NABCEP PV Installer Job Task Analysis

NABCEP PV Installer Job Task Analysis

NABCEP PV Installer Job Task Analysis

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

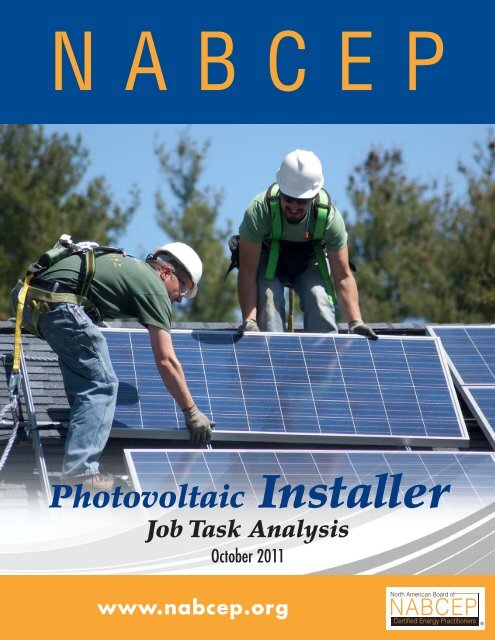

<strong>NABCEP</strong> <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong>IntroductionThis document presents a comprehensive <strong>Job</strong> <strong>Task</strong><strong>Analysis</strong> (JTA) for individuals who install photovoltaicsystems on buildings. It is important to note thatthese tasks are applicable to installation personnel—not to the system designer. This task list assumes thecertified installer starts with a system design package,complete with major components, manufacturerinstallation manuals, system schematics, and assemblyand troubleshooting instructions. While the certifiedinstaller may not design the system, he or she must beknowledgeable about many aspects of systems design,and may be required to adapt certain designs to fit aparticular application or customer need.Fundamentally, this JTA assumes that the installerbegins with adequate documentation for the systemdesign and equipment, including manuals for majorcomponents, electrical and mechanical drawings, andinstructions. While these tasks have been developedbased on conventional designs, equipment, and practiceused in the industry today, they do not seek to limitor restrict innovative equipment, designs, or installationpractice in any manner. As with any developingtechnology, it is fully expected that the skills requiredof the practitioner will develop and change over timeas new materials, techniques, codes, and standardsevolve.This document is a revision of the JTA that was releasedby <strong>NABCEP</strong> in July of 2010. The intent andpurpose of these revisions is to offer greater focus andclarity to candidates, educators, and the exam committee.The major revisions in this document are thecategorization of the task steps by level of criticalityand the organization of the knowledge statements. Aminor number of task steps were deleted from the JTAduring the revision process. The job description wasrestated to be consistent with the original descriptionof a <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong>.<strong>Job</strong> Descriptionfor <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong>Given a potential site for a solar photovoltaicsystem installation and given basic instructions,major components, schematics, and drawings,the <strong>PV</strong> <strong>Installer</strong> will: specify, adapt, implement,configure, install, inspect, and maintain any typeof photovoltaic system, including grid-connectedand stand-alone systems with or without batterystorage, that meet the performance and reliabilityneeds of customers in the United States andCanada, by incorporating quality craftsmanshipand complying with all applicable codes, standards,and safety requirements.2 • <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11

TASK STEPCATEGORYl Confirm mounting methodl Confirm torque valuesl Confirm usage of appropriate auxiliary materialsl Confirm weatherproofing materials for building penetrationsl Confirm pull-out loadsl Confirm wind loadingl Confirm shear loadsl Confirm shear strengthsl Confirm types of loadsl Confirm accuracy of bill of materials10. Review Plan Setsl Confirm AHJ requirementsl Confirm accuracy of electrical one- or three-line diagraml Confirm accuracy of site planl Confirm accuracy of system designl Generate a safety planl Assemble manufacturer’s data sheetsl Create labeling schedulel Assemble manufacturer’s instructionsl Note and address structural concernsl Complete commissioning formsl Generate string diagramImportantImportantImportantImportantUsefulUsefulUsefulUsefulUsefulUsefulImportantUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulB: Managing the Project1. Conduct Pre-Construction Meetingsl Plan weather contingenciesl Verify site conditions match designl Assemble workforce, including other trades as appropriatel Determine daily construction goalsl Communicate construction strategy to customerl Provide customer orientationl Communicate target pull-off time for crewl Document safety planl Resolve scheduling conflictsl Ensure pre-construction commitments by customer are completel Determine community issuesl Determine customer requirementsCriticalCriticalImportantImportantImportantImportantImportantImportantImportantImportantImportantImportant<strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11 • 7

