Roller Chain - Tsubaki

Roller Chain - Tsubaki

Roller Chain - Tsubaki

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

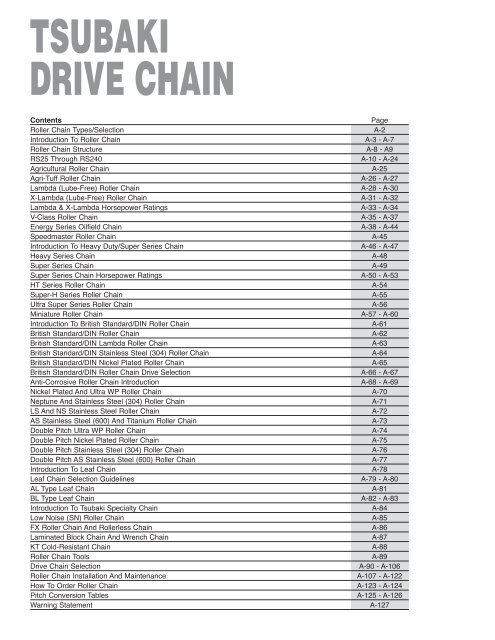

TSUBAKIDRIVE CHAINContentsPage<strong>Roller</strong> <strong>Chain</strong> Types/Selection A-2Introduction To <strong>Roller</strong> <strong>Chain</strong> A-3 - A-7<strong>Roller</strong> <strong>Chain</strong> StructureA-8 - A9RS25 Through RS240 A-10 - A-24Agricultural <strong>Roller</strong> <strong>Chain</strong> A-25Agri-Tuff <strong>Roller</strong> <strong>Chain</strong> A-26 - A-27Lambda (Lube-Free) <strong>Roller</strong> <strong>Chain</strong> A-28 - A-30X-Lambda (Lube-Free) <strong>Roller</strong> <strong>Chain</strong> A-31 - A-32Lambda & X-Lambda Horsepower Ratings A-33 - A-34V-Class <strong>Roller</strong> <strong>Chain</strong> A-35 - A-37Energy Series Oilfield <strong>Chain</strong> A-38 - A-44Speedmaster <strong>Roller</strong> <strong>Chain</strong> A-45Introduction To Heavy Duty/Super Series <strong>Chain</strong> A-46 - A-47Heavy Series <strong>Chain</strong> A-48Super Series <strong>Chain</strong> A-49Super Series <strong>Chain</strong> Horsepower Ratings A-50 - A-53HT Series <strong>Roller</strong> <strong>Chain</strong> A-54Super-H Series <strong>Roller</strong> <strong>Chain</strong> A-55Ultra Super Series <strong>Roller</strong> <strong>Chain</strong> A-56Miniature <strong>Roller</strong> <strong>Chain</strong> A-57 - A-60Introduction To British Standard/DIN <strong>Roller</strong> <strong>Chain</strong> A-61British Standard/DIN <strong>Roller</strong> <strong>Chain</strong> A-62British Standard/DIN Lambda <strong>Roller</strong> <strong>Chain</strong> A-63British Standard/DIN Stainless Steel (304) <strong>Roller</strong> <strong>Chain</strong> A-64British Standard/DIN Nickel Plated <strong>Roller</strong> <strong>Chain</strong> A-65British Standard/DIN <strong>Roller</strong> <strong>Chain</strong> Drive Selection A-66 - A-67Anti-Corrosive <strong>Roller</strong> <strong>Chain</strong> Introduction A-68 - A-69Nickel Plated And Ultra WP <strong>Roller</strong> <strong>Chain</strong> A-70Neptune And Stainless Steel (304) <strong>Roller</strong> <strong>Chain</strong> A-71LS And NS Stainless Steel <strong>Roller</strong> <strong>Chain</strong> A-72AS Stainless Steel (600) And Titanium <strong>Roller</strong> <strong>Chain</strong> A-73Double Pitch Ultra WP <strong>Roller</strong> <strong>Chain</strong> A-74Double Pitch Nickel Plated <strong>Roller</strong> <strong>Chain</strong> A-75Double Pitch Stainless Steel (304) <strong>Roller</strong> <strong>Chain</strong> A-76Double Pitch AS Stainless Steel (600) <strong>Roller</strong> <strong>Chain</strong> A-77Introduction To Leaf <strong>Chain</strong> A-78Leaf <strong>Chain</strong> Selection Guidelines A-79 - A-80AL Type Leaf <strong>Chain</strong> A-81BL Type Leaf <strong>Chain</strong> A-82 - A-83Introduction To <strong>Tsubaki</strong> Specialty <strong>Chain</strong> A-84Low Noise (SN) <strong>Roller</strong> <strong>Chain</strong> A-85FX <strong>Roller</strong> <strong>Chain</strong> And <strong>Roller</strong>less <strong>Chain</strong> A-86Laminated Block <strong>Chain</strong> And Wrench <strong>Chain</strong> A-87KT Cold-Resistant <strong>Chain</strong> A-88<strong>Roller</strong> <strong>Chain</strong> Tools A-89Drive <strong>Chain</strong> Selection A-90 - A-106<strong>Roller</strong> <strong>Chain</strong> Installation And Maintenance A-107 - A-122How To Order <strong>Roller</strong> <strong>Chain</strong> A-123 - A-124Pitch Conversion Tables A-125 - A-126Warning Statement A-127

<strong>Tsubaki</strong> <strong>Roller</strong> <strong>Chain</strong>Types/SelectionClassificationGeneralRS <strong>Roller</strong> <strong>Chain</strong>LAMBDAAdvanced FeaturesANSI Standard(excludes some items)Special sintered bushingDrive <strong>Chain</strong>Lube-FreeLAMBDA-NPX-LAMBDACU-LAMBDABS-LAMBDANickel PlatedUltra-Long LifeFor curved driveBritish and DIN standardSUPERImproved max. allowable load and tensile strengthSUPER seriesSUPER-HRS-HTStronger than SUPERImproved tensile strengthUSUltra-StrongAnti-CorrosionCorrosion ResistantSlightly anti-corrosiveHeat resistant /Anti-corrosiveHighly anti-corrosiveNPPCWPSSNEPTUNELSASNSTIPC-SYNickel PlatedSpecial coatingSpecial double coatingSUS304 + engineering PlasticSUS304SUS304 + engineering plasticMax. allowable load = SS × 1.5SUS316TitaniumTitanium + engineering plasticColdresistantKT–40C to +60C(–40F to +140F)Low NoiseSNLow noiseCurvedCUFor curved driveBritish StandardSpecialtyBSFXROLLERLESSWRENCHBLOCKISO-B seriesDurability and flexabilitySteel bushedExtended pinsLaminated blocksMiniatureMINIQuiet, compact, lightweightAgriculturalAGRIAGRI-TUFFLowspeed, moderate loadHigher strength/wera lifeLeafLEAFHigher tensile strengthA-2

Introduction to<strong>Tsubaki</strong> <strong>Roller</strong> <strong>Chain</strong>This Drive <strong>Chain</strong> Catalog outlines the important points relating to selection, installation, and maintenance of each TSUBAKI <strong>Roller</strong> <strong>Chain</strong>.Make sure to read this catalog before using the chain, and follow the correct selection procedures and method of use. Furthermore,please fully explain matters relating to installation and maintenance to those performing these tasks.Before UseOrdinary TransmissionLifting TransmissionDrive <strong>Chain</strong>CautionThe horsepower ratingstables in this catalog(excluding SUPER <strong>Chain</strong>)are for RS <strong>Roller</strong> <strong>Chain</strong>s andLambda <strong>Roller</strong> <strong>Chain</strong>s whereconnecting links havingundergone the ring coinprocess and 2-pitch offsetlinks are used.Shuttle TractionPin Gear Drive<strong>Roller</strong> <strong>Chain</strong> Safety Use■ Clear the area of all personnel when lifting <strong>Roller</strong> <strong>Chain</strong>.■ Install safety equipment to prevent injuries and damage to equipment in the eventof <strong>Roller</strong> <strong>Chain</strong> breakage.■ Inspect and replace worn <strong>Roller</strong> <strong>Chain</strong> periodically.■ Wear elongation may cause <strong>Roller</strong> <strong>Chain</strong> to break and climb up on the sprocket.(Wear life can be extended by periodically applying lubrication, or by using the lubefreeLambda <strong>Chain</strong> series.)■ Overload may cause <strong>Roller</strong> <strong>Chain</strong> to break.(Overload breakage can be avoided through careful selection, considering inertia orby using identically-sized SUPER <strong>Roller</strong> <strong>Chain</strong>.)■ Unfavorable environmental conditions such as corrosion may cause eventual <strong>Roller</strong><strong>Chain</strong> breakage.(This can be avoided by making sure the chain doesn’t come in contact withcorrosive liquids or steam, etc. Alternatively, the Anti-Corrosive series isrecommended.)■ Correctly install <strong>Roller</strong> <strong>Chain</strong> to avoid misalignment or uneven wear and possiblebreakage.A-3

Introduction to<strong>Tsubaki</strong> <strong>Roller</strong> <strong>Chain</strong>Power transmission machines use chains, gears, or belts. The table below provides a comparison of typical applications. In general,chain is an economical part of power transmission machines for low speeds and large loads. However, it is also possible to use chainin high-speed conditions like automobile engine camshaft drives. This is accomplished by devising a method of operation and lubrication.Drive <strong>Chain</strong>General Comparison ofTransmission ElementsSynchronizationTransmissionEfficiencyAnti-Shock<strong>Roller</strong> <strong>Chain</strong> Tooth Belt V Belt■■■ ■ ▲▲ ❍ ■▲Spur Gear■■▼Noise/Vibration▲ ■ ■▼SurroundingConditionsAvoid water and dust(Corrosion Resistant<strong>Roller</strong> <strong>Chain</strong> is available)Avoid heat, oil,water, and dustAvoid heat, oil,water, and dustAvoid water anddustSpaceWeightHigh SpeedLow LoadLow SpeedHigh LoadLubrication▼ ■ ❍■Compact/Light Weight▲Slightly heavy pulley▼Heavy wide pulley▼ Necessary ■ Unnecessary ■ Unnecessary❍❍Less durability due to lownumber of engaging teeth▼ NecessaryLayout FlexibilityExcess Load onBearing■ ❍ ▲■ ❍ ▼▼■■ Excellent ❍ Good ▲ Fair ▼ PoorFeatures & Points toNote about <strong>Roller</strong> <strong>Chain</strong>TransmissionFeatures1. Accommodates large speed reductions/increases (Usually up to 1 : 7)2. <strong>Chain</strong> can accommodate long shaft center distances (normally less than 4 m), and ismore versatile.3. It is possible to use chain with multiple shafts or drives with both sides of the chain.4. Ease of installation and replacement (easy to cut and connect chains).5. Drive use is possible even when shafts are vertical, as long as the chain receivessupport in short distances between the shafts.6. Standardization of chains under the American National Standards Institute (ANSI), theInternational Standardization Organization (ISO), and the Japanese IndustrialStandards (JIS) allow ease of selection.7. The sprocket diameter for a chain system may be smaller than a belt pulley, whiletransmitting the same torque.8. Sprockets are subject to less wear than gears because sprockets distribute the loadingover their many teeth.9. There is high shock absorbency compared with gears.Points to Note1. <strong>Chain</strong> has a speed variation, called chordal action, which is caused by the polygonaleffect of the sprockets.(Shock can be reduced under the same speed ratio, by either reducing the chain pitchor increasing the number of sprocket teeth.)2. During transmission, a particular method of lubrication is necessary according to speed.3. <strong>Chain</strong> wears and elongates, so you need to consider measures for adjusting chainslack.4. <strong>Chain</strong> is weak when subjected to loads from the side. It needs proper alignment.A-4

