Solutions for Reducing Borehole Costs in Rural Africa - International ...

Solutions for Reducing Borehole Costs in Rural Africa - International ...

Solutions for Reducing Borehole Costs in Rural Africa - International ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

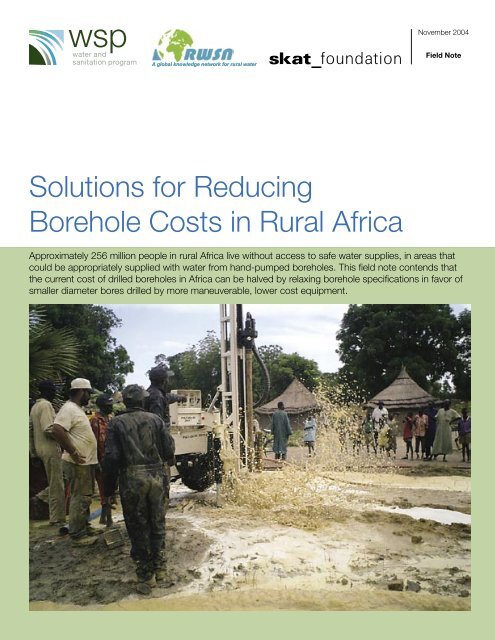

November 2004Field Note<strong>Solutions</strong> <strong>for</strong> <strong>Reduc<strong>in</strong>g</strong><strong>Borehole</strong> <strong>Costs</strong> <strong>in</strong> <strong>Rural</strong> <strong>Africa</strong>Approximately 256 million people <strong>in</strong> rural <strong>Africa</strong> live without access to safe water supplies, <strong>in</strong> areas thatcould be appropriately supplied with water from hand-pumped boreholes. This field note contends thatthe current cost of drilled boreholes <strong>in</strong> <strong>Africa</strong> can be halved by relax<strong>in</strong>g borehole specifications <strong>in</strong> favor ofsmaller diameter bores drilled by more maneuverable, lower cost equipment.

SummaryFigure 1. <strong>Africa</strong>: Water Supply CoverageGroundwater is generally a readily available sourceof water throughout <strong>Africa</strong>. However, high boreholeconstruction costs are slow<strong>in</strong>g progress on <strong>in</strong>creasedaccess. Higher costs are largely a result of us<strong>in</strong>gdrill<strong>in</strong>g equipment with specifications that are greaterthan those required <strong>for</strong> the vast majority of boreholesneeded <strong>in</strong> <strong>Africa</strong>.Us<strong>in</strong>g high cost mach<strong>in</strong>ery and support equipmentleads to high borehole costs, which <strong>in</strong> turn results <strong>in</strong>fewer boreholes be<strong>in</strong>g drilled. The smaller volume ofwork per drill<strong>in</strong>g rig creates <strong>in</strong>efficiencies <strong>in</strong> equipmentusage, and results <strong>in</strong> <strong>in</strong>creased overheads, driv<strong>in</strong>g upcosts dramatically.This field note contends that the current cost ofdrilled boreholes <strong>in</strong> <strong>Africa</strong> can be halved by relax<strong>in</strong>gborehole specifications <strong>in</strong> favor of smaller diameterbores drilled by more maneuverable, lower costequipment. The average cost of drill<strong>in</strong>g a borehole canbe reduced from USD$6,000 to USD$3,000, and sometechnological applications could br<strong>in</strong>g down the costto less than USD$1,000. These sizable cost reductionshave the potential to contribute to <strong>Africa</strong>’s atta<strong>in</strong>mentof the Millennium Development Goals (MDGs) <strong>for</strong> watersupply and sanitation 1 and the livelihoods of millions ofrural <strong>Africa</strong>ns.Clearly, new approaches are required to drill the onemillion or so boreholes that will help <strong>Africa</strong> to meet theMDGs <strong>for</strong> water and sanitation. This can be achievedby adopt<strong>in</strong>g these new approaches:• Review and revise outdated national standards thatfavor conservative borehole designs• Develop an effective small bus<strong>in</strong>ess sector, madeup of <strong>Africa</strong>n drill<strong>in</strong>g contractors, based <strong>in</strong> ruralareas and spread amongst the communities theyare required to serve• Promote new, appropriate drill<strong>in</strong>g technologies• Provide cont<strong>in</strong>uity of work <strong>for</strong> local bus<strong>in</strong>esses.Water supplycoverage0%–25%26%–50%51%–75%76%–90%91%–100%Miss<strong>in</strong>g dataSource: Global Water Supply and Sanitation Assessment Report, 2000Who drills <strong>in</strong> <strong>Africa</strong>?To understand borehole drill<strong>in</strong>g <strong>in</strong> <strong>Africa</strong>, it is important toknow who is do<strong>in</strong>g what, where and the equipment <strong>in</strong> use.Governments own, directly or <strong>in</strong>directly, most of the drill<strong>in</strong>grigs <strong>in</strong> <strong>Africa</strong>, but drill fewer holes than other operators. Nongovernmentalorganizations (NGOs) and contractors ownabout half of the rema<strong>in</strong><strong>in</strong>g mach<strong>in</strong>es <strong>in</strong> operation. Despitethe prevalence of appreciable market distortions, privatecontractors drill the greatest number of holes.Government departmentsGovernment departments responsible <strong>for</strong> drill<strong>in</strong>g typicallyprocure equipment as donations from external supportorganizations, but may then lack the management skillsand resources needed to susta<strong>in</strong> a high-production drill<strong>in</strong>gprogram. In many cases, the external support does not cater<strong>for</strong> tra<strong>in</strong><strong>in</strong>g, operations, ma<strong>in</strong>tenance and spare parts.1To halve, by 2015, the proportion of people without susta<strong>in</strong>able access to safedr<strong>in</strong>k<strong>in</strong>g water and hygienic sanitation.2

