Dekguard Clear TDS - Parchem

Dekguard Clear TDS - Parchem

Dekguard Clear TDS - Parchem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

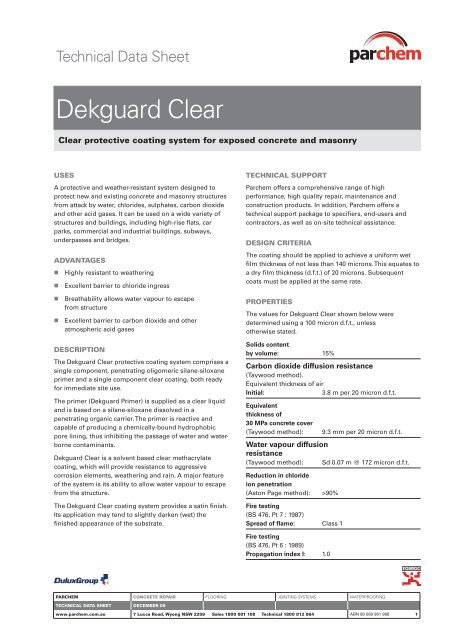

Technical Data Sheet<strong>Dekguard</strong> <strong>Clear</strong><strong>Clear</strong> protective coating system for exposed concrete and masonryUSESA protective and weather-resistant system designed toprotect new and existing concrete and masonry structuresfrom attack by water, chlorides, sulphates, carbon dioxideand other acid gases. It can be used on a wide variety ofstructures and buildings, including high-rise flats, carparks, commercial and industrial buildings, subways,underpasses and bridges.ADVANTAGES• Highly resistant to weathering• Excellent barrier to chloride ingress• Breathability allows water vapour to escapefrom structure• Excellent barrier to carbon dioxide and otheratmospheric acid gasesDESCRIPTIONThe <strong>Dekguard</strong> <strong>Clear</strong> protective coating system comprises asingle component, penetrating oligomeric silane-siloxaneprimer and a single component clear coating, both readyfor immediate site use.The primer (<strong>Dekguard</strong> Primer) is supplied as a clear liquidand is based on a silane-siloxane dissolved in apenetrating organic carrier. The primer is reactive andcapable of producing a chemically-bound hydrophobicpore lining, thus inhibiting the passage of water and waterbornecontaminants.<strong>Dekguard</strong> <strong>Clear</strong> is a solvent based clear methacrylatecoating, which will provide resistance to aggressivecorrosion elements, weathering and rain. A major featureof the system is its ability to allow water vapour to escapefrom the structure.The <strong>Dekguard</strong> <strong>Clear</strong> coating system provides a satin finish.Its application may tend to slightly darken (wet) thefinished appearance of the substrate.TECHNICAL SUPPORT<strong>Parchem</strong> offers a comprehensive range of highperformance, high quality repair, maintenance andconstruction products. In addition, <strong>Parchem</strong> offers atechnical support package to specifiers, end-users andcontractors, as well as on-site technical assistance.DESIGN CRITERIAThe coating should be applied to achieve a uniform wetfilm thickness of not less than 140 microns. This equates toa dry film thickness (d.f.t.) of 20 microns. Subsequentcoats must be applied at the same rate.PROPERTIESThe values for <strong>Dekguard</strong> <strong>Clear</strong> shown below weredetermined using a 100 micron d.f.t., unlessotherwise stated.Solids contentby volume: 15%Carbon dioxide diffusion resistance(Taywood method).Equivalent thickness of airInitial:3.8 m per 20 micron d.f.t.Equivalentthickness of30 MPa concrete cover(Taywood method):9.3 mm per 20 micron d.f.t.Water vapour diffusionresistance(Taywood method): Sd 0.07 m @ 172 micron d.f.t.Reduction in chlorideion penetration(Aston Page method): >90%Fire testing(BS 476, Pt 7 : 1987)Spread of flame: Class 1Fire testing(BS 476, Pt 6 : 1989)Propagation index I: 1.0PARCHEM CONCRETE REPAIR FLOORING JOINTING SYSTEMS WATERPROOFINGTECHNICAL DATA SHEET DECEMBER 09www.parchem.com.au 7 Lucca Road, Wyong NSW 2259 Sales 1800 801 108 Technical 1800 812 864 ABN 80 069 961 968 1

