Dept. of Metallurgical and Materials Engineering National Institute of ...

Dept. of Metallurgical and Materials Engineering National Institute of ...

Dept. of Metallurgical and Materials Engineering National Institute of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Dept</strong>. <strong>of</strong> <strong>Metallurgical</strong> <strong>and</strong> <strong>Materials</strong> <strong>Engineering</strong><strong>National</strong> <strong>Institute</strong> <strong>of</strong> TechnologyTiruchirappalli – 620 015(Established in 1967)

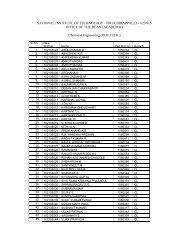

COURSES OFFERED‣ UG PROGRAMME• B.Tech. . (Met. & <strong>Materials</strong> Engg.)‣ PG PROGRAMME• M.Tech. . (Welding <strong>Engineering</strong>)• M.Tech. . (<strong>Materials</strong> Science)‣ RESEARCH• M.S.• Ph.D.QIP Center for both Ph.D. & M.Tech.

R & D Projects (from 2000)Investigator(s)Title <strong>of</strong> the ProjectDurationAmountAgencyDr.S. . RamanSankaranarayananSpectroscopic <strong>and</strong> StructuralAnalysis <strong>of</strong> Slags Used in SteelMaking <strong>and</strong> ContinuousCasting2001-20048.00MHRDDr.S. . RamanSankaranarayananEstablishment <strong>of</strong> ProcessModeling Laboratory2001 -20045.00MHRDDr.S. KumaranDevelopment <strong>of</strong> High StrengthAluminium Alloys for HighTemperature Applications byMechanical Alloying2001-20037.00MHRD

P. Bala SrinivasanStudies on Dissimilar Weld JointsComprising Duplex Stainless Steel<strong>and</strong> Carbon Steel2001-200410.26DSTDr.S. KumaranDevelopment <strong>of</strong> High Strength,High Conductivity Cu-Cr Cr in-situComposite by MechanicalAlloying2002-20058.16DSTV. Muthup<strong>and</strong>iP. Bala SrinivasanModernization <strong>of</strong> WeldingLaboratory2002-20058.00MHRDDr. K.S. P<strong>and</strong>eyStrengthening <strong>of</strong> PowderMetallurgy Laboratory2002-20057.00MHRDP.Angayar KumariModeling <strong>of</strong> TIG Welding Process2002-200510.20DST

Dr.T. . SrinivasaRao S. KumaranDevelopment <strong>of</strong> High PerformanceTi-Al Intermetallic CompositesThrough Mechanical Alloying2002-200524.97DRDODr.T. . SrinivasaRao S. KumaranStudies on Sintering Behaviour <strong>of</strong>Nano- crystallineW-NiWNi-FeComposite Powders Produced byMechanical Alloying2003-20069.00MHRDDepartment <strong>of</strong> <strong>Metallurgical</strong> <strong>Engineering</strong>(Area <strong>of</strong> Focus : Powder Metallurgy)TEQIP FUND2004-20092005-200860.0075.00DST(FIST)MHRDDr. S.RamanSankaranarayananBOF Slags2007-20083.53TataSteelsDr.S.KumaranDr.T.SrinivasaRaoDr.B.RavisankarDevelopment <strong>of</strong> Iron Based BulkMetallic Glasses through MADST-SERC2007-201024.68Dr.V.Muthup<strong>and</strong>iDr.P.BalasrinivasanCorrosionBehaviour<strong>of</strong> SuperDuplex <strong>and</strong> Super MartensiticStainless Steels WeldmentsinMarine Environments2007-201022.48NRB

Expertise Available‣ Material Characterization‣ <strong>Materials</strong> Joining‣ Powder Metallurgy‣ Corrosion Testing‣ Process Metallurgy‣ Surface <strong>Engineering</strong>‣ Nanopowder Synthesis (through MA)

Metallography EquipmentsSEMOptical MicroscopeImage AnalyserSample Mounting Press

Mechanical Testing60T UTM100T Hydraulic PressDigital TensometerFatigue Testing MachineImpact TesterVickers / Brinnel Hardness TesterMicro hardness Tester

Powder Metallurgy LaboratoryPlanetary Ball MillGlove BoxHigh Temp. FurnaceDiffusion Vacuum PumpMicrowave Sintering FurnaceLaser Particle SizerCompaction Press (UTM)

Welding LaboratoryResistance Spot WeldingPulsed TIG WeldingSAW WeldingPlasma Welding / Cutting / Surfacing Power Sources

Surface <strong>Engineering</strong> <strong>and</strong> CorrosionPotentiostat / GalvanostatHigh Temp. Wear TesterAbrasion Wear TesterPin on Disc Wear Tester

