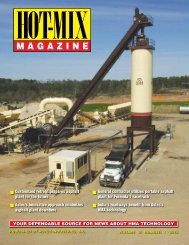

THE SUBJECT OF THIS STUDYis Diamond B Construction, Inc.,a member of The Bossier Group—which is one of Louisiana’s oldestprivately owned highway constructioncompanies. With headquarters atAlexandria in Central Louisiana, thecompany has five hot-mix asphaltplants and paving operations throughoutthe state. In addition, Diamond BConstruction offers material production(aggregate, dirt, sand, and gravel);municipal and public works construction;piling equipment and supplies;and traffic-control products.The company’s chief executive officeris Bryan Bossier, who has been withthe company most of his life. “Myfather—Leonard Bossier—started thebusiness in 1950,” recalled BryanHOT-MIX: Tell us a little bit aboutthis plant in Mermentau.BOSSIER: We bought this plant in1999 and put it down on Interstate12 near Livingston, east of BatonRouge. I’d guess that we had itdown there about nine months,running a big Interstate rehab job.They’re going to rehab all of thatInterstate through there. It’s beenneeding it for years.HOT-MIX: When did you move it?BOSSIER: We moved it up thereto Mermentau this past summer.We’re working Interstate 10 atCrowley. They’re rubbleizing theconcrete and overlaying it withhot-mix. We do love rubbleizers.The only good concrete is deadconcrete! (Laughs) Anyway, we’rejust a little south of the Interstate,so we only have a 20-mile (32-km)haul to the current project. We’reable to reach the I-10 and whateverother work we can find inthe surrounding area.HOT-MIX: What do you consideryour market area to be?BOSSIER: I suppose we couldreach out to a 40- or 50-mile (64-or 80-km) radius. We have LakeCharles to the west and Lafayetteto the east—and we’re abouthalfway between the two. So bothof those are within our market.HOT-MIX: How is the market?BOSSIER: Well, I’ll tell you. It’sreally competitive. Everybody inLouisiana does both productionand laydown. I know that someBossier during this interview. “Thenhe started Diamond B Constructionin 1975. The name of the company?Well, he loved his grandchildren andhe affectionately called them his ‘littleDiamondbacks’—or little rattlesnakes.And that’s where the name ‘DiamondB’ came from.”Diamond B Construction currentlyoperates five hot-mix plants. “Theyare all the same kind,” said Bossier.“They are all <strong>Astec</strong> Double Barrelplants. We’ve purchased five plants infour years. Our oldest plant is a 1996model. And our newest one is an <strong>Astec</strong>Double Barrel that was delivered thefirst week of October. We put that onedown in Baywood.”The plant featured in this article hasbeen in operation a little more than ayear. It is a portable <strong>Astec</strong> <strong>Turbo</strong> 400<strong>Six</strong> <strong>Pack</strong> plant that was delivered toDiamond B Construction in the lasthalf of 1999.In addition to the <strong>Astec</strong> <strong>Turbo</strong> 400Double Barrel drum mixer, the plantincludes a five-compartment coldfeedsystem; a separate RAP (reclaimedasphalt pavement) feeder; a scalpingscreen with inclined conveyor; a baghouse;a cyclone; and two 200-ton(181-tonne) New Generation storagesilos. The company recently addedanother 200-ton (181-tonne) silo whenthe plant was relocated.The plant has a Command I controlcenter that is equipped with a ProcessMate 96 control system. Other equipmentincludes a 2,000-gal. (7,570-L)Bossier’s advice on purchasing:“I’d say when you are speccing a new plant,you should get all of the bells and whistles.If you get the best stuff going in,it’s going to save you in the long run.”places, they split it up—and I findthat fascinating. But there is noneof that here in Louisiana. There are58 asphalt plants in Louisiana—and it is dog eat dog, I’ll tell youthat! This stuff is always on sale.Every so often, somebody goesbroke just because they can’t standthe competition. It’s a clearancesale that never goes away. The taxpayershere are really getting agood deal!HOT-MIX: Let’s get back to thisplant. Do you remember whenyou first become interested in<strong>Astec</strong> equipment?BOSSIER: I bought my first <strong>Astec</strong>plant in the early 1980s. I think itwas a 1982 Double Barrel plant.You know, I think that DoubleBarrel is the cat’s meow. I mean,you do your drying on the insideof the drum and then you doyour mixing on the outside... Why,liquid-additive tank and metering system;a Heatec 35,000-gal. (132,500-L) Helitank that combines a hot-oilheater with insulated storage for liquidasphalt cement. The tank has asplit compartment so it can hold20,000 gal. (75,700 L) on one side and15,000 gal. (56,800 L) on the otherside. Another Heatec 30,000-gal.(113,600-L) tank was added later.The plant began its field operations inLivingston, Louisiana—but it wasmoved this year to be closer to a newjobsite in the vicinity of Mermentau,Louisiana, about midway betweenLafayette and Lake Charles.We began the interview by askingBossier to fill us in on the history ofthis particular plant:that’s just perfect! You need tokeep that flame away from thatasphalt. And the Double Barreldoes exactly that.HOT-MIX: What do you like bestabout <strong>Astec</strong>?BOSSIER: I can’t remember whyI first got interested in <strong>Astec</strong>. Iwas a young punk and I didn’tknow anything of real value. So Idid a lot of studying. I studiedCedarapids and I studied Barber-Greene and I studied all of thoseother companies. I got to lookinginto how thick the metal was anda lot of other details like that. Andthe <strong>Astec</strong> plant just seemed to bea sturdy, well-built plant. Thepeople at <strong>Astec</strong> seemed to knowwhat they were talking about.Why, even the salesmen seemedto know the answers. I’d reallydig into the details—and it turnedout that they could answer everyone of my questions. Some ofthese cats come in here and theydon’t know what they’re talkingabout. But not <strong>Astec</strong>.HOT-MIX: I understand you justtook delivery on another <strong>Astec</strong>Double Barrel plant...BOSSIER: Yes. With that DoubleBarrel, you just can’t beat it. Thoseguys at <strong>Astec</strong> are innovators. Theyare always trying to improve it. I’mguessing that they look at what’son the market and they say, “Well,if we’d do this way, it would be alittle better.” They don’t buildplants a certain way just because(Continued to Page 26)HOT-MIX MAGAZINE 25 VOLUME 5, NUMBER 3

