Scotch-Weld - 3M

Scotch-Weld - 3M

Scotch-Weld - 3M

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

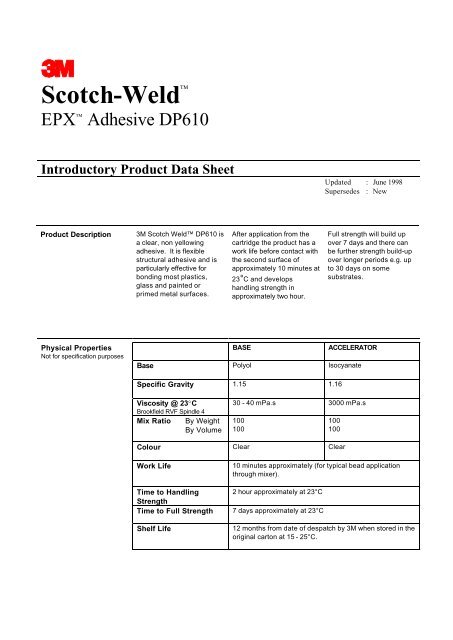

<strong>Scotch</strong>-<strong>Weld</strong> EPX Adhesive DP610Introductory Product Data SheetUpdated : June 1998Supersedes : NewProduct Description<strong>3M</strong> <strong>Scotch</strong> <strong>Weld</strong> DP610 isa clear, non yellowingadhesive. It is flexiblestructural adhesive and isparticularly effective forbonding most plastics,glass and painted orprimed metal surfaces.After application from thecartridge the product has awork life before contact withthe second surface ofapproximately 10 minutes at23°C and developshandling strength inapproximately two hour.Full strength will build upover 7 days and there canbe further strength build-upover longer periods e.g. upto 30 days on somesubstrates.Physical PropertiesNot for specification purposesBASEACCELERATORBase Polyol IsocyanateSpecific Gravity 1.15 1.16Viscosity @ 23 CBrookfield RVF Spindle 4Mix Ratio By WeightBy Volume30 - 40 mPa.s 3000 mPa.s100100100100Colour Clear ClearWork Life10 minutes approximately (for typical bead applicationthrough mixer).Time to Handling 2 hour approximately at 23°CStrengthTime to Full Strength 7 days approximately at 23°CShelf Life12 months from date of despatch by <strong>3M</strong> when stored in theoriginal carton at 15 - 25°C.

Date : June 1998EPX Adhesive DP6102PerformanceCharacteristicsNot for specification purposesOverlap Shear StrengthShear tests to BS5350 PartC5.Surface Preparation:Bond Area:Glueline Control:Test Temperature:Test Equipment:Test Speed:Cure Cycle:** Priming is recommendedon metal surfaces likely tobe exposed to damp orhumid environments.IPA wipe/7447 <strong>Scotch</strong>briteAbrade/IPA wipe12.5mm x 25mm0.250mm23°CInstron 4501 Tensometer2.5mm per minute3 days at 23°CSubstratesOverlap Shear Strength(MPa)PET (Melinex) 2.88Polystyrene 1.82Polycarbonate 3.36ABS 5.57PMMA 3.04PVC 3.04Aluminium 8.7Stainless Steel 9.8Mild Steel 10.9Floating Roller PeelSurface Preparation:Glueline Control:Test Temperature:Test Equipment:Test Speed:Cure Cycle:195 N/25mmEtched Aluminium0.250mm23°CInstron 4501 Tensometer2.5mm per minute7 days at 23°CRate of Strength Build up@ 20 CSurface Preparation:Bond Area:Glueline Control:Test Temperature:Test Equipment:Test Speed:Etched Aluminium12.5mm x 25mm0.250mm23°CInstron 4501 Tensometer2.5mm per minuteTimeOverlap Shear Strength(MPa)30 mins 01 hour 0.0482 hours 0.18563hours 1.2164hours 1.66424 hours 5.1527 days 18.304

