Preparation and properties of ionically cross-linked chitosan ...

Preparation and properties of ionically cross-linked chitosan ...

Preparation and properties of ionically cross-linked chitosan ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

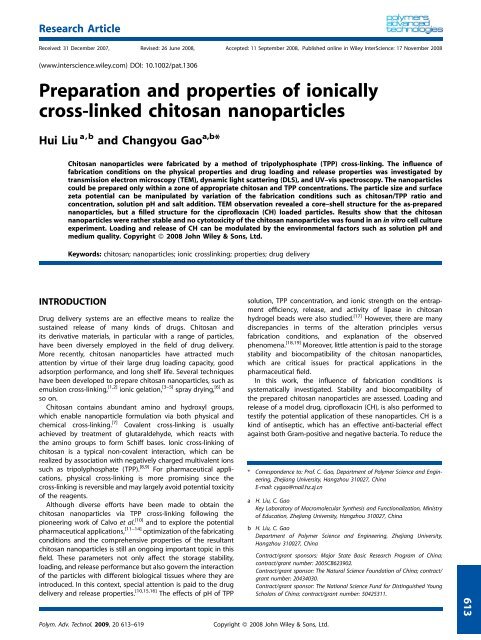

Research ArticleReceived: 31 December 2007, Revised: 26 June 2008, Accepted: 11 September 2008, Published online in Wiley InterScience: 17 November 2008(www.interscience.wiley.com) DOI: 10.1002/pat.1306<strong>Preparation</strong> <strong>and</strong> <strong>properties</strong> <strong>of</strong> <strong>ionically</strong><strong>cross</strong>-<strong>linked</strong> <strong>chitosan</strong> nanoparticlesHui Liu a,b <strong>and</strong> Changyou Gao a,b *Chitosan nanoparticles were fabricated by a method <strong>of</strong> tripolyphosphate (TPP) <strong>cross</strong>-linking. The influence <strong>of</strong>fabrication conditions on the physical <strong>properties</strong> <strong>and</strong> drug loading <strong>and</strong> release <strong>properties</strong> was investigated bytransmission electron microscopy (TEM), dynamic light scattering (DLS), <strong>and</strong> UV–vis spectroscopy. The nanoparticlescould be prepared only within a zone <strong>of</strong> appropriate <strong>chitosan</strong> <strong>and</strong> TPP concentrations. The particle size <strong>and</strong> surfacezeta potential can be manipulated by variation <strong>of</strong> the fabrication conditions such as <strong>chitosan</strong>/TPP ratio <strong>and</strong>concentration, solution pH <strong>and</strong> salt addition. TEM observation revealed a core–shell structure for the as-preparednanoparticles, but a filled structure for the cipr<strong>of</strong>loxacin (CH) loaded particles. Results show that the <strong>chitosan</strong>nanoparticles were rather stable <strong>and</strong> no cytotoxicity <strong>of</strong> the <strong>chitosan</strong> nanoparticles was found in an in vitro cell cultureexperiment. Loading <strong>and</strong> release <strong>of</strong> CH can be modulated by the environmental factors such as solution pH <strong>and</strong>medium quality. Copyright ß 2008 John Wiley & Sons, Ltd.Keywords: <strong>chitosan</strong>; nanoparticles; ionic <strong>cross</strong>linking; <strong>properties</strong>; drug deliveryINTRODUCTIONDrug delivery systems are an effective means to realize thesustained release <strong>of</strong> many kinds <strong>of</strong> drugs. Chitosan <strong>and</strong>its derivative materials, in particular with a range <strong>of</strong> particles,have been diversely employed in the field <strong>of</strong> drug delivery.More recently, <strong>chitosan</strong> nanoparticles have attracted muchattention by virtue <strong>of</strong> their large drug loading capacity, goodadsorption performance, <strong>and</strong> long shelf life. Several techniqueshave been developed to prepare <strong>chitosan</strong> nanoparticles, such asemulsion <strong>cross</strong>-linking, [1,2] ionic gelation, [3–5] spray drying, [6] <strong>and</strong>so on.Chitosan contains abundant amino <strong>and</strong> hydroxyl groups,which enable nanoparticle formulation via both physical <strong>and</strong>chemical <strong>cross</strong>-linking. [7] Covalent <strong>cross</strong>-linking is usuallyachieved by treatment <strong>of</strong> glutaraldehyde, which reacts withthe amino groups to form Schiff bases. Ionic <strong>cross</strong>-linking <strong>of</strong><strong>chitosan</strong> is a typical non-covalent interaction, which can berealized by association with negatively charged multivalent ionssuch as tripolyphosphate (TPP). [8,9] For pharmaceutical applications,physical <strong>cross</strong>-linking is more promising since the<strong>cross</strong>-linking is reversible <strong>and</strong> may largely avoid potential toxicity<strong>of</strong> the reagents.Although diverse efforts have been made to obtain the<strong>chitosan</strong> nanoparticles via TPP <strong>cross</strong>-linking following thepioneering work <strong>of</strong> Calvo et al. [10] <strong>and</strong> to explore the potentialpharmaceutical applications, [11–14] optimization <strong>of</strong> the fabricatingconditions <strong>and</strong> the comprehensive <strong>properties</strong> <strong>of</strong> the resultant<strong>chitosan</strong> nanoparticles is still an ongoing important topic in thisfield. These parameters not only affect the storage stability,loading, <strong>and</strong> release performance but also govern the interaction<strong>of</strong> the particles with different biological tissues where they areintroduced. In this context, special attention is paid to the drugdelivery <strong>and</strong> release <strong>properties</strong>. [10,15,16] The effects <strong>of</strong> pH <strong>of</strong> TPPPolym. Adv. Technol. 2009, 20 613–619solution, TPP concentration, <strong>and</strong> ionic strength on the entrapmentefficiency, release, <strong>and</strong> activity <strong>of</strong> lipase in <strong>chitosan</strong>hydrogel beads were also studied. [17] However, there are manydiscrepancies in terms <strong>of</strong> the alteration principles versusfabrication conditions, <strong>and</strong> explanation <strong>of</strong> the observedphenomena. [18,19] Moreover, little attention is paid to the storagestability <strong>and</strong> biocompatibility <strong>of</strong> the <strong>chitosan</strong> nanoparticles,which are critical issues for practical applications in thepharmaceutical field.In this work, the influence <strong>of</strong> fabrication conditions issystematically investigated. Stability <strong>and</strong> biocompatibility <strong>of</strong>the prepared <strong>chitosan</strong> nanoparticles are assessed. Loading <strong>and</strong>release <strong>of</strong> a model drug, cipr<strong>of</strong>loxacin (CH), is also performed totestify the potential application <strong>of</strong> these nanoparticles. CH is akind <strong>of</strong> antiseptic, which has an effective anti-bacterial effectagainst both Gram-positive <strong>and</strong> negative bacteria. To reduce the* Correspondence to: Pr<strong>of</strong>. C. Gao, Department <strong>of</strong> Polymer Science <strong>and</strong> Engineering,Zhejiang University, Hangzhou 310027, ChinaE-mail: cygao@mail.hz.zj.cnabH. Liu, C. GaoKey Laboratory <strong>of</strong> Macromolecular Synthesis <strong>and</strong> Functionalization, Ministry<strong>of</strong> Education, Zhejiang University, Hangzhou 310027, ChinaH. Liu, C. GaoDepartment <strong>of</strong> Polymer Science <strong>and</strong> Engineering, Zhejiang University,Hangzhou 310027, ChinaContract/grant sponsors: Major State Basic Research Program <strong>of</strong> China;contract/grant number: 2005CB623902.Contract/grant sponsor: The Natural Science Foundation <strong>of</strong> China; contract/grant number: 20434030.Contract/grant sponsor: The National Science Fund for Distinguished YoungScholars <strong>of</strong> China; contract/grant number: 50425311.Copyright ß 2008 John Wiley & Sons, Ltd.613