<strong>Solutions</strong> <strong>for</strong> <strong>Reduc<strong>in</strong>g</strong><strong>Borehole</strong> <strong>Costs</strong> <strong>in</strong> <strong>Rural</strong> <strong>Africa</strong>In such circumstances, mach<strong>in</strong>es withcapacity to drill more than 200 holes peryear end up languish<strong>in</strong>g <strong>in</strong> a brokendownstate, with no spares <strong>in</strong> stock orbudgeted <strong>for</strong> – effectively parked aside<strong>in</strong> perpetuity.<strong>International</strong> or local or iiiiior local NGOs<strong>Borehole</strong> drill<strong>in</strong>g by NGOs is associatedwith a number of disadvantages. Whereregulations are <strong>in</strong>adequate, an NGOundertak<strong>in</strong>g a drill<strong>in</strong>g program may haveto def<strong>in</strong>e its own policy, measurementand construction criteria, and qualitystandards. Coord<strong>in</strong>ation with publicadm<strong>in</strong>istration and between agencies isoften problematic where NGOs operate<strong>in</strong>dependently and autonomously.NGOs may also compete unfairly withlocal private contractors becausesome are able to import equipmentand materials duty free and to worktax free. This gives them a dist<strong>in</strong>ctcost advantage over private-sectorcompetitors who must pay local importduties and <strong>in</strong>come taxes, and whoregard the advantage of NGOs as be<strong>in</strong>gunfair.Certa<strong>in</strong> NGOs are able to respond toemergencies quickly and <strong>in</strong>dependentlyby mobiliz<strong>in</strong>g borehole drill<strong>in</strong>gequipment and provid<strong>in</strong>g water todisplaced and distressed populations.Many of such programs start off asquick-fix <strong>in</strong>terventions, but cont<strong>in</strong>ue tofunction on this basis <strong>for</strong> many yearsafterwards.<strong>International</strong> contractors<strong>International</strong> contractors are typically<strong>for</strong>eign-owned, expatriate-managedbus<strong>in</strong>ess ventures that remit profitsout of the countries from which theyoperate. The motivation is strong totake substantial contracts; capitalizewith large-scale, high-per<strong>for</strong>manceequipment; employ skilled, expatriatestaff; and to aggressively chase highproduction rates <strong>for</strong> high-specification,high-value work.The host country receives neatlycompleted packages of boreholes,and only a few local employees <strong>in</strong>heritany transferable skills. The depth ofprofessionalism and level of <strong>in</strong>vestment<strong>in</strong>volved often overwhelms the capacityof NGOs, who generally do not competeat this level.At best, these companies w<strong>in</strong>contracts on the basis of their <strong>in</strong>dividualentrepreneurial skills and their <strong>in</strong>herentability to compete <strong>in</strong> the particularmarket. At worst, they obta<strong>in</strong> workbecause of visible or <strong>in</strong>visible l<strong>in</strong>ks toconditional donor fund<strong>in</strong>g.Local contractorsSome local bus<strong>in</strong>esses are able toseize opportunities <strong>in</strong> borehole drill<strong>in</strong>gand possess skills needed to w<strong>in</strong> and<strong>in</strong>fluence award of contracts. But theyoften encounter difficulties mobiliz<strong>in</strong>gequipment, materials and skilledpersonnel required to undertake asusta<strong>in</strong>ed construction program. Thecommercial risks <strong>in</strong>volved <strong>in</strong> becom<strong>in</strong>ga drill<strong>in</strong>g contractor are reflected <strong>in</strong>the high cost of borrow<strong>in</strong>g needed <strong>for</strong>f<strong>in</strong>anc<strong>in</strong>g such an enterprise.Figure 2: <strong>Africa</strong>: Water supply coverageFigure 3: <strong>Rural</strong> water coverage by region100801008060402006040200Source: Global Water Supply and Sanitation Assessment Report, 20003

