Thursday October 27th 10am 1201 Industrial Ave ... - IRS Auctions!

Thursday October 27th 10am 1201 Industrial Ave ... - IRS Auctions!

Thursday October 27th 10am 1201 Industrial Ave ... - IRS Auctions!

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

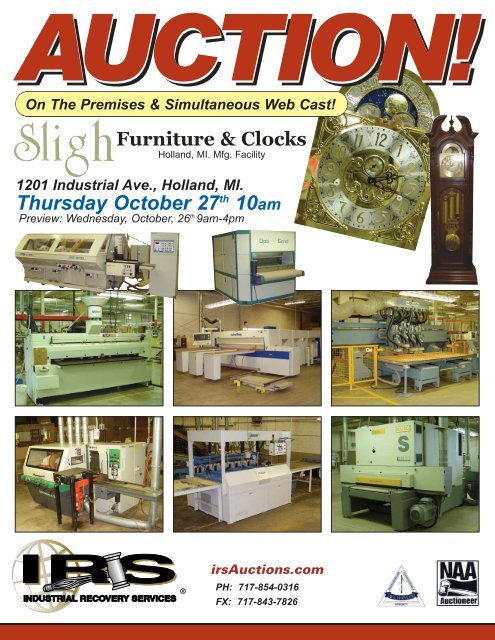

AUCTION!<br />

On The Premises & Simultaneous Web Cast!<br />

Furniture & Clocks<br />

Holland, MI. Mfg. Facility<br />

<strong>Thursday</strong> <strong>October</strong> <strong>27th</strong> <strong>1201</strong> <strong>Industrial</strong> <strong>Ave</strong>., Holland, MI.<br />

<strong>10am</strong><br />

Preview: Wednesday, <strong>October</strong>, 26th 9am-4pm<br />

PH: 717-854-0316<br />

FX: 717-843-7826

1<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Heian HR-442PF-R4-1616W CNC Router (1999)<br />

CMS Giotto M CNC MachiningCenter w/ ATC (1998)<br />

CMS Giotto M CNC Machining Center Close Ups<br />

Schelling FM-H 330/310 Rear Loading (2000)<br />

1999<br />

1998<br />

2000<br />

Schelling FM-H 330/310 Rear Loading Alternate Views<br />

CNC Routers & Machining Centers<br />

Heian HR-442PF-R4-1616W CNC Router (1999)<br />

Twin 63” x 63” vacuum tables, (4) 7.5/8.8Kw Router<br />

motors, 17,400 max RPM pneumatic tool release, (4)<br />

piggyback drill motors, 2.2KW, 17,400 RPM, Fanuc<br />

series 18i-m controller with PC, monitor, and keyboard,<br />

Servo drive on all axis, 480V, s/n 9900366H23658,<br />

Dekker Vacuum Technologies Vacuum Pump, 20hp<br />

220/440V, m/n VMX0300KA1-00, s/n AI5662.<br />

CMS Giotto M CNC Machining Center w/ ATC (1998)<br />

Twin 4’x5’ work areas with (4) moveable parts holders<br />

with (3) moveable vacuum pods each, (6) popup positioners<br />

on each table, CMS OSAI numerical controller<br />

with keyboard, (1) main router 8KW 18,000 RPM with C<br />

axis, (8) position ride along carousel tool changer, (10)<br />

vertical boring heads along Y axis, (10) vertical boring<br />

heads along X axis, (2) horizontal boring heads along Y<br />

(-) axis, (2) horizontal boring heads along Y(+) axis, (2)<br />

horizontal boring heads along X(-) axis, (2) horizontal<br />

boring heads along X(+) axis, 1.8KW boring motor for Y<br />

axis, 1.8KW boring motor for X axis, (2) Siemens 4.4KW<br />

vacuum pumps, s/n 1952<br />

CNC Panel Saw<br />

Schelling FM-H 330/310 Rear Loading (2000)<br />

10.6’W x 10.2’L x 3.15”H Max Cutting Capacity, 37.4”<br />

Working Table Height, 3.75” Max Saw Blade Projection,<br />

Main Saw 20HP, 370mm Max Main Saw Blade, Score<br />

Saw 3.4HP, 20mm max score saw blade, Saw Carriage<br />

1.4Hp AC Servo drive, 1-393 FPM Forward, 393 fpm<br />

reverse, Cross Aligning 2.75” – 86”, Allen Bradley IBM<br />

PC w/ Keyboard & mouse, (3) 23” x 83” Air flotation<br />

tables (1 fixed – 2 moveable), (8) Grippers w/ 3 .15”<br />

Opening spaced: 2.56” / 10.43” / 18.31” /30.12” / 41.93”<br />

/ 53.74” / 77.36” / 112.8”, Grandeur Powered infeed case<br />

roll section 57”W x 165”L (11) 5” dia. Powered Rolls,<br />

Grandeur Powered outfeed case roll section 57”W x<br />

165”L (11) 5” dia. Powered Rolls Powered Hydraulic<br />

Scissor Lift Section 9,900# Capacity 5.4HP 63”W x<br />

122”L 32” Max Stack Height (7) 4” dia. Powered Rolls,<br />

220/400 Volt 86/48 amp, 25KW Total, s/n 202.406<br />

www.irs<strong>Auctions</strong>.com 717.854.0316<br />

On The Premises &<br />

Simultaneous Web Cast!<br />

www.irs<strong>Auctions</strong>.com

2000<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Costa 53TR CTT 1350 Wide Belt w/ Sensing (2000)<br />