Introduction to<strong>Tsubaki</strong> <strong>Roller</strong> <strong>Chain</strong>Explanation of Terms1. ANSI Standard Minimum Tensile Strength (Tensile Breakage Strength)This is the Minimum Tensile Strength determined by ANSI. If a roller chain breaks from atensile load below this value, then it does not surpass ANSI standards. In the case ofmulti-strand roller chain, the single strand value is multiplied by the number of strands.2. Average Tensile StrengthThis is a fracture load reading obtained after a long period of actual tensile strength testingof a large number of chain strands. Of course, when any given strand of roller chainfractures, this value may be higher or lower, so it does not represent a guaranteed value.This value differs depending on the manufacturer.3. Minimum Tensile StrengthThis is a minimum value determined by statistical processing at TSUBAKI. If any rollerchain fractures by a tensile load below this value, then it does not surpass the standards.This value differs depending on the manufacturer.Drive <strong>Chain</strong>Minimum ANSI StandardTensile Strength<strong>Tsubaki</strong> Minimum Tensile StrengthAve. Tensile StrengthFrequencyTensile StrengthFig. 1 Relationship between three tensile strengths.4. Tensile Strength Testing MethodAs shown in Fig. 2, roller chain with over five links is fixed at both ends by clevises and isstretched until fracture occurs. The type of fracture is indicated by breakage of the rollerchain or failure of its parts (Fig. 3).Fig. 2 Tensile strength testFig. 3 Shape of fractureA-5

Introduction to<strong>Tsubaki</strong> <strong>Roller</strong> <strong>Chain</strong>Drive <strong>Chain</strong>5. Maximum Allowable LoadThe maximum allowable load is the tension load for which a chain is rated to carry inrunning operation. Proper chain tension is critical because excessive tension can causeaccelerated wear/breakage or chain overload and excessive slack can cause roughchain operation and may result in the chain skipping a sprocket tooth.The use of one-pitch offset links reduces the maximum allowable load – it now becomes65% of the maximum allowable load of the main chain.Two-pitch offset links do not change the maximum allowable load of the main chain.In Figure 4 below, the maximum allowable load is indicated by Pmax.Pmax = (Pm + Pa) = 2.2PaWhere a new roller chain with over 5 links receives a repetitive load with a frequency of10 6 .Fig. 4 Summary chart for repetitive loadsLoadTime6. Horsepower Ratings TableRS <strong>Roller</strong> <strong>Chain</strong> and SUPER <strong>Roller</strong> <strong>Chain</strong> HP rating tables show HP values that allow15,000 hours of operation using a two-shaft drive and 100 pitches of roller chain underconditions 1 - 5 below. The HP ratings table of LAMBDA chain is based on conditions 1- 4 and shows HP rating values when LAMBDA chain is used with two shafts. Lambda<strong>Chain</strong> has more than 14 times the wear elongation of Standard RS <strong>Roller</strong> <strong>Chain</strong>operated without lubrication (#120 and #140 have five times). X-LAMBDA has morethen five times the wear elongation life of Lambda <strong>Roller</strong> <strong>Chain</strong>.1) The chains are operated under ordinary conditions where the ambient temperature is–10°C ~ +60°C (+14°F ~ +140°F) and there is no abrasive dust.2) There are no negative effects from corrosive gasses or a high humidity.3) The two transmission shafts are in a horizontal position and the chains are properlyinstalled.4) There is minimal fluctuation in load during transmission.5) The recommended lubrication system and lubricant shown in the HP rating tables isused for RS <strong>Roller</strong> <strong>Chain</strong> and SUPER <strong>Roller</strong> <strong>Chain</strong>.7. Moment of Inertia (I / J / GD 2 )Moment of Inertia is used to show the degree of inertia in rotational movement, in otherwords, “rotation difficulty”, or “rotation ease.” This is equivalent to the mass (weight) ofthe object being used for straight-line transmission.A-6

Introduction to<strong>Tsubaki</strong> <strong>Roller</strong> <strong>Chain</strong>After almost a century of chain design, engineering and manufacturing experience, you can count on <strong>Tsubaki</strong> standard roller chain todeliver consistent superior performance and longer life. All minimizing your downtime and maximizing your output. And all for a price alot less than you might think. From the best heat-treated steel for the job to ground-breaking patents, you can trust <strong>Tsubaki</strong> to deliverthe quality difference you can see.Drive <strong>Chain</strong><strong>Tsubaki</strong>’s Patented LubeGrooves Extend Wear Lifeand Performance by up to30%Long Lasting Solid <strong>Roller</strong>sProvide Greater FatigueLife and Durability at HighSpeedsPrecision RivetingProcess Helps to WithstandSide Load ImpactWide Waist Link Plates ProvideTensile Strength and MaximumAllowable Load that Exceeds ANSIStandards<strong>Tsubaki</strong>’s Patented Ring CoiningGenerates UnsurpassedConnecting Link StrengthA-7

<strong>Roller</strong> <strong>Chain</strong> StructurePin LinkPress Fit<strong>Roller</strong> LinkPress FitSlip FitWidth between<strong>Roller</strong> Link PlatesPinDrive <strong>Chain</strong>1. Basic StructurePress Fit<strong>Roller</strong>Bushing<strong>Roller</strong>Diameter Pitch<strong>Roller</strong> Link PlateThree Basic DimensionsPitch, <strong>Roller</strong> Diameter and Widthbetween <strong>Roller</strong> Link Plates areknown as the “Three BasicDimensions of <strong>Roller</strong> <strong>Chain</strong>.”When these three dimensions areidentical, roller chain andsprockets are dimensionallycompatible.* Slip FitWhen the shafts and holes arefitted together, there is acontinuous loose fit. This is a fitwhere the range of tolerance forthe hole is larger than the rangeof tolerance for the shaft (pin orbushing).* Press FitWhen the shafts and holes arefitted together, there is acontinuous interference fit. This isa fit where the range of tolerancefor the hole is smaller than therange of tolerance for the shaft(pin or bushing).A-8Offset PinCotter PinSlip FitSpring clips, cotter pins andspring pins are the parts thatprevent the connecting linkplate from falling off the pin.These parts are critical in orderto maintain the originalstrength of the chain.Connecting Link PlateSpring ClipPin Link PlateSingle StrandPin LinkInner PlateOffset Link Connecting Link<strong>Roller</strong> <strong>Chain</strong><strong>Roller</strong> LinkMulti-Strand Pin Link(Two-strand chain shown)• PlateThe plate is the component that bears the tension placed on the chain. Usually this is a repeatedloading, sometimes accompanied by shock. Therefore, the plate must have not only great statictensile strength, but also must hold up to the dynamic forces of load and shock.• PinThe pin is subject to shearing and bending forces transmitted by the plate. At the same time, itforms a load-bearing part, together with the bushing, when the chain flexes during sprocketengagement. Therefore, the pin needs high tensile and shear strength, resistance to bending,and also must have sufficient endurance against shock and wear.• BushingThe bushing is subject to complex forces from all parts, especially from the repetition of shockloads when the chain engages the sprocket. Therefore, the bushing needs extremely high shockresistance. In addition, the bushing forms a load-bearing part together with the pin and as suchrequires great wear resistance.• <strong>Roller</strong>The roller is subject to impact load as it strikes the sprocket teeth during the chain engagementwith the sprocket. After engagement, the roller changes its point of contact and balance. It is heldbetween the sprocket teeth and bushing, and moves on the tooth face while receiving acompression load. Therefore, it must be resistant to wear and still have strength against shock,fatigue and compression. RS11 / 15 / 25 / 35 do not have rollers.• <strong>Roller</strong> LinkTwo bushings are press fit into two roller link plates and rollers are inserted to allow rotationaround the outside of the bushing. This is the same for single strand and multi-strand chain.• Pin Link and Inner PlateThe pin link consists of two pins that have been press fit into two pin link plates. In the case ofmulti-strand roller chain, an inner plate is added to the pin link. The inner plate is slip fit forStandard RS <strong>Roller</strong> <strong>Chain</strong> and press fit for SUPER <strong>Roller</strong> <strong>Chain</strong>.