The drill<strong>in</strong>g contract periods are oftenuncerta<strong>in</strong> and af<strong>for</strong>d little security offuture work as holes to be drilled areoffered <strong>in</strong> small numbers. In suchan unpredictable market, lend<strong>in</strong>g<strong>in</strong>stitutions default to demand<strong>in</strong>g 100percent recoverable collateral <strong>in</strong> the<strong>for</strong>m of property, land, or externalsecurities.The number of capable, <strong>in</strong>digenous<strong>Africa</strong>n contractors cont<strong>in</strong>ues to grow,though they operate at low capacities.Many other start-ups fail as a result ofthe handicaps and high risks that stand<strong>in</strong> the way of success. Of particularconcern is the award<strong>in</strong>g of contractson the basis of political connections orcash <strong>in</strong>ducements, rather than on abilityto fulfill the contract.What drills <strong>in</strong> <strong>Africa</strong>?A borehole is a round hole thatpenetrates the earth’s surface to a levelwhere groundwater flows. The wateris pumped to a supply po<strong>in</strong>t on thesurface. Proper l<strong>in</strong><strong>in</strong>g, seal<strong>in</strong>g, clean<strong>in</strong>gand evaluation of the borehole areessential <strong>for</strong> tapp<strong>in</strong>g clean water.A drill rig is a tool that rotates a drill pipeand allows it to descend <strong>in</strong>to, and behoisted out of, a hole <strong>in</strong> the ground. Itbasically consists of a steel frame, amechanism <strong>for</strong> rotat<strong>in</strong>g the drill pipe,and a hoist device. Some drill rigsare operated by complex hydraulic,mechanical, pneumatic or electricalsystems.Interest<strong>in</strong>gly, procurement of drill<strong>in</strong>gservices has customarily emphasizedthe technical specifications of drill<strong>in</strong>gDrill<strong>in</strong>g equipment graveyardequipment rather than the job <strong>in</strong> hand.Throughout the drill<strong>in</strong>g <strong>in</strong>dustry, unduesignificance is attached to how a drillrig functions, divert<strong>in</strong>g attention fromthe very job it is designed <strong>for</strong> - to drill aborehole (Box 1).The preoccupation with specifications ofdrill<strong>in</strong>g rigs underm<strong>in</strong>es the impact thatsmaller diameter boreholes can maketowards atta<strong>in</strong><strong>in</strong>g the MDGs <strong>for</strong> watersupply and sanitation.Almost all government and privatesectorcontractors <strong>in</strong> <strong>Africa</strong> use heavy,truck-mounted drill<strong>in</strong>g equipment. Thisequipment has the capacity to drilldeep and wide boreholes, typically 500meters and with diameters exceed<strong>in</strong>g200 millimeters. Yet such equipment areoften deployed to drill holes only 30-80meters deep.Apart from the excessive technicalcapacity, the vehicle size renders theseequipment <strong>in</strong>appropriate to meet theneeds of rural communities.In the past four decades, twotechnological advancements haverevolutionized drill<strong>in</strong>g of boreholes <strong>for</strong>water supply: the down-the-hole (DTH)hammer, and the extruded plastic pipe.Down-the-hole hammerDTH hammers are pneumaticallyoperated tools that transfer high powerfrom an air compressor mounted on thesurface to a series of tungsten buttonsunderground, pulveriz<strong>in</strong>g the hard rock.DTH hammers were <strong>in</strong>itially developed<strong>for</strong> use <strong>in</strong> rock quarries as an economicway of drill<strong>in</strong>g blast holes <strong>for</strong> explosivecharges.4

<strong>Solutions</strong> <strong>for</strong> <strong>Reduc<strong>in</strong>g</strong><strong>Borehole</strong> <strong>Costs</strong> <strong>in</strong> <strong>Rural</strong> <strong>Africa</strong>The development and use of DTHhammer technology is still dom<strong>in</strong>ated bydemands of the m<strong>in</strong><strong>in</strong>g and construction<strong>in</strong>dustries where production hammersdrill holes from 50 to 1,000 millimeters<strong>in</strong> diameter, 2 yet millions of water-supplyholes would not exist <strong>in</strong> India todaywithout the existence of this tool.Extruded plastic pipeExtruded plastic pipe can act as analternative to steel <strong>for</strong> some generalconstruction applications. The ease ofproduction, strength-to-weight ratios,resistance to corrosion, low cost perunit length, flexibility, and the ease withwhich they can be jo<strong>in</strong>ed, threaded,and slotted means that plastics haveBox 1. Sample tender <strong>for</strong> drill<strong>in</strong>g‘An all-wheel drive, truck-mountedrig, with a 15,000 kg capacity mast,capable of work<strong>in</strong>g with 6 m drillpipe. An onboard compressor, withwater-cooled diesel eng<strong>in</strong>e, capable ofdeliver<strong>in</strong>g 750 cfm air at 20 bar . . .’Instead of describ<strong>in</strong>g the equipment,the tender could be re-phrased to read:‘Required: a mobile set of drill<strong>in</strong>gequipment capable of construct<strong>in</strong>g4” diameter holes <strong>in</strong> crystall<strong>in</strong>e rockto depths of 80 m, and capable ofaccommodat<strong>in</strong>g plastic surface cas<strong>in</strong>gpipe and pump<strong>in</strong>g system to depthsof up to 25 m. Bidders must offercomplete equipment sets, <strong>in</strong>clusive oftransport and materials, to undertakethe construction of 1,000 boreholes <strong>in</strong>four years.’advantages over steel <strong>for</strong> many pip<strong>in</strong>gapplications. They are also simple tohandle and transport.Pragmatically, current tools andmaterials to advance groundwatertechnology cont<strong>in</strong>ue to be derived fromestablished markets <strong>in</strong> other <strong>in</strong>dustrialsectors.What def<strong>in</strong>es thecost of drill<strong>in</strong>g?Four elements def<strong>in</strong>e the cost of aborehole:1. The capital costs of constructionequipment – the drill rig, toolsand rig transport. The total outlay<strong>in</strong>cludes costs of shipp<strong>in</strong>g theequipment to the country of use,<strong>in</strong>clud<strong>in</strong>g import taxes and f<strong>in</strong>ancecharges. This <strong>in</strong>itial purchase priceis amortized over the lifetime of theequipment, typically between 3 and10 years. The sum is then furtherdivided by the annual productionrate to determ<strong>in</strong>e a cost per hole orper meter.2. Material or consumable costs – welll<strong>in</strong><strong>in</strong>g materials, cement, drill<strong>in</strong>gmud, gravel pack (if required), fuel,lubricants, and ma<strong>in</strong>tenance. Theseitems are listed and calculated perborehole.3. Labor costs <strong>for</strong> the constructioncrew.4. Overheads – the provision ofcapital, adm<strong>in</strong>istration, and logistics.The total sum is divided by theLow-cost hand-drll<strong>in</strong>g techniqueannual borehole production rate todeterm<strong>in</strong>e a cost per hole or permeter. Assum<strong>in</strong>g most organizationsdrill more than a s<strong>in</strong>gle borehole, amethod to calculate the total revenueof an <strong>in</strong>dividual drill<strong>in</strong>g operationfrom the overall revenue is required.Where is groundwaterlocated <strong>in</strong> <strong>Africa</strong>?The ma<strong>in</strong> geological <strong>for</strong>mations <strong>in</strong> <strong>Africa</strong>yield<strong>in</strong>g groundwater are exam<strong>in</strong>edbelow, with a brief analysis of theirpotential.Pre-cambrian basement orcrystall<strong>in</strong>e rocksPre-cambrian basement or crystall<strong>in</strong>erocks underlie the ground <strong>in</strong>habited by2Halco product range, 2001.5