Costa Top & Bottom Wide Belt Sanding Line (1996)<br />

Opti-Sand R-52-V Rotary Denibbing Sander<br />

Don’t Wait, Set Up Your<br />

Web Cast Account Today!<br />

1996<br />

2001<br />

Late Model Sanders!<br />

Wide Belt Sanders / Denibbers<br />

Costa 53TR CTT 1350 Wide Belt w/ Sensing (2000)<br />

53 ½” wide vacuum belt, 12” load space, sensing wheels<br />

prior to crossbelt, 1st Crossbelt – 20KW 150mm x<br />

7350mm belt, 2nd Contact Drum 18.5KW 1380mm x<br />

3250mm belt, 3rd Platten 14KW 1380mm x 3250mm<br />

belt, 4th Platten 14KW 1380mm x 3250mm belt, control<br />

console with monitor and keyboard, 12.5KW vacuum<br />

bed motor, min/max working thickness 3-160mm, working<br />

table height 900mm, feed motor power 4, 6KW, feed<br />

speed 3-30 m/min, thickness setting motor power 0,<br />

63KW, 480V, total amps 146, total KW 77, s/n 991103<br />

AC1.<br />

Costa Top & Bottom Wide Belt Sanding Line (1996)<br />

Bottom head machine, 47” wide vacuum belt, 26” load<br />

space, Constant pass line, 1st Contact 30KW, 2nd<br />

Contact 22KW, 3rd Contact 15KW, 7.5/8.6KW vari-drive<br />

motor, 5.5/6.4 KW vacuum blower motor, top head<br />

machine, 47” wide vacuum belt, 1st Contact 30KW, 2nd<br />

Contact 22KW, 3rd Contact 15KW, 7.5/8.6KW vari-drive<br />

motor, 5.5/6.4 KW vacuum blower motor, control console<br />

with amp gauge on each head, 440V, 263Amp, 250hp<br />

total, s/n 960423AC1.<br />

Opti-Sand R-52-V Rotary Denibbing Sander (2001)<br />

52” width capacity, the Opti-Sand R-52-V has 4 sanding<br />

spindles, (2) spindles are 64” long each with a 5hp motor<br />

and (2) spindles are 48” long each with a 3hp motor. (2)<br />

spindles rotate clockwise and (2) spindles rotate counterclockwise.<br />

The spindle speed is variable from 50-<br />

1,000 RPM by means of a frequency inverter. All of the<br />

spindles are placed on one main head, or plate, that also<br />

rotates. The head rotation adjusts from 5-25 RPM by frequency<br />

inverter. There is motorized push button<br />

up/down adjustment of the sanding heads and digital<br />

readout for sanding height. The R-52-V to be setup for<br />

460V, 3-Phase, 60Hz power. The Opti-Sand R-52-V is<br />

equipped with a variable vacuum hold-down system with<br />

(2) 10hp motors. The vacuum system is built into the<br />

base of the machine. With sound insulation material surrounding<br />

the vacuum pumps to reduce the operating<br />

noise level. The conveyor belt speed adjusts from 5-50<br />

FPM by a 3hp gear motor and frequency inverter. Net<br />

weight 6,800 lbs, 42hp, HYTROL powered roller conveyor,<br />

m/n 190-SP, 37” wide x 36’, rubber coated 2”<br />

diameter rollers.<br />

Sale On Premises With Simultaneous Web Cast! www.irs<strong>Auctions</strong>.com<br />

2

3<br />

Late!<br />

Auto. Lumber Hand. Hyd. Tilt Hoist<br />

Newman S-382 HD Dbl. Sided Planer<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Late!<br />

Mereen Johnson 424-DC/SR (1993)<br />

2001<br />

Ultimizer 800B-100 Opti.Cut-off (2001)<br />

Late! Late!<br />

Rough Mill Line<br />

Automated Lumber Handling Hydraulic Tilt Hoist<br />

14’ Capacity, (4) Arms 48” x 54”, Spaced 48” o.c., 20 HP 220/440V<br />

Hydraulic pump motor<br />

Automated Lumber Handling Chain Deck<br />

11’ Wide, (6) Chains, Spacing of Chains: 24”, 36”, 24”, 24” & 24”, 2 HP<br />

220/440V motor<br />

Newman Powered Belt Conveyor<br />

30”W x 24’L, Hydraulic operated<br />

Coe Moisture Meter Moisture Detector<br />

MR30 multi sensor LMD, s/n 58318<br />

Newman S-382 HD Double-Sided Planer<br />

30” Width Capacity, 6” Thickness Capacity, Newman Helical Carbide<br />

Cutter Heads, Bottom Head 40HP 220/440V, Top Head 75 HP 220/440V,<br />

25 HP 220/440V Hydraulic Pump Motor, Pneumatic Chip Breakers, (15)<br />

Pneumatic Drive Tires, s/n 13910<br />

Automated Lumber Handling Flat Top Chain Deck<br />

150”W x 21’L, (6) Chains, Spacing: 20”, 18”, 36”, 34” & 38”, 3 HP 220/440V<br />

motor<br />

BarrMullin Optimizer Fence<br />

(used w/ M J Gang Rip) 2 Lasers Moving<br />

147”W x 90”L Infeed Chain Deck, (6) Chains Spaced: 20”, 18”, 36”, 34”,<br />

38”, 18’L Moving Fence, (12) Canted Powered Case Rolls 40” x 4.5”D, 2<br />

HP 220/440V motor, Control Panel w/ (2) Monitors & Keyboard, (2) Moving<br />

Laser Lights<br />

Mereen Johnson 424-DC/SR (1993)<br />

24” Width Capacity, 26”W Rubberized Track, Select-A-Rip Moveable<br />

Blade, Bijur Mist Lubricating System, 3HP 220/440V Vari-Drive motor,<br />

Automated Lumber Handling Powered Belt Conveyor, 30”W x 120”L 2 HP<br />

220/440V, (2) 30” x 9” Pinch Rollers, s/n MJ-4599<br />

(2) Automated Lumber Handling Steps Over Line<br />

Automated Lumber Hand. Flat Roof Top Chain Deck<br />

12’W x 24’L, 6-chains spaced: 24”, 48”, 24”,24”, 24”, 5 HP 220/440V<br />

Ultimizer 800B-100 Optimizing Cut-off Saw (2001)<br />

Left-hand orientation, 42” saw passline, 20” blade, ICD width scanner, control<br />

console with monitor and keyboard, 7 ¾” wide belt conveyor, 7” x 4”<br />

cutting capacity (approx.), 8” wide x 16’ long double-sided marking station,<br />

9” wide x 40’ long powered belt conveyor, 7 pneumatic kickers, end scrap<br />

discharge, s/n 800B-181<br />

Late!<br />

Automated Lumber Handling Flat Roof Top Chain Deck Coe Moisture Detector Barr Mullin Opti. Fence<br />

www.irs<strong>Auctions</strong>.com 717.854.0316

2000<br />

1998<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Weinig Profimat 23 E 5-Head Moulder (2000)<br />