H. LIU AND C. GAOdrug toxicity as a result <strong>of</strong> long term application, for examplearthritis damage for children, various sustained release carrierssuch as microcapsules, gels <strong>and</strong> liposomes have been developed.Yet so far less attention has been given to the nanoparticlecarriers, in particular the <strong>chitosan</strong> nanoparticles.EXPERIMENTALMaterialsChitosan (CS, M h ¼ 620 kDa, degree <strong>of</strong> deacetylation ¼ 90%,viscosity ¼ 115 cps) is a commercial product <strong>of</strong> Haidebei HalobiosCo., Ltd. (Ji’nan, China). Sodium tripolyphosphate (TPP) waspurchased from Dongsheng Chemical Reagent Factory (Wenzhou,China). Cipr<strong>of</strong>loxacin hydrochloride (CH, C 17 H 18 FN 3 O 3 HClH 2 O)was purchased from Zhejiang Medicine Co. Ltd., XinchangPharmaceutical Factory (Shaoxing, China). Phosphotungstic acidwas purchased from Sinopharm Group Chemical Reagent Co., Ltd.(Shanghai, China). All other chemicals were <strong>of</strong> analytical grade <strong>and</strong>used as received. The water used in all experiments was tripledistilled.<strong>Preparation</strong> <strong>of</strong> the <strong>chitosan</strong> nanoparticlesThe nanoparticles were obtained based on ionic gelation <strong>of</strong> TPPwith <strong>chitosan</strong>. [10] Briefly, <strong>chitosan</strong> <strong>and</strong> TPP were dissolved inacetic acid <strong>and</strong> triple distilled water to obtain solutions <strong>of</strong> 1.0–5.0<strong>and</strong> 0.25–2.0 mg/ml, respectively. The <strong>chitosan</strong> nanoparticleswere obtained upon addition <strong>of</strong> 14 ml TPP solution into 35 ml<strong>chitosan</strong> solution under mild mechanical stirring (550 rpm) atroom temperature. The drug-loaded nanoparticles were similarlyprepared by using a <strong>chitosan</strong> solution containing the drug.CharacterizationMorphological examination <strong>of</strong> the <strong>chitosan</strong> nanoparticles wasperformed by transmission electron microscopy (TEM) (JEOLJEM-200CX, Japan). The sample was stained with 2% (w/v)phosphotungstic acid <strong>and</strong> a drop <strong>of</strong> the sample was applied ontoa carbon-coated copper meshwork, <strong>and</strong> dried at roomtemperature. The acceleration voltage was 100 kV. Zeta potential<strong>of</strong> the particles was recorded on a Zetasizer 2000. Each value wasaveraged from three parallel measurements.The particle size was measured by dynamic light scattering(DLS) (90 Plus/BI-MAS). The wavelength <strong>of</strong> laser is 658 nm.Brookhaven’s unique dust filter algorithm can remove theinfluence <strong>of</strong> a contaminating fraction <strong>of</strong> large particles (dust).Processing the fluctuating signal with a state-<strong>of</strong>-the-art digitalauto-correlator yields the particle’s diffusion coefficient, fromwhich the equivalent spherical particle size is calculated using theStokes–Einstein equation. When a broad distribution <strong>of</strong> spheres ispresent in the samples, the following auto-correlation function isused:ZgðtÞ ¼ GðGÞe Gt dGan average diameter <strong>and</strong> a distribution width (polydispersity) areobtained. It has to be noted that the most important pieces <strong>of</strong>information obtained in photon correlation spectroscopy usingany multimodal distribution analysis are the positions <strong>of</strong> thepeaks <strong>and</strong> the ratio <strong>of</strong> the peak areas. The widths <strong>of</strong> the peaks,however, are not particularly reliable, since they will narrow,typically, with increasing duration <strong>of</strong> experiment until a limit isreached. For more details, the readers can refer to the machinemanual. Each measurement was taken for 1 min with a 908 fixedangle detector. The size was averaged from five parallelmeasurements.Stability <strong>of</strong> the <strong>chitosan</strong> nanoparticlesThe stability <strong>of</strong> the <strong>chitosan</strong> nanoparticles obtained at differentfabricating conditions was examined in terms <strong>of</strong> the particle size.The nanoparticle suspensions were stored at 48C <strong>and</strong> the sizes <strong>of</strong>the nanoparticles were monitored by DLS.Biocompatibility <strong>of</strong> the <strong>chitosan</strong> nanoparticlesIn vitro cell culture was performed to determine the biocompatibility<strong>of</strong> the as-prepared <strong>chitosan</strong> nanoparticles. The <strong>chitosan</strong>nanoparticles were sterilized by UV irritation before cell culture.Human dermal fibroblasts were isolated from foreskins <strong>and</strong>routinely exp<strong>and</strong>ed. [20] The cells were cultured at 378C, in 5% CO 2 ,<strong>and</strong> 95% humidity in DMEM supplemented with penicillin (100 U/ml), streptomycin (100 mg/ml), <strong>and</strong> 10% fetal bovine serum (FBS)(complete medium), which was changed every 3 days. Cells werepassaged at confluence <strong>and</strong> the 4–8th passage <strong>of</strong> fibroblasts witha density <strong>of</strong> 2 10 5 /ml were seeded in a 96-well polystyreneplate. After 24 hr, 60 ml <strong>of</strong> nanoparticle suspension was addedinto each well. The final nanoparticle concentration was highenough for close contact between the cells <strong>and</strong> the nanoparticles.The culture medium was changed every 2 days. Meanwhile,normal culture medium was used in parallel as a negative control.The cell proliferation was measured by methylthiazoletetrazolium(MTT) assay. [21] The absorbance was recorded at a wavelength <strong>of</strong>570 nm by a microplate reader (Bio-Rad model 550). Threeparallel samples were analysed <strong>and</strong> data were expressed asmean st<strong>and</strong>ard deviation.Quantification <strong>of</strong> the relative CH amount in the <strong>chitosan</strong>nanoparticlesThe prepared nanoparticle suspension containing the CH wascentrifugated at 12,000 rpm for 70 min to obtain the supernatant,which was diluted over hundreds <strong>of</strong> times <strong>and</strong> the absorbance at276 nm was recorded by a UV–vis spectrophotometer (ShimadzuUV-2550). The supernatant <strong>of</strong> blank nanoparticles was obtainedunder the same conditions <strong>and</strong> used as a control. Theconcentration <strong>of</strong> CH in the supernatant was quantified byreferring to a calibration curve recorded from a known amount <strong>of</strong>CH at the same condition. A lower concentration found in thesupernatant implies a higher loading efficiency in the <strong>chitosan</strong>nanoparticles.614where G is related to the relaxation <strong>of</strong> the fluctuations. Forobtaining information from this equation, a method <strong>of</strong> Cumulantanalysis is applied. To get the solution, an approximation is usedby the non-negative constrained least squares (NNLS) algorithm.Moreover, Mie theory is used to calculate the weight <strong>and</strong> numberfractions from the intensity fractions. For routine determinations,Release <strong>of</strong> CHCH release was performed using a dialysis technique. The CHloaded <strong>chitosan</strong> nanoparticles were centrifugated at 12,000 rpmfor 70 min to obtain the nanoparticle precipitate, which waswashed with water twice. The nanoparticles were transferred intowww.interscience.wiley.com/journal/pat Copyright ß 2008 John Wiley & Sons, Ltd. Polym. Adv. Technol. 2009, 20 613–619