Figure 4: Hydro-geological doma<strong>in</strong>sof Sub-Saharan <strong>Africa</strong>PreCambrian"basement" rocksVolcanic rocksUnconsolidated sediments(ma<strong>in</strong>ly Quaternary)Consolidated sedimentaryrocks (post PreCambrian)Lakessome 220 million people <strong>in</strong> rural <strong>Africa</strong>.Groundwater is mostly stored <strong>in</strong> theweathered overburden and feeds <strong>in</strong>tofractures <strong>in</strong> the underly<strong>in</strong>g rock. A goodwell site there<strong>for</strong>e needs to be locatedon an adequate depth of weatheredground. There must also be a goodchance of access<strong>in</strong>g a fractured layer <strong>in</strong>the underly<strong>in</strong>g rock. In some locations,weather<strong>in</strong>g is deep and rock is heavilyfractured, mak<strong>in</strong>g successful drill<strong>in</strong>geasy. In other places, the weather<strong>in</strong>gcan be th<strong>in</strong> and the rock fractureshard to locate, lead<strong>in</strong>g to very poorsuccess rates. Geophysics can helpto site boreholes by <strong>in</strong>dicat<strong>in</strong>g areas ofdeep weather<strong>in</strong>g and likely fractures,but this should be done <strong>in</strong> conjunctionwith a good common-sense appraisalof the site and location. Drill<strong>in</strong>g to hitdeep weather<strong>in</strong>g and shallow fracturesis the key: simply drill<strong>in</strong>g deep is not asolution.Volcanic rocksIt is hard to generalize on drill<strong>in</strong>gspecifications <strong>for</strong> volcanic rocks– on which some 45 million <strong>Africa</strong>nsare settled – as they often occur<strong>in</strong> mounta<strong>in</strong>ous areas. Generally,groundwater would be expectedbetween lava flows or <strong>in</strong> lava thatis heavily faulted or even porous.Sometimes water is located deepunderground and the water qualitycan be poor. Skilled geologicalassessment, possibly assisted withsome geophysics, can help to locategood drill sites.Consolidatedsedimentary rocksSome 110 million people <strong>in</strong> <strong>Africa</strong>occupy areas of consolidatedsedimentary rocks which <strong>in</strong>cludelimestone and sandstone, and conta<strong>in</strong>water <strong>in</strong> a mixture of circumstances. Itis more important to first understandthe general geology of an area to knowthe depth horizon at which water willbe located than to select a drill<strong>in</strong>g siteon the basis of fractures. In this class ofrock types there are rocks and mixturesthat do not readily store groundwater,and <strong>in</strong> these cases more detailed<strong>in</strong>vestigations <strong>in</strong>volv<strong>in</strong>g geophysics canassist.Unconsolidated sedimentsSome 60 million rural <strong>Africa</strong>ns liveon unconsolidated sediments wherewater will be located <strong>in</strong> layers of sandsor gravels. When unconsolidatedsediments cover a large area, it is3(Driscoll 1986).consistently easy to drill good sitesrepeatedly by drill<strong>in</strong>g deep enough<strong>in</strong>to the sand or gravel layer. Thereis also a useful range of sites basedon very localized sediments (<strong>in</strong> smallriver valleys, <strong>for</strong> example), particularly<strong>in</strong> basement rock areas, as thesecan store appreciable amounts ofgroundwater from relatively shallowsediment layers.What iscurrent technologyoffer<strong>in</strong>g <strong>Africa</strong>?<strong>Borehole</strong> diameterThe DTH hammer has clearly carveda niche <strong>for</strong> itself <strong>in</strong> quarry<strong>in</strong>g, andthere are numerous benefits <strong>for</strong> thistechnology <strong>in</strong> tapp<strong>in</strong>g groundwatersupplies. In quarry<strong>in</strong>g, operators havelearned that - where fuel and capitalequipment are expensive to obta<strong>in</strong> andma<strong>in</strong>ta<strong>in</strong> they can reduce operationalcosts by reduc<strong>in</strong>g the diameter oftheir blast holes and by improv<strong>in</strong>g theper<strong>for</strong>mance of their explosive charges(Box 2).In sett<strong>in</strong>g a suitable bore diameter <strong>for</strong>a water well, the first pr<strong>in</strong>ciples of welldesign should be followed. Basically,adequate room is required to <strong>in</strong>stallthe water pump and to supply it witha flow that matches its maximumoutput. The India MKII technology,now <strong>in</strong> its third decade of operation,requires a m<strong>in</strong>imum diameter of 4”(10.2 centimeters) <strong>for</strong> <strong>in</strong>sertion. NewMKIII cyl<strong>in</strong>ders comb<strong>in</strong>ed with theAfridev handpump will fit <strong>in</strong> boreholes6