Diehl 5006 Moulder (1998) Weinig Profimat 23 E<br />

1998<br />

Diehl 5006 6-Head Through-Feed Moulder (1998)<br />

Wadkin XE 416 6-Head Through-Feed Moulder<br />

2000<br />

Diehl Vonnegut 4-Head Lg. Qty. of Moulder Heads<br />

Moulders<br />

Weinig Profimat 23 E 5-Head Moulder (2000)<br />

.787” – 9.055” width capacity, .315” – 4.725” height<br />

capacity, 1st Bottom 7.5 KW 220/440V 6000 RPM, 2nd<br />

Right 7.5 KW 220/440V 6000 RPM, 3rd Left shared<br />

motor with 2nd head, 4th Top 11 KW 220/440V 6000<br />

RPM, 5th Bottom 220/440V 7.5 KW 6000 RPM, Cardan<br />

drive, 3 KW feed motor 16-78 FPM, manual digital readouts<br />

– all heads, power height adjustment, 460V, s/n<br />

89695, Ziwo feeder, m/n CL11, 440 V, s/n 87-0898<br />

Diehl 5006 6-Head Through Feed Moulder (1998)<br />

Width capacity 9.25”, thickness capacity 4.75”, speed<br />

range 18-110 f.p.m., jointer table cut .4”, right guide<br />

movement .4”, Cardan drive, 10 hp 220/440V feed<br />

motor, outboard bearings on horizontals (except 1st bottom),<br />

1st Bottom 15 hp 220/440V 1 13/16” spindle, 2nd<br />

Right 15 hp 220/440V 1 13/16” spindle, 3rd Left 15 hp<br />

220/440V 1 13/16” spindle, 4th Top 20 hp 220/440V 1<br />

13/16” spindle, 5th Top 20 hp 220/440V 1 13/16” spindle,<br />

6th Bottom 15 hp 220/440V 1 13/16” spindle, Manual<br />

digital controls all heads, grooved and solid beds, accurate<br />

digital proscale, pneumatic door open and close,<br />

460 V, s/n 98M-6415-5831, Z drive 110 hopper feeder,<br />

s/n 110-0064<br />

Wadkin XE 416 6-Head Through-Feed Moulder<br />

230mm x 130 mm capacity, 1st Bottom 10 hp 220/440V<br />

1 13/16” spindle, 2nd Right 15 hp 220/480V 1 13/16”<br />

spindle, 3rd Left15 hp 220/440V 1 13/16” spindle, 4th<br />

Top 20 hp 220/480V 1 13/16” spindle, 5th 15 hp<br />

220/440V 1 13/16” spindle, 6th Bottom 15 hp 220/480V<br />

1 13/16” spindle, Cardan drive, 15 hp 220/440V Varidrive<br />

feed motor, 10 to 50 m.p.m., outboard bearings, manual<br />

digital readouts on each head, power raise and lower<br />

motor 1.5 hp 220/440V, 440V, s/n 93129, Z-drive 110<br />

hopper feeder, s/n 110-050.<br />

(5) Moulder Return Conveyors<br />

1 Metzgar, 4 custom<br />

Diehl Vonnegut 4-Head Moulder<br />

Hopper feed, 7” x 4” capacity (approx), 1st Top – 10hp<br />

220/440V, 2nd Left – 5hp 220/440V, 3rd Right – 5hp<br />

220/440V, 4th Bottom – 10hp 220/440V, (2) 8” long corrugated<br />

feed rolls, 3hp feed motor 220/440V, s/n D6466<br />

Moulding Heads<br />

Approximately 50, used with the above listed moulders.<br />

Sale On Premises With Simultaneous Web Cast! www.irs<strong>Auctions</strong>.com<br />

4

Cresswood LR30DST Horiz. Low Speed Grinder<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Cresswood EF-24-40 Low Speed Horiz. Grinder<br />

Radio Frequency Services Hi Freq. Gluer (2000)<br />

5<br />

2000<br />

1997<br />

Set Up Your Webcast Account Today @ www.irs<strong>Auctions</strong>.com<br />

2000<br />

Late!<br />

L&L Du-All DA50 High Frequency Gluer<br />

Low Speed Grinders / Hogs<br />

Cresswood LR30DST Destroyer Horiz. Low Speed (2000)<br />

75hp main motor 220/440V, 3hp varidrive motor, 30” wide x 18’<br />

long vibratory conveyor, complete sound enclosure, s/n 1100200<br />

Cresswood EF-24-40 Destroyer Horiz. Low Speed (1997)<br />

24"W Infeed, 40hp 220/440V Main Motor, 1 HP 220/440V Motor,<br />

vibrating infeed conveyor 23”W x 13’L, s/n1330897<br />

Williams 17545 Hammer Hog<br />

50hp 220/440V w/transfer fan<br />

High Frequency Gluers<br />

Radio Frequency Services High Freq. Gluer (2000)<br />

m/n RFSN30505A0500PC, clamping area is 50” x 100” x 10”<br />

thick, clamping pressure is applied by hydraulic cylinders and<br />

pusher shoes, pressure is capable of exerting 200 psi over full<br />

length of 10” thick load, edge pressure (100”) applied by thirtytwo<br />

(32) each 2” bore x 4” stroke hydraulic cylinders, supplied by<br />

a common manifold for uniform pressure across the full length of<br />

the panel, 15 hp hydraulic pump unit equipped with a 50 gallon<br />

tank, top pressure applied by four (4) each 2” bore x 18” stroke<br />

hydraulic cylinders (two rows), 30KW internal solid state RFS RF<br />

Generator can cure approximately 3000 sq. in. of glue line area<br />

per minute, wired for 480V 60 Cycle 3-Phase operation, 120V AC<br />

controls, Auto Cure: feature utilizes the PLC in the press to determine<br />

when the glue lines are completely cured then stops the<br />

press regardless of the timer setting, the press will still feature the<br />

standard timer which can be enabled by a switch, 54”x102” shuttle<br />

table, 1hp 220/440V motor, 53”x100” outfeed table<br />

Slat Conveyor Glue Spreader<br />

17 ¾” width capacity, 21” x 8’ infeed slat conveyor, 21” x 8’ outfeed<br />

slat conveyor, 1 hp single phase motor<br />

L&L Du-All DA50 High Frequency Gluer<br />

50” x 100” capacity, (11) pneumatic top pressure cylinder, (6)<br />

pneumatic side pressure cylinder, (2) pneumatic open & close<br />

cylinder, 440V 45 amp, s/n 87-793<br />

Workrite 4000 Wood Welder<br />

On The Premises Auction<br />

& Simultaneous Web Cast!<br />

This is a Landmark Sale, Mark Your<br />

Calendar & Plan to Attend Now!<br />

www.irs<strong>Auctions</strong>.com 717.854.0316

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Combination Dowel Equipment<br />

