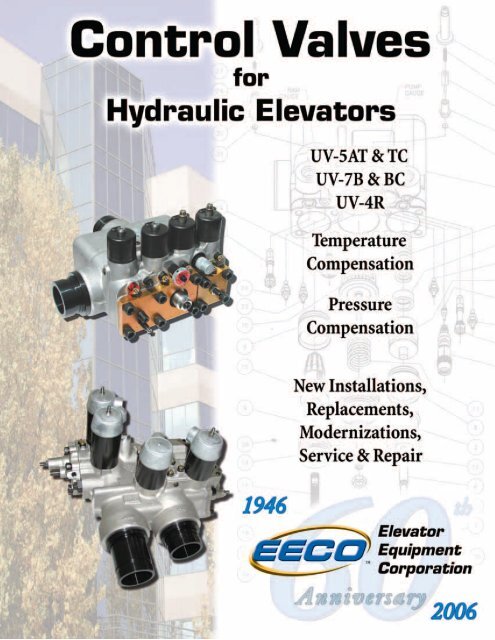

EECO Valve - elevator controls elevator drives

EECO Valve - elevator controls elevator drives

EECO Valve - elevator controls elevator drives

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comHydraulic Elevator Control <strong>Valve</strong> CatalogueFor valve sales & technical support call: (888) 577-<strong>EECO</strong> (3326)Revised 10-26-06Note: This revision supersedes all previous revisions of this document.Please Note:The following solenoid and adjuster designations were changed forsimplification on all <strong>EECO</strong> valves since August 2003:Solenoids:U1 - Up Fast (Red wires) - (was ULS)U2 - Up Slow (Yellow wires) - (was UDS)D1 - Down Fast (Black wires) - (was DMS)D2 - Down Slow (Blue wires) - (was DLS)Adjuster:US - Up Stop- (was UD)These changes are reflected in this revision of the catalogue.The following abbreviations are also used in this catalogue:CW = Clockwise (IN) CCW = Counter Clockwise (OUT) Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 1

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comElevator Equipment CorporationEquipment WarrantyElevator Equipment Corporation products carry a ONE YEAR limitedwarranty (control valves carry a TWO YEAR limited warranty) from thedate of shipment from our plant against any manufacturing defects inmaterial and workmanship which develop in service for which they wereintended or recommended. Any material which is returned to our plant withtransportation charges PREPAID, and which after our inspection is foundto be defective will be, at our discretion, either repaired or replaced free ofcharge. Call <strong>EECO</strong> Sales for details.WE WILL NOT sustain any claim for consequential damages, loss oftime or labor charges, or expense in making repairs or adjustments. Ourliability is limited to defective material or defective repairs made in ourplant in Los Angeles, California, or Richmond, Indiana.Conditions Of SaleAll technical advice and recommendations are furnished by the sellergratis, and are believed by the seller to be reliable. They are intended foruse by persons having skill and know how, at their own risk. Sellerassumes NO responsibility for damages incurred from use by buyer.From and after the date of shipment, the buyer assumes all liability andexpense because of injury, sickness or death sustained by any person, ordamage to or destruction of property arising from the use of the equipmentsold hereunder.Main Office, 4035 Goodwin Avenue, P. O. Box 39714, Los Angeles, California 90039Indiana Facility, 2230 N. W. 12th Street, Box 1544, Richmond, Indiana, 47374 ! P. O. Box 1544, Richmond, Indiana 47375<strong>Valve</strong> Sales & Technical Support: (888) 577-<strong>EECO</strong> (8:00 AM Eastern to 4:30 PM Pacific Time)E-mail: sales@eeco-mail.com - Visit us on the internet at: www.<strong>elevator</strong>equipment.com & www.eecovalves.comPage 2 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comIndexTopicPageWarranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . .2About <strong>EECO</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .5<strong>Valve</strong> Exchange & Rebuild Programs . . . . . . . . . . . . . .6<strong>Valve</strong> SizingHow To Size An <strong>EECO</strong> <strong>Valve</strong> . . . . . . . . . . . . . . . . .7Table 1A - Pressure (PSI) . . . . . . . . . . . . . . . . . . .8Table 1B - Pressure (BAR) . . . . . . . . . . . . . . . . . .9Table 2A - Flow Rate (Gallons per Minute) . . . . .10Table 2B - Flow Rate (Liter per Minute) . . . . . . . .11Table 3 - Piston Data . . . . . . . . . . . . . . . . . . . . .12UV-5AT Sizing Chart . . . . . . . . . . . . . . . . . . . . . .13UV-5ATC Sizing Chart . . . . . . . . . . . . . . . . . . . . .14UV-7B Sizing Chart . . . . . . . . . . . . . . . . . . . . . . .15UV-7BC Sizing Chart . . . . . . . . . . . . . . . . . . . . . .16<strong>EECO</strong> Control <strong>Valve</strong>s General InformationUV-5AT & TC <strong>Valve</strong> . . . . . . . . . . . . . . . . . . . . . . .17UV-5AT & TCRequest For Quote & Order Form . .18UV-7B & BC <strong>Valve</strong> . . . . . . . . . . . . . . . . . . . . . . .19UV-7B & BC Request For Quote & Order Form . .20UV-4R <strong>Valve</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . .21<strong>Valve</strong> AdjustingUV-5AT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23UV-5ATC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25UV-7B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27UV-7BC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29UV-4R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31TopicPage<strong>EECO</strong> <strong>Valve</strong> Replacement Parts, Kits & UpgradesUV-5A, UV-5AT & UV-5ATCBypass V-Guides . . . . . . . . . . . . . . . . . . . . . .52Down V-Guides . . . . . . . . . . . . . . . . . . . . . . .53Check Poppet V-Guides . . . . . . . . . . . . . . . . .54Viton Seal Kit . . . . . . . . . . . . . . . . . . . . . . . .55Viton Seal Kit O-Rings . . . . . . . . . . . . . . . . . .58Solenoid Kit . . . . . . . . . . . . . . . . . . . . . . . . .59Down Piston Replacement Kit . . . . . . . . . . . .60Bypass Piston & Spring Replacement Kit . . . .61Temperature Compensation Upgrade Kit . . . .62Pressure Compensation Upgrade Kit . . . . . . .63UV-7B & UV-7BCBypass Piston Assembly . . . . . . . . . . . . . . . .64Down Piston Assembly . . . . . . . . . . . . . . . . .64Viton Seal Kit . . . . . . . . . . . . . . . . . . . . . . . .65Viton Seal Kit O-Rings . . . . . . . . . . . . . . . . . .67Solenoid Kit . . . . . . . . . . . . . . . . . . . . . . . . .68Pressure Compensation Upgrade Kit . . . . . . .69<strong>EECO</strong> <strong>Valve</strong> OptionsSolenoid Coils . . . . . . . . . . . . . . . . . . . . . . . .70Low Pressure Switch . . . . . . . . . . . . . . . . . .71UV-5AT & TC Right Hand Jack PortAdapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72UV-5AT & TC Roped Application Options . . . .72<strong>EECO</strong> Elevator ComponentsMore Great Products from <strong>EECO</strong> . . . . .73 to 77<strong>Valve</strong> Technical InformationUV-5AT & TC <strong>Valve</strong> Dimensions . . . . . . . . . . . . .33UV-5AT & TC <strong>Valve</strong> Schematic . . . . . . . . . . . . . .34UV-7B & BC <strong>Valve</strong> Dimensions . . . . . . . . . . . . . .35UV-7B & BC <strong>Valve</strong> Schematic . . . . . . . . . . . . . . .36<strong>EECO</strong> <strong>Valve</strong> Troubleshooting Guide . . . . . . . . . . . . . . .37<strong>EECO</strong> <strong>Valve</strong> Exploded Views & Parts ListsUV-5AT Internal Parts . . . . . . . . . . . . . . . . . . . . .40UV-5ATC Internal Parts . . . . . . . . . . . . . . . . . . . .42UV-5AT & TC External Parts . . . . . . . . . . . . . . . .44UV-7B Internal Parts . . . . . . . . . . . . . . . . . . . . . .46UV-7BC Internal Parts . . . . . . . . . . . . . . . . . . . .40UV-7B & BC External Parts . . . . . . . . . . . . . . . . .50For valve technical support call: (888) 577-<strong>EECO</strong>Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 3