IONICALLY CROSS-LINKED CHITOSAN NANOPARTICLESa dialytic-bag with a cut-<strong>of</strong>f molecular weight <strong>of</strong> 3.5 kDa. Thedialytic-bag was then immersed into 100 ml phosphate bufferedsaline (PBS, pH 7.4) or H 2 Oat378C under continuous shaking. Atpredetermined time, 1 ml dialytic medium was taken out foranalysis <strong>and</strong> an equal volume <strong>of</strong> freshly prepared medium wassupplemented. Absorbance <strong>of</strong> the dialytic medium at 270 nm wasrecorded by an UV–vis spectroscopy. The released amount <strong>of</strong> CHwas quantified by referring to a calibration curve recorded fromknown amounts <strong>of</strong> CH at the same condition.RESULTS AND DISCUSSIONFabrication <strong>and</strong> <strong>properties</strong> <strong>of</strong> <strong>chitosan</strong> nanoparticleThe <strong>chitosan</strong> molecules are gelled when they encounter TPPmolecules via electrostatic interaction. [10] Firstly, the zone <strong>of</strong>particle formation is investigated. Chitosan was dissolved in 1.5%acetic acid solution to form a 10 mg/ml solution, which wasdiluted with water to various concentrations: 1.0, 2.0, 3.0, 4.0, <strong>and</strong>5.0 mg/ml. The pH value <strong>of</strong> these solutions was adjusted to 4.8.TPP was dissolved in water at various concentrations: 0.50, 0.75,1.0, 1.25, 1.50, 1.75, 2.0, <strong>and</strong> 2.5 mg/ml. Chitosan nanoparticleswere prepared by the addition <strong>of</strong> 14 ml TPP solution into 35 ml<strong>chitosan</strong> solution at room temperature under mechanicalagitation. By visual observation, the systems were classified asclear solution (), opalescent suspension (H), <strong>and</strong> aggregates (#).The results are summarized in Table 1. A clear solution wasobserved when both the <strong>chitosan</strong> <strong>and</strong> TPP concentrations weretoo small, whereas aggregates were formed spontaneously whenthey were too large. The zone <strong>of</strong> the opalescent suspension,which should represent a suspension <strong>of</strong> colloidal particles, wasfound when the <strong>chitosan</strong> <strong>and</strong> the TPP concentrations wereappropriate. Illuminating that formation <strong>of</strong> the nanoparticles isonly possible for some specific concentrations <strong>of</strong> <strong>chitosan</strong> <strong>and</strong>Table 1. Conditions for formation <strong>of</strong> the <strong>chitosan</strong> nanoparticlesCS (mg/ml)TPP (mg/ml)0.25 0.5 0.75 1.0 1.25 1.5 2.0 2.51.0 H H H H # # #2.0 H H H H H H #3.0 H H H H H H4.0 H H H H H H, clear solution; H, opalescent suspension; #, aggregates.TPP. Confirmed by DLS measurement <strong>and</strong> microscopy observation,the <strong>chitosan</strong> nanoparticles with a size <strong>of</strong> 300 nm wereobtained <strong>and</strong> well dispersed in the solution when theconcentration <strong>of</strong> <strong>chitosan</strong> <strong>and</strong> TPP was 2.0 <strong>and</strong> 1 mg/ml,respectively.Figure 1a shows that the number average size <strong>of</strong> the <strong>chitosan</strong>nanoparticles was measured as 321 nm by DLS, which isconsistent with the TEM observation (Fig. 1c, d). No severeagglomeration <strong>of</strong> the particles was observed. A magnified TEMimage (Fig. 1d) illustrates that the <strong>chitosan</strong> nanoparticles had acore–shell structure, i.e. with denser skirts <strong>and</strong> looser interiors.After loading with CH, the particle size increased slightly to337 nm (Fig. 1b) with a homogeneous structure (Fig. 1e, f),suggesting that the drug was surely loaded.For the next study, the <strong>chitosan</strong> concentration was fixed at2 mg/ml with a pH value <strong>of</strong> 4.8. Fig. 2 shows that