Koch Sprint-PTP-L CNC Boring and Dowel Machine (2001)<br />

92” length capacity (2 zone), 17 ½” x 92” work table, control consolel<br />

with PC, monitor, and keyboard, (8) moveable pneumatic<br />

hold-downs, .9 KW boring motor, 480V, 9.5A, 3-Phase, s/n<br />

A0103/6560<br />

Koch CNC Sprint-PTP Bore & Dowel Insert Machine (2000)<br />

49” working capacity, 17 ¾” x 49” table – 2 zone, .9Kw boring<br />

motor, (8) moving, pneumatic hold downs, control panel with PC,<br />

monitor, and keyboard, 480V 4Kw total, s/n A0004/6338<br />

Accu Systems DS1 Dowel Inserter Gun with Hopper<br />

s/n 96HC1173<br />

Wide Belt Sanders<br />

Timesaver 337-200B Orbital Cross Belt<br />

2-Head Sander 36 ½” wide belt, 32” load space, 6” wide crossbelts,<br />

1.5 hp 220/440V each head, power raise and lower, 3hp<br />

varidrive motor, s/n 19126<br />

Timesaver 337-3 AHB<br />

3-Head Denibber 37” wide belt, 3 denibbing heads on an angle,<br />

1st Head - 3hp 220/440V, 2nd Head – 3hp 220/480V, 3rd Head<br />

– 3hp 220/440V, frequency inverts on all heads, 3hp varidrive<br />

motor, s/n 19127<br />

Timesaver 325-2<br />

2-Head Wide Belt Sander 25” width capacity, 19” load space, 1st<br />

Head – contact drum 30 hp 220/440V, 2nd Head – Platen 2.5hp<br />

220/440V, 2hp 220/440V varidrive motor.<br />

Timesaver 125-1HD<br />

Top Head Wide Belt Sander 25” width capacity, 22” load space,<br />

single combo head, 15hp main motor 220/440V, 1hp varidrive<br />

motor 220/440V, load motor, s/n 19438Y<br />

Timesaver 125-1 HDB<br />

Bottom Head Wide Belt Sander 25” width capacity, 48” load<br />

space, single combo head, 20hp 220/440V main motor, 1.5hp<br />

varidrive motor, load meter, s/n 21939<br />

Timesaver 337-200B Orbital<br />

Timesaver Denibber<br />

Koch Sprint - PTP - L CNC Boring & Dowel (2001)<br />

Koch CNC Sprint - PTP Bore & Dowel (2000)<br />

Timesaver 337-200B & Orbital Belt 337-3 AHB<br />

Timesaver Top & Bot. Line<br />

www.irs<strong>Auctions</strong>.com<br />

Sale On Premises With Simultaneous Web Cast! www.irs<strong>Auctions</strong>.com<br />

2001<br />

2000<br />

Late!<br />

Accu Sys. DS1 Dowel Gun<br />

6

7<br />

www.irs<strong>Auctions</strong>.com<br />

Dodds SE-25CNC Single End Dovetailer (1999)<br />

Late!<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

1999<br />

Celaschi TSA-400C Double End Tenoner<br />

Timesaver Planer (1997) & Whitney Facer<br />

Dovetail Equipment<br />

Dodds SE-25CNC Single End Dovetailer (1999)<br />

25 spindles, 10hp, 12,000 RPM, spindle lubrication: auto, oil<br />

mist, digital readouts for front and backside stops, drawer<br />

height: 1 ¾” – 25”, top to bottom, drawer width: 8” – 48”, drawer<br />

depth: 7” minimum front to back, material thickness: 3/8” –<br />

3/4” sides, 7/16” 1-3/4” fronts/backs, 220V, 3-Phase, 60 cycle,<br />

41 amp, 440V, 3-Phase, 60 cycle, 32 amp, s/n D99031-168.<br />

(2) Dodds C-36 Dovetail Drawer Clamp<br />

42” opening, pneumatic traverse, 26 ½” high jaws, s/n C8974-<br />

255,s/n n/a<br />

Dodds GP Dovetail Gluer<br />

s/n 91027-305<br />

Double End Tenoner<br />

Celaschi TSA-400C Double End Tenoner<br />

113” max opening (approx.), 1st Post – Universal tilting score<br />

1.5hp/2.5 hp 600V 3600/7200 RPM, 2nd Post Front side - tilting<br />

universal, 5.8KW, 220/380V, 3000/6000 RPM, 2nd Post<br />

Back side – universal jump, 5.5/8hp, 340/600V, 3600/7200<br />

RPM, 3rd Post Front side – 5.5/8hp 340/600V, 3600/7200<br />

RPM, 3rd Post Back side – universal tilting, 5.5/8hp,<br />

340/600V, 3600/7200 RPM, power traverse, 3” wide rubberized<br />

track, pop up dogs 15 ¾” on center, Caterpillar style<br />

upper hold-down belts, Carter laser alignment light, 50 KVA<br />

frequency converter, s/n 3307<br />

Double Sided Planer Line<br />

Timesaver 337-1K Planer (1997)<br />

Gladu replaceable cutter spiral carbide head, 36” Width<br />

Capacity, 24” Load Space, 40hp 220/440V Main Motor, 10 HP<br />

220/440V Hydraulic Pump Motor, Powered Open & Close,<br />

Amp Meter, Accurate Pro-Scale, hyd. feed, s/n 25719<br />

Whitney S-600 Facer<br />

36" Width Capacity, 15 HP 220/440V Main Motor, 1.5 HP<br />

power open / close motor, Rubberized upper track, carbide<br />

cutter head, s/n 17967<br />

Metzgar Powered Belt Conveyor In between conveyor, 36”w<br />

x 10’L, ½ HP 220/440V, Allen Bradley PLC controller<br />

1997 Qty. 2<br />

Whitney S-600 Facer Timesaver 337-1K (1997) Timesaver 337-1K Planer Hd. Dodds C-36 Dovetail Clamp<br />

www.irs<strong>Auctions</strong>.com 717.854.0316

1996<br />

Profilamatic Stile Bore w/ Sanding<br />

Late!<br />

Nichols Cleat Block Machine<br />

Weinig Rondamat 931 Profile Grinder<br />

Hess Laura Case Clamp (2000)<br />

Stehle PSM Profile Grinder<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

2000<br />

Stile Bore & Sander<br />

Profilamatic Sanding Stile Bore & Sander<br />

Four 2hp drill units three spindle heads, drill distance 7/8”, 2-5/8”, 3.5” on<br />

center, pneumatic movement on individual THK ways system, independent<br />

control of each unit, four 2hp belt sanding units, two units designed as drum<br />

sander, two units designed as shoe sander, belt size 2.000” width x 109.5<br />

long, automatic tracking system, dust hood and guards, belt feed through<br />

system, holddowns and pressure systems, 4.000” wide Linatex conveyor<br />

belt, .25hp DC variable speed drive up to 45 feet per minute, (7) accurate<br />

pro-scale digital readouts,<br />

Cleat Block Machine<br />

Nichols Cleat Block Machine<br />

3” to 18” cleat length, ¾” x ¾” stock, (2) 1hp 220/440V Boring motors with<br />

3 adjustable boring heads on each side, 1.5hp 230/460V cutoff saw, 8” saw<br />

blade capacity, 2 pneumatic hold downs, pneumatic boring movement, hopper<br />

feeder, pneumatic infeed pusher, pneumatic saw movement, digital<br />

readout, average production is 20 blocks per minute.<br />

Grinding Room<br />

Weinig Rondamat 931 Profile Grinder<br />

Grinding wheel diameter max 8 - 55/64”, Grinding wheel width 13/64”,<br />

Grinding wheel bore 2-23/64”, Maximum tool diameter 11-51/64”, Minimum<br />

tool diameter 3-59/64”, Maximum tool width 9-3/64”, Grinding wheel drive<br />

1.5hp, rotation 1420 RPM, Coolant pump drive 0.28kW, Coolant tank capacity<br />

approx. 26.5 gallons, s/n 931-314.<br />

Stehle PSM Profile Grinder<br />

2.2 KW, 220V 3-phase, 10” capacity, digital RPM gauge, s/n 3796189<br />

Wadkin Optical Moulding Head Setup Reader<br />

Opticass optical computer-aided setting system, 14” capacity<br />

Case Clamps<br />

Hess Laura LA000086/003 Case Clamp (2000)<br />

50 ½” high x 97 ½” long capacity, (6) horizontal pneumatic clamps, (4) vertical<br />