<strong>Roller</strong> <strong>Chain</strong> Structure2. Assembly Parts<strong>Roller</strong> <strong>Chain</strong>s are usually made up of a number of connected links in an endless formation, or used by fixing the chain ends, but theneed for connecting links will eventually arise. Although offset links can be used when there are an odd number of links in the roller chain,please use a design that requires an even number of links as much as possible.2.1 Connecting LinksM-type Connecting Links (Formerly: Standard Connecting Link)RS <strong>Roller</strong> <strong>Chain</strong>Cotter Pin-typeClip-type Cotter Pin-type Multi-strand (2-strand shown) Spring Pin-type (RS240 only) F-type Connecting LinkClipPin Link PlatePinConnecting Link Plate(RC processing)Cotter PinPinPin Link PlateInner PlateConnectingLink PlateSpringPinPin Link PlatePin Pin PinConnecting Link PlateClipPin Link PlateConnectingLink PlateCotter PinDrive <strong>Chain</strong><strong>Chain</strong> TypePin & Connecting Link PlateFittingConnecting Link PlateFastening MethodPoints to NoteRS <strong>Roller</strong> <strong>Chain</strong>Slip FitPress FitClipCotter PinSpring PinClip / Cotter PinSpring PinT Pin• For multi-strand chain, make sure the plate with ringcoining processing is on the outer most side whenassembling.• Operating speed is indicated by the white area in theHP ratings table.• Make sure to use the chain according to the specifiedapplications on page A-90 and within the speed regionof the colored area in the HP rating tables.Lambda (Λ) <strong>Roller</strong><strong>Chain</strong>SUPER <strong>Roller</strong> <strong>Chain</strong>SUPER-H <strong>Roller</strong> <strong>Chain</strong>ULTRA SUPER <strong>Roller</strong> <strong>Chain</strong>RS-HT <strong>Roller</strong> <strong>Chain</strong>Slip FitPress FitPress FitClipCotter PinSpring PinCotter PinSpring Pin• Can be used in all areas of the HP ratings tablefor Lambda <strong>Chain</strong>.• Ring coining is carried out on the connecting linkplates.• Please use the exclusive connecting links for eachchain type.• Please use the exclusive connecting link for RS-HT<strong>Roller</strong> <strong>Chain</strong>.Heavy Duty <strong>Roller</strong><strong>Chain</strong>Press FitT Pin• There are no connecting links, so use connectingpins for assembly.2.2 Offset Links1 Pitch Offset Links (OL)Single strandOffset Link PlateMulti-strand(2-strand shown)2 Pitch Offset Links (2POL)Single Strand Multi-strand (2-strand shown)1 Pitch Offset LinksWhen an OL is used, please allowfor a 20% reduction in HP ratingscompared to that of the main chainand a 35% reduction in MaximumAllowable Load.PinCotter PinOffset Link PlatePlease refer to the dimension tables for roller chain types and sizes suitable for offset links.2.2 Identical maximum allowable load as main chain…(Slip-fit connecting link and two-pitch offset link)<strong>Tsubaki</strong> ANSI Standard <strong>Roller</strong> <strong>Chain</strong>Main chain 100%Slip-fit connecting link 100%Semi Press-fit connecting link 100%Two-pitch offset link 100%One-pitch offset link 65%Pin2 Pitch Offset linksThe pin and offset link plate of a2POL is press fit and is fastenedby a rivet. They can be used inaccordance with the HP ratingstables.The maximum allowable load on the Slip-fitconnecting link and the two-pitch offset linkhave been improved to the level of the mainchain, thereby allowing full exploitation of thechain’s performance for slow speed chainselection.A-9

RS25ANSI Standard<strong>Roller</strong> <strong>Chain</strong>1/4”PitchOL2POLDrive <strong>Chain</strong>LL1TL2φDL1φBhTHL1WL2 L1L2 L1CC CPPNotes: All pins have riveted construction.Spring clip connecting links supplied for all sizes.All dimensions in inches unless otherwise stated.Link Plate PinWidth ANSI Std. <strong>Tsubaki</strong> <strong>Tsubaki</strong>BetweenMinimum Minimum AverageInner LinkTensile Tensile TensilePlatesStrength Strength StrengthW(lbs.) (lbs.) (lbs.)MaximumAllowableLoad(lbs.)BushingTransverseApprox.<strong>Chain</strong> Pitch Dia.Thickness Height Height Dia. Length Length Length PitchWeightNumber P BT H h D L 1 + L 2 L 1 L 2 C(lbs./ft.)Single StrandRS25 0.250 0.130 0.125 0.030 0.230 0.199 0.091 0.339 0.150 0.189 - 780 920 1,050 140 0.09 480Double StrandRS25-2 0.250 0.130 0.125 0.030 0.230 0.199 0.091 0.591 0.276 0.315 0.252 1,560 1,840 2,100 240 0.18 480Triple StrandRS25-3 0.250 0.130 0.125 0.030 0.230 0.199 0.091 0.843 0.402 0.441 0.252 2,340 2,760 3,150 350 0.28 480Note: Only 2 pitch offset links are available for RS25 and RS25-2.Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213500.030.030.04Maximum Speed – Small Sprocket (rpm)Numberof linksper10 feet100 300 500 700 900 1200 1500 1800 2100 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000 7500 8000 8500 9000 100000.050.060.060.140.160.170.230.250.270.310.340.37A0.390.430.470.500.550.600.600.660.720.710.780.840.830.900.980.951.051.14Lubrication System1.131.231.34B1.291.421.541.381.571.741.161.321.490.991.121.270.860.971.100.750.860.960.670.760.860.600.680.77C0.540.610.690.490.560.630.450.510.570.410.470.530.350.400.45Remarks:A-10141516171819202122232425262830323540450.040.040.040.050.050.050.060.060.060.060.070.070.070.080.080.090.100.120.130.070.080.080.090.090.100.100.110.110.120.130.130.140.150.160.170.190.220.250.190.200.220.230.250.260.280.290.310.320.340.350.370.400.430.440.510.580.640.300.320.340.370.390.410.440.460.480.510.530.550.560.630.660.710.780.901.030.400.430.470.480.530.560.590.600.640.670.720.750.760.830.900.981.061.221.390.500.540.580.600.640.680.720.760.800.840.900.940.981.051.131.211.331.531.740.650.680.740.790.840.890.940.991.051.101.141.191.251.351.461.561.721.982.250.780.840.900.971.021.091.151.211.271.341.391.461.531.651.781.902.112.432.760.940.991.061.141.211.291.351.421.501.571.651.721.801.942.092.252.482.863.251.061.141.221.301.381.481.561.641.731.811.891.982.072.242.412.592.843.293.731.231.331.431.531.621.721.821.922.012.122.212.322.412.612.823.023.333.854.371.461.571.691.801.922.022.152.272.372.492.612.722.843.083.333.573.934.535.151) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which indicates the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.1.681.811.932.072.202.332.472.602.742.873.003.143.273.543.824.094.515.205.911.892.042.192.332.482.632.782.923.083.233.383.543.694.004.304.615.085.876.661.661.842.032.222.422.622.833.053.273.503.733.934.104.444.795.145.656.537.421.421.571.731.902.072.242.422.602.792.983.183.383.594.014.454.905.606.858.151.231.361.501.641.791.942.102.262.422.592.762.933.113.473.854.254.865.937.081.081.201.321.441.571.701.841.982.122.272.422.572.733.053.383.734.265.216.210.961.061.171.281.391.511.631.761.882.012.152.282.422.703.003.303.784.625.510.860.951.051.141.251.351.461.571.691.801.922.042.172.422.682.963.384.134.930.770.860.941.031.121.221.321.421.521.621.731.841.952.182.422.673.053.734.450.700.780.860.941.021.111.201.291.381.471.571.671.771.982.202.422.773.384.040.640.710.780.860.931.011.091.171.261.351.441.531.621.812.012.212.533.093.690.590.650.720.790.860.931.001.081.161.241.321.401.491.661.842.032.322.833.380.500.560.610.670.730.790.860.920.991.061.121.201.271.421.571.731.982.422.89

3/8”PitchANSI Standard<strong>Roller</strong> <strong>Chain</strong>RS35OL2POLL2 L1TφDL1φBTWL2 L1L2 L1CC CDrive <strong>Chain</strong>hHLL1PPAll dimensions in inches unless otherwise stated.Link Plate PinWidthBetweenBushing Inner Link<strong>Chain</strong> Pitch Dia. Plates Thickness Height Height Dia. Length Length LengthNumber P B W T H h D L 1 + L 2 L 1 L 2Notes: All pins have riveted construction.Spring clip connecting links supplied for all sizes.OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)Single StrandRS35 0.375 0.200 0.188 0.049 0.354 0.307 0.141 0.500 0.230 0.270 0.531 - 1,950 2,200 2,530 480 0.22 320Double StrandRS35-2 0.375 0.200 0.188 0.049 0.354 0.307 0.141 0.898 0.429 0.469 0.965 0.398 3,900 4,400 5,060 810 0.46 320Triple StrandRS35-3 0.375 0.200 0.188 0.049 0.354 0.307 0.141 1.295 0.630 0.665 1.362 0.398 5,850 6,600 7,590 1,210 0.70 320Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213500.160.170.19Maximum Speed – Small Sprocket (rpm)Approx.Weight(lbs./ft.)100 300 500 700 900 1200 1500 1800 2100 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000 7500 8000 8500 9000 100000.300.320.350.780.860.941.231.351.481.661.842.00A2.092.292.512.712.983.253.313.633.973.904.294.684.484.925.383.864.404.96Lubrication System2.923.353.752.322.662.991.902.172.45B1.581.822.051.351.561.741.181.351.501.031.181.330.911.051.170.820.941.050.740.840.940.670.760.860.600.700.78C0.560.640.72Numberof linksper10 feet0.480.550.6214151617181920212223242526283032354045Remarks:0.200.210.230.250.270.280.300.310.320.350.360.380.390.430.460.500.540.630.710.380.400.430.470.500.520.550.580.620.640.670.700.740.790.860.911.011.171.331.011.091.171.251.331.411.491.571.651.731.811.891.972.132.312.472.723.143.571.601.721.851.972.092.232.352.482.602.742.862.993.123.383.653.904.304.985.652.162.332.492.672.843.023.183.353.533.703.884.054.224.574.935.285.826.737.642.712.923.143.353.573.774.004.214.434.644.855.085.305.746.186.627.318.449.573.513.804.064.334.614.895.165.445.736.016.296.576.877.438.018.589.4510.912.44.304.634.965.305.655.986.326.667.007.357.708.058.399.099.7910.511.613.415.25.075.465.856.256.647.047.447.848.258.669.079.489.8810.711.512.413.715.717.85.826.266.727.177.638.098.569.019.489.9510.410.911.412.313.214.215.718.120.55.556.166.777.428.098.779.4710.210.911.612.212.713.314.315.616.618.421.224.04.214.655.105.596.096.607.137.678.318.889.4710.110.711.913.214.616.620.424.31) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.3.343.704.084.474.875.285.706.136.587.057.507.998.469.4810.511.513.216.119.32.723.033.343.663.984.324.675.025.385.776.136.546.927.758.579.4410.813.215.82.292.532.803.063.343.623.904.214.514.835.155.485.816.497.177.919.0711.113.21.962.172.392.612.843.083.343.593.854.134.394.664.965.556.146.767.729.4511.31.701.882.072.272.472.682.903.113.343.583.804.054.304.815.325.866.718.199.791.491.651.821.982.172.352.532.722.923.143.343.573.774.224.675.145.877.198.601.311.461.611.771.922.092.252.412.602.792.963.163.343.744.144.565.226.377.631.181.311.431.581.721.862.012.172.332.492.642.822.993.353.704.084.675.706.831.061.181.301.421.541.681.821.962.092.252.392.552.703.023.343.674.215.140.971.071.181.291.411.531.651.771.902.042.172.312.452.743.033.343.824.670.870.981.071.181.291.381.501.621.741.861.982.112.242.512.763.043.490.800.900.991.071.181.271.411.491.601.721.821.942.052.312.532.803.210.680.760.830.931.011.091.181.271.351.461.541.651.741.962.17A-11

