High-Vacuum Pumps in Mass Spectrometers

High-Vacuum Pumps in Mass Spectrometers

High-Vacuum Pumps in Mass Spectrometers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

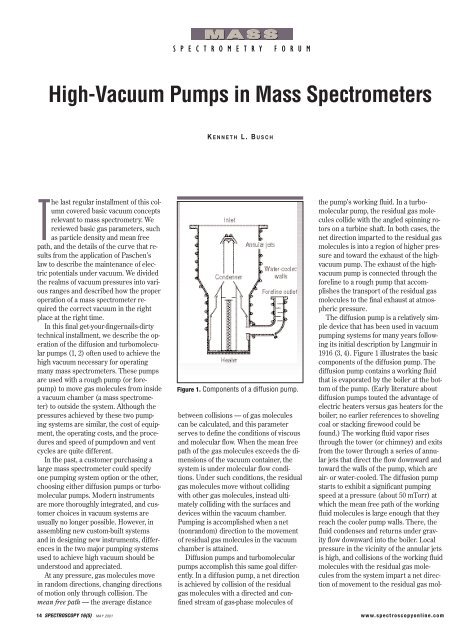

S P E C T R O M E T R Y F O R U M<strong>High</strong>-<strong>Vacuum</strong> <strong>Pumps</strong> <strong>in</strong> <strong>Mass</strong> <strong>Spectrometers</strong>K ENNETHL. BUSCHThe last regular <strong>in</strong>stallment of this columncovered basic vacuum conceptsrelevant to mass spectrometry. Wereviewed basic gas parameters, suchas particle density and mean freepath, and the details of the curve that resultsfrom the application of Paschen’slaw to describe the ma<strong>in</strong>tenance of electricpotentials under vacuum. We dividedthe realms of vacuum pressures <strong>in</strong>to variousranges and described how the properoperation of a mass spectrometer requiredthe correct vacuum <strong>in</strong> the rightplace at the right time.In this f<strong>in</strong>al get-your-f<strong>in</strong>gernails-dirtytechnical <strong>in</strong>stallment, we describe the operationof the diffusion and turbomolecularpumps (1, 2) often used to achieve thehigh vacuum necessary for operat<strong>in</strong>gmany mass spectrometers. These pumpsare used with a rough pump (or forepump)to move gas molecules from <strong>in</strong>sidea vacuum chamber (a mass spectrometer)to outside the system. Although thepressures achieved by these two pump<strong>in</strong>gsystems are similar, the cost of equipment,the operat<strong>in</strong>g costs, and the proceduresand speed of pumpdown and ventcycles are quite different.In the past, a customer purchas<strong>in</strong>g alarge mass spectrometer could specifyone pump<strong>in</strong>g system option or the other,choos<strong>in</strong>g either diffusion pumps or turbomolecularpumps. Modern <strong>in</strong>strumentsare more thoroughly <strong>in</strong>tegrated, and customerchoices <strong>in</strong> vacuum systems areusually no longer possible. However, <strong>in</strong>assembl<strong>in</strong>g new custom-built systemsand <strong>in</strong> design<strong>in</strong>g new <strong>in</strong>struments, differences<strong>in</strong> the two major pump<strong>in</strong>g systemsused to achieve high vacuum should beunderstood and appreciated.At any pressure, gas molecules move<strong>in</strong> random directions, chang<strong>in</strong>g directionsof motion only through collision. Themean free path — the average distanceFigure 1. Components of a diffusion pump.between collisions — of gas moleculescan be calculated, and this parameterserves to def<strong>in</strong>e the conditions of viscousand molecular flow. When the mean freepath of the gas molecules exceeds the dimensionsof the vacuum conta<strong>in</strong>er, thesystem is under molecular flow conditions.Under such conditions, the residualgas molecules move without collid<strong>in</strong>gwith other gas molecules, <strong>in</strong>stead ultimatelycollid<strong>in</strong>g with the surfaces anddevices with<strong>in</strong> the vacuum chamber.Pump<strong>in</strong>g is accomplished when a net(nonrandom) direction to the movementof residual gas molecules <strong>in</strong> the vacuumchamber is atta<strong>in</strong>ed.Diffusion pumps and turbomolecularpumps accomplish this same goal differently.In a diffusion pump, a net directionis achieved by collision of the residualgas molecules with a directed and conf<strong>in</strong>edstream of gas-phase molecules ofthe pump’s work<strong>in</strong>g fluid. In a turbomolecularpump, the residual gas moleculescollide with the angled sp<strong>in</strong>n<strong>in</strong>g rotorson a turb<strong>in</strong>e shaft. In both cases, thenet direction imparted to the residual gasmolecules is <strong>in</strong>to a region of higher pressureand toward the exhaust of the highvacuumpump. The exhaust of the highvacuumpump is connected through theforel<strong>in</strong>e to a rough pump that accomplishesthe transport of the residual gasmolecules to the f<strong>in</strong>al exhaust at atmosphericpressure.The diffusion pump is a relatively simpledevice that has been used <strong>in</strong> vacuumpump<strong>in</strong>g systems for many years follow<strong>in</strong>gits <strong>in</strong>itial