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comAboutElevator Equipment Corporation (<strong>EECO</strong>) was founded in1946 by Mr. Alvin Conley, who manufactured and sold singlefunction valves, jacks, power units, switches, and other componentsused in the installation of hydraulic <strong>elevator</strong>s.The industry standard UV-5AT/TC and UV-7B/BChydraulic control valves are manufactured and assembled atour original plant in California, where jack units, hatchwayswitches, car slings and platforms as well as other hydraulic<strong>elevator</strong> components are produced.Our commitment to innovative technology and customersupport is second to none. <strong>EECO</strong> is a long time supplier memberof both the U.S. NAEC and the Canadian CECA associations.Most <strong>EECO</strong> products are certified by both UL and CSAorganizations.Since its beginning in Los Angeles, California, <strong>EECO</strong> hasexpanded into facilities in Richmond, Indiana, where jacks,power units, car slings and platforms, and other mechanicaland structural items are also manufactured in our modernhigh production plants.<strong>EECO</strong> is pleased to list all major <strong>elevator</strong> companies ascustomers. <strong>EECO</strong> valves and jack units have been furnished tothese companies for installation in projects throughout theU.S. and Canada and in many European, South American,Asian and other foreign countries. The list of companies andfacilities that we have been privileged to work with is extensive.<strong>EECO</strong>’s engineering, management and research staff ishighly trained, with individuals who have many years experiencein the manufacture and design of hydraulic <strong>elevator</strong>equipment. A number of these individuals hold undergraduateand advanced degrees in their field, including registered professionalengineers.<strong>EECO</strong> Elevator Products are designed and manufacturedmainly for hydraulic <strong>elevator</strong>s. These products include individualcomponents to complete <strong>elevator</strong> systems.Having served the <strong>elevator</strong> industry since 1946, <strong>EECO</strong>continues to supply quality hydraulic <strong>elevator</strong> products thatare designed and manufactured in the USA. In addition, <strong>EECO</strong>continues to improve its products and expand its facilities tobetter server its customers needs. <strong>EECO</strong> now offers its customersaccess to product information and company news 24hours a day, seven days a week via its internet web sites at:www.<strong>elevator</strong>equipment.com and www.eecovalves.com.Page 4 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.com<strong>EECO</strong> Contact InformationCall toll free:(888) 577-3326NOTE: <strong>Valve</strong> technical support is available Monday through Friday (except holidays)between the hours of 8:00 AM Eastern time and 4:30 PM Pacific time.<strong>Valve</strong> Technical Support:Peter Aguirre, Ext. 128Don Brown, Ext. 145Benny Vazquez, Ext. 124Abe Salehpour, Ext. 141Extended Hours <strong>Valve</strong> Support:**at (800) 428-6564 (Richmond, IN)George Brown, Ext. 220Gale Huntsman, Ext. 229Quality Control:Los Angeles - Mike Young, Ext. 129Richmond, IN - Jim Snyder, Ext. 230*<strong>Valve</strong> Sales:Los Angeles - Peter Aguirre, Ext. 128Richmond, IN - George Brown, Ext. 220**At (800) 428-6564 **Before 8:00 AM Pacific Time.Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 5

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.com<strong>Valve</strong> Exchange & Rebuild ProgramsThe “<strong>EECO</strong> Exchange Program”Elevator Equipment Corporation has developed the <strong>EECO</strong> Exchange, to provide our customers a convenient alternative tosending their <strong>EECO</strong> valves into <strong>EECO</strong> to be rebuilt, which can cause unacceptable delays at the job site. The <strong>EECO</strong> Exchangeoffers an immediate, and economical alternative that allows our customers to receive a rebuilt valve, with a two-year limitedwarranty. <strong>EECO</strong> rebuilt valves come with all new internal parts, including the latest features now available on our standardvalves.HOW IT WORKSThe customer orders a rebuilt valve through the <strong>EECO</strong> Exchange. The <strong>EECO</strong> Exchange rebuilt valve can usually be shipped tothe customer within one business day, subject to availability. The customer must then return the old, undamaged, valve that isbeing replaced to <strong>EECO</strong> Los Angeles within fifteen (15) business days (see below). Please retain your original coils as <strong>EECO</strong>rebuilt valves are not furnished with coils. If you need new coils please advise <strong>EECO</strong> Sales at the time of order.NECESSARY INFORMATIONPrior to ordering a rebuilt valve through the <strong>EECO</strong> Exchange, the customer needs to have the following information ready:• Old valve serial number (Required)• <strong>Valve</strong> type (i.e. UV-5A, UV-5AT, UV-5ATC, UV-7B or UV-7BC)• Line connections for UV-5A, T & TC = 2” NPT or 2” Grooved; UV-7B & UV-7BC = 2.5” NPT or 2.5” GroovedUpon placing the order, and after the serial number is verified, the usual information will be required including a purchaseorder number, “ship to” address, and the method of shipment. Customers will not be able to exchange one valve model for acompletely different model. For example, a UV-5AT valve will only be exchanged for a UV-5AT valve, not for a UV-7B valve.<strong>EECO</strong> will then provide the customer with an Exchange Material Authorization (EMA) number. It is very important that theEMA number be included on the outside label and on all the documentation included with the valve being returned to <strong>EECO</strong>. Theold valve must be received at <strong>EECO</strong>'s Los Angeles facility NO LATER than fifteen (15) business days from the ship date of therebuilt valve. The customer will be invoiced for a “core valve body” if <strong>EECO</strong> does not receive the old valve within 15 days or if itis determined that it is damaged (at <strong>EECO</strong>’s discretion) in any way and cannot be reused. In addition, if the valve is returned late(or not returned at all), the customer will no longer be eligible to purchase a future <strong>EECO</strong> Exchange rebuilt valve. Please scheduleshipment of the old valve prior to ordering the exchange valve to prevent late returns.The <strong>EECO</strong> “<strong>Valve</strong> Rebuild Program”<strong>EECO</strong> also offers our customers a <strong>Valve</strong> Rebuild Program (VRP) through the <strong>EECO</strong> Factory Service Center. Customersneeding their valves rebuilt, should contact the <strong>EECO</strong> Sales Department for an RMA (Return Material Authorization) number.Please allow at least ten (10) business days for the valve to be checked, rebuilt, and tested before it can be shipped back. If afaster turnaround is required, you may wish to consider the <strong>EECO</strong> Exchange program mentioned above. The rebuild programonly includes the cleaning of the valve and replacement of the adjusters, seals and solenoid components. If, upon inspection by<strong>EECO</strong>, it is determined that other major components of the valve must be replaced or the valve has missing components, thecustomer will be contacted and additional charges will apply. All <strong>EECO</strong> rebuilt valves carry a two year limited warranty.NOTE: All older <strong>EECO</strong> brass valves and F series unit valves are exempt from the <strong>EECO</strong> Exchange and Rebuild Programs.<strong>EECO</strong> no longer manufactures nor supports these valves.To order or to reach <strong>EECO</strong> valve technical support call:(888) 577-<strong>EECO</strong> (3326)Page 6 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

How To Size An <strong>EECO</strong> <strong>Valve</strong>4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comIf the flow rate is known, the valve can now be sized. However, ifthe flow rate is not known, the car speed and jack piston diameterare required. Table 2A (or 2B, metric), provided on pages 10 (or 11),can then be used to obtain the flow rate. The flow rate can also becalculated by multiplying the car speed by the displacement factorfor the specified piston diameter provided in Table 3 on page 12.As mentioned before, down contract speed is down speed with fullload on the car. Down speed with empty car is less than contractspeed depending on the ratio of full-load to no-load pressures(approximately 25% less for a two to one pressure ratio). If constantdown speed is required between no-load and full-load conditions,UV-5ATC or UV-7BC valves should be used. Again, statice pressureand flow rate are required to size the valve.Sizing An <strong>EECO</strong> <strong>Valve</strong>We encourage you to have <strong>EECO</strong> size your valve. This assuresproper valve sizing for your specific application. To have <strong>EECO</strong> sizeyour valve, please fill out the form on pages 18 (for the UV-5AT/TC)or page 42 (for the UV-7B/BC) and fax it to <strong>EECO</strong>.A major consideration for proper operation of a hydraulic <strong>elevator</strong>system is proper sizing of the control valve in that system. By valvesizing, we are only referring to the proper selection of the internalcomponents of the valve, not to the physical size of the valve or thesize of its ports.If down contract speed (full down speed with rated load on thecar) is the same as the up, then the size of the standard valve (eitherthe UV-5AT or UV-7B) is determined by the size of the bypass pistononly. Sizing of the bypass piston requires only static pressure andflow rate. Locating the intersection of static pressure and flow rateon the sizing charts provided in Figure 1 and Figure 3 (on pages 13and 15) provides the size of the valve. If Down contract speed isdifferent from the Up, please contact <strong>EECO</strong>.If the valve is for an existing installation, then the static pressurecan be read from a pressure gage installed in the jack (ram) gageport of the existing valve when the empty car is resting at the bottomlanding. However, if the valve is for a new installation or static pressurecan not be physically measured, then empty car weight (weightof everything above the platen plate plus 1/2 of the piston weight)and jack piston diameter are required. With this information on hand,you can then calculate the static pressure by dividing the empty carweight by the cross sectional area of the piston, or use Table 1A (or1B, metric), provided on pages 8 (or 9), to obtain the static pressure.Size the Up (bypass) section of the UV-5ATC by using the sizingchart in Figure 1 (page 13). Then size the Down section of the UV-5ATC by using the sizing chart in Figure 2 (page 14).Size the Up (bypass) section of the UV-7BC by using the sizingchart in Figure 3 (page 15). Then size the Down section of the UV-7BC by using the sizing chart in Figure 4 (page 16).Sometimes changes in the system specification would make itnecessary to modify the operating condition in the field. The changemay require the size of an existing valve to be changed at the job.This means that the bypass, check and down pistons may have to bereplaced. If the size of the valve is changed in the field, we recommendthat you indicate the new valve size on top of the valve. Thiswill prevent confusion when the valve is serviced in the future.UV-7B - shown withoptional 2.5” groovedconnections.If you still have questions on valve sizing, please call the<strong>EECO</strong> Sales or Technical Support Departmentsand we’ll help get you the right size valve for your application.(888) 577-<strong>EECO</strong>8:00 AM Eastern to 4:30 PM Pacific time, Monday through Friday, except holidaysCopyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 7

