CAFS-Force Nozzle Brochure (pdf) - Task Force Tips

CAFS-Force Nozzle Brochure (pdf) - Task Force Tips

CAFS-Force Nozzle Brochure (pdf) - Task Force Tips

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

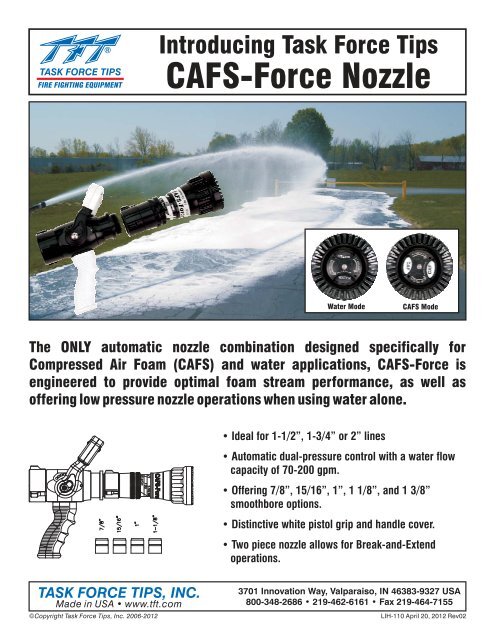

®TASK FORCE TIPSFIRE FIGHTING EQUIPMENTIntroducing <strong>Task</strong> <strong>Force</strong> <strong>Tips</strong><strong>CAFS</strong>-<strong>Force</strong> <strong>Nozzle</strong>Water Mode<strong>CAFS</strong> ModeThe ONLY automatic nozzle combination designed specifically forCompressed Air Foam (<strong>CAFS</strong>) and water applications, <strong>CAFS</strong>-<strong>Force</strong> isengineered to provide optimal foam stream performance, as well asoffering low pressure nozzle operations when using water alone.• Ideal for 1-1/2”, 1-3/4” or 2” lines• Automatic dual-pressure control with a water flowcapacity of 70-200 gpm.• Offering 7/8”, 15/16”, 1”, 1 1/8”, and 1 3/8”smoothbore options.• Distinctive white pistol grip and handle cover.• Two piece nozzle allows for Break-and-Extendoperations.TASK FORCE TIPS, INC.Made in USA • www.tft.com©Copyright <strong>Task</strong> <strong>Force</strong> <strong>Tips</strong>, Inc. 2006-20123701 Innovation Way, Valparaiso, IN 46383-9327 USA800-348-2686 • 219-462-6161 • Fax 219-464-7155LIH-110 April 20, 2012 Rev02

