K27100 Ramsbottom Carbon Residue Apparatus & Data ... - Labequip

K27100 Ramsbottom Carbon Residue Apparatus & Data ... - Labequip

K27100 Ramsbottom Carbon Residue Apparatus & Data ... - Labequip

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

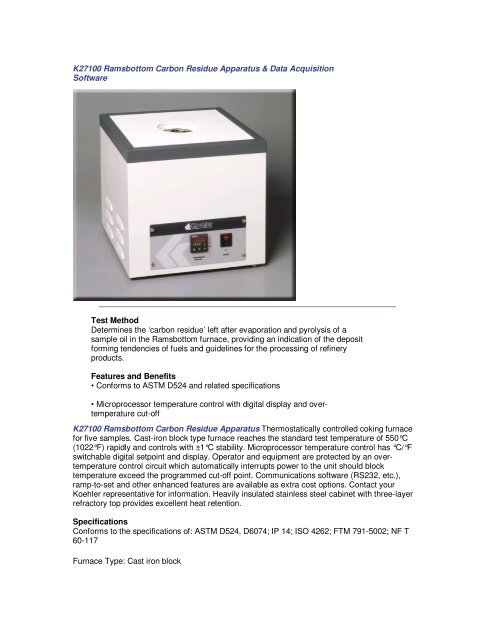

<strong>K27100</strong> <strong>Ramsbottom</strong> <strong>Carbon</strong> <strong>Residue</strong> <strong>Apparatus</strong> & <strong>Data</strong> AcquisitionSoftwareTest MethodDetermines the ‘carbon residue’ left after evaporation and pyrolysis of asample oil in the <strong>Ramsbottom</strong> furnace, providing an indication of the depositforming tendencies of fuels and guidelines for the processing of refineryproducts.Features and Benefits• Conforms to ASTM D524 and related specifications• Microprocessor temperature control with digital display and overtemperaturecut-off<strong>K27100</strong> <strong>Ramsbottom</strong> <strong>Carbon</strong> <strong>Residue</strong> <strong>Apparatus</strong> Thermostatically controlled coking furnacefor five samples. Cast-iron block type furnace reaches the standard test temperature of 550°C(1022°F) rapidly and controls with ±1°C stability. Microprocessor temperature control has °C/°Fswitchable digital setpoint and display. Operator and equipment are protected by an overtemperaturecontrol circuit which automatically interrupts power to the unit should blocktemperature exceed the programmed cut-off point. Communications software (RS232, etc.),ramp-to-set and other enhanced features are available as extra cost options. Contact yourKoehler representative for information. Heavily insulated stainless steel cabinet with three-layerrefractory top provides excellent heat retention.SpecificationsConforms to the specifications of: ASTM D524, D6074; IP 14; ISO 4262; FTM 791-5002; NF T60-117Furnace Type: Cast iron block

Capacity: 5 coking bulbsMaximum Temperature: 650°C (1200°F)Controller Sensitivity: ±1°C (± 2°F)Heater: 0-2400W, ceramic band heaterElectrical Requirements115V, 50/60Hz, Single Phase, 20.8A220-240V, 50/60Hz, Single Phase, 10.9A<strong>K27100</strong>-SFW <strong>Ramsbottom</strong> Software <strong>Ramsbottom</strong> Software retrieves temperature data andautomatically performs calculations of carbon residue or carbon residue on 10% distillate as perASTM D524 in real-time. Direct communication with the Koehler analytical balance eliminatesweighing errors and provides hands-free data acquisition. The sophisticated Windows®-basedsoftware package features an easy-to-navigate operation, a straightforward user interface,minimal draw on Windows® memory resources, automatic real-time data acquisition via RS232connection, and a timer / stopwatch feature for general laboratory use. The "test intelligent"software simplifies the testing process by providing sequential test prompts for assisting theoperator with each step of the test procedure. The active zoom, pan, and trace feature allows theability to change axes and the magnification of any sector of the pressure or temperature graphsto view data in greater detail. The final test data is exported with graphs and test parameterseither directly to Microsoft® Excel, in ASCII file format for use with LIMS or any other spreadsheetprograms, or directly to a printer with a test report according to ISO guidelines. Test data is savedin a database format for determining test averages, standard deviations, and ASTM testrepeatability. The software package requires no PC hardware installation and includes thesoftware installation CD and computer connection cables.Computer RequirementsPC Processor: Intel® Pentium II or similar (minimum)Processor Speed: 500 MHz or higherOperating System: Windows ® 98 SE, 2000, NT, ME, XPMemory (RAM): 64 Mb RAM (128 Mb RAM recommended)Hard Disk Space: 15 Mb free space (minimum)Communication Ports: one or two RS232 portsOther Software: Microsoft ® Excel (97 or above)AccessoriesCatalogNumber332-007-001362-010-001382-018-001K27320K27200Product DescriptionCoking BulbPyrex, with capillaryConforms to ASTM D524 specificationsSample Charging SyringeNeedle, 18 gauge, 2"Coking Bulb Filling DeviceConvenient time saving device fills up to five coking bulbs at a time. Ideal for viscousfluids that are difficult to handle at room temperature.Control BulbStainless steel, with IC thermocouple.

May be used with a thermocouple pyrometer* to verify compliance of the furnace withASTM performance requirements.K29310 Digital Thermometer, 115VK29319 Digital Thermometer, 220-240V