pneumatic clamps, 220V 75Kw power with Open/Close motor, s/n<br />

LA0000861003<br />

Hess Case Clamp<br />

53”high x 98” long capacity, (8) vertical pneumatic clamps, (6) horizontal<br />

pneumatic clamps, .55Kw 220V power raise/lower motor, s/n<br />

100712/101989<br />

Hess Case Clamp<br />

On The Premises Auction<br />

& Simultaneous Web Cast!<br />

This is a Landmark Sale,<br />

Mark Your Calendar<br />

Plan to Attend Now!<br />

www.irs<strong>Auctions</strong>.com<br />

Sale On Premises With Simultaneous Web Cast! www.irs<strong>Auctions</strong>.com<br />

8

9<br />

Nissan 35 Forklift<br />

Kalmar LP Forklift<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Qty. 5<br />

Lancaster 1861-B & 1410-B Frame Clamps<br />

Overview of Forklifts<br />

Late! Late!<br />

Nissan 30 Forklift<br />

Late!<br />

Crown Stand-Up Forklift<br />

2001<br />

Giardina G95/08 2-head roll coat line w/oven<br />

Frame Clamps<br />

(3) Lancaster 1410-B-275 Easel Clamps<br />

2 pneu. cyl., 93” x 62” cap., (High Jaws) 55”x84” cap., 46”x84”<br />

cap. s/n 1410-B-275,1410-B-393, 1410-B-186<br />

(2) Lancaster 1861-B-211 Frame Clamps<br />

46”x84” cap., (2) pneu. pressure cyl. s/n 1861-B-211, 1861-73<br />

Lancaster 1200-B-409 End Clamp Pneu..<br />

(2) Handy 967 Frame Clamp<br />

3 pneu. cyl., s/n M6XC967, E1XB967<br />

Forklifts<br />

Nissan 35 CPJ01A18V Forklift<br />

3,500lb. cap. LP gas, sideshift, 2852 hours, s/n CPJ010-9N1600<br />

Nissan 30 N0115V Forklift<br />

3,000 lb. cap. Elect., sideshift, 2900 lb. lift cap., 169” lifting ht.,<br />

3447 hrs., s/n N01-700595<br />

Kalmar ACC100RC LP Forklift<br />

6,500 cap. LP gas, 171” lift ht., dual front tires, 2214 hrs., s/n<br />

650024<br />

Yale Type E Forklift<br />

2,000# cap., elect., 1059 hours, s/n 162G<br />

Crown Lift & Ride TWR3540-280<br />

24V, 34” x 25” lift platform, s/n 6A201265<br />

Crown RC3000 Stand-Up Forklift<br />

Elect., sideshift, 2750# lift cap.,190” lift ht.,1563 hours, s/n<br />

1A200607<br />

Crown Electric Walk Behind, 2000 lb. cap., s/n 1A208229<br />

Schaeff E-2000B Stand-Up Forklift<br />

Elect., 8275 hrs., s/n 10268710<br />

Big Joe Walk Behind Electric Forklift<br />

2000# Cap., Built-in Charger, s/n 346393<br />

Walk Behind Electric Forklifts<br />

Crown 2000#, m/n W21-90-S, s/n L-6386-2, Crown 2000# s/n<br />

1A231439, Prime Mover 2000# m/n SN-20, s/n 1555, Crown<br />

2000# s/n 1A208229, Crown 1500# m/n WT-90-S, s/n L-6180,<br />

Prime Mover 4500# m/n PMX2, s/n PMX2 237359, Crown<br />

2000# s/n 1A1011294<br />

Factory Cart FC1001 floor cleaner, s/n 34-11320<br />

Finishing Lines<br />

Giardina G95/08 2-head roll coat line w/oven (2001)<br />

Machine width 1,350mm, 1,320mm working width, loading belt<br />

conveyor 55” wide x 75” long, .5HP, roll coat machine, .75HP, Jethot<br />

air drying tunnel, equipped with 3 infra-red twin courts lamps,<br />

9.75KW each, suitable for application of UV high and medium<br />

viscosity putties & waterbase, s/n 1151/2 More info available<br />

upon request.<br />

Finishing Line<br />

(12) Spray Booths, 11', 8’deep x 10’ high x 10’ wide, pneumatic<br />

sliding doors, (2) explosion-proof lights, Drying Tunnel, (6)<br />

Flammable Cabinets, (16) Pressure Spray Pots, Red Devil Paint<br />

Shaker s/n F13167<br />

www.irs<strong>Auctions</strong>.com 717.854.0316

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

On The Premises & Simultaneous<br />

Web Cast!<br />

Qty. 5<br />

(5) Great Dane 48'Trailers<br />

Ford L9000 Semi Tractor Stoughton Trailer 53’ (2000)<br />

Ford E-350 Van<br />

Amer. Air Filters Collector<br />

Black Bros. Cold Press<br />

2000<br />

Dust Star Collector (1990)<br />

Pneumafil 13.5 Collector<br />

Saws Cut Off & Miter<br />

Omga V235 Double Miter Saw (2000)<br />

14” blades, 5” x 99” table, pneu. stop, 3.6Kw 460V, s/n 2-921<br />

Whirlwind 212L Chop Saw (2000)<br />

10HP, 3 phase, 230/460 volt motor, (1) 18” diameter cut-off<br />

blade, 2” x 12” capacity, foot pedal actuation, s/n 6580548L<br />

Pistorius C Miter Chopper, s/n 75489<br />

Rolling Stock<br />

Stoughton Van Trailer 53’ (2000)<br />

Vin# IDW1A53231B483186<br />

(5) Great Dane 48'Trailers<br />

65,000lbs,Vin# 1GRFA9624DB113714,<br />

1GRFA9620DB113709, 1GRFA962CDB113703,<br />

1GRFA9625EF049801 & 1GRFA9629FB049803<br />

Ford L9000 Semi Tractor<br />

422,621, sgl. axle, VIN #1FDYR90L5HVA47414<br />

Ford Club Wagon E-350 Van<br />

15 passenger, 77,000 miles, V-8 engine, AC/Rear AC / PW<br />

/ PL/ TW/ AM-FMCass. / CC, vin# 1FBSS31L5WHB25619<br />