TASK STEP2. Secure Permits and Approvalsl Coordinate inspectionsl Schedule inspectionsl Confirm job permitsl Resolve AHJ conflictsl Submit plans to utilitiesl Resolve utility conflictsl Obtain sign-off on final building permitl Determine additional agency permits (e.g. zoning, solar access,Homeowners’ Association, historic district)3. Manage Project Laborl Coordinate with subcontractorsl Determine order of tasksl Allocate resourcesl Supervise project crewsl Communicate aspects of safety planl Coordinate with other tradesl Orient contractors to job site conditionsl Track man hoursl Conduct toolbox talksl Resolve disputes4. Adapt System Designl Identify potential conflicts in designl Document changes to proposed designl Maintain as-built documentationl Submit modification proposalsl Acquire approvals to change designl Submit any change orders5. Manage Project Equipmentl Take delivery of componentsl Schedule deliveriesl Identify lifting and handling areasl Perform equipment inspectionl Perform equipment maintenancel State site equipmentl Schedule machineryl Ensure equipment operator certificationl Install pedestrian barriersCATEGORYImportantImportantImportantImportantUsefulUsefulUsefulUsefulCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantUsefulCriticalCriticalCriticalImportantImportantImportantImportantImportantImportantImportantImportantUsefulUsefulUsefulUseful8 • <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11

TASK STEP6. Implement a Site-Specific Safety Planl Perform hazard analysisl Identify job site hazardsl Implement ladder safetyl Implement fall protection planl Execute electrical safetyl Select personal protective equipment (PPE)l Develop site-specific safety planl Implement vehicle safetyl Install site safety barriersl Identify access points to sitel Identify site evacuation pointsl Post hospital map routesl Post emergency contact numbersl Ensure material safety data sheets (MSDS) are on-sitel Post contingency planCATEGORYCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantImportantImportantImportantImportantUsefulC: Installing Electrical Components1. Mitigate Electrical Hazardsl Implement the site safety planl Implement the lock-out, tag-out proceduresl Determine voltage levels of interconnectionsl Maintain clear work areal Clarify the maximum working voltagel Select required PPE based on system design(arc flash, shock, burn, voltage, etc.)l Disconnect all unnecessary live circuitsl Determine working clearancesl Demonstrate situational awarenessl Measure voltage on equipment before proceeding with workl Inspect safety equipmentl Inspect test equipmentl Maintain safety equipmentl Inspect hand and power toolsl Measure current on equipment before proceeding with workl Maintain hand and power toolsCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantUsefulUseful<strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11 • 9

TASK STEP2. Install Grounding Systemsl Install module groundingl Install inverter groundingl Install mounting system groundingl Ground all noncurrent-carrying metal partsl Bond metallic racewaysl Install grounding electrode conductorl Bond all electrical equipmentl Apply antioxidant materiall Prepare surfaces for electrical connectionsl Make grounding electrode connectionl Install grounding electrode(s)l Install supplementary ground electrodel Install system groundsl Determine grounding conductor sizel Install DC ground-fault protectionl Locate underground hazards3. Install Conduit and Racewaysl Plan conduit routingl Penetrate building envelopel Support and secure conduitl Tighten all fittingsl Select fittings according to applicationl Install above ground electrical racewaysl Install conduit bushingsl Make knockouts in electrical racewaysl Install underground electrical racewaysl Remove sharp edges (deburr)l Install service entry mastl Locate underground utilitiesl Create underground trenchesl Backfill underground trenchesl Mark underground cablesl Mark underground trenches4. Install Electrical Componentsl Select location of DC disconnectl Mount electrical enclosuresl Install DC combinerl Label equipmentCATEGORYCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantImportantImportantUsefulCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantUsefulUsefulUsefulUsefulUsefulUsefulCriticalCriticalCriticalCritical10 • <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11

TASK STEPCATEGORYl Install <strong>PV</strong> system disconnectsl Install inverter disconnectsl Install utility required disconnectsl Install array wiring transition boxl Install inverterl Install underground electrical componentsl Install AC combinerl Install meter basesl Select label materialsl Install junction boxes in the attic5. Install Circuit Conductorsl Pull conductorsl Label conductorsl Terminate conductorsl Wire the inverterl Wire modulesl Select the correct wire type, color, and gaugel Secure conductorsl Measure wiresl Set up the wire installation (tugger, fish tape, rope)l Test conductor installationl Test DC source circuitsl Test DC currentsl Set up pull stationsl Clear the electrical racewayl Splice electrical conductors6. Install Utility Interconnectionl Install overcurrent protection device (OCPD)l Install disconnectsl Test utility voltagel Coordinate AHJ inspectionl Verify fill ratesl Terminate conductorsl Implement lock-out, tag-out proceduresl Evaluate existing service entrance equipmentl Install generation meteringl Test conductor insulationl Select connection locationl Coordinate utility shutdownsCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantImportantCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportant<strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11 • 11

