Surface Roughness Optimization Of Machining Parameters In ...

Surface Roughness Optimization Of Machining Parameters In ...

Surface Roughness Optimization Of Machining Parameters In ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

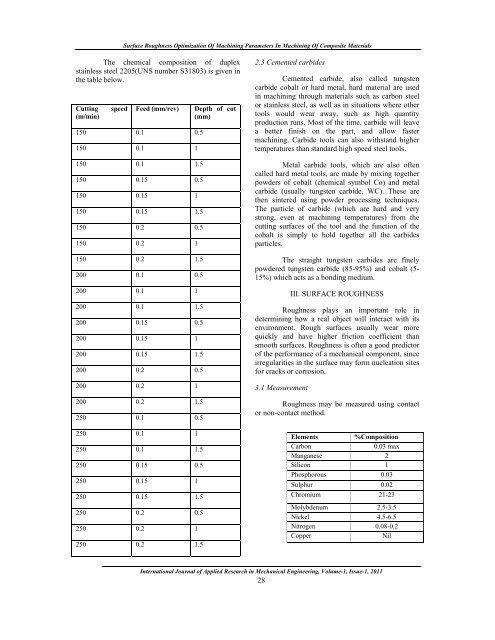

<strong>Surface</strong> <strong>Roughness</strong> <strong>Optimization</strong> <strong>Of</strong> <strong>Machining</strong> <strong>Parameters</strong> <strong>In</strong> <strong>Machining</strong> <strong>Of</strong> Composite MaterialsThe chemical composition of duplexstainless steel 2205(UNS number S31803) is given inthe table below.Cutting(m/min)speedFeed (mm/rev)150 0.1 0.5150 0.1 1150 0.1 1.5150 0.15 0.5150 0.15 1150 0.15 1.5150 0.2 0.5150 0.2 1150 0.2 1.5200 0.1 0.5200 0.1 1200 0.1 1.5200 0.15 0.5200 0.15 1200 0.15 1.5200 0.2 0.5200 0.2 1200 0.2 1.5250 0.1 0.5250 0.1 1250 0.1 1.5250 0.15 0.5250 0.15 1250 0.15 1.5250 0.2 0.5250 0.2 1250 0.2 1.5Depth of cut(mm)2.3 Cemented carbidesCemented carbide, also called tungstencarbide cobalt or hard metal, hard material are usedin machining through materials such as carbon steelor stainless steel, as well as in situations where othertools would wear away, such as high quantityproduction runs. Most of the time, carbide will leavea better finish on the part, and allow fastermachining. Carbide tools can also withstand highertemperatures than standard high speed steel tools.Metal carbide tools, which are also oftencalled hard metal tools, are made by mixing togetherpowders of cobalt (chemical symbol Co) and metalcarbide (usually tungsten carbide, WC). These arethen sintered using powder processing techniques.The particle of carbide (which are hard and verystrong, even at machining temperatures) from thecutting surfaces of the tool and the function of thecobalt is simply to hold together all the carbidesparticles.The straight tungsten carbides are finelypowdered tungsten carbide (85-95%) and cobalt (5-15%) which acts as a bonding medium.III. SURFACE ROUGHNESS<strong>Roughness</strong> plays an important role indetermining how a real object will interact with itsenvironment. Rough surfaces usually wear morequickly and have higher friction coefficient thansmooth surfaces. <strong>Roughness</strong> is often a good predictorof the performance of a mechanical component, sinceirregularities in the surface may form nucleation sitesfor cracks or corrosion.3.1 Measurement<strong>Roughness</strong> may be measured using contactor non-contact method.Elements%CompositionCarbon0.03 maxManganese 2Silicon 1Phosphorous 0.03Sulphur 0.02Chromium 21-23Molybdenum 2.5-3.5Nickel 4.5-6.5Nitrogen 0.08-0.2CopperNil<strong>In</strong>ternational Journal of Applied Research in Mechanical Engineering, Volume-1, Issue-1, 201128