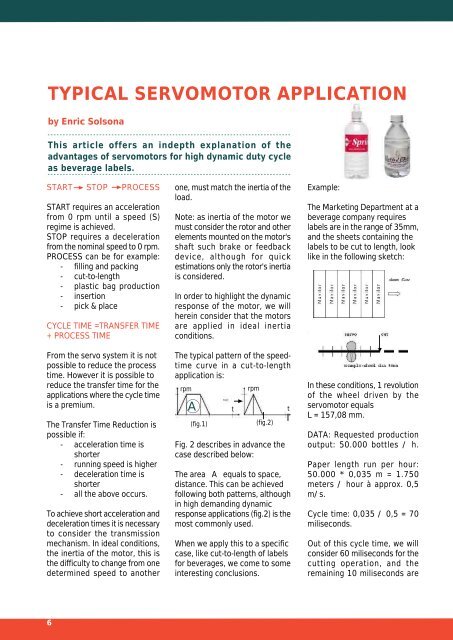

TYPICAL SERVOMOTOR APPLICATIONby Enric SolsonaThis article offers an indepth explanation of theadvantages of servomotors for high dynamic duty cycleas beverage labels.START STOP PROCESSSTART requires an accelerationfrom 0 rpm until a speed (S)regime is achieved.STOP requires a decelerationfrom the nominal speed to 0 rpm.PROCESS can be for example:- filling and packing- cut-to-length- plastic bag production- insertion- pick & placeCYCLE TIME =TRANSFER TIME+ PROCESS TIMEFrom the servo system it is notpossible to reduce the processtime. However it is possible toreduce the transfer time for theapplications where the cycle timeis a premium.The Transfer Time Reduction ispossible if:- acceleration time isshorter- running speed is higher- deceleration time isshorter- all the above occurs.To achieve short acceleration anddeceleration times it is necessaryto consider the transmissionmechanism. In ideal conditions,the inertia of the motor, this isthe difficulty to change from onedetermined speed to anotherone, must match the inertia of theload.Note: as inertia of the motor wemust consider the rotor and otherelements mounted on the motor'sshaft such brake or feedbackdevice, although for quickestimations only the rotor's inertiais considered.In order to highlight the dynamicresponse of the motor, we willherein consider that the motorsare applied in ideal inertiaconditions.The typical pattern of the speedtimecurve in a cut-to-lengthapplication is:rpmA(fig.1)Fig. 2 describes in advance thecase described below:trpm(fig.2)The area A equals to space,distance. This can be achievedfollowing both patterns, althoughin high demanding dynamicresponse applications (fig.2) is themost commonly used.When we apply this to a specificcase, like cut-to-length of labelsfor beverages, we come to someinteresting conclusions.tExample:The Marketing Department at abeverage company requireslabels are in the range of 35mm,and the sheets containing thelabels to be cut to length, looklike in the following sketch:In these conditions, 1 revolutionof the wheel driven by theservomotor equalsL = 157,08 mm.DATA: Requested productionoutput: 50.000 bottles / h.Paper length run per hour:50.000 * 0,035 m = 1.750meters / hour à approx. 0,5m/s.Cycle time: 0,035 / 0,5 = 70miliseconds.Out of this cycle time, we willconsider 60 miliseconds for thecutting operation, and theremaining 10 miliseconds are6

<strong>Mavilor</strong> Express - Núm. 28 - July 2005for accelerating and deceleratingbefore stopping for a new cut.In order to ensure 5 milisecondsfor the acceleration, the timeconstant of the motor must be ofaround 2 miliseconds, andtherefore, the maximum theoreticalacceleration 157.000 rad/s2.Let's take a usual AC brushlessservomotor around 750W or1.000W. In reality can be smallerof 200W or as big as 2,0 kW, sameapplies when comparing theMAVILOR servomotors to others.It is frequent that the MAVILORcompetitors' motors have timeconstants in the range of 10 ms,for what the approximate timerequired to achieve 100% value ofa set speed is at least 15miliseconds.speed(rpm)3.0001.3382.5 ms5 ms50 ms time (s)Would the label be shorter, insteadof 35 mm as per the aboveexample, the limitations due to poordynamic response motors are stillmore evident.For labels 35mm high, a linearspeed of 0,5 m/s requires a totaltransfer time of 10 ms, which is notachievable unless the servomotor'stime constant value is close to 2ms.D = label lengthSpeed 2.675 r.p.m.= 280 rad/s.D = (speed * time) / 2 = [280 rad/s* 0,01 s * 157,08 mm/ 2*pi rad]/2 = 35 mm.RECAPITULATION-The application requires a transfertime of 10ms for 35mm labels-A servomotor of 10ms responsetime would not achieve more than1.338 r.p.m. and the distance runin 10ms would be 8,75 mm < 35mm. Not suitable, in this case.FACTORS AFFECTING THE TIMECONSTANT VALUEThe mechanical time constant iscalculated followingInertia *RMechanical time constant =Kt*EMF constantWhere: R is the winding resistancein ohm, and Kt is the torqueconstant.Motors with a design such thatthey deliver the same outputtorque as other motors but witha smaller frame size, will offeran inertia lower than biggerframe size motors and a lowertime constant. Equally, motorswith a higher resistance valuewill result in a higher timeconstant.Motors with a higher resistancevalue, increase the losses due tovoltage drop, for what theeffective voltage is lower thanfor less resistive motors, andtherefore the EMF constantvalues must be kept low in orderto achieve speed values of 3.000r.p.m. or higher.This has a negative effect againon the mechanical time constant.SOME CONCLUSIONSThe resulting cycle time as transfertime + process time variesdepending on the transfer time,because the process time is fix.Necessary cycle time = 10 ms +60 ms = 70 ms.Production rate: 3.600 seconds/ 0,07 seconds = 51.428bottles/h > 50.000 (correct)Production rate with a poordynamic performance motor of20ms + 60 ms = 80 ms.600seconds / 0,08 seconds =45.000 bottles/h < 50.000 (notcorrect)A MAVILOR servomotor wouldhelp achieving the productionrate, with an additional 14%output compared with the longerresponse time motor.In our example, the potentialCustomer is confronted to thefollowing situation:-He has bought the motoraccording to what he foundavailable in the catalogue: 100W,200W, 400W, 750W, 1,0kWbrushless servomotors-The above powers are related toa rated speed of 3.000 r.p.m.However the motor reaches1.338 r.p.m., which means thatwith a similar rated torque thereal output power is 50%. Thesekind of applications are highdynamic response oriented.The MAVILOR servomotors 220VAC up to a rated power of 3,0kWat 3.000 r.p.m. have timeconstant values of less than 2,5miliseconds.The acceleration required toreach 3.000rpm in 10ms, forinstance, is 31.400 rad/s2,and for 2ms like the mentionedMAVILOR servomotors, inexcess of 150.000 rad/s2.7