<strong>Dekguard</strong> <strong>Clear</strong>Freeze/thaw salt scalingASTM C672 (50 cycles):Reduction in waterabsorption ASTM C642: 84%SPECIFICATION CLAUSESUnaffectedCLEAR METHACRYLATE PROTECTIVE/WEATHERRESISTANT SURFACE COATINGThe protective coating shall comprise a penetratingoligomeric siloxane primer and <strong>Dekguard</strong> <strong>Clear</strong>, a singlecomponent methacrylate coating. The total dry filmthickness of the system shall be not less than 20 micronsand shall give a reduction in chloride ion penetration notless than 90%.APPLICATION INSTRUCTIONSDEKGUARD PRIMERNumber of coats:Theoretical applicationrate:Minimum dry filmthickness:Overcoating timeat 20°C:DEKGUARD CLEARNumber of coats:Theoretical applicationrate:As required to achieveabsorption of specified quantity0.4 litres / m 2 / coatN/A2 hoursAs necessary to give requiredcarbon dioxide diffusionresistance0.14 litres / m 2 / coatPREPARATIONAll surfaces should be dry and free from contaminationsuch as oil, grease, loose particles, decayed matter, moss,algal growth, laitance, and all traces of mould release oilsand curing compounds. This is best achieved by lightlygrit-blasting the surface. Where moss, algae or similargrowths have occurred, treatment with a proprietarybiocide should be carried out after the grit-blastingprocess.Note: it is not necessary to remove Fosroc’s Nitobond ARcuring membrane prior to the application of <strong>Dekguard</strong><strong>Clear</strong>.Where application over existing sound coatings isrequired, trials should be conducted to ensurecompatibility and retention of the bond between theunderlying coating and substrate. For further advice,consult your local <strong>Parchem</strong> sales office.It is essential to produce an unbroken coating of <strong>Dekguard</strong><strong>Clear</strong>. To ensure this is achieved, surfaces containingblowholes or similar areas of pitting should first be filledusing Renderoc FC, a cementitious fairing coat (for furtherdetails, refer to separate Technical Data Sheet). RenderocFC should be allowed to cure for approximately 48 hoursdependent on ambient conditions before the application of<strong>Dekguard</strong> <strong>Clear</strong>.APPLICATIONIn order to obtain the protective properties of the<strong>Dekguard</strong> <strong>Clear</strong> system, it is important that the correctrates of application and overcoating times are observed.Minimum dry filmthickness:Overcoating timeat 20°C:20 microns per coat6 hoursApplication of either <strong>Dekguard</strong> Primer or <strong>Dekguard</strong> <strong>Clear</strong>should not commence if the temperature of the substrateis below 2°C.Any areas of glass should be masked. Plants, grass, jointsealants, asphalt and bitumen-painted areas should beprotected during application.<strong>Dekguard</strong> Primer should be applied in 1 or more coatsuntil the recommended application rate of 0.4 litres persquare metre has been achieved. This is best accomplishedby using portable spray equipment of the knapsack-type.Porous surfaces may require the application of NitoprimeDG as an alternative primer, or may require other specialtreatment.Nitoprime DG should be applied at the same coverage rateas <strong>Dekguard</strong> Primer but in continuous, multiple coats asnecessary. If in doubt about the condition of the substrate,your local <strong>Parchem</strong> sales office should be consulted.The primer should be allowed to dry for a minimum of 2hours (at 20°C) before continuing. Under no circumstancesshould the primer be overcoated with <strong>Dekguard</strong> <strong>Clear</strong> untilthe surface is properly dry.<strong>Dekguard</strong> <strong>Clear</strong> may be applied by the use of suitablebrushes or rollers. For further information aboutapplication techniques, please consult your local <strong>Parchem</strong>sales office prior to the commencement of work.2

