AutoPack Brochure - Hot Melt Technologies, Inc.

AutoPack Brochure - Hot Melt Technologies, Inc.

AutoPack Brochure - Hot Melt Technologies, Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

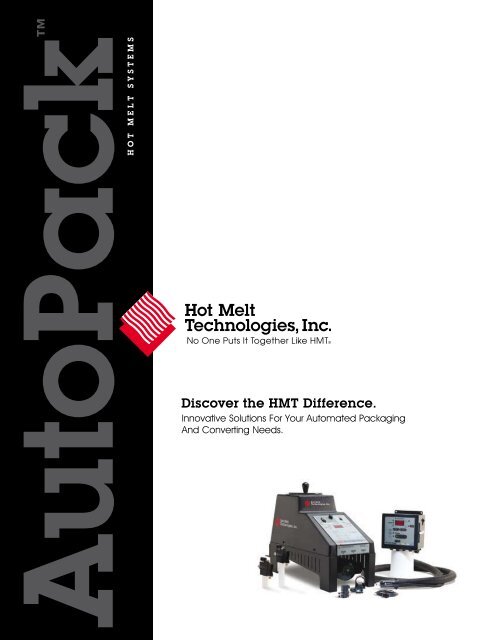

<strong>AutoPack</strong>HOT MELT systemsDiscover the HMT Difference.Innovative Solutions For Your Automated PackagingAnd Converting Needs.

Discover The HMT ®DifferenceWhen you purchase a hot melt application system, you expect long-term durability, reliability and performance.And most importantly, you expect value without compromise.You should also expect years of trouble free operation with minimal preventative maintenance and repair. And after manyyears of service, your hot melt system should be able to be replaced or refurbished at a reasonable cost.<strong>AutoPack</strong> Systems from HMT…Innovative, Built Tough And Designed For Easy Serviceability.The differences are easy to see – and appreciate –in <strong>AutoPack</strong> Systems from <strong>Hot</strong> <strong>Melt</strong> <strong>Technologies</strong>(HMT ® ). After all, we’ve been manufacturing hot meltequipment for over 20 years servicing some of themost demanding industries throughout the world.Configured especially for packaging and convertingapplications, <strong>AutoPack</strong> Systems are built tough andsmart. Modular in design and long-lasting inperformance, you get the exact system youwant… and, down the road, you can easilyrepair or replace components.<strong>AutoPack</strong> HP-20<strong>AutoPack</strong> HP-20 System with a 15 lb. melt tank, a heated hose, high-performance 900-SeriesAutomatic Guns on Mini-Manifolds. Also shown with the DF-224 Pattern Control Timer.No Matter The Application…There’s An <strong>AutoPack</strong> System To MeetYour Needs.<strong>AutoPack</strong> 500 Systemwith a 35 lb. <strong>Melt</strong> Tank<strong>AutoPack</strong> 900 Systemwith a 50 lb. <strong>Melt</strong> Tank<strong>AutoPack</strong> R-Serieswith 200 lb. <strong>Melt</strong> Tank

Production-Prove For Every Application.Our <strong>AutoPack</strong> Systems incorporate all the factory-proven design and performancefeatures of our ProFlex ® and Benchmark ® industrial hot melt systems. They feature 10gauge steel base platforms, hardened-steel spur gear pumps that provide maximumperformance and durability; high-torque fractional-horsepower drive motors designedfor continuous duty under the most extreme conditions; patented melt-on-demandmelt tanks designed for quick change and cleaning ease; and sophisticated,yet simple to operate process and temperature controls.Long-Lasting Performance DesignedInto Every HMT Component.All HMT <strong>AutoPack</strong> Systems are built for long-lasting performance and easyserviceability. That’s why we use only top quality, modular components onall our hot melt application systems.Simple, Yet Sophisticated System Controls<strong>AutoPack</strong> System controls are simple, secure and smart.Programming is intuitive behind a tamper-proof, lockablepanel. Each control panel has redundant fail-safe featuresalong with easy-to-understandpanel diagnostics.Wear Resistant Steel Gear PumpsIntegral to all <strong>AutoPack</strong> Systems, hardened steelspur gear pumps provide reliable,continuous operation. Electrically driven,these pumps deliver steady,pulse-free adhesive flow.Durable, Continuous-Duty Drive MotorsHigh-torque, fractional horsepower drivemotors on <strong>AutoPack</strong> Systems aredesigned for continuous duty in themost extreme conditions.Available in constant orvariable speedconfigurations, thesemotors will provide yearsof trouble-free provenperformance.Patented Modular <strong>Melt</strong> TanksAll <strong>AutoPack</strong> Systems feature HMT-patented modular melttanks. With interchangeable capacities up to 200 lbs., melttanks can be easily changed, notonly for cleaning, but to meet yourchanging needs. Constructed fromPTFE-coated, extruded tubularaluminum, HMT tanks featuremelt-on-demand technology forreduced energy consumptionand to minimize adhesivedegradation. Tanks are mountedto an independent heater platewith easily serviced interchangeablecartridge heaters.