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comTable 1A - Pressure, PSI (for one jack)Piston Diameter (Inches)Load Above Piston - PoundsLoad Above Piston - Pounds2 2 1/2 2 3/4 3 3 7/16 3 1/2 3 7/8 4 4 3/8 4 1/2 5 5 7/16 5 1/2 6 6 1/2 7 7 1/2 8 8 1/2 9 1/2 10 5/8 12 5/8 13 7/8 15 7/81000 318 204 168 141 108 104 85 80 67 63 51 43 42 35 30 26 23 20 18 14 11 8 7 5 10001500 477 306 253 212 162 156 127 119 100 94 76 65 63 53 45 39 34 30 26 21 17 12 10 8 15002000 637 407 337 283 216 208 170 159 133 126 102 86 84 71 60 52 45 40 35 28 23 16 13 10 20002500 796 509 421 354 269 260 212 199 166 157 127 108 105 88 75 65 57 50 44 35 28 20 17 13 25003000 955 611 505 424 323 312 254 239 200 189 153 129 126 106 90 78 68 60 53 42 34 24 20 15 30003500 1114 713 589 495 377 364 297 279 233 220 178 151 147 124 105 91 79 70 62 49 39 28 23 18 35004000 815 673 566 431 416 339 318 266 252 204 172 168 141 121 104 91 80 70 56 45 32 26 20 40004500 917 758 637 485 468 382 358 299 283 229 194 189 159 136 117 102 90 79 63 51 36 30 23 45005000 1019 842 707 539 520 424 398 333 314 255 215 210 177 151 130 113 99 88 71 56 40 33 25 50005500 1120 926 778 593 572 466 438 366 346 280 237 231 195 166 143 124 109 97 78 62 44 36 28 55006000 1010 849 647 624 509 477 399 377 306 258 253 212 181 156 136 119 106 85 68 48 40 30 60006500 1094 920 700 676 551 517 432 409 331 280 274 230 196 169 147 129 115 92 73 52 43 33 65007000 990 754 728 594 557 466 440 357 301 295 248 211 182 158 139 123 99 79 56 46 35 70007500 1061 808 780 636 597 499 472 382 323 316 265 226 195 170 149 132 106 85 60 50 38 75008000 1132 862 832 678 637 532 503 407 345 337 283 241 208 181 159 141 113 90 64 53 40 80008500 916 883 721 676 565 534 433 366 358 301 256 221 192 169 150 120 96 68 56 43 85009000 970 935 763 716 599 566 458 388 379 318 271 234 204 179 159 127 102 72 60 45 90009500 1024 987 806 756 632 597 484 409 400 336 286 247 215 189 167 134 107 76 63 48 950010000 1078 1039 848 796 665 629 509 431 421 354 301 260 226 199 176 141 113 80 66 51 1000012000 1018 955 798 755 611 517 505 424 362 312 272 239 211 169 135 96 79 61 1200014000 1114 931 880 713 603 589 495 422 364 317 279 247 198 158 112 93 71 1400016000 1064 1006 815 689 673 566 482 416 362 318 282 226 180 128 106 81 1600018000 1132 917 775 758 637 542 468 407 358 317 254 203 144 119 91 1800020000 1019 861 842 707 603 520 453 398 352 282 226 160 132 101 2000025000 1077 1052 884 753 650 566 497 441 353 282 200 165 126 2500030000 1061 904 780 679 597 529 423 338 240 198 152 30000Pressure (psi) = Load (lbs.) / (.7854 x (piston diameter in inches) 2 )Page 8 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comTable 1B - Pressure, BAR (for one jack)Piston Diameter (Millimeters)Load Above Piston - Kilograms60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400200 6.9 3.9 2.5 1.7 1.3 1.0 0.8 0.6 0.5 0.4 0.4 0.3 0.3 0.2 0.2 0.2 0.2 0.2 200400 13.9 7.8 5.0 3.5 2.6 2.0 1.5 1.3 1.0 0.9 0.7 0.6 0.6 0.5 0.4 0.4 0.3 0.3 400600 20.8 11.7 7.5 5.2 3.8 2.9 2.3 1.9 1.5 1.3 1.1 1.0 0.8 0.7 0.6 0.6 0.5 0.5 600800 27.8 15.6 10.0 6.9 5.1 3.9 3.1 2.5 2.1 1.7 1.5 1.3 1.1 1.0 0.9 0.8 0.7 0.6 8001000 34.7 19.5 12.5 8.7 6.4 4.9 3.9 3.1 2.6 2.2 1.8 1.6 1.4 1.2 1.1 1.0 0.9 0.8 10001200 41.7 23.4 15.0 10.4 7.7 5.9 4.6 3.8 3.1 2.6 2.2 1.9 1.7 1.5 1.3 1.2 1.0 0.9 12001400 48.6 27.3 17.5 12.2 8.9 6.8 5.4 4.4 3.6 3.0 2.6 2.2 1.9 1.7 1.5 1.4 1.2 1.1 14001600 55.6 31.3 20.0 13.9 10.2 7.8 6.2 5.0 4.1 3.5 3.0 2.6 2.2 2.0 1.7 1.5 1.4 1.3 16001800 62.5 35.2 22.5 15.6 11.5 8.8 6.9 5.6 4.6 3.9 3.3 2.9 2.5 2.2 1.9 1.7 1.6 1.4 18002000 69.4 39.1 25.0 17.4 12.8 9.8 7.7 6.3 5.2 4.3 3.7 3.2 2.8 2.4 2.2 1.9 1.7 1.6 20002200 76.4 43.0 27.5 19.1 14.0 10.7 8.5 6.9 5.7 4.8 4.1 3.5 3.1 2.7 2.4 2.1 1.9 1.7 22002400 46.9 30.0 20.8 15.3 11.7 9.3 7.5 6.2 5.2 4.4 3.8 3.3 2.9 2.6 2.3 2.1 1.9 24002600 50.8 32.5 22.6 16.6 12.7 10.0 8.1 6.7 5.6 4.8 4.1 3.6 3.2 2.8 2.5 2.3 2.0 26002800 54.7 35.0 24.3 17.9 13.7 10.8 8.8 7.2 6.1 5.2 4.5 3.9 3.4 3.0 2.7 2.4 2.2 28003000 58.6 37.5 26.0 19.1 14.6 11.6 9.4 7.7 6.5 5.5 4.8 4.2 3.7 3.2 2.9 2.6 2.3 30003200 62.5 40.0 27.8 20.4 15.6 12.3 10.0 8.3 6.9 5.9 5.1 4.4 3.9 3.5 3.1 2.8 2.5 32003400 66.4 43.5 29.5 21.7 16.6 13.1 10.6 8.8 7.7 6.3 5.4 4.7 4.6 3.7 3.3 2.9 2.7 34003600 70.3 45.0 31.3 23.0 17.6 13.9 11.3 9.3 7.8 6.7 5.7 5.0 4.2 3.9 3.5 3.1 2.8 36003800 74.2 47.5 33.0 24.2 18.6 14.7 11.9 9.8 8.2 7.0 6.1 5.3 4.6 4.1 3.7 3.3 3.0 38004000 78.1 50.0 34.7 25.5 19.5 15.4 12.5 10.3 8.7 7.5 6.4 5.6 4.9 4.3 3.9 3.5 3.1 40004500 56.3 39.1 28.7 22.0 17.4 14.1 11.6 9.8 8.3 7.2 6.3 5.5 4.9 4.3 3.9 3.5 45005000 62.5 43.4 31.9 24.4 19.3 15.6 12.9 10.9 9.2 8.0 6.9 6.1 5.4 4.8 4.3 3.9 50005500 68.8 47.7 35.1 26.9 21.2 17.2 14.2 11.9 10.2 8.8 7.6 6.7 5.9 5.3 4.8 4.3 55006000 75.0 52.1 38.3 29.3 23.1 18.8 15.5 13.0 11.1 9.6 8.3 7.3 6.5 5.8 5.2 4.7 60007000 60.8 44.6 34.3 27.0 21.9 18.1 15.2 12.9 11.2 9.7 8.5 7.6 6.8 6.1 5.5 70008000 69.4 51.0 39.1 30.9 25.0 20.7 17.4 14.8 12.8 11.1 9.8 8.7 7.7 6.9 6.3 80009000 78.1 57.4 43.9 34.7 28.1 23.2 19.5 16.6 14.3 12.5 11.0 9.7 8.7 7.8 7.0 900010000 63.8 48.8 38.6 31.3 25.8 21.7 18.5 15.9 13.9 12.2 10.8 9.6 8.7 7.8 1000015000 73.2 57.9 46.9 38.7 32.6 27.7 23.9 20.8 18.3 16.2 14.5 13.0 11.7 1500020000 77.2 62.5 51.7 43.4 37.0 31.9 27.8 24.4 21.6 19.3 17.3 15.6 20000Load Above piston - KilogramsPressure (BAR) = Load (kg) / (.008 x (piston diameter in mm) 2 )Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 9