THE<strong>CAFS</strong>CHALLENGE<strong>CAFS</strong>, or compressed air foam systems, continue to be evaluated by fireservice professionals worldwide for use in interior structural attack operations.With over 4% of all pumping apparatus being delivered today with <strong>CAFS</strong>capabilities, there are several common misconceptions about the overallversatility of this manner of ClassAfoam application.<strong>CAFS</strong> is a high-energy delivery system for Class A foam. Just as anozzle or a nozzle with a foam aspiration tube is a low-energy deliverymethod. Class A foam is nothing more than the soap agent that makesthe water foam up as it is agitated. Often, departments do not realizethat common pumping systems and regular nozzles and attachmentswill work fine with ClassAfoam.As has been proven many times in testing done by NFPA/UL and theNational Institute for Standards and Technology, the foam applicationmethod has no effect on the necessary critical application rate. It isimportant to remember that the chemical chain reaction we call firerequires a minimum application rate of water to absorb the BTUs beinggenerated. Foam (water) either from a <strong>CAFS</strong> attack or from a standardnozzle must be applied in sufficient quantity for successful suppressionto take place. ClassAfoam is an enhancement to, not a replacement for,water.Hose handling characteristics of high-energy <strong>CAFS</strong> lines requireadditional training and understanding for crews to be safe and effective.Though lightweight and easy-to-maneuver, these lines are actuallystoring the energy of the air compressor’s pressurization. When openedand the stored energy is released, substantial nozzle reaction can beexpected. Crews need to be prepared for this force.Additionally, kinkingof a <strong>CAFS</strong> line will certainly change both foam quality and flow rate andultimately could cause “slug flow.” Slug flow is an inconsistent mixture ofair, water, and foam concentrate in the hose that causes the line to reactuncontrollably.Many firefighters that have viewed finished <strong>CAFS</strong> streams areamazed by the consistent bubble structure of the highly expanded“shaving cream” quality foam. This “dry” foam is outstanding forexposure pretreatment, but often lacks the necessary water within thebubble structure to drain into the fuels to which it was applied. It is notuncommon to have a fire continuing to burn in fuels that have had <strong>CAFS</strong>foam applied to them. This is due to the limited drain out of water in thebubble structure and can lead to rekindling and overhaul challenges.Using a wetter foam is often more preferable when dealing with deepseatedfires.<strong>CAFS</strong>-PAK21Factors that can affect quality of finished foam through a <strong>CAFS</strong> line.1) Quality of the ClassAFoam Concentrate - Cheap foam often has to be used at ahigher injection ratio (up to 1%) to make good foam. Potential cost savings cango right out the window. Cheaper may not be the most cost effective.2) Water Quality - Very hard water (ph or mineral content) has a negative effect onmaking lots of bubbles.3) Water/Air Temperature - The colder it is, the harder it is to make bubbles. Ofteninjection percentages have to be increased dramatically in cold weather toproduce an acceptable quality/quantity of finished foam.4) Hose —a) Length - too short or too long of a pre-connect and you may not get properbubble creation in the hose line.b) Construction - rougher interior hose linings produce more consistent bubblestructure, smoother linings less consistent.c) Kink Resistance - kinking can cause stripping of bubbles in the line resultingin an “unsafe” slug flow at the tip.5) Pump/Air Compressor Operations - Though many of the commerciallyavailable integrated <strong>CAFS</strong> systems provide automatic air/water pressure andflow balancing and control, operator error can easily generate “unsafe” slugflow, poor foam quality or foam concentrate waste.6) Foam Proportioning Systems - Proper concentrate injection accuracy andadequate mixing of the solution with air is imperative for the best foamperformance.Though systems are often pre-engineered and designed to work.7) The <strong>Nozzle</strong> - The wrong nozzle choice can negate the performance of the entireengineered <strong>CAFS</strong> system. The more a nozzle “directs”, “constricts” or “shapes”a <strong>CAFS</strong> stream, the more it will strip out the bubble structure ultimately creatinga “wetter” type of foam. But, having a “fog” pattern is necessary to many usersfor firefighter protection or applying foam to a wide area.The best source of information on the use of <strong>CAFS</strong> in structural firefighting is“NFPA1145 – Guide for the Use of ClassAFoams in Manual Structural Firefighting –2000 edition.” This guide offers suggested nozzle choices for different manualfirefighting challenges.Exterior or Interior DirectAttack“When using a high-energy foam system (<strong>CAFS</strong>), the system should be adjusted toprovide a wet foam. A conventional nozzle can be used to provide a protective fogpattern, though reach and foam quality may be diminished.”Exposure Protection“The appropriate foam can be produced by varying the mix ratio, and/or changing thedischarge device. Smooth bore nozzles or open ball valves should be used for thedelivery of dry foam in <strong>CAFS</strong>.”Ultimately, the selection of the nozzle used in <strong>CAFS</strong> applications is key to thesuccessful suppression of the fire. <strong>Task</strong> <strong>Force</strong> <strong>Tips</strong>, Inc. recommends a combinationof our VITG series of integral smooth bore/ball valve in combination with our <strong>CAFS</strong><strong>Force</strong> Dual-Pressure Automatic tip. This break-apart combination will providemaximum performance for all <strong>CAFS</strong> applications. The smooth bore inserts can becustomized to your system for dry foam applications and the Dual-Pressure tip canprovide a protective fog pattern for your attack crew or wetter foam for penetration.TASK FORCE TIPS, INC.Made in USA • www.tft.com©Copyright <strong>Task</strong> <strong>Force</strong> <strong>Tips</strong>, Inc. 2006-20123701 Innovation Way, Valparaiso, IN 46383-9327 USA800-348-2686 • 219-462-6161 • Fax 219-464-7155LIH-110 April 20, 2012 Rev02