RS42 (38)RS43 (37)ANSI Standard<strong>Roller</strong> <strong>Chain</strong>1/2”PitchOL2POLTL1L1LTφDφRDrive <strong>Chain</strong>L2L1hPPHWNotes: All pins have riveted construction.Spring clip connecting links supplied for this chain.All dimensions in inches unless otherwise stated.WidthBetweenInner LinkPlatesLink Plate Pin<strong>Roller</strong>Approx.<strong>Chain</strong> Pitch Dia.Thickness Height Height Dia. Length Length LengthWeightNumber P R W T H h D L 1 + L 2 L 1 L 2 L (lbs.) (lbs.) (lbs.) (lbs.) (lbs./ft.)RS42 (38) 0.500 0.306 0.188 0.040 0.386 0.331 0.143 0.496 0.236 0.280 0.555 na 1,830 2,110 370 0.24 240Note: refer to section on "<strong>Roller</strong> <strong>Chain</strong> Selection" for details on selecting for slow speed.OffsetPinLengthANSI Std.MinimumTensileStrength<strong>Tsubaki</strong>MinimumTensileStrength<strong>Tsubaki</strong>AverageTensileStrengthMaximumAllowableLoadNumberof linksper10 feetOL2POLTL1hHL1TLL1φDφRWL2PPAll dimensions in inches unless otherwise stated.Link Plate PinWidthBetweenInner LinkPlatesNotes: All pins have riveted construction.Spring clip connecting links supplied for this chain.<strong>Roller</strong>Approx.<strong>Chain</strong> Pitch Dia.Thickness Height Height Dia. Length Length LengthWeightNumber P R W T H h D L 1 + L 2 L 1 L 2 L (lbs.) (lbs.) (lbs.) (lbs.) (lbs./ft.)RS43 (37) 0.500 0.306 0.134 0.040 0.386 0.331 0.143 0.425 0.201 0.232 0.490 na 1,830 2,110 370 0.19 240Note: refer to section on "<strong>Roller</strong> <strong>Chain</strong> Selection" for details on selecting for slow speed.OffsetPinLengthANSI Std.MinimumTensileStrength<strong>Tsubaki</strong>MinimumTensileStrength<strong>Tsubaki</strong>AverageTensileStrengthMaximumAllowableLoadNumberof linksper10 feetA-12

1/2”PitchANSI Standard<strong>Roller</strong> <strong>Chain</strong>RS41OL2POLTTLL1L1L1L2φDhφRHWDrive <strong>Chain</strong>PPNotes: All pins have riveted construction.Spring clip connecting links supplied for this chain.All dimensions in inches unless otherwise stated.Link Plate PinWidthBetweenInner LinkPlates<strong>Chain</strong> Pitch<strong>Roller</strong>Dia.Thickness Height Height Dia. Length Length LengthApprox.WeightNumber P R W T H h D L 1 + L 2 L 1 L 2 L (lbs.) (lbs.) (lbs.) (lbs.) (lbs./ft.)RS41 0.500 0.306 0.250 0.050 0.386 0.331 0.141 0.579 0.266 0.313 0.594 1,500 2,310 2,640 500 0.27 240OffsetPinLengthANSI Std.MinimumTensileStrength<strong>Tsubaki</strong>MinimumTensileStrength<strong>Tsubaki</strong>AverageTensileStrengthMaximumAllowableLoadNumberof linksper10 feetMaximum Horsepower RatingsNo. ofTeethSmallSpkt.111213100.040.040.042.202.412.63Maximum Speed – Small Sprocket (rpm)25 50 100 200 300 400 500 700 900 1000 1200 1400 1600 1800 2100 2400 2700 3000 3500 4000 5000 6000 7000 80000.090.090.110.160.190.200.310.340.36A0.580.630.680.820.900.981.061.171.271.301.421.551.761.932.102.272.592.90Lubrication System1.711.952.201.361.551.75B1.111.271.430.931.061.200.740.840.950.610.690.780.510.580.650.430.490.560.340.390.440.280.320.360.200.230.260.150.170.200.120.140.16C0.100.110.1314151617181920212223242526283032354045Remarks:0.050.050.050.070.070.070.070.080.080.080.090.090.090.110.110.120.130.160.170.110.120.130.130.150.160.160.170.190.190.200.210.230.240.250.280.310.350.400.210.230.240.250.280.290.310.320.350.360.380.400.420.440.480.510.580.660.750.390.430.460.480.520.550.580.620.640.670.710.740.760.830.900.971.061.231.390.740.790.840.910.971.021.091.141.191.261.311.381.431.551.681.801.982.292.601.061.141.221.311.391.471.551.651.731.811.901.982.062.242.412.592.853.303.741.371.471.581.691.801.902.022.132.222.352.452.572.682.913.123.363.704.264.851.681.811.942.082.202.332.472.602.732.873.003.143.283.553.824.104.525.215.922.282.452.632.802.983.163.343.523.703.894.074.254.444.815.175.556.117.068.032.853.073.303.513.743.974.204.414.644.875.115.335.566.036.496.967.678.8610.13.143.383.623.864.114.364.614.855.115.365.605.866.116.627.137.658.439.7311.12.462.733.013.293.593.894.244.564.885.215.565.916.277.017.778.569.8011.513.01) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.1.952.172.392.612.863.103.333.593.854.114.384.664.945.526.136.757.729.4311.31.601.771.952.142.332.532.732.943.153.373.593.814.054.525.015.526.327.729.211.341.491.641.791.952.122.292.462.642.823.013.203.393.794.204.635.296.477.721.061.181.301.421.551.681.811.952.092.242.392.542.693.013.333.674.205.136.130.870.961.061.161.271.381.491.601.711.831.952.082.202.462.733.013.444.205.010.730.810.890.981.061.151.241.341.441.541.641.741.852.062.292.522.883.524.200.620.690.760.830.910.981.061.141.231.311.401.491.581.761.952.152.463.013.590.490.550.600.660.720.780.840.910.971.041.111.181.251.401.551.711.952.392.850.400.450.490.540.590.640.690.740.800.850.910.961.021.141.271.401.601.952.330.290.320.350.390.420.460.490.530.570.610.650.690.730.820.911.001.141.400.220.240.270.290.320.350.380.400.430.460.490.530.560.620.690.170.190.210.230.250.280.300.320.340.370.390.140.160.170.19A-13

hHL2CL1L1L1RS40ANSI Standard<strong>Roller</strong> <strong>Chain</strong>1/2”PitchOL2POLCLDrive <strong>Chain</strong>CL1TL1L2φDφRTWL2PPNotes: All pins have riveted construction. Spring clip connecting links supplied for single / double strand. Cotter type connecting links supplied for triple strand chain and above.All dimensions in inches unless otherwise stated.Link Plate Pin<strong>Roller</strong>WidthBetweenInner LinkOffsetPin TransverseANSI Std.MinimumTensile<strong>Tsubaki</strong>MinimumTensile<strong>Tsubaki</strong>AverageTensileMaximumAllowable Approx.Numberof links<strong>Chain</strong> Pitch Dia. Plates Thickness Height Height Diameter Length Length Length Length Pitch Strength Strength Strength Load Weight perNumber P R W T H h D L 1 + L 2 L 1 L 2 L C (lbs.) (lbs.) (lbs.) (lbs.) (lbs./ft.) 10 feetSingle StrandRS40 0.500 0.312 0.313 0.059 0.472 0.409 0.156 0.717 0.325 0.392 0.709 - 3,120 3,960 4,290 810 0.43 240Double StrandRS40-2 0.500 0.312 0.313 0.059 0.472 0.409 0.156 1.283 0.608 0.675 1.319 0.567 6,240 7,920 8,580 1,380 0.85 240Triple StrandRS40-3 0.500 0.312 0.313 0.059 0.472 0.409 0.156 1.843 0.892 0.951 1.886 0.567 9,360 11,880 12,870 2,040 1.28 240Quadruple StrandRS40-4 0.500 0.312 0.313 0.059 0.472 0.409 0.156 2.409 1.177 1.232 2.453 0.567 12,480 15,840 17,160 2,680 1.70 240Quintuple StrandRS40-5 0.500 0.312 0.313 0.059 0.472 0.409 0.156 2.980 1.461 1.520 3.024 0.567 15,600 19,800 21,450 3,170 2.12 240Sextuple StrandRS40-6 0.500 0.312 0.313 0.059 0.472 0.409 0.156 3.547 1.744 1.803 3.591 0.567 18,720 23,760 25,740 3,740 2.55 240Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213100.080.090.094.655.115.57Maximum Speed – Small Sprocket (rpm)25 50 100 200 300 400 500 700 900 1000 1200 1400 1600 1800 2100 2400 2700 3000 3500 4000 5000 6000 7000 80000.190.200.230.350.380.420.640.710.761.211.311.43A1.731.902.072.242.472.682.743.003.293.704.084.445.115.626.13Lubrication System6.026.617.216.817.608.295.586.367.16B4.675.315.993.704.224.763.033.453.892.552.903.262.152.472.791.721.962.211.411.601.811.011.141.290.760.870.98C0.620.680.780.500.580.6414151617181920212223242526283032354045Remarks:0.110.110.120.130.130.150.160.160.170.170.190.200.200.230.240.250.280.320.380.240.250.280.300.310.340.350.380.390.420.430.440.470.510.550.590.640.750.840.440.480.520.550.590.620.660.700.720.760.800.830.870.951.021.091.211.391.580.830.900.971.031.101.171.231.291.351.421.491.561.621.771.902.042.242.592.951.561.681.801.922.042.172.292.412.532.672.792.913.043.303.553.814.204.845.502.242.412.592.762.953.123.303.473.663.844.024.204.394.755.115.486.036.977.932.913.143.353.583.814.054.284.514.734.985.205.445.676.146.627.097.829.0410.33.553.844.104.394.674.955.235.515.796.076.366.656.937.518.108.689.5611.112.54.815.195.555.936.326.697.077.467.848.228.619.009.3910.211.011.712.914.917.06.036.506.977.447.918.398.869.359.8310.310.811.311.812.813.714.816.218.821.36.647.157.668.188.709.239.7510.310.811.311.912.412.914.115.216.217.820.723.57.828.429.039.6410.210.911.512.112.713.413.914.615.316.517.819.021.124.327.61) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.8.979.6710.411.111.812.513.213.914.615.316.116.817.619.020.421.924.127.931.68.018.889.7910.711.712.713.714.815.816.918.018.919.721.523.124.727.231.535.76.717.438.188.979.7610.511.112.413.214.115.016.017.019.021.123.226.632.538.65.315.896.497.117.758.419.089.7610.511.211.912.713.515.016.818.421.125.730.64.364.835.315.826.346.887.537.998.579.169.7610.411.012.313.515.017.221.125.13.654.044.454.885.315.776.226.717.197.688.188.709.2410.311.412.614.317.621.13.113.453.814.174.554.925.315.736.136.567.007.437.898.819.7610.812.315.018.02.472.743.023.313.613.924.224.554.875.205.545.896.257.007.758.549.7611.914.22.022.242.472.712.963.213.453.713.984.264.554.835.125.736.347.007.999.7611.71.451.601.771.942.112.292.472.662.863.063.253.453.664.094.555.005.737.001.101.221.341.481.601.741.882.022.172.322.472.632.763.113.450.870.971.071.171.271.381.491.601.721.841.960.710.790.870.97A-14

