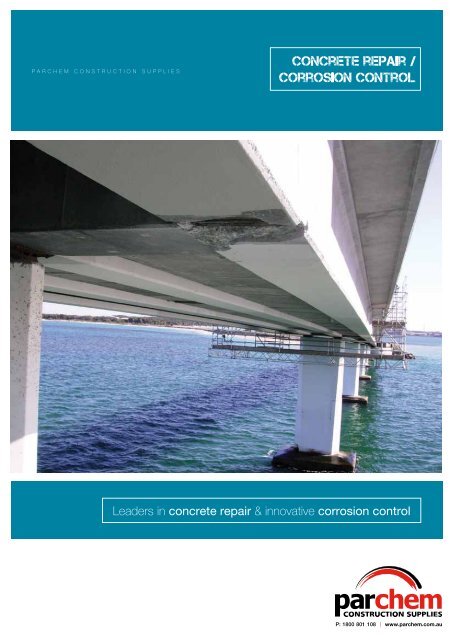

P A R C H E M C O N S T R U C T I O N S U P P L I E S<strong>concrete</strong> <strong>repair</strong> /<strong>corrosion</strong> <strong>control</strong>Leaders in <strong>concrete</strong> <strong>repair</strong> & innovative <strong>corrosion</strong> <strong>control</strong>P: 1800 801 108 www.parchem.com.au

<strong>concrete</strong> <strong>repair</strong>Concrete Repair SolutionsConcrete Repair - CementitiousConcrete distress in buildings and structures requires <strong>repair</strong> solutions utilising products and systemscompatible with the host <strong>concrete</strong> and which provide long term durability.The Renderoc cement based <strong>repair</strong> products include a range of compatible <strong>repair</strong> mortars, high buildmortars, micro-fluid <strong>concrete</strong>s and fairing coats which have been synonymous with quality and leadingtechnology. They provide engineers and specialist contractors with superior <strong>repair</strong> solutions supported byexperienced technical sales staff.RenderocGuncrete ERenderoc FC: Polymer modified, fairing mortarscreed.Renderoc HB: Polymer modified, general purposepatch <strong>repair</strong> mortar.Reneroc HB25: Light-weight, low shrinkage, <strong>repair</strong>mortar for <strong>concrete</strong> > 15 MPa.Renderoc HB40: Medium-weight, low shrinkage,<strong>repair</strong> mortar for <strong>concrete</strong> > 30 MPa.Renderoc HB70: High-build, high strength, <strong>repair</strong>mortar for <strong>concrete</strong> > 45 MPa.Renderoc LA55: Super-fluid, high strength, micro<strong>concrete</strong>reinstatement mortar.Renderoc Rapid: Extremely fast setting,reinstatement mortar.Guncrete E: Spray-applied <strong>repair</strong> mortar with highbuild and high strength.Concrete Repair - EpoxyConcrete distress in structures requires <strong>repair</strong> solutions utilising products and systems capable ofwithstanding severe chemical and abrasion attack.The Nitomortar range of epoxy based <strong>repair</strong> products include high strength, high build mortars, crackinjection systems, chemical and abrasion resistant mortars.Nitomortar 903: Epoxy binder system.Nitomortar 908: Epoxy patch <strong>repair</strong> mortar.Nitomortar EL: Epoxy lining mortar, chemical and abrasionresistant.Nitomortar ELS: Sprayable epoxy high build lining mortar,chemical and abrasion resistant.Nitofill LV: Low viscosity, epoxy crack injection system.Nitomortar AP: Multi purpose, epoxy adhesive <strong>repair</strong> paste.Nitomortar ELS2 I <strong>Parchem</strong> Construction Supplies Pty Ltd (ABN 80 069 961 968)

<strong>corrosion</strong> <strong>control</strong><strong>Parchem</strong> in conjunction with Fosroc and Vector provide a comprehensive range ofconstructive solutions to ensure long term durability of reinforced <strong>concrete</strong> structures.Solutions for Corrosion ProblemsGalvanic and Impressed Current Cathodic ProtectionGalvashield XP/XPT: Tied-on sacrificial anodes, for patch <strong>repair</strong>s, to inhibit incipient anode formation.Galvashield XP2/4: Tied-on sacrificial anodes with increased protection, for patch <strong>repair</strong>s, to inhibitincipient anode formation.Galvashield CC: Embedded sacrificial anodes, for general <strong>corrosion</strong> <strong>control</strong> and protection of, as yet,undamaged <strong>concrete</strong>.Galvashield LJ: Cathodic protection and <strong>concrete</strong> <strong>repair</strong> solutions for marine and semi-submergedstructures without the need for external power or monitoring.Galvanode DAS: Distributed anode for Corrosion Control and Cathodic Protection.Ebonex ICCP Anodes: Discrete anodes for Impressed Current Cathodic Protection of steel reinforcementin <strong>concrete</strong> subject to severe exposure conditions.Galvashield XPTGalvashield XP2Galvashield XP4Galvanode DASGalvashield XP2Galvashield LJConcrete Repair / Corrosion Control I 3

trade storesWe’ve gotthe gearyou needNew South WalesBeresfield 02 4964 4277Coffs Harbour 02 6652 3599Fyshwick 02 6228 1313Narellan 02 4647 0623Padstow 02 9771 6626Penrith 02 4722 9259Riverstone 02 9627 9133Tuggerah 02 4352 2287Wetherill Park 02 9756 5494QueenslandArundel 07 5500 5600Brendale 07 3889 7600Gladstone 07 4978 0128Morningside 07 3902 2300Springwood 07 3808 8133Townsville 07 4779 4750Western AustraliaBelmont 08 6279 9799VictoriaBrunswick 03 9380 2400Campbellfield 03 9308 6133Dandenong 03 8710 7000South AustraliaHindmarsh 08 8241 6000www.parchem.com.auCustomer Service 1800 801 108National Head Office: 7 Lucca Road, Wyong NSW 2259 02 4350 5000Please recycleThe range of products will vary by location so please contact your nearest store for the range of products in stock.P: 1800 801 108 www.parchem.com.au