description by Langmuir <strong>in</strong>1916 (3, 4). Figure 1 illustrates the basiccomponents of the diffusion pump. Thediffusion pump conta<strong>in</strong>s a work<strong>in</strong>g fluidthat is evaporated by the boiler at the bottomof the pump. (Early literature aboutdiffusion pumps touted the advantage ofelectric heaters versus gas heaters for theboiler; no earlier references to shovel<strong>in</strong>gcoal or stack<strong>in</strong>g firewood could befound.) The work<strong>in</strong>g fluid vapor risesthrough the tower (or chimney) and exitsfrom the tower through a series of annularjets that direct the flow downward andtoward the walls of the pump, which areair- or water-cooled. The diffusion pumpstarts to exhibit a significant pump<strong>in</strong>gspeed at a pressure (about 50 mTorr) atwhich the mean free path of the work<strong>in</strong>gfluid molecules is large enough that theyreach the cooler pump walls. There, thefluid condenses and returns under gravityflow downward <strong>in</strong>to the boiler. Localpressure <strong>in</strong> the vic<strong>in</strong>ity of the annular jetsis high, and collisions of the work<strong>in</strong>g fluidmolecules with the residual gas moleculesfrom the system impart a net directionof movement to the residual gas mol-14 SPECTROSCOPY 16(5) MAY 2001 www.spectroscopyonl<strong>in</strong>e.com

............................. MASS SPECTROMETRY FORUM .............................Figure 2. Components of a turbomolecularpump.ecules. Repeated collisions move theresidual gas molecules toward the regionof higher pressure at the bottom of thediffusion pump. At the ejector jet, thepressure (300–500 mTorr) is such thatthe rough pump attached to the forel<strong>in</strong>ecan capture and exhaust the residual gasmolecules to the atmosphere.The work<strong>in</strong>g fluid used <strong>in</strong> diffusionpumps is a low-vapor-pressure hydrocarbonfluid such as Octoil, Convoil, or Santovac5 (all proprietary product names),or a silicone oil fluid such as DC 702, DC704, or DC 705 (also proprietary). Therequisite characteristics of the work<strong>in</strong>gfluid are an appropriate vapor pressureand chemical <strong>in</strong>ertness. The ultimate vacuumpressure atta<strong>in</strong>able with a diffusionpump is directly related to the vapor pressureof the work<strong>in</strong>g fluid; the lower thevapor pressure, the lower the ultimatevacuum. Of course, a lower vapor pressuremeans that a higher boiler temperatureis needed to evaporate the fluid andachieve a pump<strong>in</strong>g action.The chemical <strong>in</strong>ertness is important ongeneral pr<strong>in</strong>ciples, but also especiallydur<strong>in</strong>g the vent and pumpdown cyclesequences, and especially if the propersequences are not followed (5).Hydrocarbon-based oils will crack and oxidizeto tar if exposed to air when hot.The resultant tar coat<strong>in</strong>g the boiler of adiffusion pump and clogg<strong>in</strong>g the annularjets is difficult to remove. An abused silicone-basedoil will crystallize <strong>in</strong> theboiler; the crystals are strik<strong>in</strong>g <strong>in</strong> appearance,but the residue is often impossibleto remove, and the entire pump may needto be replaced.Backstream<strong>in</strong>g is a term that refers tothe migration of work<strong>in</strong>g fluid out of thediffusion pump <strong>in</strong>to the ma<strong>in</strong> vacuumchamber. Backstream<strong>in</strong>g occurs whenthe operat<strong>in</strong>g pressure of the diffusionpump is too high, and the net downwardmotion of the work<strong>in</strong>g fluid moleculescannot be reta<strong>in</strong>ed. The gas molecule motionsbecome randomized, and the work<strong>in</strong>gfluid molecules diffuse back <strong>in</strong>to thema<strong>in</strong> vacuum chamber, coat<strong>in</strong>g the relativelycool metal surfaces that they eventuallyencounter. A vacuum systemdisassembled for <strong>in</strong>spection will often exhibita th<strong>in</strong>, greasy-look<strong>in</strong>g film on <strong>in</strong>teriormetal surfaces; this is the result ofbackstream<strong>in</strong>g of a hydrocarbon-basedwork<strong>in</strong>g fluid. Backstream<strong>in</strong>g occurs to asmall degree even <strong>in</strong> normal