TASK STEPCATEGORYl Coordinate with customers and other regarding shutdownsl Move existing circuits7. Install System Instrumentationl Test systeml Install power and energy meteringl Install data communication cablesl Install communication systemsl Install environmental sensorsl Install controllersl Install electrical sensorsl Install inverter interfacel Install power supplyl Install battery temperature sensorsl Install outlet for monitoring systemImportantImportantCriticalImportantUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulUseful8. Install Battery Componentsl Test each unit before placement (voltage, specific gravity, polarity) Importantl Terminate fine stranded cablesImportantl Install maintenance disconnectImportantl Confirm battery bank locationImportantl Install battery enclosureImportantl Install battery enclosure ventingImportantl Install battery spill containmentImportantl Install batteriesImportantl Prepare battery terminals (e.g. clean)Usefull Install battery interconnection conductorsUsefull Install battery unitsUsefull Apply antioxidant compoundsUsefull Calculate ampacityUsefull Install charge controller Useful *l Seal conduit entry to battery boxUsefull Label battery unitsUsefull Label battery enclosureUsefull Label battery room Useful *l Establish maintenance scheduleUsefull Test final assembled battery polarity and voltage Useful *l Install safety stationUseful* The items noted were deemed to be useful or important primarily because most installations do not involve batteries and assuch installers do not frequently perform the tasks. Each of these tasks becomes critical when installing battery systems andshould be so noted.12 • <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11

TASK STEPCATEGORYD: Installing Mechanical Components1. Install Equipment Foundationl Locate center points of holesl Place anchor hardwarel Install grounding equipment conductor (GEC)l Excavate to design specificationsl Build concrete formsl Coordinate foundation inspectionsl Identify location of underground utilitiesl Add structural reinforcementl Install wire racewaysl Place concrete to design specificationsl Install driven postsl Strip concrete formsl Backfill excavationl Place mounting posts2. Install Mounting Systeml Install roof attachmentsl Weatherproof penetrationsl Locate structural roof membersl Determine array attachment locationsl Install structural attachmentsl Install module support framel Install rack componentsl Locate array footprintl Confirm compatibility with existing roofing systeml Plumb array structurel Level array structurel Apply corrosion protection to cut surfacesl Install tracking apparatusl Install actuator motorsl Install supplementary structural supportsl Confirm row spacingl Confirm structural analysis has been performedl Install structural membersl Locate ballast for mounting systeml Install seismic and wind loadingImportantImportantImportantUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantImportantImportantUsefulUseful<strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11 • 13

TASK STEP3. Install <strong>PV</strong> Modulesl Unpack <strong>PV</strong> modulesl Stage <strong>PV</strong> modulesl Secure module wiringl Inspect module for physical damagel Fasten modules to structurel Torque module fastenersl Confirm module frame groundingl Align modules aestheticallyl Determine project workflowl Test <strong>PV</strong> modulesl Prep <strong>PV</strong> modulesCATEGORYCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantE: Complete System Installation1. Test the Systeml Verify mechanical connection integrityl Verify system groundingl Verify electrical connection torquel Verify polarityl Measure DC voltages (string, output)l Verify inverter operationl Measure DC currentsl Compare measured values with expected valuesl Measure AC system valuesl Perform physical inspectionl Verify conduit fitting tightnessl Verify conduit and wiring supportsl Verify workmanshipl Measure irradiance levelsl Calculate expected electrical parametersl Verify anti-islanding systeml Test for ground faultl Measure insulation resistancel Measure environmental levelsl Confirm phase rotationCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantUsefulUsefulUseful14 • <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11

TASK STEP2. Commission the Systeml Turn on systeml Initiate start-up procedures per manufacturer instructionsl Program variable set pointsl Measure all electrical parametersl Compare measured values to expected valuesl Monitor start-up processl Record anomalous conditionsl Document design changesl Verify as-built documentationl Verify labeling accuracyl Note data and time of system start-upl Repair anomalous conditionsl Record environmental conditionsl Record prior values on inverterl Measure voltage of energy storage systeml Verify calculation of Total Solar Resource Fractionl Verify polarity of energy storage systeml Verify anti-islanding performancel Record voltage of energy storage system3. Complete System Documentationl File project photographsl Record component serial numbersl Deliver as-built documentsl File permitsl Record certificates of inspectionl File inspection formsl File commissioning formsl File data sheetsl File proof of system test resultsl Complete equipment warranty registrationl Complete installation warranty registrationCATEGORYCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantImportantImportantUsefulUsefulUsefulCriticalImportantImportantImportantImportantImportantImportantImportantImportantUsefulUseful<strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11 • 15