5/8”PitchANSI Standard<strong>Roller</strong> <strong>Chain</strong>RS50OL2POLL1TL2L1Drive <strong>Chain</strong>hHL2CCCL1φDφRWTLL2L1L1PPNotes: All pins have riveted construction. Spring clip connecting links supplied for single / double strand. Cotter type connecting links supplied for triple strand chain and above.All dimensions in inches unless otherwise stated.Link Plate PinWidthANSI Std. <strong>Tsubaki</strong> <strong>Tsubaki</strong>BetweenOffsetMinimum Minimum Average MaximumNumber<strong>Roller</strong> Inner LinkPin Transverse Tensile Tensile Tensile Allowable Approx. of links<strong>Chain</strong> Pitch Dia. Plates Thickness Height Height Dia.Length Pitch Strength Strength Strength Load Weight perNumber P R W T H h DL C (lbs.) (lbs.) (lbs.) (lbs.) (lbs./ft.) 10 feetLengthL 1 + L 2LengthL 1LengthL 2Single StrandRS50 0.625 0.400 0.375 0.079 0.591 0.512 0.200 0.874 0.406 0.469 0.886 - 4,880 6,380 7,040 1,430 0.70 192Double StrandRS50-2 0.625 0.400 0.375 0.079 0.591 0.512 0.200 1.594 0.762 0.833 1.646 0.713 9,760 12,760 14,080 2,420 1.39 192Triple StrandRS50-3 0.625 0.400 0.375 0.079 0.591 0.512 0.200 2.307 1.118 1.189 2.358 0.713 14,640 19,140 21,120 3,580 2.07 192Quadruple StrandRS50-4 0.625 0.400 0.375 0.079 0.591 0.512 0.200 3.020 1.474 1.545 3.071 0.713 19,520 25,520 28,160 4,730 2.75 192Quintuple StrandRS50-5 0.625 0.400 0.375 0.079 0.591 0.512 0.200 3.732 1.831 1.902 3.787 0.713 24,400 31,900 35,200 5,590 3.44 192Sextuple StrandRS50-6 0.625 0.400 0.375 0.079 0.591 0.512 0.200 4.449 2.189 2.260 4.504 0.713 29,280 38,280 42,240 6,580 4.13 192Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213100.160.190.207.678.429.199.6210.611.5Maximum Speed – Small Sprocket (rpm)25 50 100 200 300 400 500 700 900 1000 1200 1400 1600 1800 2100 2400 2700 3000 3500 4000 4500 5000 5500 60000.380.420.460.710.780.861.331.461.602.482.722.98A3.583.934.284.645.105.555.666.226.7910.611.612.7Lubrication System10.311.713.28.149.2710.46.657.598.56B5.586.367.164.435.045.703.624.134.653.043.463.902.592.953.332.072.352.641.681.922.161.411.611.811.211.371.56C1.051.191.340.931.0514151617181920212223242526283032354045Remarks:0.210.230.250.270.280.310.320.340.350.380.390.400.430.460.500.540.590.670.760.500.540.580.620.660.680.720.760.800.840.890.930.971.051.131.211.331.541.740.930.991.071.141.221.291.351.431.501.581.661.731.811.962.112.272.492.873.271.731.862.002.132.272.402.532.682.822.953.083.233.373.653.934.214.645.366.093.223.473.733.974.224.484.734.995.245.515.776.026.296.817.347.878.6610.011.44.645.005.365.736.096.456.837.197.567.948.308.689.059.8210.611.312.514.516.46.016.486.957.427.898.378.849.329.8010.310.811.311.712.713.714.616.218.621.27.357.938.499.079.6410.210.811.412.012.613.213.814.315.616.818.019.722.825.99.9510.711.512.313.013.814.615.416.217.017.818.619.421.122.724.326.831.035.112.513.414.315.416.417.318.419.320.421.322.423.324.426.428.430.433.538.844.013.714.815.816.918.019.020.121.222.423.524.525.626.829.031.233.536.942.648.414.816.418.019.721.222.523.725.126.327.629.030.231.534.236.739.443.450.357.01) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.11.713.014.315.717.018.520.021.523.124.726.327.929.633.136.740.446.356.565.69.5610.611.712.813.915.216.417.618.820.121.522.824.327.030.033.338.146.455.18.028.899.7910.711.712.713.714.815.816.918.019.220.222.725.127.831.638.846.16.367.057.768.509.2710.010.811.712.513.414.315.216.118.019.822.025.130.736.65.205.776.366.967.598.228.899.5710.211.011.712.413.214.816.418.020.725.130.04.364.835.325.836.366.897.448.028.609.199.7910.411.012.313.715.217.221.125.13.734.134.554.995.425.896.366.847.347.848.358.899.4310.511.712.914.818.021.52.953.273.613.964.304.675.045.425.826.226.647.057.478.359.2710.211.714.32.432.682.953.233.533.824.134.444.765.105.425.776.136.847.598.359.562.022.252.472.712.953.213.463.734.004.284.554.835.145.741.731.922.112.312.522.742.953.183.411.501.661.842.01A-15

RS60ANSI Standard<strong>Roller</strong> <strong>Chain</strong>3/4”PitchOL2POLDrive <strong>Chain</strong>L1TL2φDφRhHL2CL2TCLL1L1WCL1L1PPNotes: All pins have riveted construction. Spring clip connecting links supplied for single / double strand. Cotter type connecting links supplied for triple strand chain and above.All dimensions in inches unless otherwise stated.<strong>Roller</strong>Dia.RWidthBetweenInner LinkPlatesWLink Plate PinLengthL 1 + L 2LengthL 1LengthL 2OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)<strong>Chain</strong>NumberPitchPThicknessTHeightHHeighthDia.DSingle StrandRS60 0.750 0.469 0.500 0.094 0.713 0.614 0.235 1.087 0.506 0.581 1.110 - 7,030 9,020 9,900 1,980 1.03 160Double StrandRS60-2 0.750 0.469 0.500 0.094 0.713 0.614 0.235 1.988 0.955 1.033 2.071 0.898 14,060 18,040 19,800 3,360 2.04 160Triple StrandRS60-3 0.750 0.469 0.500 0.094 0.713 0.614 0.235 2.906 1.404 1.502 2.972 0.898 21,090 27,060 29,700 4,950 3.04 160Quadruple StrandRS60-4 0.750 0.469 0.500 0.094 0.713 0.614 0.235 3.803 1.852 1.951 3.870 0.898 28,120 36,080 39,600 6,530 4.05 160Quintuple StrandRS60-5 0.750 0.469 0.500 0.094 0.713 0.614 0.235 4.705 2.303 2.402 4.772 0.898 35,150 45,100 49,500 7,720 5.05 160Sextuple StrandRS60-6 0.750 0.469 0.500 0.094 0.713 0.614 0.235 5.606 2.752 2.854 5.669 0.898 42,180 54,120 59,400 9,110 6.06 160Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213100.300.320.3510.011.012.011.813.014.1Maximum Speed – Small Sprocket (rpm)Approx.Weight(lbs./ft.)25 50 100 150 200 300 400 500 600 700 800 900 1000 1100 1200 1400 1600 1800 2000 2500 3000 3500 4000 45000.670.740.801.261.381.522.352.592.823.393.714.06A4.394.815.266.326.957.588.199.009.8013.514.916.2Lubrication System15.316.818.217.018.620.415.617.820.113.515.617.411.913.515.2B9.4110.712.17.708.779.906.457.358.305.516.297.083.944.495.073.003.423.85C2.392.713.061.942.232.51Numberof linksper10 feet1.641.8614151617181920212223242526283032354045Remarks:0.390.420.440.470.510.540.560.590.630.660.680.720.750.820.870.941.031.191.350.870.941.011.091.151.221.291.351.421.501.571.641.721.852.002.152.362.723.101.641.761.892.012.152.282.402.532.672.792.923.063.193.463.734.004.405.085.773.063.293.533.774.004.244.484.734.985.225.465.715.956.456.957.468.219.4810.84.404.735.085.425.776.126.466.817.167.517.878.228.589.2910.010.711.813.715.65.706.136.577.037.477.918.378.829.289.7410.210.611.112.013.013.915.317.720.18.218.849.4710.110.811.412.112.713.414.114.615.316.017.318.620.022.125.529.010.611.512.313.113.914.815.616.517.318.119.019.820.822.424.125.928.633.037.513.013.915.016.017.018.119.020.121.222.323.224.325.327.529.631.835.040.445.915.316.517.718.920.121.322.523.724.926.127.428.629.932.334.937.441.247.654.017.618.920.221.723.124.425.927.228.730.031.532.934.337.140.142.947.354.662.119.821.322.924.426.027.629.130.732.333.935.537.138.842.045.248.453.461.670.01) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.22.023.725.527.229.030.732.534.235.937.739.441.243.046.750.253.859.368.577.822.424.827.429.931.833.735.737.539.441.443.345.347.351.255.359.165.275.485.619.421.623.726.028.330.733.135.738.240.943.646.449.255.060.264.571.182.193.217.018.820.922.924.927.129.231.533.836.138.240.643.248.353.558.967.582.398.313.515.016.518.119.721.523.124.826.628.430.332.234.238.242.446.753.465.778.411.112.313.514.816.117.618.920.221.923.324.826.428.031.434.738.243.753.563.79.2710.311.312.413.514.615.817.018.219.420.822.123.526.129.132.136.644.853.47.918.779.6710.611.512.513.514.515.616.817.818.920.022.424.827.431.438.245.65.666.296.927.588.268.969.6710.411.111.912.713.514.316.017.819.622.427.432.64.324.775.265.776.296.817.357.918.499.089.6710.310.912.213.514.917.03.423.804.174.574.995.405.836.296.737.197.678.158.552.803.103.423.744.084.43A-16