Cushman Electric Car Minute Miser s/n 95003932<br />

Dust Collection<br />

Dust Star 12-456-704 Dust Collector (1990)<br />

IAP 542 EHD B ARR 1 transfer fan, approx. 65,000 cfm @<br />

14" sp, 250hp, 460v, 40hp aux. transfer fan, 12' bags, 456<br />

bags, s/n IAP #901082, Rotary Air Lock, s/n 90-36012-1,<br />

order #1290 36012<br />

Pneumafil 13.5 Dust Collector<br />

250hp 460V Main Transfer Fan, 20 HP 220/440V Auxiliary<br />

Transfer Fan, (2)Rotary Air Lock, s/n 31149-2<br />

American Air filters Dust Collector<br />

size 1-306, 125hp transfer fan, 25hp transfer fan (to bin), 4<br />

rotary air locks, s/n AT240025<br />

Wheelabrator Dust Collector s/n A180543<br />

150hp 460V main transfer fan, 20 HP 220/440V auxiliary<br />

1152 Bags 10’long, s/n A180543<br />

American Air Filters Dust Collector<br />

size 1-306, 125hp transfer fan, 25hp transfer fan (to bin), 4<br />

rotary air locks, s/n AT240025<br />

Grecon Spark Detection Extinguishing Sys. (1998)<br />

m/n CC704, 12-zone, s/n 2466<br />

Presses<br />

Black Bros. Cold Press<br />

38” x 102 ½” work area, (4) independent platens, 25 ½” 38”<br />

each, adjustable daylight opening to 26”, popup infeed/outfeed<br />

rollers, 60 minute timers on each platen, s/n 172623<br />

Evans 0256 62" Wide Pinch Roller<br />

115V, s/n 565212<br />

2000<br />

Whirlwind 212L Saw Omga Double Miter Saw<br />

Sale On Premises With Simultaneous Web Cast! www.irs<strong>Auctions</strong>.com<br />

2000<br />

10

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Diehl 750 Straight Line Rip Saw<br />

Powermatic 81 20” Tannewitz GH 36”<br />

(4) Delta 28-245 14"<br />

Tannewitz XJ Table Saw Tannewitz U Table Saw<br />

11<br />

On The Premises &<br />

Simultaneous Web Cast!<br />

Qty. 4<br />

Qty. 5<br />

Qty. 4<br />

(4) Delta Unisaws<br />

Hitachi Resaw<br />

Ritter R-813 Hor. Borer<br />

Straight Line Rip Saw<br />

Diehl 750 Straight Line Rip Saw, 24” throat, 80” x 63” table, 15<br />

hp 220/440V main motor, variable feed 60 to 180 f.p.m., short<br />

stop electronic motor break, straightening fence, s/n 62-2765<br />

Resaws<br />

Hitachi CB100F Band Re-Saw w/ Feeder, 25 ½” x 3 ½” wheels,<br />

10hp 220/440V main motor, 29” x 32” tilting table, 16” underguide,<br />

Tyler power belt feed deck 10A 115V 5” wide belt, s/n 845011<br />

Cut Off Saws<br />

Copco 47A20 Hydracut, 5 HP (approx) s/n 860025<br />

Bandsaws<br />

Tannewitz GH 36”, 5hp 220/440V, s/n 14896<br />

Tannewitz RHE 42", 7.5hp 220/440V, 36”x37” table, s/n 76060<br />

Oliver 116 36” 5hp, 440V, s/n 32704<br />

Powermatic 81 20”, 20" cap., 3-phase, s/n 8381045<br />

(4) Delta 28-245 14", ½hp, 115V, s/n 90E35875, 89651045, 86-<br />

B00943, 83K05343<br />

General 490 15”, s/n V4660 1/2hp, 115V, s/n<br />

Astro WB8-14 14", 115V, s/n 86017755<br />

Table Saws<br />

Tannewitz U Table Saw, 5hp 3500 RPM 220/440V, 14 amp total,<br />

s/n 12348<br />

Tannewitz XJ Table Saw with Feeder, 5hp 220/440V, 14 amp<br />

total, 3,600 RPM, 4-roll HOLZ feeder, s/n 11162<br />

(3)Tannewitz J Table Saw, 5hp 220/440V (approx.), s/n 3756,<br />

2892<br />

(4) Delta 34-806 Unisaw, 5hp 220/440V, s/n 88F38435, s/n 42-<br />

6275, 89D18940<br />

Darra James Table Saw with Feeder, 2hp 220/440V, Nandina 3-<br />

Roll feeder<br />

Wards 64TDW227 Table Saw, Approx. 2hp 220/440V, s/n 912SC<br />

Boring Machines<br />

Ritter R-813 Horizontal Borer (1995), 13-spindles, 2" centers,<br />

3hp 220/440V, (3) pneumatic hold-downs, foot pedal, 36”x12”<br />

table<br />

Drill Presses<br />

Root GM Borer, 2hp 3,600/1,800 RPM, 460V s/n 8154<br />

Oliver 72D Drill Press, 2hp 220/440V, s/n 36101<br />

Oliver 72-D Drill Press, 2hp 440V, s/n 95492<br />

Delta Rockwell 15-665 15” Drill Press<br />

3/4hp Single-phase, pneumatic drill movement, s/n 1491609<br />

Routers<br />

Onsrud A-1124 Pin Router, s/n 9182<br />

www.irs<strong>Auctions</strong>.com 717.854.0316

On The Premises<br />

& Simultaneous<br />

Web Cast!<br />

Qty. 2<br />

Oakley H-5 Edgesander<br />

Oakley H-5 Edgesander<br />

Crouch Edgesander<br />

Qty. 2<br />

Qty. 2<br />

Oakley H648 Edgesander<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Edge Sanders<br />

(2) Oakley H-5, Oscillating, (2) 9” x 52” platens, s/n 490133. 73-1/2" x 11" platen,<br />

s/n 4473R<br />

(2)Oakley H648, Oscillating, (2) 9” x 49” platens, 7.5hp 220/440V, s/n 3637, 3852<br />

Oakley H6 Oscillating, (2) 37”x7” platens, 5hp 220/440V, s/n 3363<br />

Ekstrom Carlson 112, Oscillating, 9” x 58” platen, 5hp 220/440V, s/n 112/329<br />