Date : June 1998EPX Adhesive DP6103Ageing CharacteristicsSurface Preparation:Bond Area:Glueline Control:Test Temperature:Test Equipment:Test Speed:Etched Aluminium12.5mm x 25mm0.250mm23°CInstron 4501 Tensometer2.5mm per minute*BS EN 29142 D3 Environmental Cycle.4 hours @ 70°C16 hours @ 38°C / 95%RH4 hours @ -20°CAgeing CycleOverlap Shear Strength(MPa)10 days @ 50°C 23.044 weeks @ 50°C / 95% RH 14.144 weeks Water Immersion 18.724 weeks BS EN 29142 D3* 23.144 weeks RT controls 22.91Temperature PerformanceSurface Preparation:Bond Area:Glueline Control:Test Temperature:Test Equipment:Test Speed:Cure Cycle :Etched Aluminium12.5mm x 25mm0.250mm-40°C, 23°C, 80°CInstron 4501 Tensometer2.5mm per minute7 days @ 23°CTest Temperature: Average overlap shearstrength (Mpa)-40°C 33.9223°C 22.9180°C 2.72Storage ConditionsStore product at 15°C to25°C for maximum storagelife. In the foil pouch usedto wrap the cartridge theproduct has a storage life of1 year from date of receiptby customer.After opening the pouch,product should be usedwithin a few weeks andshould be stored in a dryatmosphere.

Date : June 1998EPX Adhesive DP6104Directions for UsePlace the cartridge into the<strong>3M</strong> EPX Applicator and clipinto position.Remove the resealable cap.Expel a small quantity ofadhesive and ensure bothcomponents flow freely.Attach correct mixer nozzle(this should have 20 ormore elements).Dispense the adhesive asrequired.When finished either leavethe nozzle in place andstore, or remove the nozzle,wipe clean the tip, andreplace cap.To re-start after storageremove the old nozzle withcured adhesive and re-fit anew nozzle, or remove thecap and fit a new nozzle.Surface Preparation:The degree of surfacepreparation depends on thebond strength required andthe environment likely to beencountered by the bondedstructure.For most applicationssolvent wiping with <strong>3M</strong>VHB Surface Cleaner,followed by abrasion with<strong>3M</strong> <strong>Scotch</strong>brite 7447,followed by a further solventwipe until clean, will givegood performance (exceptfor acetal, polyethylene andpolypropylene and someother low surface energymaterials). The sameprocess will also give goodadhesion to metal surfaces.Where humid environmentsare likely to be encounteredwe recommend additionalpriming with <strong>3M</strong> <strong>Scotch</strong>-<strong>Weld</strong> 1945B/A for metalsurfaces.Clean UpClean-Up:Excess uncured adhesivecan be removed with thefollowing products:<strong>3M</strong> VHB Surface Cleaner(mild alcohol basedcleaner)<strong>3M</strong> <strong>Scotch</strong>-Grip SolventNo2. (Ketone blend)<strong>3M</strong> Industrial Cleaner(Aerosol).Health & SafetyInformationFor further informationplease contact theToxicology Department atthe Bracknell CustomerTechnical Centre on (0344)860678<strong>3M</strong>, EPX, Duo-Pak, <strong>Scotch</strong>-Grip, <strong>Scotch</strong>brite and <strong>Scotch</strong>-<strong>Weld</strong> are trademarks of the <strong>3M</strong> Company.Values presented have been determined by standard test methods and are average values not to be used for specification purposes.Our recommendations on the use of our products are based on tests believed to be reliable but we would ask that you conduct yourown tests to determine their suitability for your applications.This is because <strong>3M</strong> cannot accept any responsibility or liability direct or consequential for loss or damage caused as a result of ourrecommendations.Tapes & Adhesives © <strong>3M</strong> United Kingdom PLC 1996<strong>3M</strong> United Kingdom PLC<strong>3M</strong> House,28 Great Jackson Street,Manchester,M15 4PAProduct Information :Tel 0870 60 800 50Fax 0870 60 700 99<strong>3M</strong> Ireland<strong>3M</strong> House, Adelphi Centre,Upper Georges Street,Dun Laoghaire,Co. Dublin,IrelandCustomer Service :Tel (01) 280 3555Fax (01) 280 3509