<strong>Solutions</strong> <strong>for</strong> <strong>Reduc<strong>in</strong>g</strong><strong>Borehole</strong> <strong>Costs</strong> <strong>in</strong> <strong>Rural</strong> <strong>Africa</strong>Box 2. <strong>Borehole</strong> Efficiency and <strong>Costs</strong>A borehole is def<strong>in</strong>ed by its diameter and depth, calculated as volume. Thelarger the volume, the more the construction work. The surface area of a 4”diameter hole is close to half that of a 6” diameter hole. When multiplied byits depth, this will equate to a 4” hole be<strong>in</strong>g half the volume of a 6” hole.exist<strong>in</strong>g practice and would lead to thedisappearance of high-cost equipmentand high-value contracts. A realignmentof exist<strong>in</strong>g markets would ensue andequipment that is too large and costly tooperate would fall <strong>in</strong>to disuse.Hard rock drill<strong>in</strong>g spoil is cleared out by blow<strong>in</strong>g compressed air up theborehole <strong>in</strong> the space between the drill pipe and drilled hole (annular area).The compressed air must travel above a certa<strong>in</strong> speed (drillers refer to thisas ‘up-hole velocity’) to achieve sufficient lift of the spoil. This means thatthere is a direct ratio between the compressed air flow and the boreholediameter (a 6” hole requires twice the volume of compressed air than a 4”hole).The same ratio applies to the direct cost of construct<strong>in</strong>g a 4” diameterhole which should be half the cost of a 6” diameter hole when the properselection of plant is made. This is because a 4” hole is half the work of a 6”hole. The drilled diameter has little effect on the volume of water availablefrom the borehole. It has been established that every time a boreholediameter is doubled, the available water <strong>in</strong>flow will <strong>in</strong>crease only by 10percent. (Driscoll 1986).with a diameter of less than 4”, and it isfeasible to make <strong>in</strong>stallations <strong>for</strong> 3” (7.6-centimeter) holes. 3TraditionThe DTH hammer is still relatively newtechnology <strong>in</strong> a notoriously conservative<strong>in</strong>dustry. Without a DTH hammer,there are two options <strong>for</strong> penetrat<strong>in</strong>grock. The first is to use a tricone bitwith heavy drill collars and torque.But to get enough weight of steel <strong>in</strong>toa hole <strong>in</strong> a short length, the optimumdiameter would have to be at least 6”(15.2 centimetres). Alternatively, a cabletool with a chisel and s<strong>in</strong>ker bars couldbe used. This set up calls <strong>for</strong> a similarcritical mass and also leads to drill bitsof 6” or larger. Prior to the <strong>in</strong>troductionof DTH technology, it was easier andcheaper to drill boreholes at 6” diameteror above than it was to drill smallerdiameters.Drill<strong>in</strong>g regulations and standards,worldwide, are based on the applicationof these now superseded technologies.With DTH technology, however, it iseasier and cheaper to drill smallerdiameters. A DTH hammer will producethe lowest cost per meter <strong>in</strong> hard rockby a wide marg<strong>in</strong>. An important provisois that the production rate has to bekept high to amortize the high capitalcosts of the equipment (Table 1).Vested <strong>in</strong>terestsClearly, the adoption of alternativeborehole designs constructed withsmaller equipment departs fromWhile such a scenario would bebeneficial <strong>in</strong> terms of service coverage,it would clearly not go unopposed.Radical realignment of the bus<strong>in</strong>essenvironment <strong>in</strong> favor of smaller boreswould oblige established rig ownersand contractors to make a starkchoice – adapt to the change, orgo out of bus<strong>in</strong>ess. New <strong>in</strong>vestorswould be presented with considerableopportunities to w<strong>in</strong> contracts, requir<strong>in</strong>ga fraction of the resources currentlyneeded. With smaller bore diameters,the establishment of rural-based <strong>Africa</strong>ncontractors who could drill directly <strong>for</strong>their own communities would becomean atta<strong>in</strong>able goal.The diameter of the DTH hammerdef<strong>in</strong>es the drill-pipe diameter,compressor capacity, eng<strong>in</strong>e power,and rig size, weight and transportationmethod. Basically, the diameter ofthe borehole determ<strong>in</strong>es whether thecompressor is towed by a small pick-upor mounted on a four-wheel-drive truck,and whether the rig package costsUSD$60,000 or USD$150,000.By adopt<strong>in</strong>g new borehole designs thatspecify smaller holes, large equipmentis effectively made economically<strong>in</strong>efficient even though a small-diameterdrill pipe can still be used on a large rig.The <strong>in</strong>creased use of commercial drill<strong>in</strong>gcontractors would lead to construction7