Wysong & Miles, Oscillating, two sided, 5hp 220/480V, 9” x 37” platens<br />

Crouch 60, 8” x 60” platen, 5hp 220/440V, s/n 081789<br />

(2) Powematic 013, 6-3/4” x 33-3/4” platen, 1-1/2”hp 115/230V<br />

Indiana, 10.5” x 42.5” platen, 5hp 220/440V<br />

Drawer Sanders<br />

Oakley H-15, 14” wide belt, 5hp 220/440V motor, s/n 3107<br />

(4) Peerless, 3hp 220/440V, 14” wide belt, s/n 6470<br />

Sanders Misc.<br />

State B4 Spindle Sander, 115V,<br />

Pearson Spl. Sand. Tilting, 1hp 220/440V, s/n 298A<br />

Wysong & Miles Spindle Sander, 3/4hp 220/440V<br />

(3) Delta 31-730 Belt & Disc Sander, 115V<br />

Jet JSG-6DC Belt/Disc Sander, 1-1/2hp, 115/230V,<br />

Craftsman 113.225930 Belt/Disc Sander, 3/4hp, 115V<br />

(4) Powermatic 33 Vert. Belt Sander, 115V, 6” wide belt<br />

(2) Delta Vert. Belt Sander, 6” belt, 115V,<br />

Enco 163-4900 Vert. Belt Sander, 6” x 9” belt & disk<br />

(3) Delta 31-125, 12” Disc Sander, 1hp, 115/230V<br />

Porter Cable BG8 Vert. Belt Sander, 5hp 220/440V,<br />

9” wide belt, s/n 6076 3/4hp, 115V, s/n 100-7280<br />

Planer & Jointers<br />

Powermatic 100 Planer, 12” width capacity, 5” thick cap.<br />

, 3hp 220/440V, s/n 8410221<br />

Delta 8" Jointer, 3-Phase<br />

Porter 6” Jointer, 1hp, 220/440V<br />

(2) Boice Crane 6" Jointer, 115V, 3/4hp<br />

Shapers<br />

Baxter Whitney 139 Double, 30” centers, (2) 5hp 220/440V, s/n 12894, Delta<br />

Shaper, Feeder, s/n HC870<br />

Porter 203 Shaper w/ Feeder, 5hp 220/440V, 3,600 RPM, 3-Roll feeder, s/n 2309<br />

Qty. 3<br />

Ekstrom Carlson Edgesander Oakley H-15 Drawer Sander Delta Belt & Disc Sanders Powermatic 100 Planer<br />

Sale On Premises With Simultaneous Web Cast! www.irs<strong>Auctions</strong>.com<br />

12

Manipulator Strongarm<br />

Sligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

SP Industries Bailer Speedy Foam System<br />

(11) Ergolift Electric Pallet jacks<br />

(11) H. Kallesoe KG1000 Airlift Pallet Jacks<br />

Compair 218 Compressors<br />

Compair Air Dryer<br />

13<br />

Qty. 11<br />

Qty. 11<br />

Qty. 3<br />

Zeks Air Dyer<br />

Manipulators<br />

Strongarm / J&J Manufacturing Case Manipulator, 3 HP<br />

220/440V Rotation motor, 3 HP 220/440V Lift motor, 24” x 40”<br />

Jaws, 15” – 97” Opening, (2) Pneumatic Cylinders, s/n 001642<br />

Feeder/Stacker Pneu. Vacuum Lift, (8) Vacuum pods<br />

Manipulator w/Scissor Lift, 2000 lb. cap.<br />

Pallet Jacks<br />

(11) H. Kallesoe KG1000 Airlift Pallet Jacks,1000kg max.,<br />

(11) Ergolift Electric Pallet jacks, (25) Manual Hyd. Pallet Jacks<br />

Air Compressors & Dryers<br />

(3) Compair Kellogg 218 Hydrovane compressors, 50hp each,<br />

s/n 2HV59/309, n/a & n/a<br />

Zeks 400H8FA400 Compressed Air Dryer, s/n 190780<br />

Air Compressor 340-33, 10hp, 230/460V, s/n 142876-L<br />

Pioneer R40A Air Dryer, 115V, s/n 61923E5A17<br />

Compair Kellogg Compressed Air Dryer, s/n 190780<br />

Posizorb Oil/Water Separator<br />

Large Air Tank<br />

Pallet Racking<br />

Pallet Racking, (55) sections<br />

1000+ Stackable Racks, 36” x 48” x 10” (majority)<br />

Package Equipment<br />

Thermolok Packaging Systems Strapper, 39.5” x 42.25”<br />

Banding Area, ½” Banding, 480V, s/n0000140<br />

Speedy Packers SP3-6251 Foam Packing System (2000)<br />

Viking Industries Titan Hot Melt Gluer<br />

Bailer<br />

SP Ind. VB-72-HD Bailer, 6' cap., wired 480V, s/n 92070276<br />

Huge Quantity of Scissor Lifts<br />

(22) Southworth X-Lift, 2000 lb., (1) Southworth 4,000 Lb. X-<br />

Lift, (4) American 2000 lb., X-Lift,<br />

Maintenance Lift<br />

MEC 2033ES Maintenance Scissor Lift, 50# Capacity (2 persons),<br />

32”x90” platform, 30”x32” platform extension, on-board<br />

charger<br />

Qty. 22<br />

Sample Views of (22) Southworth X-Lifts<br />

www.irs<strong>Auctions</strong>.com 717.854.0316<br />

1999<br />

MEC 2033ES Maintenance X- Lift

Bridgeport Vertical Mill<br />

Rigid 300 Pipe Threader<br />

Qty. 5<br />

Jesco Self Dump Hoppers<br />

Slligh Furniture & Clocks ~ Holland, MI. <strong>October</strong> 27 th <strong>10am</strong><br />

Maintenance<br />

Wilton 3300 Horizontal Metal Bandsaw, 1/3 hp single phase, s/n 864063,<br />

Abrasive Cut-off Saw, 5hp 220/440V 16” cutting wheel<br />

Atlas 4804 Metal Lathe, 36” between centers, 12” swing, 3/4 hp, s/n 150135,<br />

Bridgeport 96084 Vertical Milling Machine, 1hp 220/440V, s/n J-93453,<br />

12 Ton Hydraulic Press, Resolve Industries Parts Washer, Delta 20” Drill Press,<br />

70-200, 1hp, 115/230V, s/n R9504, Hobart Handler 120 MIG Welder, Miller<br />

Thunderbolt Welder, Wilton Metal Band Saw, 1/2hp, 1ph, Rigid 300 Pipe Threading<br />

Machine, Miller Blue Star 2-E Arc Welder, Gas powered engine, Wilton Horiz. Metal<br />

Bandsaw, 1/2hp, 115/230V, m/n 3230, s/n 877091<br />

Misc. Support Equipment<br />

Porter carver/sander, Ritter Shape master Jig, (8) Airflow Systems F70 Air<br />

Cleaners, DTI 5000 Hopper Feed Screw Driver, (2) Delta 34-080 10” Miter Saw,<br />

120V, s/n K8929, s/n 9124, Factory Cat Floor Sweeper, 12V DC System, Charger, 238<br />

Hours, s/n 34-11320, Self Dumping Hoppers, (5) Jesco self dumping hoppers,<br />

Plastic Dump Hoppers, (25+ available), Cecor metal bins (27+ available) (3) Hytrol<br />

Power (26) roller Sections.<br />

General Miscellaneous<br />

Miscelleneous: Dandy scissor lift, dock lights, staple guns, nail guns, clamps (bar, pipe<br />