1”PitchANSI Standard<strong>Roller</strong> <strong>Chain</strong>RS80OL2POLL1TLL2φDL1φRTWL2 L1L2 L1CC CDrive <strong>Chain</strong>hHL1All dimensions in inches unless otherwise stated.<strong>Roller</strong>Dia.RWidthBetweenInner LinkPlatesWPPLink Plate PinLengthL 1 + L 2LengthL 1LengthL 2OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)<strong>Chain</strong>NumberPitchPThicknessTHeightHHeighthDia.DSingle StrandRS80 1.000 0.625 0.625 0.126 0.949 0.819 0.313 1.398 0.640 0.758 1.417 - 12,500 16,060 17,600 3,300 1.78 120Double StrandRS80-2 1.000 0.625 0.625 0.126 0.949 0.819 0.313 2.551 1.217 1.335 2.657 1.154 25,000 32,120 35,200 5,610 3.53 120Triple StrandRS80-3 1.000 0.625 0.625 0.126 0.949 0.819 0.313 3.705 1.795 1.909 3.815 1.154 37,500 48,180 52,800 8,250 5.29 120Quadruple StrandRS80-4 1.000 0.625 0.625 0.126 0.949 0.819 0.313 4.862 2.372 2.490 4.972 1.154 50,000 64,240 70,400 10,890 7.04 120Quintuple StrandRS80-5 1.000 0.625 0.625 0.126 0.949 0.819 0.313 6.020 2.951 3.069 6.126 1.154 62,500 80,300 88,000 12,870 8.78 120Sextuple StrandRS80-6 1.000 0.625 0.625 0.126 0.949 0.819 0.313 7.169 3.528 3.642 7.280 1.154 75,000 96,360 105,600 15,180 10.54 120Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213100.660.720.7914.215.616.9Notes: Cotter type connecting links supplied for this chain.18.420.122.022.424.726.826.429.031.6Maximum Speed – Small Sprocket (rpm)Approx.Weight(lbs./ft.)25 50 100 150 200 300 400 500 600 700 800 900 1000 1100 1200 1400 1600 1800 2000 2200 2400 2700 3000 34001.521.661.812.823.103.385.275.786.307.588.339.08A9.8310.811.830.333.436.3Lubrication System27.531.235.323.126.129.819.622.325.2B17.019.421.914.917.019.211.813.515.29.7011.012.58.139.2510.46.937.908.926.016.857.72C5.276.016.794.435.045.693.774.304.85Numberof linksper10 feet1.7014151617181920212223242526283032354045Remarks:0.860.930.991.061.131.191.261.331.391.481.541.611.681.821.962.112.322.673.031.962.122.272.412.572.722.883.043.193.353.513.673.824.144.474.795.286.106.923.663.944.224.524.805.105.385.675.976.266.566.857.157.748.348.949.8411.412.96.837.367.898.428.969.4910.010.611.111.712.212.813.314.515.616.618.421.224.19.8410.611.412.112.913.714.515.316.116.817.618.419.220.822.424.026.430.634.712.813.714.815.716.817.718.819.720.821.722.823.924.827.029.031.134.339.644.918.419.821.222.724.125.527.028.429.931.432.934.335.838.841.844.849.357.064.823.725.627.529.431.233.135.036.938.840.642.544.546.450.354.258.164.073.983.929.131.433.535.838.140.542.845.147.349.852.054.456.761.466.271.178.290.410334.236.939.642.244.947.650.453.155.858.661.364.166.972.478.083.792.110612139.442.445.548.551.654.757.861.064.167.370.473.676.883.389.796.210612213939.443.748.152.757.561.765.368.872.375.979.483.086.693.91011081191381571) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.33.336.940.644.348.152.356.560.765.069.674.278.983.793.510411413115317428.231.234.537.741.244.548.151.855.559.363.767.771.780.288.997.511213716224.427.129.832.735.738.641.744.848.151.454.857.961.869.176.784.496.611714221.523.926.128.731.233.936.639.442.245.148.151.154.260.667.274.084.810312317.018.920.822.724.827.029.031.233.535.838.240.643.048.153.458.767.282.298.013.915.417.018.620.222.023.925.627.429.431.233.335.339.443.648.155.067.280.211.712.914.215.617.018.419.821.523.124.726.127.829.533.036.640.446.156.367.29.9611.012.213.314.515.717.018.419.621.122.323.925.228.231.234.539.448.154.28.649.5710.511.512.613.514.816.017.018.219.420.721.924.427.129.834.120.07.588.419.2510.111.012.012.913.914.916.017.018.119.221.523.926.16.367.047.768.499.2510.010.811.712.513.414.215.216.15.426.016.627.257.908.57A-17

RS100ANSI Standard<strong>Roller</strong> <strong>Chain</strong>1 1/4”PitchOL2POLDrive <strong>Chain</strong>L1TLL2φDL1φRhTWL2 L1L2 L1CC CHL1All dimensions in inches unless otherwise stated.<strong>Roller</strong>Dia.RWidthBetweenInner LinkPlatesWPPNotes: Cotter type connecting links supplied for this chain.Link Plate PinLengthL 1 + L 2LengthL 1LengthL 2OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)<strong>Chain</strong>NumberPitchPThicknessTHeightHHeighthDia.DSingle StrandRS100 1.250 0.750 0.750 0.157 1.185 1.024 0.376 1.677 0.778 0.900 1.748 - 19,530 23,980 26,400 5,060 2.67 96Double StrandRS100-2 1.250 0.750 0.750 0.157 1.185 1.024 0.376 3.091 1.484 1.606 3.209 1.409 39,060 47,960 52,800 8,602 5.26 96Triple StrandRS100-3 1.250 0.750 0.750 0.157 1.185 1.024 0.376 4.504 2.191 2.313 4.618 1.409 58,590 71,940 79,200 12,650 7.89 96Quadruple StrandRS100-4 1.250 0.750 0.750 0.157 1.185 1.024 0.376 5.913 2.896 3.018 6.028 1.409 78,120 95,920 105,600 16,700 10.52 96Quintuple StrandRS100-5 1.250 0.750 0.750 0.157 1.185 1.024 0.376 7.327 3.602 3.724 7.437 1.409 97,650 119,900 132,000 19,730 13.09 96Sextuple StrandRS100-6 1.250 0.750 0.750 0.157 1.185 1.024 0.376 8.740 4.309 4.431 8.846 1.409 117,180 143,880 158,400 23,270 15.73 96Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213101.101.211.3316.418.019.623.625.928.330.633.536.637.441.044.8B44.048.452.7Maximum Speed – Small Sprocket (rpm)Approx.Weight(lbs./ft.)25 50 100 150 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1600 1800 2000 2200 2400 26002.522.763.02A4.715.165.638.779.6410.512.613.915.240.145.751.5Lubrication System32.937.342.127.531.435.323.526.730.220.223.226.117.820.222.915.818.020.2C14.216.118.211.613.214.99.7111.112.58.309.4510.67.198.199.246.327.198.101.29Numberof linksper10 feet14151617181920212223242526283032354045Remarks:1.431.541.651.771.882.002.112.232.332.452.562.682.803.033.263.503.864.455.063.273.533.784.044.294.554.805.075.325.595.856.126.386.917.447.988.8010.211.56.106.577.057.528.018.498.979.459.9410.410.911.411.912.913.914.916.418.921.611.412.313.214.114.915.816.817.718.519.420.421.322.324.025.927.830.635.440.216.417.718.920.221.522.824.125.326.728.029.430.732.134.737.440.144.151.057.921.222.924.526.127.929.531.232.934.636.338.139.741.444.948.451.957.166.075.030.633.035.437.740.142.544.947.549.952.354.757.359.764.669.774.782.395.110839.742.845.748.952.055.158.361.464.667.770.974.277.483.890.396.810712313948.452.255.959.863.667.571.275.179.082.986.890.794.510211011813015017257.161.666.070.475.079.483.988.593.197.610210711112113013915417720157.563.870.477.183.991.196.410210711211712312813814916017720423247.152.257.563.068.774.680.586.692.899.21061131191331481621862282611) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.39.443.748.352.857.562.467.372.477.883.088.594.199.911212413515619022833.737.341.245.149.153.257.561.866.470.975.680.385.395.210611613316419429.232.535.739.042.546.149.953.657.561.465.669.673.982.691.610111514116825.628.431.434.337.340.543.747.150.453.957.561.264.872.480.388.510112414822.725.227.830.433.135.938.841.744.847.951.154.257.564.271.278.689.811013120.222.524.827.229.632.134.737.340.042.845.648.551.457.563.770.380.398.211716.618.420.222.324.326.328.430.632.935.037.339.742.147.152.257.565.880.345.313.515.617.018.820.222.023.925.627.529.431.433.335.339.443.745.255.111.913.214.516.017.418.820.221.923.525.126.728.430.233.710.010.311.412.613.815.016.417.619.020.27.749.0510.011.10.79A-18

1 1/2”PitchANSI Standard<strong>Roller</strong> <strong>Chain</strong>RS120OL2POLL1TLL2φDL1φRTWL2 L1L2 L1CC CDrive <strong>Chain</strong>hHL1All dimensions in inches unless otherwise stated.<strong>Roller</strong>Dia.RWidthBetweenInner LinkPlatesWPPNotes: Cotter type connecting links supplied for this chain.Link Plate PinLengthL 1 + L 2LengthL 1LengthL 2OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)<strong>Chain</strong> PitchThickness Height Height Dia.Number PT H h DSingle StrandRS120 1.500 0.875 1.000 0.189 1.425 1.228 0.437 2.118 0.980 1.138 2.197 - 28,120 33,220 37,400 6,820 3.97 80Double StrandRS120-2 1.500 0.875 1.000 0.189 1.425 1.228 0.437 3.906 1.874 2.031 4.063 1.787 56,240 66,440 74,800 11,590 7.84 80Triple StrandRS120-3 1.500 0.875 1.000 0.189 1.425 1.228 0.437 5.701 2.772 2.929 5.850 1.787 84,360 99,660 112,200 17,050 11.75 80Quadruple StrandRS120-4 1.500 0.875 1.000 0.189 1.425 1.228 0.437 7.488 3.665 3.823 7.638 1.787 112,480 132,880 149,600 22,500 15.65 80Quintuple StrandRS120-5 1.500 0.875 1.000 0.189 1.425 1.228 0.437 9.280 4.561 4.719 9.425 1.787 140,600 166,100 187,000 26,600 19.54 80Sextuple StrandRS120-6 1.500 0.875 1.000 0.189 1.425 1.228 0.437 11.067 5.455 5.612 11.213 1.787 168,720 199,320 224,400 31,370 23.42 80Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213102.022.232.4323.225.527.830.033.035.943.247.551.855.961.667.168.475.281.958.566.675.1Maximum Speed – Small Sprocket (rpm)11.212.814.3Approx.Weight(lbs./ft.)25 50 100 150 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000A4.615.075.538.619.4710.316.117.719.3B46.352.859.5Lubrication System38.043.248.731.836.240.827.131.034.923.526.830.220.723.526.618.420.923.516.418.821.1C14.816.819.013.415.317.212.213.915.710.4 9.6011.8 10.9013.3 12.31Numberof linksper10 feet14151617181920212223242526283032354045Remarks:2.632.833.033.233.453.653.864.064.284.494.694.915.125.555.986.417.078.159.275.996.456.927.397.868.338.819.289.7610.210.711.211.712.713.714.616.118.621.211.212.012.913.814.615.616.517.318.219.020.020.921.923.625.527.430.034.739.420.922.524.125.727.429.030.732.333.935.737.339.040.844.147.551.056.164.873.630.032.334.737.039.441.844.146.548.951.453.856.258.663.668.473.480.993.310638.942.044.948.051.154.257.360.363.466.569.672.875.982.388.695.110512113756.160.364.869.273.577.982.586.991.395.910010510911912813715017419872.778.383.989.695.210110711311812413013514215316517719622525686.895.610311011712413013814515215816617318820221723927631483.993.110311212213314315416517718819620422123925628232536966.573.981.489.097.110511412213113914616016918920923126332238454.460.566.572.879.486.192.91001071151221301381541721882152633141) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.45.650.755.861.066.572.177.983.890.096.210210911512914315818022026339.043.247.652.256.961.766.571.676.782.187.492.998.711012213515418822433.837.441.345.249.253.457.762.166.571.175.980.685.495.610611713316419429.632.936.239.643.246.850.754.458.562.566.570.775.183.892.910211714317226.329.132.135.338.441.644.948.351.855.459.062.866.574.382.590.810412780.123.526.128.731.534.337.340.143.246.349.552.856.259.566.573.981.492.959.521.223.525.928.431.033.536.239.041.844.747.650.753.860.166.573.447.719.221.323.525.728.230.432.935.438.040.543.245.948.754.442.417.619.421.523.525.627.830.032.334.637.039.441.326.616.118.019.721.623.525.527.529.616.614.916.518.219.811.38.94A-19