Table 1: Representative borehole costs <strong>for</strong> conventional and reduced diameter drill rigsConventional <strong>Africa</strong> RigPurchaseCost US$PerboreholeReduced Diameter <strong>Africa</strong> RigPurchaseCost US$PerboreholeRig150,000Rig25,000Capital cost of a set ofborehole constructionequipmentMount<strong>in</strong>g vehicleDrill<strong>in</strong>g ToolsCompressor 750CFM x 15 barSupport Truck80,00070,00080,00060,000Drill<strong>in</strong>g ToolsCompressor 250CFM x 10 barPick Up Truck15,00025,00030,000Pick Up Truck30,000Total470,000Total95,000Amortized 30 holes per year over5 years = 150 boreholesAmortized 30 holes per year over3,133 5 years = 150 boreholes633Surface Cas<strong>in</strong>g 6" 20m depthUS$20 per metre400Surface Cas<strong>in</strong>g 4" 20m depthUS$10 per metre200Cement - borehole seal & apron10 bags @ US$8 per bag80Cement - borehole seal & apron10 bags @ US$8 per bag80Sand & aggregate <strong>for</strong> apron120Sand & aggregate <strong>for</strong> apron120Drill<strong>in</strong>gconsumablesFuel <strong>for</strong> compressor based on400 litres consumption@ 80 US cents per litre320Fuel <strong>for</strong> compressor based on200 litres consumption@ 80 US cents per litre160Drill bit wear & rig consumables250Drill bit wear & rig consumables125Hand PumpTotal600Hand Pump6001,770 Total1,285DrillerDrillerLabor costsDrivers x 2Asst Rig operators x 4Drivers x 1Asst Rig operators x 2Masons x 2Masons x 2600 400Equipment is attached to an officewith 50 staff - 2 rigs - 6 hand dugwell teams and 5 pumpma<strong>in</strong>tenance crew. Base has6 offices, store and ma<strong>in</strong>tenancefacilities + 5 support vehiclesPer annumEquipment is operated from a yardor a town plumb<strong>in</strong>g shop - ownerlives <strong>in</strong> his compound and employs6 staff <strong>in</strong> his shop and storesPer annumOverheadsTotal spend on overheads300,000Total spend on overheads30,000Assume above attracts <strong>in</strong>come of1 US$ million per annum.30 boreholes @ US$10,000 each= US$300,000 revenueAssume above attracts <strong>in</strong>come ofUS$300,000 per annum.30 boreholes @ US$3,000 each= US$90,000 revenue30% overhead cost assigned to Rig100,00030% overhead cost assigned to Rig10,000Divided by production of30 boreholes3,333Divided by production of30 boreholes333TOTAL COST PER BOREHOLEUS$8,837TOTAL COST PER BOREHOLEUS$2,6528

<strong>Solutions</strong> <strong>for</strong> <strong>Reduc<strong>in</strong>g</strong><strong>Borehole</strong> <strong>Costs</strong> <strong>in</strong> <strong>Rural</strong> <strong>Africa</strong>programs that are more efficient andeffective than the direct labor activitiesof many governments. If boosted byrevision of drill<strong>in</strong>g standards <strong>in</strong> favor ofsmaller bores, this outsourc<strong>in</strong>g policycould also promote re-adjustment bythe drill<strong>in</strong>g <strong>in</strong>dustry to demands ofthe restructured market. Commercialcontractors would then gradually phaseout oversized drill<strong>in</strong>g rigs <strong>in</strong> favor ofsmaller and more profitable equipment.<strong>Borehole</strong> design<strong>in</strong> hard rockThe use of DTH hammer technologyhas made it easier to access watersupplies <strong>in</strong> hard rock where the costswere too prohibitive to allow extensivedrill<strong>in</strong>g with older technologies. It wasthere<strong>for</strong>e generally preferable to drill <strong>for</strong>water <strong>in</strong> softer sediments and overly<strong>in</strong>gareas. However, a clean water supply <strong>in</strong>loose ground requires a well screen toact as a barrier to prevent soft soil fromcollaps<strong>in</strong>g <strong>in</strong>to the hole.reduce the available water flow andcreate a structure likely to be clogged bychemical or microbiological action overtime. Under such circumstances, neithermeasure is likely to improve the clarity ofthe orig<strong>in</strong>al water.Holes drilled <strong>in</strong>to the <strong>Africa</strong>n basementor crystall<strong>in</strong>e rock do not need l<strong>in</strong><strong>in</strong>gto depth. In India, some three millionhandpump holes have been drilled<strong>in</strong>to hard rock, all of which are unl<strong>in</strong>edand unscreened. As well as doubl<strong>in</strong>gthe drill<strong>in</strong>g cost, screen<strong>in</strong>g and gravelpack<strong>in</strong>g block water from flow<strong>in</strong>g freely<strong>in</strong>to the hole.The very few rock holes that genu<strong>in</strong>elyrequire well screens and gravel packsto produce clean water can still usetelescop<strong>in</strong>g materials to m<strong>in</strong>imize drill<strong>in</strong>gcosts.Soft sedimentsAn appreciable number of holes aredrilled <strong>in</strong> soft sediments us<strong>in</strong>g mudpumps and mud pits to circulate drill<strong>in</strong>gfluids. The borehole volume dictates thesize of the mud pump needed, and theamount of water that must to be hauledand stored at the drill site. Reductions<strong>in</strong> borehole diameter there<strong>for</strong>e lead tosav<strong>in</strong>gs, even when a DTH hammer isnot required.Holes <strong>in</strong> sediments usually require wellscreens (and possibly gravel packs)to create a filter, ensur<strong>in</strong>g clean, clearwater <strong>in</strong> the well. Convention generallykeeps the construction diameter ofthe bore uni<strong>for</strong>m from top to bottom.However, telescop<strong>in</strong>g sizes opens up allsorts of possibilities <strong>for</strong> m<strong>in</strong>imiz<strong>in</strong>g theIn some countries, old regulations areenshr<strong>in</strong>ed <strong>in</strong> convention, and nationalstandards <strong>in</strong>sist on l<strong>in</strong><strong>in</strong>g all boreholesto full depth. These regulations takeno account of the <strong>in</strong>herent strengthof underly<strong>in</strong>g hard rock <strong>for</strong>mationsthat DTH hammers are capable ofpenetrat<strong>in</strong>g. Hav<strong>in</strong>g drilled through afissure crack and reached a supply of1,000 liters per hour of crystal clearwater, the driller is then obliged to shieldthe water flow<strong>in</strong>g <strong>in</strong>to the hole.A slotted pipe has to be first fitted <strong>in</strong> theabstraction zone, and then a curta<strong>in</strong> ofgravel placed between the fissure andthe pipe. Both these measures activelyA reduced-diameter drill rig <strong>in</strong> operation.9