& spring), hammers, disc sanders, screw guns, air hose, squares, air blow offs, wrenches,<br />

wood clamps, belt sanders, parts bins, fans, trash cans vertical inspection lights, staples,<br />

(4) clamp tables, ultra max sprayer, etc.<br />

(50) Lineberry factory carts.<br />

Real Estate Available by Private Negotiation!<br />

Real Estate<br />

Prime Real Estate in Holland, MI.<br />

Building has beautiful offices. It has<br />

large manufacturing and warehousing<br />

areas. There is plenty of dock<br />

door access and it is located close to<br />

major interstates.<br />

Total Sq. Ft.: 224,200<br />

Mfg. & Warehouse Sq. Ft. 213,200<br />

Office Sq. Ft. 11,000<br />

Address: <strong>1201</strong> <strong>Industrial</strong> <strong>Ave</strong>.,<br />

Holland MI. 49423, Allegan County,<br />

Acreage: 19.72<br />

Proximity: US 31 1 mile, Interstate<br />

196 1.3 miles.<br />

Zoning: 1-2<br />

Sprinkler System: 100%<br />

Availability: 1-1-2006<br />

For more informatioin please contact<br />

us at 717-849-5042<br />

Sale On Premises With Simultaneous Web Cast! www.irs<strong>Auctions</strong>.com<br />

14

TERMS OF SALE<br />

REGISTRATION & DEPOSIT:<br />

A minimum, refundable deposit of $200.00 paid in cash or check will be mandatory in order<br />

to receive a bidder's paddle. All checks (blank or otherwise) must be made payable to<br />

<strong>Industrial</strong> Recovery Services Inc. and accompanied by a Bank Letter of Guarantee. A deposit<br />

of 25% must be maintained throughout the sale. All purchases must be paid for at the end of<br />

each auction day. No lots will be removed until payment is made in full. NO EXCEPTIONS!<br />

All purchases are subject to MI. State Sales Tax. If you are exempt, you must provide proper<br />

exemption documents.<br />

PAYMENT:<br />

Only Cash, Certified or Cashier’s check payable to <strong>Industrial</strong> Recovery Services will be<br />

accepted. Company or Personal Checks (blank or otherwise) payable to “<strong>Industrial</strong> Recovery<br />

Services” will be accepted only if accompanied by a Bank Letter of Guarantee made payable<br />

to the auctioneer showing a statement of limits and dated for the day of the sale. Your Bank<br />

Letter of Guarantee must be good for 10 days beyond sale dates & should be similar to the<br />

following:<br />

Mr. “Customer’s Name” on account #____is a customer of this bank. This bank will guarantee<br />

unqualified payment to <strong>Industrial</strong> Recovery Services, Inc. up to the amount of $____. This<br />

letter is for purchases made at the Sligh Auction being held on <strong>October</strong> <strong>27th</strong>, 2005, in<br />

Holland, MI. This letter is valid until November 7th, 2005.<br />

Payments made by wire transfer will be only be accepted if arrangements have been made<br />

(2) days prior to the auction with our auction office.<br />

BUYER’S PREMIUM:<br />

A 10% Buyer’s Premium will be applied to all on-location purchases.<br />

A 13% Buyer’s Premium will be applied to all Web-Cast purchases.<br />

ABSENTEE BIDDING:<br />

If you have a problem attending the auction and would like the auctioneer to bid on you<br />

behalf, please call and ask us to explain our proxy bidding process. All proxy bids must be<br />

received two days prior to the auction and accompanied by a 25% deposit. The above mentioned<br />

standard 10% Buyer’s Premium will be applied to all absentee purchases.<br />

INTERNET BIDDING / WEB-CAST:<br />

Simultaneous, real-time Internet bidding will be available on major equipment. Please contact<br />

our office (no less then three days prior to the auction) to set up your web-cast account. A<br />

13% Buyer’s Premium will be added to all Web-Cast purchases. Web-Cast participation will<br />

be for large items only. Visit us at www.irs<strong>Auctions</strong>.com for details on internet bidding.<br />

IMPORTANT NOTICE:<br />

The Buyer acknowledges that he/she or an agent has inspected all the assets upon which<br />

he/she will be bidding on and/or does purchase. Buyer agrees to accept assets purchased<br />

“as is”, “where is”, “in place”, and “with all faults”. The Buyer expressively waives any claim<br />

in respect to any possible future use of any asset purchased for any purposes whatsoever.<br />

The Buyer does hereby assume and does agree to indemnify, defend and hold the Auctioneer<br />

and Seller harmless for any future claim which shall pertain to the fitness, merchantability,<br />

suitability for any particular purpose, or use of that asset as being purchased. Neither the<br />

Auctioneer nor the Seller assumes any liability for errors, omissions and/or accuracy in this<br />

listing. All assets will be offered subject to prior sale. Everything will be offered to the highest<br />

bidder for cash in accordance with the Auctioneer’s customary “Terms of Sale”, copies of<br />

which will be posted on the premises. Sale subject to other terms announced the day of the<br />

sale.<br />

Sorry, but due to insurance reasons & disruption of the sale, there will be no removal<br />

of any large non-hand carriable items during the day of the auction!<br />

INDUSTRIAL RECOVERY SERVICES<br />

P.O. Box 5086 • York, PA 17405<br />

RETURN SERVICE REQUESTED<br />

®<br />

Hampton Inn<br />

12427 Felch St<br />

Holland, MI 49424<br />

Furniture & Clocks<br />

Holland, MI. Mfg. Facility<br />

Thurs. Oct. 27 th 10:00am<br />

Preview: Wednesday, <strong>October</strong>, 26th 9am-4pm<br />

<strong>1201</strong> <strong>Industrial</strong> <strong>Ave</strong>., Holland, MI.<br />

AUCTION<br />

DIRECTIONS:<br />

From Grand Rapids Airport: Turn left from Airport enterance<br />

to M-6 west. Follow M-6 to merge with Interstate 196<br />

west to Holland. Take exit 49 (M-40) north (right). Follow left<br />

curve, factory on right.<br />

From South Central: From south central take US 131 north<br />

to M-6 west. Follow M-6 to merge with Interstate 196 west to<br />

Holland. Take exit 49 (M-40) north (right) north. Follow left<br />

curve, factory on right.<br />

From South West (Chicago): Take Interstate 96 east to<br />

Interstate 196 east. Follow Interstate 196 towards Grand<br />

Rapids. Take exit 49 (M-40) north (left). Follow left curve, factory<br />

on right.<br />

Accommodations:<br />

616-399-8500<br />

Residence Inn<br />

631 Southpointe Ridge Rd<br />

Holland, MI 49423<br />

616-393-6900<br />

PLEASE FORWARD TO<br />

MACHINERY BUYER<br />

Fairfield Inn<br />

2854 W Shore Dr<br />

Holland, MI 49424<br />

616-786-9700