RS140ANSI Standard<strong>Roller</strong> <strong>Chain</strong>1 3/4”PitchOL2POLDrive <strong>Chain</strong>LL1L1L1TφDL2hφRHTWL2 L1L2 L1CC CPPAll dimensions in inches unless otherwise stated.<strong>Roller</strong>Dia.RWidthBetweenInner LinkPlatesWLink Plate PinLengthL 1 + L 2LengthL 1LengthL 2OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)<strong>Chain</strong>NumberPitchPThicknessTHeightHHeighthDia.DSingle StrandRS140 1.750 1.000 1.000 0.220 1.661 1.433 0.500 2.307 1.059 1.248 2.343 - 38,280 43,340 48,400 9,020 5.02 68Double StrandRS140-2 1.750 1.000 1.000 0.220 1.661 1.433 0.500 4.232 2.022 2.211 4.421 1.925 76,560 86,680 96,800 15,334 9.94 68Triple StrandRS140-3 1.750 1.000 1.000 0.220 1.661 1.433 0.500 6.165 2.986 3.179 6.350 1.925 114,840 130,020 145,200 22,550 14.87 68Quadruple StrandRS140-4 1.750 1.000 1.000 0.220 1.661 1.433 0.500 8.091 3.949 4.142 8.276 1.925 153,120 173,360 193,600 29,766 19.11 68Quintuple StrandRS140-5 1.750 1.000 1.000 0.220 1.661 1.433 0.500 10.016 4.913 5.102 10.201 1.925 191,400 216,700 242,000 35,178 24.77 68Sextuple StrandRS140-6 1.750 1.000 1.000 0.220 1.661 1.433 0.500 11.949 5.878 6.071 12.126 1.925 229,680 260,040 290,400 41,492 29.68 68Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213103.163.493.8036.239.843.446.951.656.357.463.268.8Notes: Cotter type connecting links supplied for this chain.67.774.381.1B77.885.493.287.796.3105Maximum Speed – Small Sprocket (rpm)Approx.Weight(lbs./ft.)25 50 100 150 200 250 300 350 400 450 500 550 600 700 800 900 1000 1100 1200 1300 1400 1500 16007.237.948.66A13.514.916.225.227.630.297.5107117Lubrication System87.099.111275.286.497.466.075.284.952.459.767.342.948.955.335.941.046.330.735.039.426.630.334.2C23.326.630.020.723.626.618.521.123.916.819.021.515.217.319.4Numberof linksper10 feet14151617181920212223242526283032354045Remarks:4.124.434.755.075.395.736.056.376.717.037.367.708.038.699.3710.011.112.814.59.3910.110.811.612.313.013.814.515.316.116.817.618.419.821.322.925.229.133.117.618.920.221.622.924.425.727.128.629.931.432.734.237.039.842.847.154.461.832.735.337.740.442.945.548.050.753.255.958.561.263.769.174.479.887.810211547.150.754.358.161.765.469.273.076.780.584.288.091.999.510711512714616661.065.770.475.279.984.889.694.599.410410911411912913914916418921574.680.386.191.997.810411011512112713313914515817018220123226387.894.71021081151221291351431501571651721852002152362743101011091171241321411491571651731811891972132292472713143571141231311411491581681761851942042132232402592783063544011261371461561661761861962072162272362472672883083413934471251381531681821932042162272372492602712943163393744324911) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.10912013214515817218519821322824325927430633937040847153594.810511612713815016117618820121522824126829832937545954775.283.492.010111011912813814815816918019021323626029836343461.768.475.282.589.897.510511312113013814815617419321324329835551.657.363.269.275.281.788.194.810210911612313114616217820424929844.148.953.859.064.269.775.281.086.992.899.010511212513815217421323738.242.446.751.155.860.565.270.375.280.585.791.296.710812013215217892.833.537.341.044.948.953.057.361.766.070.775.280.184.994.810511613029.833.036.339.843.347.150.854.658.662.666.870.975.284.193.226.629.532.535.738.842.145.548.952.456.159.763.624.026.629.432.135.038.021.9A-20

2”PitchANSI Standard<strong>Roller</strong> <strong>Chain</strong>RS160OL2POLL1TL2φDφRTWL2 L1L2 L1CC CDrive <strong>Chain</strong>hHL1LL1All dimensions in inches unless otherwise stated.Link Plate PinWidthBetween<strong>Chain</strong>NumberPitchP<strong>Roller</strong>Dia.RInner LinkPlatesWThicknessTHeightHHeighthDia.DPPLengthL 1 + L 2LengthL 1LengthL 2OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)Single StrandRS160 2.000 1.125 1.250 0.252 1.898 1.638 0.563 2.705 1.254 1.451 2.795 - 50,000 57,200 62,700 11,880 6.77 60Double StrandRS160-2 2.000 1.125 1.250 0.252 1.898 1.638 0.563 5.012 2.407 2.604 5.205 2.303 100,000 114,400 125,400 20,196 13.43 60Triple StrandRS160-3 2.000 1.125 1.250 0.252 1.898 1.638 0.563 7.319 3.561 3.758 7.508 2.303 150,000 171,600 188,100 29,700 20.11 60Quadruple StrandRS160-4 2.000 1.125 1.250 0.252 1.898 1.638 0.563 9.622 4.715 4.907 9.811 2.303 200,000 228,800 250,800 39,204 26.84 60Quintuple StrandRS160-5 2.000 1.125 1.250 0.252 1.898 1.638 0.563 11.929 5.868 6.061 12.114 2.303 250,000 286,000 313,500 46,332 33.43 60Sextuple StrandRS160-6 2.000 1.125 1.250 0.252 1.898 1.638 0.563 14.236 7.020 7.217 14.417 2.303 300,000 343,200 376,200 54,648 40.15 60Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213104.775.245.7154.659.965.470.777.684.886.594.9104Notes: Cotter type connecting links supplied for this chain.B102112122117129141Maximum Speed – Small Sprocket (rpm)Approx.Weight(lbs./ft.)25 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 1000 1100 1200 1300A10.912.013.020.222.324.338.041.745.5132145158113129146Lubrication System96.711012483.795.510873.583.794.465.274.383.758.366.475.052.659.967.6C47.754.461.343.649.656.140.045.651.434.138.944.029.633.738.126.029.633.423.126.329.6Numberof linksper10 feet14151617181920212223242526283032354045Remarks:6.206.667.157.638.138.619.119.5910.110.611.111.612.113.114.115.216.619.221.914.115.216.417.418.519.620.821.923.124.125.326.427.629.932.234.538.043.949.926.428.430.432.534.636.638.840.942.945.147.249.351.555.860.164.470.981.993.149.253.056.960.664.568.472.376.280.284.188.092.096.010411212013215317370.876.381.887.492.998.610411011512112713213815016117319022024991.798.81061131201281351421501571641721801942092242472863251121211301381481561651741821922012092192372562743023493961321421531641731841942052162272362472572793023233554104671521641761882002122232352482602722842963213463714094725361721851982122252392522662792923073213343623904184615326051621811982172372572782953103263413573714024334655125916721391561701862022202372552742923123313513934364805506507391) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.12013314816117619020522123725527228830634238041647658269510511712914115416818019420822323725226729833136541751461393.610411412513514816017218419721122323726629432337045253983.792.810211212213214315416517618820021223726329033140448375.583.792.310111011912913914915916918019221523726129836541868.576.083.791.799.910811712613514315416417319421523727133134962.669.576.483.791.299.010711512313213914915817719621624730227157.463.770.376.883.790.898.210511312112913714516218019822725718949.154.459.965.671.577.583.790.196.710311011712413915416918042.547.151.957.062.167.272.778.283.789.695.510110812037.341.445.649.954.459.063.768.533.1A-21