both the particlesize (Fig. 2a) <strong>and</strong> zeta potential (Fig. 2b) decreased along with theincrease <strong>of</strong> TPP concentration. This alteration tendency isconsistent with the results <strong>of</strong> Gan et al., [18] but is the oppositeFigure 1. (a,b) Size distribution <strong>and</strong> (c–f) TEM images <strong>of</strong> (a,c,d) <strong>chitosan</strong> nanoparticles <strong>and</strong> (b,e,f) CH loaded <strong>chitosan</strong> nanoparticles, respectively. The<strong>chitosan</strong> <strong>and</strong> TPP concentrations were 2 <strong>and</strong> 1 mg/ml, respectively. This figure is available in color online at www.interscience.wiley.com/journal/pat.Polym. Adv. Technol. 2009, 20 613–619 Copyright ß 2008 John Wiley & Sons, Ltd. www.interscience.wiley.com/journal/pat615

H. LIU AND C. GAOFigure 2. Influence <strong>of</strong> TPP concentration on: (a) the particle size, (b) zeta potential, <strong>and</strong> (c) <strong>chitosan</strong> concentration on the particle size at a fixed CS to TPPmass ratio <strong>of</strong> 4:1. The error bar indicates the st<strong>and</strong>ard deviation averaged from five measurements unless specifically indicated.to the results <strong>of</strong> Pan. [22] We think the decrease is more acceptable,since at higher TPP concentration, the <strong>cross</strong>-linking degree <strong>of</strong>the <strong>chitosan</strong> nanoparticles is also higher. This will result in a morecompact particle structure. Moreover, the neutralization degree<strong>of</strong> the charged amino groups is simultaneously improved, leadingto smaller net charge in the particles as shown in Fig. 2b. Due tothe compact structure <strong>and</strong> weakened charge repulsion, theparticles prepared at higher TPP concentration a have smallersize.At a fixed ratio <strong>of</strong> CS to TPP concentration, the particle sizeincreased along with the increase <strong>of</strong> CS <strong>and</strong> TPP concentration (c)(Fig. 2c). At a given spatial interaction distance, the particle sizeshould be roughly increased by a factor <strong>of</strong> c 1/3 . Apparently theparticle size shown in Fig. 2c does not follow this law. The reasoncan be both the change <strong>of</strong> spatial interaction distance <strong>and</strong> theparticle inner structure, e.g. the compactness <strong>of</strong> the molecules.As the association is driven by ionic interaction, <strong>and</strong> thecharging degree <strong>of</strong> both <strong>chitosan</strong> <strong>and</strong> TPP is influenced by pHvalue, a pH variation during the fabrication is expected toinfluence the formulation <strong>and</strong> structure <strong>of</strong> the <strong>chitosan</strong>nanoparticles. Figure 3a shows that the nanoparticle sizeincreased rapidly until pH 3.5, <strong>and</strong> then decreased slowlyuntil pH 5.5, the measured pH value so far. A similar alterationtendency for the zeta potential was recorded with a slightlyFigure 3. Influence <strong>of</strong> <strong>chitosan</strong> solution pH value on: (a) the particle size <strong>and</strong> (b) zeta potential.616Figure 4. Influence <strong>of</strong> particle suspension pH value on: (a) the size <strong>and</strong> (b) zeta potential.www.interscience.wiley.com/journal/pat Copyright ß 2008 John Wiley & Sons, Ltd. Polym. Adv. Technol. 2009, 20 613–619