operationbut is m<strong>in</strong>imized by the use of cold capsor cold traps.The aftermath of a vacuum accident —the un<strong>in</strong>tentional or too-rapid vent<strong>in</strong>g of a“hot” system — will be a thorough dispersalof work<strong>in</strong>g fluid throughout the massspectrometer, and therefore the need fora lengthy, <strong>in</strong>volved, and complete clean<strong>in</strong>gand parts replacement, <strong>in</strong> addition toa rejuvenation of the diffusion pump itself.The proper vent cycle <strong>in</strong>cludes acooldown for the diffusion pump oil beforevent<strong>in</strong>g (30–60 m<strong>in</strong>). A warm-uptime is also required dur<strong>in</strong>g the pumpdowncycle for the system to reach itsfull pump<strong>in</strong>g speed. The ability ofturbomolecular-pumped systems to cyclefrom atmosphere to work<strong>in</strong>g vacuum <strong>in</strong> ashorter time is an advantage <strong>in</strong> some situations,but the <strong>in</strong>itial cost of a diffusionpumpedsystem is lower. Costs of electricityand cool<strong>in</strong>g water required fordiffusion pump operation also have to befigured <strong>in</strong>to a cost-based decision betweenthe two approaches to achiev<strong>in</strong>ghigh vacuum.The turbomolecular pump must alsoimpose a net directional motion to theresidual gas molecules <strong>in</strong> the vacuum system.The turbomolecular pump does soby repeated collisions of the residual gasmolecules with rotat<strong>in</strong>g blades of a turb<strong>in</strong>erotor (Figure 2). The blades of therotor sp<strong>in</strong> at speeds of 20,000–50,000rpm; the edge speed of the rotors approachesthe velocities of the residual gasmolecules themselves. When a collisionoccurs, a direction is imparted to the motionof the residual gas molecules towarda region of higher pressure and towardthe pump exhaust (aga<strong>in</strong>, a rough pumpoperat<strong>in</strong>g on the forel<strong>in</strong>e).There are several stages of sp<strong>in</strong>n<strong>in</strong>grotors, with the angles of the rotor bladeschang<strong>in</strong>g along the profile of the pumpfrom <strong>in</strong>let to exhaust, as shown <strong>in</strong> Figure2. Residual gas-phase molecules aremoved toward the exhaust and then areremoved from the forel<strong>in</strong>e by the roughpump. <strong>High</strong>er molecular mass gas moleculesare pumped more efficiently by theturbomolecular pump than lower molecularmass molecules; therefore, there isvery little backstream<strong>in</strong>g of lubrication oilmolecules <strong>in</strong>to the ma<strong>in</strong> vacuum chamber.The turbomolecular pump has thecharacteristic of be<strong>in</strong>g a clean pump<strong>in</strong>gsystem with no backstream<strong>in</strong>g.Clearly there is no heater to warm upor cool down <strong>in</strong> a turbomolecular pump.A system so pumped can be vented to atmosphereand then pumped down morequickly than can a diffusion-pumped system(m<strong>in</strong>us the use of isolation gatevalves <strong>in</strong> the latter, which decrease the effectivepump<strong>in</strong>g speed). Diffusion pumpsmust be mounted at the bottom of a vacuumchamber, and <strong>in</strong> a vertical orientationso that gravity can return the condensedwork<strong>in</strong>g fluid to the boiler. Aturbomolecular pump can be mounted <strong>in</strong>any orientation relative to the vacuumchamber. There is residual vibration froma turbomolecular pump, so the mount<strong>in</strong>gsystem often <strong>in</strong>cludes an <strong>in</strong>tegral vibrationisolation device. F<strong>in</strong>ally, although thepump<strong>in</strong>g speed is not as high as with diffusionpumps, the smaller size of the turbomolecularpump is often an advantage<strong>in</strong> today’s smaller mass spectrometers,and there is no need for a cool<strong>in</strong>g waterconnection.<strong>Mass</strong> spectrometrists seem to pay lessattention to vacuum-related issues todaythan <strong>in</strong> the past. <strong>High</strong> vacuum has becomeeasier to atta<strong>in</strong>, pumps are more reliable,and pump<strong>in</strong>g systems are moreautomated. In vacuum, as with so muchelse, the modern mass spectrometrist exhibitsthe habit of deferr<strong>in</strong>g or ignor<strong>in</strong>gma<strong>in</strong>tenance. And, as with much else,there is an ultimate cost to be paid for sodo<strong>in</strong>g. In a mass spectrometer, the cost isdecreased performance <strong>in</strong> terms of lowersensitivity or lower resolution; mass spectrathat deviate from those measured andarchived under more ideal conditions;and shorter lifetimes for replaceableitems such as electron multipliers, ionizationgauges, and source filaments. Therough pump has the f<strong>in</strong>al task of exhaust-16 SPECTROSCOPY 16(5) MAY 2001 www.spectroscopyonl<strong>in</strong>e.com