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comTable 2A - Flow Rate (gallons per minute, gpm)Car Speed - Feet Per Minute (fpm)10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 2002 2 3 5 7 8 10 11 13 15 16 18 20 21 23 24 26 28 29 31 332 1/2 3 5 8 10 13 15 18 20 23 25 28 31 33 36 38 41 43 46 48 512 3/4 3 6 9 12 15 19 22 25 28 31 34 37 40 43 46 49 52 56 59 623 4 7 11 15 18 22 26 29 33 37 40 44 48 51 55 59 62 66 70 733 7/16 5 10 14 19 24 29 34 39 43 48 53 58 63 67 72 77 82 87 92 963 1/2 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 1003 7/8 6 12 18 25 31 37 43 49 55 61 67 74 80 86 92 98 104 110 116 1234 7 13 20 26 33 39 46 52 59 65 72 78 85 91 98 104 111 117 124 131Jack Piston Diameter (Inches)4 3/8 8 16 23 31 39 47 55 62 70 78 86 94 102 109 117 125 133 141 148 1564 1/2 8 17 25 33 41 50 58 66 74 83 91 99 107 116 124 132 140 149 157 1655 10 20 31 41 51 61 71 82 92 102 112 122 133 143 153 163 173 184 194 2045 7/16 12 24 36 48 60 72 84 96 109 121 133 145 157 169 181 193 205 217 229 2415 1/2 12 25 37 49 62 74 86 99 111 123 136 148 160 173 185 197 210 222 234 2476 15 29 44 59 73 88 103 117 132 147 162 176 191 206 220 235 250 264 279 2946 1/2 17 34 52 69 86 103 121 138 155 172 190 207 224 241 259 276 293 310 327 3457 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 4007 1/2 23 46 69 92 115 138 161 184 207 229 252 275 298 321 344 367 390 413 436 4598 26 52 78 104 131 157 183 209 235 261 287 313 339 366 392 418 444 470 496 5228 1/2 29 59 88 118 147 177 206 236 265 295 324 354 383 413 442 472 501 531 560 5909 1/2 37 74 110 147 184 211 258 295 331 368 405 442 479 515 522 589 626 663 700 73610 5/8 46 92 138 184 230 276 322 368 415 461 507 533 599 645 691 737 783 829 875 92112 5/8 65 130 195 260 325 390 455 520 585 650 715 780 845 910 975 1040 1105 1170 1236 130113 7/8 79 157 236 314 393 471 550 628 707 785 864 942 1021 1100 1178 1257 1335 1414 1492 157115 7/8 103 206 308 411 514 617 720 823 925 1028 1131 1234 1337 1439 1542 1645 1748 1851 1953 205617 7/8 130 261 391 521 652 782 912 1043 1173 1304 1434 1564 1695 1825 1955 2086 2216 2346 2477 2607NOTE:Flow rate (gallons per minute, gpm) = car speed (feet per minute, fpm) x displacement (gallons per foot, gpf)Displacement (gallons per foot, gpf) = 0.0408 x (piston O. D. in inches) 2Page 10 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comTable 2B - Flow Rate (liter per minute, lpm)Car Speed - Meters Per Minute (Mpm)1 2 3 4 5 6 7 8 9 10 15 20 25 30 35 40 45 50 55 60 6560 3 6 10 13 16 19 22 25 29 32 48 63 79 95 111 127 143 158 174 190 20680 4 8 12 15 19 23 27 31 35 38 58 77 96 115 134 153 173 192 211 230 249100 5 9 14 18 23 27 32 36 41 46 68 91 114 137 160 182 205 228 251 273 296Jack Piston Diameter (Millimeters)120 5 11 16 22 27 33 38 44 49 55 82 109 137 164 191 218 246 273 300 328 355140 6 12 19 25 31 37 43 50 56 62 93 124 155 186 217 248 279 310 341 372 403160 8 15 23 30 38 46 53 61 69 76 114 152 190 228 266 305 343 381 419 457 495180 8 16 24 32 41 49 57 65 73 81 122 162 203 243 284 324 365 406 446 487 527200 10 19 29 39 48 58 68 78 87 97 145 194 242 291 339 388 436 485 533 582 630220 10 21 31 41 51 62 72 82 92 103 154 205 256 308 359 410 462 513 564 615 667240 13 25 38 51 63 76 89 101 114 127 190 253 317 380 443 507 570 633 697 760 823260 15 30 45 60 75 90 105 120 135 150 225 300 374 449 524 599 674 749 824 899 974280 15 31 46 61 77 92 107 123 138 153 230 307 383 460 563 613 690 766 843 920 996300 18 36 55 73 91 109 128 146 164 182 274 365 456 547 639 730 821 912 1003 1095 1186320 22 45 67 89 122 134 156 178 201 223 335 446 558 669 781 892 1004 1115 1227 1338 1450340 25 50 74 99 124 149 174 199 223 248 372 497 621 745 869 993 1117 1241 1365 1490 1614360 29 57 86 114 143 171 200 228 257 285 428 570 713 855 998 1140 1283 1425 1568 1710 1853380 32 65 97 130 162 195 227 259 292 324 486 649 811 973 1135 1297 1459 1621 1783 1946 2108400 37 73 110 146 183 220 256 293 329 366 549 732 915 1098 1281 1464 1647 1830 2013 2196 2379NOTE:Flow rate (liters per minute, lpm) = car speed (meters per minute, Mpm) x displacement (liters per meter, lpM)Displacement (liters per meter, lpM) = 0.0007854 x (piston O. D. in mm) 2Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 11

Table 3 - Piston Data4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comPISTON DIAMETER PISTON AREA DISPLACEMENTINCHES MILLIMETERS IN 2 CM 2 GALLONS PER FOOT (gpf) LITERS PER METER (lpM)2 50.80 3.142 20.268 0.163 2.0262 1/4 57.15 3.976 25.652 0.207 2.5652 1/2 63.50 4.909 31.669 0.255 3.1662 3/4 69.85 5.94. 38.320 0.309 3.8313 76.20 7.069 45.604 0.367 4.5593 7/16 87.31 9.28 59.87 0.482 5.9863 1/2 88.90 9.621 62.072 0.500 6.2063 3/4 95.25 11.045 71.256 0.574 7.1243 7/8 98.43 11.793 76.085 0.613 7.6074 101.60 12.566 81.073 0.653 8.1064 1/4 107.95 14.186 91.524 0.737 9.1504 3/8 111.13 15.033 96.987 0.781 9.6974 1/2 114.30 15.904 102.608 0.826 10.2594 3/4 120.65 17.721 144.326 0.921 11.4305 127.00 19.635 126.677 1.020 12.6655 1/4 133.35 21.648 139.661 1.125 13.9635 7/16 138.11 23.221 149.815 1.206 14.9785 1/2 139.70 23.758 153.279 1.234 15.3255 3/4 146.05 25.967 167.530 1.349 16.7496 152.40 28.274 182.415 1.469 18.2386 1/4 158.75 30.680 197.933 1.594 19.7896 1/2 165.10 33.183 214.084 1.724 21.4046 3/4 171.45 35.785 230.869 1.859 23.0827 177.80 38.485 248.287 1.999 24.8237 1/2 190.50 44.179 285.023 2.295 28.4967 3/4 196.85 47.173 304.341 2.451 30.4288 203.20 50.265 324.293 2.611 32.4228 1/2 215.90 56.745 366.096 2.948 36.6028 3/4 222.25 60.132 387.948 3.124 38.7879 228.60 63.617 410.433 3.305 41.0359 1/2 241.30 70.882 457.303 3.682 45.7219 3/4 247.65 74.662 481.689 3.879 48.15910 254.00 78.540 506.707 4.080 50.66010 1/4 260.35 82.516 532.360 4.287 53.22510 1/2 266.70 86.590 558.645 4.498 55.85310 5/8 269.88 88.664 572.025 4.606 57.19010 3/4 273.05 90.763 585.564 4.715 58.54411 279.40 95.033 613.116 4.937 61.29911 1/4 285.75 99.402 641.302 5.164 64.11711 1/2 292.10 103.869 670.121 5.396 66.99811 3/4 298.45 108.434 699.573 5.633 69.94212 304.80 113.097 729.659 5.875 72.95012 1/4 311.15 117.859 760.378 6.123 76.02212 1/2 317.50 122.718 791.730 6.375 79.15612 5/8 320.68 125.185 807.644 6.503 80.74713 7/8 352.43 151.201 975.491 7.855 97.52815 7/8 403.23 197.933 1276.982 10.282 127.67117 7/8 454.03 250.947 1619.010 13.036 161.867NOTE: Gallons per Minute (gpm) or Liters per Minute (lpm) = Displacement (gpf or lpm) x Car Speed (fpm or Mpm)Page 12 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comFigure 1Sizing Chart for UV-5AT (Standard <strong>Valve</strong>)Note: Also use this chart to size the “Up Section” of the UV-5ATC (Constant Down Speed valve) only.To size the “Down Section” of the UV-5ATC, please use Figure 2.(BAR) psi(34.5) 500(31.0) 450(27.9) 400Static (Minimum) Pressure(System pressure when empty car is resting at bottom landing)(24.1) 350(20.6) 300(17.2) 250(13.8) 200(10.3) 1501/81/4 1/23/4 1 1 1/4 UV-7B(6.9) 100(3.5) 50gpm 0 20 40 60 80 100 120 140 160 180 200 220(lpm) 0 (76) (151) (227) (303) (379) (454) (530) (606) (681) (757) (833)Flow RateBP adjuster @ 12 turns open & 150 SSU oil @ 100° F (38 O C).NOTES:1. The point of intersection of “Static Pressure” and “Flow Rate” identifies the correct valve size.2. It is assumed that Up and Down contract speeds are the same. If the Down contract speed is different from theUp, contact <strong>EECO</strong>.3. Down contract speed is full down speed with rated load on the car.CAUTION: When adjusting the UV-5AT valve, set the empty car down speed at 25% LESS than the down contract speed. Ifconstant down speed is required between no-load and full-load conditions, use the UV-5ATC valve.Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 13

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comFigure 2Sizing Chart for Down Section Of UV-5ATC Only(Constant Down Speed <strong>Valve</strong>)Note: To Size UV-5AT (Standard <strong>Valve</strong>), or the “Up Section” of the UV-5ATC(Constant Down Speed <strong>Valve</strong>), please use Figure 1.(BAR) psi(34.5) 500(31.0) 450(27.9) 400Static (Minimum) Pressure(System pressure when empty car is resting at bottom landing)(24.1) 350(20.6) 300(17.2) 250(13.8) 2001/41/23/4 1 1 1/4 UV-7BC(10.3) 1501 1/2(6.9) 100(3.5) 50gpm 0 20 40 60 80 100 120 140 160 180 200 220(lpm) 0 (76) (151) (227) (303) (379) (454) (530) (606) (681) (757) (833)Flow RateNOTE: The point of intersection of “Static Pressure” and “Flow Rate” identifies the correct valve size.Page 14 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comFigure 3Sizing Chart for UV-7B (Standard <strong>Valve</strong>)Note: Also use this chart to size the “Up Section” of the UV-7BC (Constant Down Speed <strong>Valve</strong>) only.To size the “Down Section” of the UV-7BC, please use Figure 4.(BAR) psi(27.9) 400(24.1) 350Static (Minimum) Pressure(System pressure when empty car is resting at bottom landing)(20.6) 300(17.2) 250(13.8) 200(10.3) 150(6.9) 1007 PORT (STD)9 PORT11 PORT13 PORT16 PORT(3.5) 50gpm 150 200 250 300 350 400(lpm) (568) (757) (946) (1136) (1325) (1515)Flow RateBP Adjuster @ 10 Turns Open & 150 SSU Oil @ 100° F (38 O C).NOTES:1. The point of intersection of “Static Pressure” and “Flow Rate” identifies the correct valve size.2. It is assumed that Up and Down contract speeds are the same. If the Down contract speed is different from theUp, contact <strong>EECO</strong>.3. Down contract speed is full down speed with rated load on the car.CAUTION: When adjusting the UV-7B valve, set the empty car down speed at 25% LESS than the down contract speed. Ifconstant down speed is required between no-load and full-load conditions, use the UV-7BC valve.Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 15