IONICALLY CROSS-LINKED CHITOSAN NANOPARTICLESFigure 5. Influence <strong>of</strong> NaCl concentration on: (a) the particle size <strong>and</strong> (b) zeta potential.Figure 6. Alteration <strong>of</strong> average size <strong>of</strong> <strong>chitosan</strong> nanoparticles with: (a) different TPP concentration <strong>and</strong> (b) at different pH during a storage time <strong>of</strong> 385days at 48C.higher transition pH value (pH 4) (Fig. 3b). This alteration behavioris dependent on charging <strong>properties</strong> <strong>and</strong> the interplay betweenthe <strong>chitosan</strong> <strong>and</strong> the TPP molecules. At a critical low pH, most <strong>of</strong>the amino groups <strong>of</strong> <strong>chitosan</strong> are protonated, enabling the<strong>chitosan</strong> molecule with an extension confirmation due to strongcharge repulsion. The TPP molecule is also protonated, leading tolower charging density <strong>of</strong> the molecule. In this case, the <strong>chitosan</strong>molecules cannot be sufficiently <strong>cross</strong>-<strong>linked</strong> by TPP to formstable particles. Along with increase <strong>of</strong> the pH value, thedeprotonation degree <strong>of</strong> TPP is increased gradually, while theprotonation degree <strong>of</strong> <strong>chitosan</strong> is less influenced when the pHvalue is below 5. At a proper pH such as pH 3.5, the chargeinteraction between these two molecules becomes strongenough, thus stable <strong>chitosan</strong> nanoparticles are obtained witha relatively larger size. At a still higher pH value, the chargingdegree <strong>of</strong> TPP molecule is enhanced again, which neutralizes the<strong>chitosan</strong> to a greater extent. Consequently, the particles shrinktheir size again.Besides the fabrication process, the pH variation also influencesthe size <strong>of</strong> the formed nanoparticles as shown in Fig. 4a. The samedecreasing tendency <strong>of</strong> the particle size was found exactly whenthe pH value was increased from 4.5 to 6.0. Meanwhile, the zetapotential was decreased too (Fig. 4b). However, the zeta potentialshowed an increasing regime when the pH value was increasedfrom 1 to 3.5, the same phenomenon as shown in Fig. 3b. Ifconsidering only the interaction <strong>of</strong> <strong>chitosan</strong> <strong>and</strong> TPP, the zetapotential should be larger or at least should remain constant atlow pH. The reason for this abnormal low value at low pH is notvery clear so far. Nevertheless, this phenomenon implies that thepositive surface charge <strong>of</strong> the <strong>chitosan</strong> particles is shielding,which can be a result <strong>of</strong> reorganization <strong>of</strong> the molecule structure,or/<strong>and</strong> adsorption <strong>of</strong> other negative charged ions at low pH. Ofcourse, ionic strength effect at a critical low pH can not beexcluded.Figure 7. Cytoviability <strong>of</strong> fibroblasts measured by MTT assay as a function<strong>of</strong> culture time. Blank control was made by culture medium. Threeparallel samples were analysed <strong>and</strong> data were expressed as mean st<strong>and</strong>ard deviation.Polym. Adv. Technol. 2009, 20 613–619 Copyright ß 2008 John Wiley & Sons, Ltd. www.interscience.wiley.com/journal/pat617

H. LIU AND C. GAOFigure 8. (a) Influence <strong>of</strong> <strong>chitosan</strong> solution pH value on the drug loading. (b) Release pr<strong>of</strong>iles <strong>of</strong> CH from the <strong>chitosan</strong> nanoparticles in different media at378C as a function <strong>of</strong> time. This figure is available in color online at www.interscience.wiley.com/journal/pat.618To clarify this point, the <strong>chitosan</strong> particles were incubated inNaCl solution with different concentrations. Figure 5 shows thatboth the particle size <strong>and</strong> zeta potential were decreased