Heated Hoses Built To LastHMT builds heated hoses to the most exacting engineering and safety standards. The core of each hose is hand-wound usingmulti-strand nichrome heater wire imbedded in 60 mils of silicon, wrapped with insulation, and covered withextra tough outside braiding. All hosesincorporate our industry-exclusivereplaceable RTD sensors. Andafter assembly, each hose isindividually tested and theheat profile is recorded andmaintained.Automatic Guns And Nozzles For Every ApplicationAll HMT automatic guns feature air-to-open and air-to-close for superior on/offcontrol. HMT guns also feature reduced cavity needle-in-nozzle technology forenhanced performance and clog-resistant operation. All needles are turnedfrom one piece of stainless steel for strength and trueness. Each is precisionground to a #8 finish and electro polished for ultra smoothness. Using glass-filledPTFE seals and viton o-rings, HMT valves can be operated at speeds of up to8000 cycles per minute.If you are involved in low- or high-speed case and carton sealing, tray making,sift-proof packaging, or high-volume box or bag making operations, HMT buildsguns and nozzles for every application. And we look forward to building unique,one-of-a-kind guns and nozzles to meet your special needs.• Aimable, Low Profile• Bead• Dual Orifice• Extended• Fine Tip• Sift-proof• Multi-Bead• Spray• Slot• Swirl• And more…

<strong>Melt</strong> Unit SpecificationsSystem Type• Benchmark ® and ProFlex ®• High-Performance, Industrial• Packaging and Converting• 220vac Electric (no air required)Maximum Hoses and Guns• 4 hoses and 4 guns<strong>Melt</strong> Tank• Modular (HMT patent)• Interchangeable• Extruded Tubular Aluminum• PTFE Coated<strong>Melt</strong> Tank Capacities (lbs.)• HP-20: 15 lbs.• 500 Series: 17, 25, 35 or 50 lbs.• 900 Series: 17, 25, 35 or 50 lbs.• “R” Series: 50, 85, 135 or 200 lbs.<strong>Melt</strong> Tank Heaters• Interchangeable Cartridge Type• ServiceableMotor• Fractional Horsepower• Constant Speed (standard)• Variable Speed (optional)Pump• Hardened Steel Spur Gear• Positive Displacement• Pulse Free Up To 600 psi (40 bar)<strong>Melt</strong> Rate• HP-20: Up to 15 lbs. /hr.• 500 and 900 Series: Up to 50 lbs. /hr.• “R” Series: Up to 100 lbs. /hr.CONTROL SpecificationsControl Type• Benchmark 500 or Proflex G Series• Modular• Full Feature Solid-State, Microprocessor• Tamper ProofProcess Control• <strong>Melt</strong>-On-Demand• 100ohm RTD Sensors (all zones)• P.I.D. Temp. Control (all zones)Front Panel Display• Run Temp. Display• Set-Point Display• High Limit Display• Readout in °F or °C• Manual StandbyRun Temperature Range• 100°F to 475°F, ± 1°FSafety Limits• High Set Point Limit, 250°F to 475°F• O.T. Protection with Auto Shutoff• Pump-Ready Lock OutSafety Timers• Auto-Standby• Auto-OffOptional Timers• 24-Hour/7-Day On/Off SchedulerServiceability• Plug-in Control Relays• Plug-in Microprocessor• Plug-in ICs• Plug-in Fuses• DiagnosticsHOSE SpecificationsHose Lengths• Up to 30 ft.Electrical• 220vac• 30 Watts per ft.Maximum Operating Temp.• Up to 475° FMax. Hydraulic Pressure (#6 core)• Up to 2000psiConstruction• PTFE Lined Stainless Steel Core• Stainless Steel Fittings• Layered Aramid-Felt Insulation• Super-Tuff Nylon Outer SleeveHeater• Kapton Coated Nichrome• Multi-Stranded for Max. Durability• Silicone Wrapped• Closely Spaced for Max. Flexibility• Fiberglass BeddingSensor• 100ohm Platinum RTD• ReplaceableAutomatic Gun SpecificationsGun Type• Air-to-Open, Air-to-Close• Reduced Cavity, Needle-in-Nozzle• Stainless Steel Needle• Adjustable Stroke• 2-Piece ConstructionElectrical• 220vacOperating Temperature• Up to 475° FOperating Air Pressure• 80 to 100psiMax Working Hydraulic Pressure• 1,500psiOperating Speed• 600 Series: 3500 cycles/ min.• 850 Series: 3500 cycles/ min.• 900/950 Series: 4000 cycles/ min.• 900-HP Series: 8000 cycles/ min.Recommended Solenoid Valves• Standard Industrial 24vdcDFS EngineeringReduces YourCost Of Ownership<strong>Hot</strong> melt systems operate at hightemperatures for extended periodsof time. Eventually and at differenttimes, the melt tank, pump, heatedhoses, guns and nozzles will need tobe cleaned, repaired or replaced.At HMT, we adhere to theengineering protocol “Designfor Serviceability” (DFS) in all our<strong>AutoPack</strong> products and components.This has led to our industry exclusiveDFS® Service and Repair Kits and ourNXP ® New Exchange Program.A review of our component repairand replacement costs will impressyour maintenancedepartment andplease yourfront office.“ HMT is a choiceyou can makewith confidence.”