(BAR) psi(27.9) 4004035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comFigure 4Sizing Chart for Down Side of UV-7BC Only(Constant Down Speed <strong>Valve</strong>)Note: To Size UV-7B (Standard <strong>Valve</strong>), or the “Up Section” of the UV-7BC(Constant Down Speed <strong>Valve</strong>), please use Figure 3.(24.1) 350Static (Minimum) Pressure(System pressure when empty car is resting at bottom landing)(20.6) 300(17.2) 250(13.8) 200(10.3) 150(6.9) 1007 PORT (STD)9 PORT11 PORT13 PORT16 PORT(3.5) 50gpm 150 200 250 300 350 400(lpm) (568) (757) (946) (1136) (1325) (1515)Flow RateNOTE: The point of intersection of “Static Pressure” and “Flow Rate” identifies the correct valve size.Page 16 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-5AT & UV-5ATC (Constant Down Speed) Control <strong>Valve</strong>sContinuing its tradition of providing the <strong>elevator</strong> industry with innovative quality products, <strong>EECO</strong> now offers a revolutionaryimprovement of our flagship UV-5A control valve. The Compensated UV-5AT is now available and comes equipped with fullTemperature Compensation over its entire operational temperature range of 80 O to 150 O F (27 O C to 65 O C). It incorporates specialcomponents to compensate for variations of oil temperature and viscosity, therefore, maintaining consistent <strong>elevator</strong> operationregardless of oil temperature. In addition, all UV-5A valves manufactured since January 2001 are equipped with high temperatureViton seals throughout as a standard feature.The optional UV-5ATC also offers Pressure Compensation for constant down speed control. This modification of the downpiston assembly delivers constant Down Speed Control between no load and full load conditions.<strong>EECO</strong> also offers owners of older UV-5A control valves the ability to upgrade their existing valves currently in service withboth the temperature and pressure compensation features. This allows for a simple in-the-field retrofit of the valve with <strong>EECO</strong>supplied modification kits.UV-5ATUV-5ATCFeaturesSmooth Up Start:Up Transition:Up Leveling:Up Stop:Lowering <strong>Valve</strong>:Check <strong>Valve</strong>:Connections:Allows the pump motor to reach full running speed before load is applied to the motor. Providesa single adjustment for soft start and smooth acceleration.Provides unvarying transition through a wide pressure range.Maintains leveling speed regardless of change of system pressure, oil viscosity or pump output.Provides smooth up stop which is solenoid operated and adjustable.Provides controlled down acceleration, precise contract down speed, down transition, adjustableleveling speed and soft stop. Tool-less manual lowering feature is standard.Locks the <strong>elevator</strong> on a column of oil while the car is stopped.2 inch NPT standard with optional grooved connections for all three ports.Left hand jack port connection standard. NEW: Right hand jack port connection adapter option!Additional Features: Include a lightweight, heat-treated, high strength aluminum body. All control adjustments aremade from the front of the valve. Moving parts are restricted to sliding sealed pistons. The valvehas a fully adjustable pressure relief valve. Viton seals throughout.RatingsCertified by both UL (T) & CSA-B44 - ASME A17.1.UL (T) and CSA-B44 rated at 90 psi (6.2 bar) minimum and 800 psi (55.2 bar) maximum. The temperature range is80 O F (27 O C) minimum, 150 O F (65 O C) maximum.For oil service, use of a good brand of grade 32 turbine oil with a viscosity of 150 ssu at 100 O F (38 O C) and a minus pourpoint is recommended.Size all UV-5AT/TC valves to bypass the entire capacity of the pump at minimum pressure.Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 17

" Request For Quote " Order, PO #4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-5AT & UV-5ATC Quotation & Order FormCompanyContactDateTelephone ( )Fax ( )Date Required1. Quantity Required 22. Coil Voltage 23. Existing valve (If any): <strong>EECO</strong> UV-5A (Size)Other (Mfg, model, size)4. Static Pressure 1 or Empty Car Weight (lbs)(psi), Empty car atbottom landing.Plunger Diameter (in)or Circumference (in)5. Flow Rate (GPM) 1 or Car Speed (FPM) UpAlso need plungerinfo in #4 above. Down7. Total Travel (ft)If different6. Max Operating or Capacity (lbs)Pressure (psi)Also need empty carRequired for UV-5ATC.weight info in #4 above.8. Line Connections 2 Pump Jack Return2” NPT 3 " " "2” Grooved 4 " " "9. Jack Port Left Hand 3 " Right Hand 4 "10. Constant Down Speed (UV-5ATC) 4 Yes " No "11. Pressure Gage Quick Disconnect 4 Jack " Pump "12. 0-1000 psi Liquid Filled Pressure Gage 4 Yes " No "13. Low Pressure Switch 4 Yes " No "14. Roped Application Options:(Contact<strong>EECO</strong>)(a) Modified Down Piston To CloseAt Low Pressure (less than 50 psi) 4 Yes " No "(b) Manual Lowering With LowPressure Cutoff 4 Yes " No "15. Dual voltage down leveling coil foremergency (battery backup) lowering 4 Yes " No "1 Required for sizing, 2 Required, 3 Standard, 4 OptionalPlease fax this form to <strong>EECO</strong> at (323) 245-9771UV-5ATB44ASME 17.1Page 18 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-7B & UV-7BC (Constant Down Speed) Control <strong>Valve</strong>sThe <strong>EECO</strong> UV-7B hydraulic control valve performs all the necessary functions for the operation of a hydraulic <strong>elevator</strong> inboth directions of travel. The UV-7B is the ideal solution for low pressure, high flow rate applications.The optional cover for the UV-7B control valve enhances protection for the coils and coil wires. It also provides a single exitport for all four pair of coil wires, simplifying installation. In addition, all UV-7B valves manufactured since January 2001 containhigh temperature Viton seals throughout as a standard feature.Also available is the Pressure Compensated UV-7BC which maintains Constant Down Speed between no load and full loadconditions.UV-7BUV-7BCSmooth Start:Up Transition:Up Leveling:Up Stop:Lowering <strong>Valve</strong>:Check <strong>Valve</strong>:<strong>Valve</strong> Cover:FeaturesAllows the pump motor to reach full running speed before load is applied to the pump. Providesa single adjustment for soft start and smooth acceleration.Provides unvarying transition through a wide pressure range.Maintains leveling speed regardless of change of system pressure, oil viscosity or pump output.Provides smooth up stop which is solenoid operated and adjustable.Provides controlled down acceleration, precise contract down speed, down transition, adjustableleveling speed and soft stop. Tool-less manual lowering feature is standard.Locks the <strong>elevator</strong> on a column of oil while the car is stopped.The UV-7B is available with an optional valve cover which is specially designed to provide a singleexit port for all four pairs of solenoid wires.Additional Features: A lightweight, heat-treated, high strength aluminum body. Moving parts are restricted to slidingsealed pistons. The valve has a fully adjustable pressure relief valve and optional 2 1/2” groovedconnections.RatingsCSA-B44 - ASME A17.1 & UL (B) Certified.UL and CSA-B44 rated at 50 psi (3.4 bar) minimum and 500 psi (34.5 bar) maximum. The temperature range is80 O F (27 O C) minimum, 150 O F (65 O C) maximum.Flow rate: minimum 75 gpm to maximum 400 gpm (284 -1514 l/min).For oil service, use of a good brand of grade 32 turbine oil with a viscosity of 150 ssu at 100 O F (38 O C) and aminus pour point is recommended. Also compatible with grade 46 and biodegradable (vegetable) oil.Size all UV-7B/BC valves to bypass the entire capacity of the pump at minimum pressure.Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 19

" Request For Quote " Order, PO #4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-7B & UV-7BC Quotation & Order FormCompanyContactDate1. Quantity Required 22. Coil Voltage 23. Existing valve (If any): <strong>EECO</strong> UV-7B (Size)Other (Mfg, model, size)4. Static Pressure 1 or Empty Car Weight (lbs)(psi), Empty car atbottom landing.Plunger Diameter (in)or Circumference (in)5. Flow Rate (GPM) 1 or Car Speed (FPM) UpAlso need plungerinfo in #4 above.DownIf different6. Max Operating or Capacity (lbs)Pressure (psi)Also need empty carRequired for UV-7BC.weight info in #4 above.Telephone ( )Fax ( )Date Required7. Total Travel (ft)8. Line Connections 2 Pump Jack Return2.5” NPT 3 " " "2.5” Grooved 4 " " "9. Constant Down Speed (UV-7BC) 4 Yes " No "10. Pressure Gage Quick Disconnect 4 Jack " Pump "11. <strong>Valve</strong> Cover 4 Yes " No "12. 0-1000 psi Liquid Filled Pressure Gage 4 Yes " No "13. Low Pressure Switch 4 Yes " No "14. Manual lowering With Low PressureCutoff for Roped Applications 4 Yes " No "1 Required for sizing, 2 Required, 3 Standard, 4 OptionalPlease fax this form to <strong>EECO</strong> at (323) 245-9771UV-7BB44ASME 17.1UV-7B with optional 2.5” groovedconnections.2.5” NPT ports standardUV-7B with optional<strong>Valve</strong> Cover.Page 20 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