Equipment purchased under TEQIP1. Scanning Electron Microscope (Rs.41.79 lakhs)2. Wear & Friction Testing Unit (Rs.4.5 lakhs)3. Pulse Rectifier (Rs.1.35 lakhs)4. Thermocalc s<strong>of</strong>tware (Euro 13810)5. Metallography Unit (Rs.2.26 lakhs)(Belt grinder, Disc polishers, specimen mounting press)6. High resolution microscope with digital camera (Rs.1.7 lakhs)7. Trinocular optical microscope (Rs.0.70 lakhs)

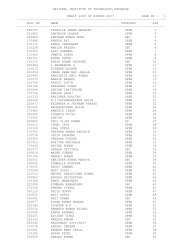

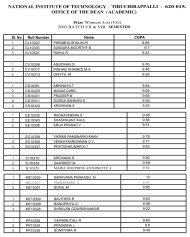

Equipments purchased under DST-FISTName (with Model &make)Order dateInstallation dateCost in INRInduction Sintering Furnacewith Controlled Atmosphere(Strayfield Heaters P Ltd,Bangalore)11.02.2005Installed <strong>and</strong> not satisfied9,63,000Atomic AbsorptionSpectrophotometer(S2 & Milestone, Italy)11.02.200506.04.20067,49,544Servo Hydraulic UniversalTesting Machine , BiSS18.02.200529.07.200626,99,674Furniture / Civil Works10.03.200516.08.20051,65,430Total45,77,648

Name <strong>of</strong> the Equipment : Atomic Absorption SpectroscopyModel Number : Thermo AAS / S2 CompleteSpecificationsDouble beam optics, 6 Lamp automatic, wide b<strong>and</strong> PMT (180-900nm) B<strong>and</strong>Pass 0.2, 0.5 <strong>and</strong> 1nm Focal Length 270mm Facility for automatic flameignition, flame shutdown, <strong>and</strong> s<strong>of</strong>tware controlled oxidant change over <strong>and</strong> fuelgas. Quadline D2 background correction with max. error <strong>of</strong> 2%.Cost : Rs. 7,49,544/-Analysis CapabilityTo determine the chemical composition <strong>of</strong>a wide range <strong>of</strong> <strong>Engineering</strong> <strong>Materials</strong>including Ferrous <strong>and</strong> Non-Ferrous Alloysrange from ppm to 100%

Name <strong>of</strong> the Equipment : Induction Sintering Furnace withControlled AtmosphereModel Number : Custom MadeComplete Specifications : 10KW, 50Hz RF Induction Sintering furnace withcontrolled furnace, ID 30mm / 70 mm Infrared Pyrometer Temp. 1300ºC,Processing Chamber 304SS, 300mm X 300mm-inside dimension, bottom loading /unloading flange, Vacuum pump, filter, gauge <strong>and</strong> valves, Flow meter, <strong>and</strong> pressuregauge.Actual Cost (in Indian Rupees) : Rs. 9,63,000/-Dedicated for research <strong>and</strong> Development inPowder MetallurgyPresently, PG students are doing projects ,Induction sintering furnace is addeddemonstration experiment in the PowderMetallurgy Laboratory for VIII Semester<strong>Metallurgical</strong> <strong>Engineering</strong> students in the2006 regulations.

Name <strong>of</strong> the Equipment : SERVO HYDRAULIC UNIVERSAL TESTING MACHINEMachine Model Number :Bi-03-104 A Complete Specifications Servohydraulic Universal Testing Machine -50kN,with facility for conducting fatigue <strong>and</strong> fracture mechanics tests Details <strong>of</strong>Manufacturer,Name : Bangalore Integrated System Solutions (p) Ltd Address 302 / 4, Shed No. 5,Seetharam Industrial Estate, V.P.Road.Jalahalli, BangaloreCost : Rs. 26,99,674/-CapabilityTo perform controlled strain rate tensile testing,compression testing, Low Cycle <strong>and</strong> High CycleFatigue, Fracture Toughness, etc.

Some Results Obtained from Servo Hydraulic SystemStress, kN/sq-mm0.9000.8000.7000.6000.5000.4000.3000.2000.1000.0000.000 0.100 0.200 0.300 0.400 0.500 0.600StrainStress, MPa800.000600.000400.000200.0000.000-200.000-400.000-600.000-0.005 -0.004 -0.003 -0.002 -0.001 0.000 0.001 0.002 0.003 0.004 0.005StrainTensile Test- Mild Steel Compression Test- Aluminum LCF – Mild SteelRegression line Eq : lnJ = lnC1 + C2ln(Delta CL/k) , k = 1lnJ = 2.861164 + 0.8897648ln(Delta CL/k)30.0001000.00025.000900.000800.00020.000700.000J, kJ/sq-m600.000500.000400.000Load, kN15.00010.000300.000200.0005.000100.0000.0000.0000.000 0.500 1.000 1.500 2.000 2.500J v/s Delta CLDelta CL, mmJmax Construction Line0.15 Exclusion 0.2 Exclusion 1.5 ExclusionRegression Line-5.000-2.000 -1.500 -1.000 -0.500 0.000 0.500 1.000 1.500 2.000 2.500 3.000COD, mmJ-R Curve – Mild SteelKIc – Fracture Toughness