Proxon 21022.indd - Castolin Eutectic

Proxon 21022.indd - Castolin Eutectic

Proxon 21022.indd - Castolin Eutectic

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

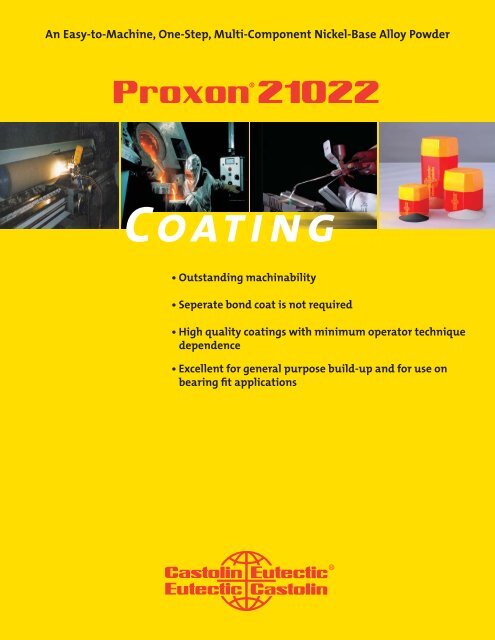

An Easy-to-Machine, One-Step, Multi-Component Nickel-Base Alloy Powder<strong>Proxon</strong>®21022• Outstanding machinability• Seperate bond coat is not required• High quality coatings with minimum operator techniquedependence• Excellent for general purpose build-up and for use onbearing fit applications

DESCRIPTION:<strong>Proxon</strong> 21022 is a machinable, one-step powder whichconsistently produces high quality coatings with minimumoperator technique dependence. Designed for <strong>Eutectic</strong>TeroDyn® Systems 2000 and 3000, it can also be applied withRotoTec® Systems and conventional plasma non-transferredarc systems. A separate bond coat is not required.An outstanding feature of 21022 is its machinability.Traditional, composite, one-step materials produce coatingswhich are difficult to machine, cause excessive tool wearand particle pull-out which leaves and irregular surfacetexture. Coatings produced with 21022, a multi-componentnickel base powder, can be machined to excellent finisheswith a minimum of tool wear.21022 is recommended for general purpose build-up andbearing fit applications, especially where surface finish iscritical. Coatings exhibit good wear resistance and do notcontain any free (unalloyed) elements.Good machined finishes can be obtained using carbide toolssuch as D shape, K68 and low turning speeds in the rangeof 50 to 80 surface feet per minute. Roughing can be doneat 0.004 inch per revolution crossfeed with infeed of 0.010to 0.030 inch. Finishing can be done at less than 0.004 inchper revolution crossfeed with infeed of less than 0.005 inch(turning speed can be increased somewhat for finishing).Coolants and applications involving corrosion should beavoided unless the coating is first treated with a sealer suchas RotoGuard® or SealTec®-LTTM.APPLICATIONS:TECHNICAL DATA:Coating Properties:Combustion PlasmaMacrohardness: HRB 85 HRB 80Microhardness: DPH 220 DPH 200Coating Density: 6.9 g/cc 7.2 g/ccCoating Wt. (lb/ft 2 @0.001”): 0.037 0.035Interconnected porosity: 5000 psiMaximum Service Temp.: 1200°F 1200°FThickness Limit: >0.125” >0.125”Powder Properties:Melting Point: 1950°-2500°F (1054°-1352°C)HEALTH & SAFETY:Observe normal spraying practices, respiratory protectionand proper air flow pattern advised. For general spray practices,see AWS Publications AWS C2. 1-73, “RecommendedSafe Practices for Thermal Spraying and AWS TSS-85, “ThermalSpraying, Practice, Theory and Application.” Thermalspraying is a completely safe process when performed inaccordance with proper safety measures. Become familiarwith local safety regulations before starting spray operations.DO NOT operate your spraying equipment or use thespray material supplied, before you have thoroughly readthe equipment instruction manual. Refer to the <strong>Eutectic</strong>web site for Material Safety Data Sheet (MSDS) information.DISREGARDING THESE INSTRUCTIONS MAY BE HAZARDOUSTO YOUR HEALTHUtility: Pump shaft bearing fit,; Pump pistons,Impeller shaftsGeneral: Electric motor shafts, end bells, Grinder spindlebearings, Drill press quillsYOUR RESOURCE FOR PROTECTION, REPAIR AND JOINING SOLUTIONS<strong>Eutectic</strong> CorporationN94 W14355 Garwin Mace DriveMenomonee Falls, WI 53051 USAP 800-558-8524 • F 262-255-5542www.eutectic.com<strong>Eutectic</strong> Canada428, rue Aime VincentVaudreuil-Dorion, Quebec J7V 5V5Phone: (800) 361-9439Fax: (514) 695-8793www.eutectic.com<strong>Eutectic</strong> MexicoKM 36.5 AutopistaMexico-Quertaro54730 Cautitlan-IzcalliEstado de Mexico, MexicoPhone: 011 (52) 55-5872-1111e-mail: eutectic@eutectic.com.mxStatement of Liability: Due to variations inherent in specific applications, the technical information contained herein, including any information as to suggested product applications orresults, is presented without representation or warranty, expressed or implied. Without limitation, there are no warranties of merchantability or of fitness for a particular purpose. Eachprocess and application must be fully evaluated by the user in all respects, including suitability, compliance with applicable law and non-infringement of the rights of others, and <strong>Eutectic</strong>Corporation and its affi liates shall have no liability in respect thereof.21022 03-07-13© 2008, <strong>Eutectic</strong> Corporation, ® Reg. T.M., Printed in the U.S.A.