Figures 5 & 6: Low cost borehole designs <strong>for</strong> crystall<strong>in</strong>e rock and unconsolidated materialTOP SOILSANDSILTS & CLAYTYPICALLYDrilled 6" (150mm.)Dragbitwith 'Air, Form' or 'Mud'Flush4" (113 x 102 mm.) PVCcas<strong>in</strong>gTypical water table risesabove water <strong>in</strong> fissuresSANDDrilled 6 1/2" (165mm.)Dragbit with 'Mud' flushonlySOFTWEATHEREDROCKCement / bentonitesealWATER TABLE4" (113X102mm.) PVCcas<strong>in</strong>gGRANITEHand pump cyl<strong>in</strong>der or4" submersible pumpSILTS & CLAY TYPICALLYHand pump cyl<strong>in</strong>der or4" submersible pump.Cement / bentonite seal'crack' or'fissures'stor<strong>in</strong>g water113 x 63mm. PVC theadedadaptor2" (63 x 62mm.) well screenSlot size 0.5-1.0mm.Graded gravel packDrilled 100mm. Buttonbit3" DTH HAMMERSAND AQUIFER VERYFINE PARTICLESuse 0.7-1.5mm. gradedwashed sandto gravel pack <strong>for</strong> 0.5 slot size- use 1.0-2.0mm. gravel pack<strong>for</strong> 1.0 slot sizes113 x 63mm. PVC threadedadapterSump section 4" (113 x102mm.)PVC cas<strong>in</strong>g 3.6 meter long113 x 102mm. cas<strong>in</strong>g po<strong>in</strong>tTypical depth 20-80 metersTypical depth 15-150 metersReduced diameter well screen <strong>for</strong> very f<strong>in</strong>e sands requir<strong>in</strong>g an even gravel packdiameters of drilled holes. Interest<strong>in</strong>gly,telescoped designs would alsocontribute hugely to the enhancedper<strong>for</strong>mance of bottom-supporteduPVC ris<strong>in</strong>g ma<strong>in</strong>s <strong>for</strong> deep-sethandpumps.Appropriate EquipmentBy def<strong>in</strong><strong>in</strong>g the m<strong>in</strong>imum requirementsof a community water supply basedon groundwater access rather than onthe equipment to be used, the localcontractor can then be left to determ<strong>in</strong>ehow the hole is constructed. Where thegroundwater is shallow and the waterlevel is relatively stable through dryseasons, a hand-dug well rema<strong>in</strong>s asound option.When groundwater is a little moredifficult to access, there are a numberof tripod-based drill<strong>in</strong>g methods,largely hand operated, that producefully acceptable water supplies atvery modest costs up to depths of 20meters.As drill<strong>in</strong>g gets deeper and <strong>in</strong>volvesthe penetration of hard rock, largermach<strong>in</strong>es are needed. These mach<strong>in</strong>esshould be based on the boreholeconstruction required where the smallerthe borehole diameter, the lighterthe correspond<strong>in</strong>g drill<strong>in</strong>g rig (and itssupport equipment) can be.By def<strong>in</strong>ition, hard rock aquifersare fragile <strong>in</strong> terms of their rechargepotential. It is very easy to over pumpthem, as has happened <strong>in</strong> Indiaover the past two decades. Largediameter bore holes lend themselvesto power pump<strong>in</strong>g, the abstractionof large volumes of water and heavydraw down – beyond the reachof most handpumps. Advocat<strong>in</strong>g<strong>for</strong> smaller diameter wells is alsomore environmentally friendly s<strong>in</strong>cehandpumps do not damage aquifers.10