alongwith the increase in NaCl concentration. It is known that thecharge interaction can be effectively screened by electrolytessuch as NaCl. Charge screening weakens charge repulsionbetween the <strong>chitosan</strong> molecules, leading to shrinkage <strong>of</strong> thenanoparticles. The sample explanation can be applied to the zetapotential too.Stability <strong>and</strong> biocompatibility <strong>of</strong> the nanoparticlesFor pharmaceutical applications, the storage stability <strong>and</strong>biocompatibility <strong>of</strong> the nanoparticles is a great concern. It isknown that tiny particles are inclined to agglomerate with eachother to reduce the surface area, <strong>and</strong> hence to reduce the freesurface energy. Figure 6 presents the sizes <strong>of</strong> the nanoparticlesprepared with different TPP concentration (Fig. 6a) <strong>and</strong> atdifferent pH values (Fig. 6b) during a storage time <strong>of</strong> 385 days.Here the storage temperature was kept constant at 48C. All theparticles were rather stable with neglectable size fluctuationwithin 15 days, <strong>and</strong> then some <strong>of</strong> them showed size increment atday 85 by a factor <strong>of</strong>

IONICALLY CROSS-LINKED CHITOSAN NANOPARTICLESdescribed here is not restricted to CH, but can also be extended toother types <strong>of</strong> drugs, proteins, enzymes, <strong>and</strong> growth factors fordifferent applications.REFERENCES[1] B. C. Thanoo, M. C. Sunny, A. Jayakrishnan, J. Pharm. Pharmacol. 1992,44, 283–286.[2] I. Genta, M. Costantini, A. Asti, B. Conti, L. Montanari, Carbohydr.Polym. 1998, 36, 81–88.[3] Y. Pan, Y. J. Li, H. Y. Zhao, J. M. Zheng, H. Xu, G. Wei, J. S. Hao, F. D. Cui,Int. J. Pharm. 2002, 249, 139–147.[4] J. Berger, M. Reist, J. M. Mayer, O. Felt, N. A. Peppas, R. Gurny, Eur. J.Pharm. Biopharm. 2004, 57, 19–34.[5] J. A. Ko, H. J. Park, S. J. Hwang, J. B. Park, J. S. Lee, Int. J. Pharm. 2002,249, 165–174.[6] P. He, S. S. Davis, L. Illum, Int. J. Pharm. 1999, 187, 53–65.[7] T. López-León, E. L. S. Carvalho, B. Seijo, J. L. Ortega-Vinuesa, D.Bastos-González, J. Colloid Interface Sci. 2005, 283(2), 344–351.[8] Y. Kawashima, T. H<strong>and</strong>a, H. Takenaka, S. Y. Lin, Y. Ando, J. Pharm. Sci.1985, 74(3), 264–268.[9] Y. Kawashima, T. H<strong>and</strong>a, A. Kasai, H. Takenaka, S. Y. Lin, Chem. Pharm.Bull. 1985, 33(6), 2469–2474.[10] P. Calvo, C. Remuñán-López, J. L. Vila-Jato, M. J. Alonso, J. Appl. Polym.Sci. 1997, 63(1), 125–132.[11] S. Shiraishi, T. Imai, M. Otagiri, J. Control. Release 1993, 25, 217–225.[12] Z. Aydin, J. Akbuğa, Int. J. Pharm. 1996, 131(1), 101–103.[13] P. Calvo, C. Remuñán-López, J. L. Vila-Jato, M. J. Alonso, Pharm. Res.1997, 14(10), 1431–1436.[14] X. Z. Shu, K. J. Zhu, Int. J. Pharm. 2000, 201(1), 51–58.[15] K. A. Janes, M. P. Fresneau, A. Marazuela, A. Fabra, M. J. Alonso,J. Control. Release 2001, 73(2–3), 255–267.[16] A. Vila, A. Sánchez, M. Tobío, P. Calvo, M. J. Alonso, J. Control. Release2002, 78(1–3), 15–24.[17] I. A. Alsarra, S. H. Neau, M. A. Howard, Biomaterials 2004, 25,2645–2655.[18] Q. Gan, T. Wang, C. Cochrane, P. McCarron, Colloids Surf. B. Biointerfaces2005, 44, 65–73.[19] L. Y. Chen, M. Subirade, Biomaterials 2005, 26, 6041–6053.[20] Z. W. Mao, L. Ma, C. Y. Gao, J. C. Shen, J. Control. Release 2005, 104,193–202.[21] Y. Y. Liu, A. Yoshikoshi, B. C. Wang, A. Sakanishi, Colloid Surf. B.Biointerfaces 2003, 27, 287–293.[22] Y. Pan, Y. J. Li, H. Y. Zhao, J. S. Hao, J. M. Zheng, J.Chin. Pharmaceut. Sci.2002, 11(3), 97–100.Polym. Adv. Technol. 2009, 20 613–619 Copyright ß 2008 John Wiley & Sons, Ltd. www.interscience.wiley.com/journal/pat619