RS180ANSI Standard<strong>Roller</strong> <strong>Chain</strong>2 1/4”PitchOL2POLDrive <strong>Chain</strong>L1TL2LφDL1φRhHTWL1L2 L1L2 L1CC CPPNotes: Cotter type connecting links supplied for this chain.All dimensions in inches unless otherwise stated.Link Plate PinWidthBetween<strong>Chain</strong>NumberPitchP<strong>Roller</strong>Dia.RInner LinkPlatesWThicknessTHeightHHeighthDia.DLengthL 1 + L 2LengthL 1LengthL 2OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)Single StrandRS180 2.250 1.406 1.406 0.281 2.134 1.843 0.687 3.075 1.404 1.671 3.173 - 63,280 75,460 82,940 13,640 9.01 54Double StrandRS180-2 2.250 1.406 1.406 0.281 2.134 1.843 0.687 5.673 2.707 2.967 5.949 2.591 126,560 150,920 165,880 23,190 17.77 54Triple StrandRS180-3 2.250 1.406 1.406 0.281 2.134 1.843 0.687 8.276 4.004 4.272 8.539 2.591 189,840 226,578 288,420 34,100 25.61 54Quadruple StrandRS180-4 2.250 1.406 1.406 0.281 2.134 1.843 0.687 10.870 5.301 5.569 11.134 2.591 253,120 301,840 331,760 45,010 34.10 54Quintuple StrandRS180-5 2.250 1.406 1.406 0.281 2.134 1.843 0.687 13.465 6.598 6.866 13.724 2.591 316,400 377,300 414,700 53,200 42.61 54Sextuple StrandRS180-6 2.250 1.406 1.406 0.281 2.134 1.843 0.687 16.059 7.896 8.163 16.315 2.591 379,680 452,760 497,640 62,740 51.10 54Maximum Horsepower RatingsNo. ofTeethSmallSpkt.11121310A6.176.777.3948.953.858.670.577.584.591.3100109112123134B132145158149169190Maximum Speed – Small Sprocket (rpm)40.546.352.237.542.848.3Approx.Weight(lbs./ft.)25 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 110014.115.416.926.328.831.4152166181124142161Lubrication System10612113592.010511880.792.010371.681.792.064.173.182.357.865.874.3C52.459.767.547.954.661.644.050.256.534.9 32.539.7 37.144.8Numberof linksper10 feet14151617181920212223242526283032354045Remarks:7.998.629.249.8710.511.111.812.413.013.714.315.015.616.918.219.621.524.828.218.219.721.122.523.925.326.828.329.831.232.634.135.538.641.644.549.156.764.434.136.739.342.044.747.350.052.755.558.260.963.766.472.077.583.191.610612063.668.473.478.383.388.493.398.410410911411912413414515617019722491.598.61061131201271341421491571641721781932082242472843231191281371461561651741841932022122212322512702903193694181451561681781902012132242362482592712833063303543904515111701841972112242372512642782923063193333613894174605316021962122272412572722883043193353513673824144474795286106922132362562722903073253433613783964144324685045405956887281781982192392602833063293533774014264525065616016616606801521691862042232412602803003233453663864324795276036106321) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.13214616117719220822524326027829631533437441445652257557811512814115616918419821322824426027829432936540145952451410211412513715016217618920221623124526029132235540646544192.010211212313414515716918119420722023326029031936539836182.992.010111112113114115216417618619821123526028732932527175.483.592.010011011912813814816016918019221323626029124468.876.284.192.010010911712613514515416417419421623922063.270.077.284.592.099.910811612413314215216017819858.264.571.177.984.992.099.410711512313113953.959.765.872.178.685.392.099.150.255.561.3A-22

2 1/2”PitchANSI Standard<strong>Roller</strong> <strong>Chain</strong>RS200OL2POLL1TLL2φDL1L1φRTWL2 L1L2 L1CC CDrive <strong>Chain</strong>hHPPNotes: Cotter type connecting links supplied for this chain.All dimensions in inches unless otherwise stated.Link Plate PinWidthBetween<strong>Chain</strong> Pitch<strong>Roller</strong>Dia.Inner LinkPlates Thickness Height Height Dia.Number P R W T H h DLengthL 1 + L 2LengthL 1LengthL 2OffsetPinLengthLTransversePitchCANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)Single StrandRS200 2.500 1.562 1.500 0.315 2.374 2.047 0.781 3.299 1.535 1.764 3.437 - 78,120 95,700 105,600 16,060 11.05 48Double StrandRS200-2 2.500 1.562 1.500 0.315 2.374 2.047 0.781 6.122 2.947 3.175 6.346 2.819 156,240 191,400 211,200 27,300 21.86 48Triple StrandRS200-3 2.500 1.562 1.500 0.315 2.374 2.047 0.781 8.945 4.360 4.585 9.173 2.819 234,360 287,100 316,800 40,150 32.84 48Quadruple StrandRS200-4 2.500 1.562 1.500 0.315 2.374 2.047 0.781 11.768 5.772 5.996 11.996 2.819 312,480 382,800 422,400 53,000 43.66 48Quintuple StrandRS200-5 2.500 1.562 1.500 0.315 2.374 2.047 0.781 14.591 7.181 7.409 14.815 2.819 390,600 478,500 528,000 62,630 54.48 48Sextuple StrandRS200-6 2.500 1.562 1.500 0.315 2.374 2.047 0.781 17.413 8.593 8.821 17.638 2.819 468,720 574,200 633,600 73,870 65.39 48Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213Maximum Speed – Small Sprocket (rpm)10 15 20 30 40 50 70 100 150 200 250 300 350 400 450 500 550 600 650Lubrication SystemABC7.36 10.6 13.7 19.8 25.6 31.4 42.4 58.5 84.2 109 133 157 181 162 135 115 100 87.8 77.98.09 11.7 15.2 21.7 28.2 34.5 46.7 64.2 92.5 120 146 173 198 184 154 132 114 1008.82 12.7 16.5 23.7 30.7 37.5 50.8 70.0 101 131 160 188 216 208 174 148 129 113Approx.Weight(lbs./ft.)Numberof linksper10 feet14151617181920212223242526Remarks:9.56 13.8 17.8 25.7 33.3 40.6 55.1 75.9 109 142 173 204 235 232 194 166 143 12610.3 14.9 19.2 27.6 35.8 43.9 59.3 81.8 118 153 186 220 252 257 215 184 160 13911.0 16.0 20.7 29.6 38.5 46.9 63.6 87.7 126 164 200 236 271 284 237 202 176 15411.8 17.0 22.0 31.6 41.0 50.2 67.9 93.6 135 174 213 252 290 311 260 223 192 16912.5 18.1 23.3 33.7 43.6 53.4 72.3 99.5 143 186 227 268 307 338 284 243 209 18413.3 19.2 24.8 35.7 46.3 56.6 76.6 106 152 197 241 284 326 367 307 261 227 19814.1 20.2 26.1 37.8 48.9 59.8 81.0 112 161 208 255 300 345 389 333 283 24514.8 21.3 27.6 39.8 51.5 63.0 85.3 118 169 220 268 316 363 409 358 306 26415.6 22.4 29.1 41.8 54.2 66.2 89.7 124 178 231 282 333 382 430 384 327 28316.4 23.5 30.4 43.9 56.9 69.5 94.1 130 186 243 296 349 401 452 409 349 30317.2 24.7 31.9 46.0 59.5 72.8 98.6 135 196 253 310 365 420 473 437 373 32317.8 25.7 33.4 48.0 62.2 76.0 103 142 204 266 323 382 439 495 464 396 34318.6 26.8 34.7 50.2 64.9 79.4 107 148 213 276 338 398 457 516 492 420 3651) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.A-23

RS240ANSI Standard<strong>Roller</strong> <strong>Chain</strong>3”Pitch1POL2POLL1Drive <strong>Chain</strong>L1L2 L1TφDφRhHLTWL2 L1L2 L1CC CPPNote: All pins have riveted construction.All dimensions in inches unless otherwise stated.Link Plate PinWidth<strong>Chain</strong> Pitch<strong>Roller</strong>Dia.BetweenInner LinkPlates Thickness Height Height Dia. Length Length LengthOffsetPinLengthTransversePitchNumber P R W T H h D L 1 + L 2 L 1 L 2 L CANSI Std.MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>MinimumTensileStrength(lbs.)<strong>Tsubaki</strong>AverageTensileStrength(lbs.)MaximumAllowableLoad(lbs.)Single StrandRS240 3.000 1.875 1.875 0.374 2.850 2.457 0.937 4.071 1.886 2.185 4.201 - 112,500 139,700 154,000 22,220 16.42 40Double StrandRS240-2 3.000 1.875 1.875 0.374 2.850 2.457 0.937 7.531 3.618 3.913 7.811 3.457 225,000 279,400 308,000 37,770 32.23 40Triple StrandRS240-3 3.000 1.875 1.875 0.374 2.850 2.457 0.937 10.984 5.348 5.636 11.272 3.457 337,500 419,100 462,000 55,550 47.97 40Quadruple StrandRS240-4 3.000 1.875 1.875 0.374 2.850 2.457 0.937 14.453 7.079 7.374 14.732 3.457 450,000 558,800 616,000 73,320 63.72 40Quintuple StrandRS240-5 3.000 1.875 1.875 0.374 2.850 2.457 0.937 17.913 8.809 9.104 18.189 3.457 562,500 698,500 770,000 86,660 79.46 40Sextuple StrandRS240-6 3.000 1.875 1.875 0.374 2.850 2.457 0.937 21.370 10.539 10.831 21.657 3.457 675,000 838,200 924,000 102,210 95.21 40Maximum Horsepower RatingsNo. ofTeethSmallSpkt.111213Approx.Weight(lbs./ft.)5 10 15 20 25 30 40 50 60 80 100 125 150 175 200 250 300 350 400 4506.817.488.1512.713.915.218.220.121.9A23.726.028.429.031.834.734.237.540.944.348.553.054.059.464.8Maximum Speed – Small Sprocket (rpm)63.770.076.3BLubrication System82.690.799.0101111121123135148145160174168184200188207225231253276271298325C228260294188213240156Numberof linksper10 feet14151617188.849.5210.210.911.616.517.719.020.421.623.725.627.529.231.130.733.135.538.040.437.540.543.446.449.344.347.751.254.758.257.461.866.470.875.470.175.681.186.592.182.789.095.5102108107115124132141131141152161172160173185197211189204219232248217233251267284244263283302321299322345369392353380388397406329363372381390268298329359377192021222312.313.013.714.315.222.924.325.626.828.233.034.936.738.840.642.845.247.750.252.652.355.358.361.364.261.765.268.772.175.879.884.488.993.698.297.6103109114120115122128134141149157166174184182193202213224223235248261274263278292307322302319335353370339359378398418416439463487496425443463471481408424440455469393408421436448242526Remarks:15.816.517.329.530.832.242.544.446.455.157.560.167.370.473.479.482.986.51031071121261311371481541611922002091) Multiply the value given above by the multiple factor (page A-91) in order to obtain the transmission horsepower of multiple strand chain.2) For Lubrication Methods, A, B & C, refer to page A-110 for explanation. Please consult <strong>Tsubaki</strong> for use of horsepower ratings to the right of theboundary line which represents the peak torque.3) Refer to the procedures for selecting roller chain beginning on page A-90.235245256287299312338353369388405422437457477531550561504520532483496510A-24

Agricultural <strong>Roller</strong> <strong>Chain</strong>An economical choice in drive applications where the speed is low, the load is moderate or where the center is relatively long. <strong>Tsubaki</strong>double pitch agricultural drive chains are also available in stainless steel and nickel plated anti-corrosive coatings.Drive <strong>Chain</strong>TL1L2φDφRH WPPAll dimensions in inches unless otherwise stated.<strong>Roller</strong>DiameterRWidthBetweenInner LinkPlatesWLink Plate PinAverageTensileStrength(lbs.)<strong>Chain</strong>NumberPitchPThicknessTHeightHDiameterDLengthL 1 + L 2LengthL 1LengthL 2A2040 1.000 0.312 0.312 0.060 0.472 0.156 1.083 0.325 0.380 3,700A2050 1.250 0.400 0.375 0.080 0.590 0.200 1.413 0.406 0.469 6,100A2060 1.500 0.469 0.500 0.094 0.709 0.234 1.543 0.506 0.600 8,500A2080 2.000 0.625 0.625 0.125 0.906 0.312 1.543 0.640 0.754 14,500ApproximateWeight(lbs./ft.)0.260.420.631.03Number oflinks per10 feet120968060A-25