............................. MASS SPECTROMETRY FORUM .............................<strong>in</strong>g the gas molecules to atmosphere, andma<strong>in</strong>tenance of the rough pump is probablymost important.Rough pump ma<strong>in</strong>tenance <strong>in</strong>volveschang<strong>in</strong>g the rough-pump oil on schedule,check<strong>in</strong>g and replac<strong>in</strong>g the sealswhen necessary, manag<strong>in</strong>g the heat generatedby these pumps, and regularly <strong>in</strong>spect<strong>in</strong>gvacuum hoses and clamps. Buthigh-vacuum diffusion and turbomolecularpumps also require ma<strong>in</strong>tenance. Internalma<strong>in</strong>tenance requirements are described<strong>in</strong> the operators’ manuals and<strong>in</strong>structions; these requirements may <strong>in</strong>volvecheck<strong>in</strong>g the pump oil properties <strong>in</strong>a diffusion pump, or seals and rotor ma<strong>in</strong>tenanceprocedures <strong>in</strong> a turbomolecularpump. Diffusion pumps generate a greatdeal of heat; the pump may be air cooled,<strong>in</strong> which case the fan and ductwork mustbe kept clean. If the diffusion pump iswater- or fluid cooled, there is more to bedone. A closed-loop chiller will engenderits own specific ma<strong>in</strong>tenance requirements,<strong>in</strong>clud<strong>in</strong>g regular checks of thethermal trips that shut down the systemwhen there is a loss of chill<strong>in</strong>g capacity. Atap water–cooled diffusion pump systemwill <strong>in</strong>clude an <strong>in</strong>-l<strong>in</strong>e filter that requiresregular replacement. If you dr<strong>in</strong>k tap water,don’t look too closely at the filter orth<strong>in</strong>k too deeply about why monthly filterreplacement is needed. Check the <strong>in</strong>tegrityof the water connections on a regularbasis. A flooded laboratory is not apleasant way to beg<strong>in</strong> one’s morn<strong>in</strong>g,mop <strong>in</strong> hand, with abject apologies to colleagueson the floor beneath yet to bemade.REFERENCES(1) G. Lew<strong>in</strong>, An Elementary Introduction to<strong>Vacuum</strong> Technique (American <strong>Vacuum</strong>Society, New York, 1987).(2) N. Harris, Modern <strong>Vacuum</strong> Practice (Mc-Graw-Hill, New York, 1989).(3) M. Hablanian, Diffusion Pump Performanceand Operation (American <strong>Vacuum</strong>Society, New York, 1983).(4) Web site: http://web2.thesphere.com/SAS/SciAm/1996/<strong>Vacuum</strong>/<strong>Vacuum</strong>3.html.(5) Web site: http://www.ee.ualberta.ca/~schmaus/vacf/vacsys.html.Kenneth L. Busch is associate dean of SponsoredPrograms and a professor of chemistryat Kennesaw State University (Kennesaw,Georgia). He can be reached bye-mail at kbusch@kennesaw.edu. He hasspent a few morn<strong>in</strong>gs <strong>in</strong> the laboratorywith mop <strong>in</strong> hand, reflect<strong>in</strong>g on why waterconnections on diffusion pumps alwaysseem to fail at 3:00 A.M. local time, regardlessof the actual geophysical location of thelab. Retentive <strong>in</strong> nature, he has kept a 25-year observation log of diffusion-pumpcool<strong>in</strong>g-water connections, not<strong>in</strong>g that approximately15% of home-built systems areplumbed <strong>in</strong> reverse. The coldest water directlyfrom the tap should enter at the highvacuumtop of the diffusion pump. Late atnight, he wonders who first came up withthe term “guppy pump” and whether theworld would be a better place if mass spectrometristsheld all positions of power and<strong>in</strong>fluence. ◆Circle 1818 SPECTROSCOPY 16(5) MAY 2001 www.spectroscopyonl<strong>in</strong>e.com