TASK STEP4. Orient Customer to Systeml Explain start-up and shutdown proceduresl Answer customer questionsl Explain safety procedures to customerl Explain maintenance proceduresl Address customer concernsl Train customer on maintenance and operation proceduresl Explain equipment clearance requirementsl Perform customer walk-throughl Provide contact information to customerl Explain normal operational performanceCATEGORYCriticalCriticalCriticalCriticalImportantImportantImportantImportantImportantImportantF: Conducting Maintenance and Troubleshooting Activities1. Perform Visual Inspectionl Verify equipment groundingl Inspect module mounting systeml Identify hazardsl Inspect weatherproofing systemsl Inspect for wiring damagel Inspect module integrityl Check inverter statusl Inspect electrical equipmentl Identify damage due to corrosionl Identify array shadingl Identify array soilingl Inspect cells for discolorationl Verify grounding system integrityl Look for unsupported wiringl Identify damage to module glazingl Document findingsl Identify mismatched equipmentl Inspect for working clearancesl Identify electrical connections damage due to overheatingl Confirm equipment serial numbersl Inspect module back skinl Check conduit fitting tightnessl Inspect for evidence of animalsl Identify vegetation growthl Identify water pondingl Identify ice damageCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantImportantImportantImportantImportantImportant16 • <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11

TASK STEP2. Verify System Operationl Measure system electrical parametersl Document found electrical parametersl Calculate expected electrical parametersl Compare expected parameters with found parametersl Note anomalous conditionsl Test system electrical equipment operationsl Recommend corrective actionsl Verify source circuits are connectedl Interview customerl Document customer’s concernsl Compare historical kWh performance againstexpected kWh performancel Measure equipment temperaturesl Note interannual weather variabilityl Measure terminal temperaturesl Verify operation of battery venting systemsl Verify battery auxiliary systems3. Perform Corrective Actionsl Replace defective modulesl Check equipment variable set pointsl Perform scheduled maintenancel Replace frayed wiresl Replace blown fusesl Replace faulty componentsl Locate ground faultsl Repair ground faultsl Mitigate negative local conditionsl Locate line to line faultsl Repair line to line faultsl Document corrective actionsl Clean arraysl Service ventilation systemsl Clean batteriesl Recalibrate equipment at variable set pointsl Wipe down power conditioning equipmentl Clean heat sinksl Schedule manufacturer on-site service calll Seal compromised weatherproofing systemsl Perform battery maintenanceCATEGORYCriticalCriticalCriticalCriticalCriticalCriticalCriticalCriticalImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantImportantUsefulUsefulUsefulUsefulUsefulUsefulUsefulUsefulUseful<strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11 • 17

TASK STEPCATEGORYl Perform controlled overchargel Clean system labelingl Replace system labeling4. Verify Effectiveness of Corrective Actionsl Retest system operationsl Retest electrical parametersl Retest environmental conditionsl Compare pre-maintenance values to post-maintenance valuesl Retest weatherproofing systeml Reorient customer to systemUsefulUsefulUsefulCriticalImportantImportantImportantUsefulUseful* The items noted were deemed to be useful or important primarily because most installations do not involve batteries and assuch installers do not frequently perform the tasks. Each of these tasks becomes critical when installing battery systems andshould be so noted.18 • <strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11

Knowledge Groups for <strong>NABCEP</strong> 2011Refocused <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong>The topic list below provides the broad content areas from which the JTA was developed.The test items for the certification examination will be based upon the stated competenciesin the JTA and not from general content in this topic list. Successful candidates will need tohave knowledge in the topics listed below.A detailed version of this list that includes subtopics is available on the <strong>NABCEP</strong> website(www.nabcep.org). This list is included as valuable information to help candidates evaluatetheir readiness for examination.• Basic Electricity• Building Codes• Blueprint Reading• Customer Relations• Construction Processes• Instrumentation and Measurements• Mathematics• National Electrical Code• Occupational Safety and Health• <strong>PV</strong> System Design• <strong>PV</strong> System Installation• Residential and Commercial Wiring• Solar and <strong>PV</strong> Fundamentals<strong>NABCEP</strong> wishes to acknowledge and thank the following individualsfor their contribution in developing this JTA:Ward BowerDave ClickRichard DeanJason FisherGeoff GreenfieldMarvin HamonWill HerendonEd KnaggsMichael KuhnMatt LaffertyChris La ForgeDan LichtmanScott McCalmontTom McCalmontDan RiceBen RogersBob-O SchultzeGregg StephensAndrew TruittChris WarfelSean WhiteJohn WilesNorth American Board ofCertified Energy Practitioners56 Clifton Country Road, Suite 202Clifton Park, NY 12065800-654-0021 / info@nabcep.orgwww.nabcep.orgv.102011<strong>NABCEP</strong> Certified <strong>PV</strong> <strong>Installer</strong> <strong>Job</strong> <strong>Task</strong> <strong>Analysis</strong> 10.11 • 19