UV-4R Residential Control <strong>Valve</strong>4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comNEW!!!AFour Coil <strong>Valve</strong>VForResidential&LULAApplications!Continuing our tradition of providing the <strong>elevator</strong> industry with innovative quality products, <strong>EECO</strong> now offers a small, compacthydraulic <strong>elevator</strong> control valve for residential, LULA & handicapped applications.The UV-4R has all the performance qualities of larger commercially available hydraulic control valves. Qualities like full levelingin the up and down directions and pressure regulation to maintain constant down speed. Jack ports are provided on boththe right and left sides of the valve for easy installation. The UV-4R is capable of handling flow rates of 3 to 35 GPM.FeaturesSmooth Up Start:Up Transition:Up Leveling:Up Stop:Lowering <strong>Valve</strong>:Check <strong>Valve</strong>:Additional Features:Allows the pump motor to reach full running speed before load is applied to the motor.Provides a single adjustment for soft start and smooth acceleration.Provides consistent transition through the full pressure range.Maintains leveling speed regardless of change of system pressure, oil temperature &viscosity or pump output.Provides smooth up stop which is solenoid operated and adjustable.Provides controlled down acceleration and deceleration and maintains contract down andleveling speeds.Locks the <strong>elevator</strong> on a column of oil while the car is stopped.High temperature Viton seals are standard in this valve. Moving parts are restricted tosliding sealed pistons. The valve has a fully adjustable pressure relief valve. Uses solenoidcoils that are UL and CSA listed.Copyright © 2006 Elevator Equipment Corportion, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 21

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comThis page blank.Page 22 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corportion, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-5AT (Standard <strong>Valve</strong>) Adjustment ProcedureNotes:1. This information is to be used only by qualified hydraulic <strong>elevator</strong> professionals.2. The optimum oil temperature to adjust the valve is between 80° to 100°F (27 O to 38 O C). If oil temperature exceeds 100°F (38 O C), make down stop firmer.3. The following instructions are for adjusting the valve starting with adjusters on preset. However, each new valve is adjusted to a set of standard conditions atthe factory and you do not have to preset adjusters. You only need to adjust DM and BP. Other adjusters may require fine-tuning to suit your application.4. Hand tighten the seal nuts on the adjusters - DO NOT over tighten.5. <strong>Valve</strong> must be mounted with solenoids in vertical position. Five (5) inches (127mm) minimum clearance is required to remove valve cover for service.6. When disconnecting solenoids, do it electrically, not physically.7. Both UA and DC adjusters have screened inputs and must be kept clean. <strong>EECO</strong> recommends use of a 5-micron filtration system.8. If DC requires further fine-tuning after DA is adjusted, first open DA 3 turns, fine-tune DC and then readjust DA.9. Down contract speed is full down speed with rated load on the car. Down speed with empty car is less than contract speed depending on the ration offull-load to no-load pressures, approximately 25% less for a 2 to 1 pressure ratio (i.e., empty car down speed = full load (contract) down speed x .75). Ifconstant down speed is required between no-load and full-load conditions, use UV-5ATC valve.10. DO NOT adjust the valve to suit switches. Adjust the switches (vanes / magnets) to suit the valve.U1 - Up Fast solenoidUp Adjustments (From Preset)U2 - Up Slow solenoid1) BP Bypass - Car at lower floor with no load. Disconnect U2. Register an up call. Car should not move. Turn BP CW until car moves, then CCW untilcar stalls plus a minimum of 1/2 turn. Stop pump motor. Reconnect U2.2) UA Up Acceleration - Car at lower floor with no load. Turn UA CCW 2 1/2 turns from fully closed position. Register an up call and observe up acceleration.Turn UA CCW for faster or CW for slower up acceleration. Car should reach full speed in no more than 2 1/2 feet (.8m). DO NOT drag out acceleration.3) UL Up Leveling - Car at lower floor with no load. Disconnect U1. Register an up call. Turn UL CCW (faster) or CW (slower) to set up leveling speed at10 to 13 fpm (.05 to .07 m/sec). Leave U1 disconnected.4) UT Up Transition - Car at lower floor with no load. Register an up call with U2 energized only. Car will move up at leveling speed. Turn UT CW until carspeeds up, then slowly CCW until car slows down again. Reconnect U1. Register an up call and observe up transition. Turn UT CW (slower) or CCW(faster) until up transition is satisfactory. Slowdown switch should be located to give 3 to 4 inches (75 to 100mm) of stabilized leveling (see note 10).5) US Up Stop - Car at lower floor with no load. Disconnect U2. Register an up call. Car should not move. Turn US CW until car moves, then CCW until carstops again. Reconnect U2. Register an up call and observe up stop. Turn US CW for softer stop or CCW for firmer stop. NOTE: Pump motor mustrun approximately 1 second after car has stopped.D1 - Down Fast solenoidDown Adjustments (From Preset)D2 - Down Slow solenoid1) DL Down Leveling - Car at upper floor with no load. Turn DC CW 8 1/2 turns from fully open position. Disconnect D1. Register a down call. Adjust DLto set down leveling speed at 7 to 9 fpm (.04 to .05 m/sec). Reconnect D1.2) DM Down Main - Car at upper floor with no load. Register a down call. Turn DM CW (slower) or CCW (faster) to set down speed at 25% less thancontract (full load) speed (see note 9).3) DC Down Closing - Cycle empty car and observe down stop. Turn DC CW (softer stop) or CCW (firmer stop) until down stop is satisfactory (see note 8).4) DT Down Transition - Cycle empty car and observe down transition. If DT requires adjustment, send empty car to upper floor. Disconnect D1. Register adown call. Car should come down at leveling speed. Turn DT CCW until car speeds up, then slowly CW until car slows down again. Reconnect D1.Cycle car and turn DT CCW (slower) or CW (faster) until down transition is satisfactory. Readjust DL to maintain down leveling at 7 to 9 fpm (.04 to.05 m/sec). Slowdown switch should be located to give 3 to 4 inches (75 to 100mm) of stabilized leveling (see note 10).5) DA Down Acceleration - Car at upper floor with no load. Turn DA CW to stop. Register a down call. Car should not move. Turn DA slowly CCW until carbreaks away from the floor. Turn DA CW (slower) or CCW (faster) until down acceleration is satisfactory.ML Manual Lowering - Turn ML out CCW to lower car at leveling speed. All electrical power MUST be off when using manual lowering!Relief <strong>Valve</strong> (RV):1. With fully loaded car and a pressure gageinstalled on the pump gage port, register an upcall and record maximum pressure as car nearstop landing.2. Close main line valve and turn RV and UA outCCW to stop.3. Register an up call. Turn RV CW to set reliefpressure as required by local code (not toexceed 50% above maximum pressure recordedearlier).4. Restart pump to check pressure relief setting.Seal RV as required. Open main line valve to thejack. Readjust UA for proper up acceleration.CW = Clockwise (IN) Adjuster Presetting CCW = Counter Clockwise (OUT)UpDownADJUSTER PRESETTING FUNCTIONBP Bypass CCW to stop, then CW 2 turns. (CCW - Delays up start)UA Up Acceleration CW to stop. (CCW - Faster acceleration)UL Up Leveling CW to stop. (CCW - Faster speed)UT Up Transition CCW to stop, then CW 7 1/2 turns.(CW - Slower transition)US Up Stop CCW to stop, then CW 7 1/2 turns.(CW - Softer stop)RV Relief <strong>Valve</strong> Factory set at 550 psi (38 bars). (CW - Increase pressure setting)DL Down Leveling CW to stop, then CCW 5 1/2 turns. (CW - Slower speed)DM Down Main CW to stop, then CCW 5 1/2 turns. (CW - Slower speed)DC Down Closing CCW to stop. (CCW - Firmer stop)DT Down Transition Closed flush with end of lock nut. (CCW - Slower transition)DA Down Acceleration CCW to stop. (CCW - Faster acceleration)ML Manual Lowering CW to stop. (CCW - Opens valve)Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 23