<strong>Solutions</strong> <strong>for</strong> <strong>Reduc<strong>in</strong>g</strong><strong>Borehole</strong> <strong>Costs</strong> <strong>in</strong> <strong>Rural</strong> <strong>Africa</strong>ConclusionsThis analysis of borehole drill<strong>in</strong>gtechniques suggests that the follow<strong>in</strong>gmeasures could make possible a huge<strong>in</strong>crease <strong>in</strong> borehole construction, andrural water supply coverage throughout<strong>Africa</strong>.Relax the outdated nationalstandards that favorconservative borehole designsSmaller diameters holes shouldbe drilled to reduce the cost of theconstruction equipment and the<strong>in</strong>frastructure needed to support them.<strong>Borehole</strong> designs need to embracevariations <strong>in</strong> geology, the occurrence ofgroundwater, and <strong>in</strong>novations <strong>in</strong> drill<strong>in</strong>gtechnology.Develop an effective smallbus<strong>in</strong>ess sector made up of<strong>Africa</strong>n drill<strong>in</strong>g contractors,based <strong>in</strong> rural areas, and spreadbetween the communities theyare required to serveThe alternative technology choice opensthe door to huge cost reductions <strong>in</strong>borehole drill<strong>in</strong>g <strong>for</strong> water supplies, butthis technology needs skilful operationbased on both knowledge andexperience.An ideal world would see rurally basedsmall bus<strong>in</strong>esses operat<strong>in</strong>g drill<strong>in</strong>gmach<strong>in</strong>es <strong>for</strong> local community watersupplies. Such bus<strong>in</strong>esses would drillnew schemes, as well as have thecapacity to undertake well rehabilitation,pump improvements, and ma<strong>in</strong>tenanceduties.A portable drill<strong>in</strong>g rig with DTH capacity.However, lack of specialized technicaland bus<strong>in</strong>ess skills h<strong>in</strong>ders the abilityof local enterprise to undertake suchactivities. Seed schemes that couldprovide technical and bus<strong>in</strong>ess tra<strong>in</strong><strong>in</strong>gto entrepreneurs, l<strong>in</strong>ked with credit <strong>for</strong>capital equipment purchase, wouldimprove the success rate of such firms.Promote new, appropriatedrill<strong>in</strong>g technologiesAcceptable borehole constructionsneed to be established and thenbroadened to the application of simplemach<strong>in</strong>es capable of achiev<strong>in</strong>g thesestandards. M<strong>in</strong>imum quality controlthresholds <strong>for</strong> all new or modifiedborehole designs need to be developed.Provide cont<strong>in</strong>uity of work <strong>for</strong>local bus<strong>in</strong>essContractual frameworks that allow smallpractic<strong>in</strong>g bus<strong>in</strong>esses some cont<strong>in</strong>uityof work should be created. Advantageswould <strong>in</strong>clude maximiz<strong>in</strong>g mach<strong>in</strong>eusage and availability with<strong>in</strong> a fixedset of overheads, and <strong>in</strong>creas<strong>in</strong>g theconfidence levels of commercial lend<strong>in</strong>g<strong>in</strong>stitutions <strong>in</strong> the local drill<strong>in</strong>g <strong>in</strong>dustry.Such confidence would be <strong>in</strong>creased bytra<strong>in</strong><strong>in</strong>g and other methods designed tocontrol quality of drill<strong>in</strong>g construction.11

References and further read<strong>in</strong>gMacDonald, A. M., and J. Davies. 2000. A Brief Review of Groundwater <strong>for</strong> <strong>Rural</strong>Water Supply <strong>in</strong> Sub-Saharan <strong>Africa</strong>. Nott<strong>in</strong>gham: British Geological Survey(Technical report WC/00/33).Driscoll, F. G. 1986. Groundwater and Wells. St Paul, M<strong>in</strong>nesota: JohnsonDivision.USCS Open File Report 97-470A, 1997UNTCD, Groundwater <strong>in</strong> North and West <strong>Africa</strong>, 1998UNTCD, Groundwater <strong>in</strong> Eastern, Central and Southern <strong>Africa</strong>, 1988Foster SSD, <strong>Africa</strong>n groundwater development - the challenges <strong>for</strong>hydrogeological science, IAHS 144, 1984Guiraud R. L'hydrogeologie de l'Afrique, Journal of <strong>Africa</strong>n Earth Sciences, 7 519-543, 1988.About the authorPeter Ball, PAT-Drill Europe Ltd.For over 30 years, Peter Ball has worked as a water-well drill<strong>in</strong>g eng<strong>in</strong>eer <strong>for</strong>NGOs and <strong>in</strong>ternational and national contractors throughout <strong>Africa</strong>. He hasspecialized <strong>in</strong> low-technology approaches to drill<strong>in</strong>g water-supply boreholes,design<strong>in</strong>g equipment and implement<strong>in</strong>g construction programs that dramaticallyreduce technology levels and construction costs.November 2004The <strong>Rural</strong> Water Supply NetworkRWSN is a global knowledge network <strong>for</strong>promot<strong>in</strong>g sound practices <strong>in</strong> rural watersupply. RWSN grew out of the need tofocus greater attention on rural watersupply challenges and to encourage theexchange of experience and knowledge ofwhat works between the many public, NGOand private agencies <strong>in</strong>volved <strong>in</strong> rural waterdevelopment.RWSN SecretariatSKAT Foundation, Vadianstrasse 42CH-9000 St. GallenSwitzerlandPhone: +41 71 288 5454Fax: +41 71 288 5455Email: rwsn@skat.chWebsite: www.rwsn.chACKNOWLEDGEMENTS:This field note was prepared by Peter Ball. Itwas peer reviewed by Jon Lane (IndependentConsultant), Rupert Talbot (Consultant <strong>for</strong> UNICEF),Bob Roche (The World Bank), Julian Jones andErich Baumann (both of RWSN/SKAT). JosephNarkevic (the Task Manager) and Piers Cross(WSP-<strong>Africa</strong> Team Leader) provided valuable ideasand guidance on the paper.Editors: Melanie Low and Toni Sittoni.Photo credits: Peter Ball, PAT-Drill Europe and EnterpriseworksDesign & layout: Kul Graphics Ltd.Publisher: WSP-<strong>Africa</strong>