<strong>Dekguard</strong> <strong>Clear</strong>All primed substrates should be treated with minimum 1coat of <strong>Dekguard</strong> <strong>Clear</strong>. The material should be stirredthoroughly before use and be applied to all areas by theuse of suitable brushes or rollers to achieve a uniformcoating with a wet film thickness not less than 140microns.Subsequent coats should be applied exactly as detailedabove, again achieving a uniform coating with a wet filmthickness not less than 140 microns per coat. Each coatshould be allowed to dry for not less than 6 hours at 20°C.CLEANINGRenderoc FC should be removed from tools andequipment with clean water immediately after use.<strong>Dekguard</strong> Primer, Nitoprime DG and <strong>Dekguard</strong> <strong>Clear</strong>should be removed from tools and equipment usingSolvent 10.ESTIMATINGSUPPLY<strong>Dekguard</strong> <strong>Clear</strong>:<strong>Dekguard</strong> Primer:Nitoprime DG:(porous substrates)Renderoc FC:Solvent 10:COVERAGERenderoc FC:<strong>Dekguard</strong> Primer:Nitoprime DG20 litre drum20 litre drum20 litre drum15 kg bag4 and 20 litre drums9 litres(3.0 m 2 at 3 mm thickness)2.5 m 2 per litre (total)2.5 m 2 per litre (total)LIMITATIONSThe <strong>Dekguard</strong> <strong>Clear</strong> system is formulated for applicationto clean, sound concrete or masonry. Where applicationover existing sound coatings or paints is required, trialsshould be conducted to ensure compatibility and retentionof the bond between the underlying coating and thesubstrate. When applied over existing coatings or paints,the performance characteristics of <strong>Dekguard</strong> <strong>Clear</strong> may beimpaired and its fire rating invalidated. Compatibility andsoundness should be assessed on a trial area. For furtheradvice, consult your local <strong>Parchem</strong> sales office.Application should not commence if the temperature ofthe substrate is below 2°C.<strong>Dekguard</strong> <strong>Clear</strong> should not be applied in windy conditionswhere early-age dust adhesion may occur, or where rain islikely within 2 hours at 20°C or 20 hours at 5°C (up to 80%RH). It should not be applied when the prevailing relativehumidity exceeds 90%.<strong>Dekguard</strong> <strong>Clear</strong>:7 m 2 per litre per coatThe coverage figures given are theoretical - due towastage factors and the variety and nature of possiblesubstrates, practical coverage figures will be reduced.STORAGESHELF LIFEAll products have a shelf life of 12 months if kept in a drystore in the original, unopened packs.STORAGE CONDITIONSStore in cool, dry conditions, away from sources of heatand naked flames, in the original, unopened packs. Ifstored at high temperatures and/or high humidityconditions the shelf life may be reduced.3

<strong>Dekguard</strong> <strong>Clear</strong>ADDITIONAL INFORMATION<strong>Parchem</strong> provides a wide range of complementary productswhich include:• concrete repair – cementitious and epoxy• grouts and anchors – cementitious and epoxy• waterproofing membranes – liquid applied,cementitious and bituminous sheet membranes• waterstops – pvc and swellable• joint sealants – building, civil and chemical resistant• industrial flooring systems – cementitious andepoxy• architectural coatings• filler boards – swellable cork, bituminous andbacking rod• ancillary productsFor further information on any of the above, please consultwith your local <strong>Parchem</strong> sales office.IMPORTANT NOTICEA Material Safety Data Sheet (MSDS) and Technical Data Sheet(<strong>TDS</strong>) are available from the <strong>Parchem</strong> website or upon requestfrom the nearest <strong>Parchem</strong> sales office. Read the MSDS and<strong>TDS</strong> carefully prior to use as application or performance datamay change from time to time. In emergency, contact anyPoisons Information Centre (phone 13 11 26 within Australia)or a doctor for advice.PRODUCT DISCLAIMERThis Technical Data Sheet (<strong>TDS</strong>) summarises our best knowledge ofthe product, including how to use and apply the product based on theinformation available at the time. You should read this <strong>TDS</strong> carefullyand consider the information in the context of how the product will beused, including in conjunction with any other product and the type ofsurfaces to, and the manner in which, the product will be applied. Ourresponsibility for products sold is subject to our standard terms andconditions of sale. <strong>Parchem</strong> does not accept any liability either directlyor indirectly for any losses suffered in connection with the use orapplication of the product whether or not in accordance with anyadvice, specification, recommendation or information given by it.*Manufactured and sold under license from Fosroc InternationalLimited. Fosroc and the Fosroc logo are trade marks of FosrocInternational Limited, used under license. *Denotes a trade mark ofFosroc International Limited.PARCHEM CONCRETE REPAIR FLOORING JOINTING SYSTEMS WATERPROOFINGTECHNICAL DATA SHEET DECEMBER 09www.parchem.com.au 7 Lucca Road, Wyong NSW 2259 Sales 1800 801 108 Technical 1800 812 864 ABN 80 069 961 9684