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-5AT Operational DataPERFORMANCE CHART FOR UV-5AT VALVES PLEASE NOTE NEW SOLENOID LABELING (since August 2003):Solenoids: U1 - Up Fast (Red wires) - (was ULS)U2 - Up Slow (Yellow wires) - (was UDS)D1 - Down Fast (Black wires) - (was DMS)D2 - Down Slow (Blue wires) - (was DLS)Adjuster: US - Up Stop - (was UD)PRESSURECSA-B44/UL Minimum/Maximum: 90 - 800 psi (6.2 - 55.2 bars). Standardpressure rating 50 psi minimum to 1150 psi maximum (3.4 - 79.3 bars).FLOW RATEMinimum 20 gpm to maximum 200 gpm (76 -836 l/min).OPERATING TEMPERATURE80 O F (27 O C) minimum to 150 O F (66 O C) maximum.GAGE PORTS“Ram”(jack) and “Pump” gage ports are 1/8” NPT and are provided on top ofthe valve. Optional quick connect/disconnect fittings as well as 0-1000 psi liquidfilled pressure gages can be installed and/or supplied with the valve uponrequest.OIL SPECIFICATIONSRecommended oil: A good brand of 32 grade turbine oil with a viscosityof 150 SSU at 100 O F (38 O C). Other oils: The UV-5AT is also compatible with46 grade as well as biodegradable (vegetable) oil.LINE CONNECTIONFactory standard for each of the three valve ports is 2” NPT, 2” grooved portsare optional.STANDARD CSA-B44/UL APPROVED SOLENOID COILS24 VDC, 110 VAC, 208 VAC, 220 VAC/110 VDC, 440 VAC/220 VDC. For emergency(battery backup) lowering: 110 VAC/12 VDC (dual voltage). For othercoil options, please contact <strong>EECO</strong>.B44ASME 17.1Up Start:A) “ATL” (Across The Line) start: pump motor “ON”.Energize both U2 and U1 solenoids to run up at fast speed.B) “Y” start: Pump motor “ON” (reduced voltage).“Delta” run: Pump motor “ON” full voltage.Energize both U2 and U1 solenoids to run up at fast speed.De-energize U1 to slowdown to leveling speed.De-energize U2 to stop at floor.CAUTION: Never energize U2 and U1 during “Y” start, only after “Delta” run!SEQUENCE OF SOLENOID OPERATIONDown Start:Energize D1 and D2 to lower car at fast speed.De-energize D1 to slowdown to leveling speed.De-energize D2 to stop at floor.Note 1: For additional clarification on the sequence of operation pleaserefer to the Performance Chart above.Note 2: Pump motor must be timed to run approximately 1 second aftercar has stopped.Page 24 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-5ATC (Constant Down Speed <strong>Valve</strong>) Adjustment ProcedureNotes:1. This information is to be used only by qualified hydraulic <strong>elevator</strong> professionals.2. The optimum oil temperature to adjust the valve is between 80° to 100°F (27 O to 38 O C). If oil temperature exceeds 100°F (38 O C), make down stop firmer.3. The following instructions are for adjusting the valve starting with adjusters on preset. However, each new valve is adjusted to a set of standard conditionsat the factory and you do not have to preset adjusters. You only need to adjust DM and BP. Other adjusters may require fine-tuning to suit your application.4. Hand tighten the seal nuts on the adjusters - DO NOT over tighten.5. <strong>Valve</strong> must be mounted with solenoids in vertical position. Five (5) inches (127mm) minimum clearance is required to remove valve cover for service.6. When disconnecting solenoids, do it electrically, not physically.7. Both UA and DC adjusters have screened inputs and must be kept clean. <strong>EECO</strong> recommends use of a 5-micron filtration system.8. If DC requires further fine-tuning after DA is adjusted, first open DA 3 turns, fine-tune DC and then readjust DA.9. DO NOT adjust the valve to suit switches. Adjust the switches (vanes / magnets) to suit the valve.U1 - Up Fast solenoidUp Adjustments (From Preset)U2 - Up Slow solenoid1) BP Bypass - Car at lower floor with no load. Disconnect U2. Register an up call. Car should not move. Turn BP CW until car moves, then CCW until carstalls plus a minimum of 1/2 turn. Stop pump motor. Reconnect U2.2) UA Up Acceleration - Car at lower floor with no load. Turn UA CCW 2 1/2 turns from fully closed position. Register an up call and observe up acceleration.Turn UA CCW for faster or CW for slower up acceleration. Car should reach full speed in no more than 2 1/2 feet (.8m). DO NOT drag out acceleration.3) UL Up Leveling - Car at lower floor with no load. Disconnect U1. Register an up call. Turn UL CCW (faster) or CW (slower) to set up leveling speed at 10to 13 fpm (.05 to .07 m/sec). Leave U1 disconnected.4) UT Up Transition - Car at lower floor with no load. Register an up call with U2 energized only. Car will move up at leveling speed. Turn UT CW until carspeeds up, then slowly CCW until car slows down again. Reconnect U1. Register an up call and observe up transition. Turn UT CW (slower) or CCW(faster) until up transition is satisfactory. Slowdown switch should be located to give 3 to 4 inches (75 to 100mm) of stabilized leveling (see note 9).5) US Up Stop - Car at lower floor with no load. Disconnect U2. Register an up call. Car should not move. Turn US CW until car moves, then CCW until carstops again. Reconnect U2. Register an up call and observe up stop. Turn US CW for softer stop or CCW for firmer stop. NOTE: Pump motor mustrun approximately 1 second after car has stopped.D1 - Down Fast solenoidDown Adjustments (From Preset)D2 - Down Slow solenoid1) DL Down Leveling - Car at upper floor with no load. Turn DC CW 8 1/2 turns from fully open position. Disconnect D1. Register a down call. Adjust DL toset down leveling speed at 7 to 9 fpm (.04 to .05 m/sec).Reconnect D1.2) DM Down Main - Car at upper floor with no load and DSC on preset (CCW to stop). Register a down call. Turn DM CW (slower) or CCW (faster) to setdown speed at contract (full load) speed.3) DSC Down Speed Control - Pressure compensation for down speed control is achieved automatically when DSC is completely out (CCW to stop). To closeoff DSC, relieve system pressure by landing car in pit, turn DSC CW until snap ring is flush with the end of DM adjuster. To reactivate down speedcontrol, turn DSC adjuster CCW to stop.4) DC Down Closing - Cycle empty car and observe down stop. Turn DC CW (softer stop) or CCW (firmer stop) until down stop is satisfactory (see note 8).5) DT Down Transition - Cycle empty car and observe down transition. If DT requires adjustment, send empty car to upper floor. Disconnect D1. Register adown call. Car should come down at leveling speed. Turn DT CCW until car speeds up, then slowly CW until car slows down again. Reconnect D1.Cycle car and turn DT CCW (slower) or CW (faster) until down transition is satisfactory. Readjust DL to maintain down leveling at 7 to 9 fpm (.04 to.05 m/sec). Slowdown switch should be located to give 3 to 4 inches (75 to 100mm) of stabilized leveling (see note 9).6) DA Down Acceleration - Car at upper floor with no load. Turn DA CW to stop. Register a down call. Car should not move. Turn DA slowly CCW until carbreaks away from the floor. Turn DA CW (slower) or CCW (faster) until down acceleration is satisfactory.MLManual Lowering - Turn ML out CCW to lower car at leveling speed. All electrical power MUST be off when using manual lowering!Relief <strong>Valve</strong> (RV):1. With fully loaded car and a pressure gageinstalled on the pump gage port, register an upcall and record maximum pressure as car nearstop landing.2. Close main line valve and turn RV and UA outCCW to stop.3. Register an up call. Turn RV CW to set reliefpressure as required by local code (not toexceed 50% above maximum pressure recordedearlier).4. Restart pump to check pressure relief setting.Seal RV as required. Open main line valve to thejack. Readjust UA for proper up acceleration.CW = Clockwise (IN) Adjuster Presetting CCW = Counter Clockwise (OUT)UpDownADJUSTER PRESETTING FUNCTIONBP Bypass CCW to stop, then CW 2 turns. (CCW - Delays up start)UA Up Acceleration CW to stop. (CCW - Faster acceleration)UL Up Leveling CW to stop. (CCW - Faster speed)UT Up Transition CCW to stop, then CW 7 1/2 turns.(CW - Slower transition)US Up Stop CCW to stop, then CW 7 1/2 turns.(CW - Softer stop)RV Relief <strong>Valve</strong> Factory set at 550 psi (38 bars). (CW - Increase pressure setting)DL Down Leveling CW to stop, then CCW 5 1/2 turns. (CW - Slower speed)DM Down Main CW to stop, then CCW 5 1/2 turns. (CW - Slower speed)DSC Down Speed Control CCW to stop.(No adjustment required)DC Down Closing CCW to stop. (CCW - Firmer stop)DT Down Transition Closed flush with end of lock nut. (CCW - Slower transition)DA Down Acceleration CCW to stop. (CCW - Faster acceleration)ML Manual Lowering CW to stop. (CCW - Opens valve)Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 25

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-5ATC Operational DataPERFORMANCE CHART FOR UV-5ATC VALVES PLEASE NOTE NEW SOLENOID LABELING (since August 2003):Solenoids: U1 - Up Fast (Red wires) - (was ULS)U2 - Up Slow (Yellow wires) - (was UDS)D1 - Down Fast (Black wires) - (was DMS)D2 - Down Slow (Blue wires) - (was DLS)Adjuster: US - Up Stop - (was UD)PRESSURECSA-B44/UL Minimum/Maximum: 90 - 800 psi (6.2 - 55.2 bars). Standardpressure rating 50 psi minimum to 1150 psi maximum (3.4 - 79.3 bars).FLOW RATEMinimum 20 gpm to maximum 200 gpm (76 - 836 l/min).OPERATING TEMPERATURE80 O F (27 O C) minimum to 150 O F (66 O C) maximum.GAGE PORTS“Ram”(jack) and “Pump” gage ports are 1/8” NPT and are provided on top ofthe valve. Optional quick connect/disconnect fittings as well as 0-1000 psi liquidfilled pressure gages can be installed and/or supplied with the valve uponrequest.OIL SPECIFICATIONSRecommended oil: A good brand of 32 grade turbine oil with a viscosity of150 SSU at 100 O F (38 O C). Other oils: The UV-5ATC is also compatible with46 grade as well as biodegradable (vegetable) oil.LINE CONNECTIONFactory standard for each of the three valve ports is 2” NPT, 2” grooved portsare optional.STANDARD CSA-B44/UL APPROVED SOLENOID COILS24 VDC, 110 VAC, 208 VAC, 220 VAC/110 VDC, 440 VAC/220 VDC. For emergency(battery backup) lowering: 110 VAC/12 VDC (dual voltage). For othercoil options, please contact <strong>EECO</strong>.B44ASME 17.1Up Start:A) “ATL” (Across The Line) start: pump motor “ON”.Energize both U2 and U1 solenoids to run up at fast speed.B) “Y” start: Pump motor “ON” (reduced voltage).“Delta” run: Pump motor “ON” full voltage.Energize both U2 and U1 solenoids to run up at fast speed.De-energize U1 to slowdown to leveling speed.De-energize U2 to stop at floor.CAUTION: Never energize U2 and U1 during “Y” start, only after “Delta” run!SEQUENCE OF SOLENOID OPERATIONDown Start:Energize D1 and D2 to lower car at fast speed.De-energize D1 to slowdown to leveling speed.De-energize D2 to stop at floor.Note 1: For additional clarification on the sequence of operation pleaserefer to the Performance Chart above.Note 2: Pump motor must be timed to run approximately 1 second aftercar has stopped.Page 26 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comUV-7B (Standard <strong>Valve</strong>) Adjustment ProcedureNotes:1. This information is to be used only by qualified hydraulic <strong>elevator</strong> professionals.2. The optimum oil temperature to adjust the valve is between 80° to 100°F (27 O to 38 O C). If oil temperature exceeds 100°F (38 O C), make down stop firmer.3. The following instructions are for adjusting the valve starting with adjusters on preset. However, each new valve is adjusted to a set of standard conditions atthe factory and you do not have to preset adjusters. You only need to adjust DM and BP. Other adjusters may require fine-tuning to suit your application.4. Hand tighten the seal nuts on the adjusters - DO NOT over tighten.5. <strong>Valve</strong> must be mounted with solenoids in vertical position. Eight (8) inches (203mm) minimum clearance is required to remove valve cover for service.6. When disconnecting solenoids, do it electrically, not physically.7. Both UA and DC adjusters have screened inputs and must be kept clean. <strong>EECO</strong> recommends use of a 5-micron filtration system.8. If DC requires further fine-tuning after DA is adjusted, first open DA 3 turns, fine-tune DC and then readjust DA.9. Down contract speed is full down speed with rated load on the car. Down speed with empty car is less than contract speed depending on the ration offull-load to no-load pressures, approximately 25% less for a 2 to 1 pressure ratio (i.e., empty car down speed = full load (contract) down speed x .75). Ifconstant down speed is required between no-load and full-load conditions, use UV-7BC valve.10. DO NOT adjust the valve to suit switches. Adjust the switches (vanes / magnets) to suit the valve.U1 - Up Fast solenoidUp Adjustments (From Preset)U2 - Up Slow solenoid1) BP Bypass - Note: UA must be on preset (CW to stop). Car at lower floor with no load. Disconnect U2. Register an up call. Turn BP CW until car moves,then CCW until car stalls plus a minimum of 1/2 turn. Stop pump motor and reconnect U2.2) UA Up Acceleration - Car at lower floor with no load. Turn UA CCW 2 1/2 turns from fully closed position. Register an up call and observe upacceleration. Turn UA CCW for faster or CW for slower up acceleration. Car should reach full speed in 2 1/2 feet (.8 m). DO NOT drag out acceleration.3) UL Up Leveling - Car at lower floor with no load. Disconnect U1. Register an up call. Adjust UL to set up leveling speed at 10 to 13 fpm (.05 to .07 m/sec).Reconnect U1.4) UT Up Transition - Car at lower floor with no load. Register an up call and observe up transition. Turn UT CW (slower) or CCW(faster) until up transition is satisfactory. Slowdown switch should be located to give 3 to 4 inches (75 to 100 mm) of stabilized leveling (see note 10).5) US Up Stop - Car at lower floor with no load. Disconnect U2. Register an up call. Car should not move. Turn US CW until car moves, then CCW until carstops again. Reconnect U2. Register an up call and observe up stop. Turn US CW for softer stop, CCW for firmer stop. NOTE: Pump motor must runapproximately 1 second after car has stopped.D1 - Down Fast solenoidDown Adjustments (From Preset)D2 - Down Slow solenoid1) DL Down Leveling - Car at upper floor with no load. Turn DC CW 2 1/2 turns from fully open position position. Disconnect D1. Register a down call. AdjustDL to set down leveling speed at 7 to 9 fpm (.04 to .05 m/s). Reconnect D1.2) DM Down Main - Car at upper floor with no load. Register a down call. Turn DM CW (slower) or CCW (faster) to set down speed at 25% less thancontract (full load) speed (see note 9).3) DC Down Closing - Cycle empty car and observe down stop. Turn DC CW (softer stop) or CCW (firmer stop) until down stop is satisfactory (see note 8).4) DT Down Transition - Cycle empty car and observe down transition. If DT requires adjustment, send empty car to upper floor. Disconnect D1. Register adown call. Car should come down at leveling speed. Turn DT CCW until car speeds up, then slowly CW until car slows down again. Reconnect D1.Cycle car and turn DT CCW (slower) or CW (faster) until down transition is satisfactory. Readjust DL to maintain down leveling at 7 to 9 fpm (.04 to.05 m/sec). Slowdown switch should be located to give 3 to 4 inches (75 to 100mm) of stabilized leveling (see note 10).5) DA Down Acceleration - Car at upper floor with no load. Turn DA CW to stop. Register a down call. Car should not move. Turn DA slowly CCW until carbreaks away from floor. Turn DA CW (slower) or CCW (faster) until down acceleration is satisfactory.ML Manual Lowering - Turn ML out CCW to lower car at leveling speed. All electrical power MUST be off when using manual lowering!Relief <strong>Valve</strong> (RV):1. With fully loaded car and a pressure gage installedon the pump gage port, register an up call andrecord maximum pressure as car nears top landing.2. Close main line valve and turn RV and UA outCCW to stop.3. Register an up call. Turn RV CW to set reliefpressure as required by local code (not toexceed 50% above maximum pressure recordedearlier).4. Restart pump to check pressure relief setting.Seal RV as required. Open main line valve to thejack. Readjust UA for proper up acceleration.UpDownCW = Clockwise (IN) Adjuster Presetting CCW = Counter Clockwise (OUT)ADJUSTER PRESETTING FUNCTIONBP Bypass CCW to stop, then CW 2 turns. (CCW - Delays up start)UA Up Acceleration CW to stop (flush with end of lock nut). (CCW - Faster acceleration)UL Up Leveling CCW to stop. (CW - Faster speed)UT Up Transition CCW to stop, then CW 2 1/2 turns. (CW - Slower transition)US Up Stop CCW to stop. (CW - Softer stop)RV Relief <strong>Valve</strong> Factory set at 500 psi (34 bars). (CW - Increase pressure)DL Down Leveling CW to stop, then CCW 5 1/2 turns. (CW - Slower speed)DM Down Main CW to stop, then CCW 5 1/2 turns. (CW - Slower speed)DT Down Transition CW to stop (flush with end of lock nut). (CCW - Slower transition)DA Down Acceleration CCW to stop. (CW - Slower acceleration)DC Down Closing CCW to stop. (CW - Softer stop)ML Manual lowering CW to stop. (CCW - Opens valve)Copyright © 2006 Elevator Equipment Corporation, all rights reserved<strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06) - Page 27

4035 Goodwin Avenue, Los Angeles, CA 90039 - (800) 423-28002230 N.W. 12th Street, Richmond, IN 47374 - (800) 428-6564LA Fax: (323) 245-9771 - Richmond, IN Fax: (765) 966-7299www.<strong>elevator</strong>equipment.com and www.eecovalves.comPERFORMANCE CHART FOR UV-7B VALVESUV-7B Operational DataPLEASE NOTE NEW SOLENOID LABELING (since August 2003):Solenoids: U1 - Up Fast (Red wires) - (was ULS)U2 - Up Slow (Yellow wires) - (was UDS)D1 - Down Fast (Black wires) - (was DMS)D2 - Down Slow (Blue wires) - (was DLS)Adjuster: US - Up Stop - (was UD)PRESSURECSA-B44/UL Minimum/Maximum: 50 - 500 psi (3.5 - 34.5 bars).B44ASME 17.1FLOW RATEMinimum 75 gpm to maximum 400 gpm (284 -1514 l/min). For higher flowrates contact <strong>EECO</strong>.OPERATING TEMPERATURE80°F (27°C) minimum to 150°F (65°C) maximum.GAGE PORTSGage ports are 1/8” NPT and are provided on the top of the valve. Please referto the illustration at right. Optional quick connect/disconnect fittings as wellas 0-1000 psi liquid filled pressure gage can be supplied with the valve uponrequest.OIL SPECIFICATIONSRecommended oil: A good brand of 32 grade turbine oil with a viscosity of150 ssu at 100°F (38°C). Other oils: The UV-7B is also compatible with 46grade as well as biodegradable (vegetable) oil.STANDARD CSA/UL APPROVED SOLENOID COILS110 VAC, 208 VAC, 220 VAC, 440 VAC, 110 VDC, 220 VDC, For other coiloptions, please contact <strong>EECO</strong>.Up Start:A) “ATL” (Across The Line) start: pump motor “ON”.Energize both U2 and U1 solenoids to run up at fast speed.B) “Y” start: Pump motor “ON” (reduced voltage).“Delta” run: Pump motor “ON” full voltage.Energize both U2 and U1 solenoids to run up at fast speed.De-energize U1 to slowdown to leveling speed.De-energize U2 to stop at floor.CAUTION: Never energize U2 and U1 during “Y” start, only after “Delta” run!SEQUENCE OF SOLENOID OPERATIONDown Start:Energize D1 and D2 to lower car at fast speed.De-energize D1 to slowdown to leveling speed.De-energize D2 to stop at floor.Note 1: For additional clarification on the sequence of operation pleaserefer to the Performance Chart above.Note 2: Pump motor must be timed to run approximately 1 second aftercar has stopped.Page 28 - <strong>EECO</strong> Control <strong>Valve</strong> Catalogue (Revised, 10-26-06)Copyright © 2006 Elevator Equipment Corporation, all rights reserved