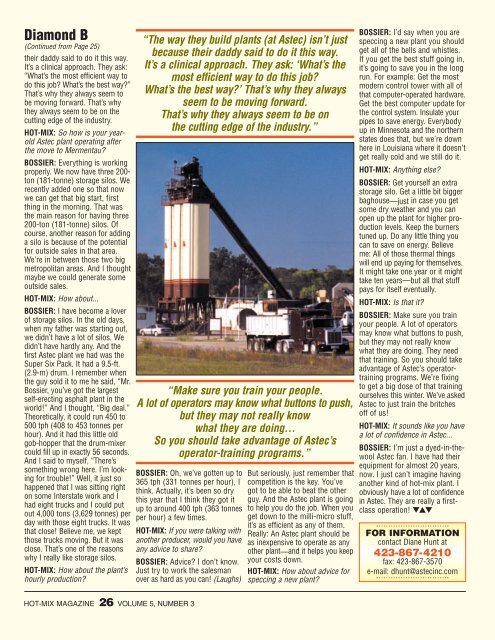

Diamond B(Continued from Page 25)their daddy said to do it this way.It’s a clinical approach. They ask:“What’s the most efficient way todo this job? What’s the best way?”That’s why they always seem tobe moving forward. That’s whythey always seem to be on thecutting edge of the industry.HOT-MIX: So how is your yearold<strong>Astec</strong> plant operating afterthe move to Mermentau?BOSSIER: Everything is workingproperly. We now have three 200-ton (181-tonne) storage silos. Werecently added one so that nowwe can get that big start, firstthing in the morning. That wasthe main reason for having three200-ton (181-tonne) silos. Ofcourse, another reason for addinga silo is because of the potentialfor outside sales in that area.We’re in between those two bigmetropolitan areas. And I thoughtmaybe we could generate someoutside sales.HOT-MIX: How about...BOSSIER: I have become a loverof storage silos. In the old days,when my father was starting out,we didn’t have a lot of silos. Wedidn’t have hardly any. And thefirst <strong>Astec</strong> plant we had was theSuper <strong>Six</strong> <strong>Pack</strong>. It had a 9.5-ft.(2.9-m) drum. I remember whenthe guy sold it to me he said, “Mr.Bossier, you’ve got the largestself-erecting asphalt plant in theworld!” And I thought, “Big deal.”Theoretically, it could run 450 to500 tph (408 to 453 tonnes perhour). And it had this little oldgob-hopper that the drum-mixercould fill up in exactly 56 seconds.And I said to myself, “There’ssomething wrong here. I’m lookingfor trouble!” Well, it just sohappened that I was sitting righton some Interstate work and Ihad eight trucks and I could putout 4,000 tons (3,629 tonnes) perday with those eight trucks. It wasthat close! Believe me, we keptthose trucks moving. But it wasclose. That’s one of the reasonswhy I really like storage silos.HOT-MIX: How about the plant’shourly production?“The way they build plants (at <strong>Astec</strong>) isn’t justbecause their daddy said to do it this way.It’s a clinical approach. They ask: ‘What’s themost efficient way to do this job?What’s the best way?’ That’s why they alwaysseem to be moving forward.That’s why they always seem to be onthe cutting edge of the industry.”“Make sure you train your people.A lot of operators may know what buttons to push,but they may not really knowwhat they are doing...So you should take advantage of <strong>Astec</strong>’soperator-training programs.”BOSSIER: Oh, we’ve gotten up to365 tph (331 tonnes per hour), Ithink. Actually, it’s been so drythis year that I think they got itup to around 400 tph (363 tonnesper hour) a few times.HOT-MIX: If you were talking withanother producer, would you haveany advice to share?BOSSIER: Advice? I don’t know.Just try to work the salesmanover as hard as you can! (Laughs)But seriously, just remember thatcompetition is the key. You’vegot to be able to beat the otherguy. And the <strong>Astec</strong> plant is goingto help you do the job. When youget down to the milli-micro stuff,it’s as efficient as any of them.Really: An <strong>Astec</strong> plant should beas inexpensive to operate as anyother plant—and it helps you keepyour costs down.HOT-MIX: How about advice forspeccing a new plant?BOSSIER: I’d say when you arespeccing a new plant you shouldget all of the bells and whistles.If you get the best stuff going in,it’s going to save you in the longrun. For example: Get the mostmodern control tower with all ofthat computer-operated hardware.Get the best computer update forthe control system. Insulate yourpipes to save energy. Everybodyup in Minnesota and the northernstates does that, but we’re downhere in Louisiana where it doesn’tget really cold and we still do it.HOT-MIX: Anything else?BOSSIER: Get yourself an extrastorage silo. Get a little bit biggerbaghouse—just in case you getsome dry weather and you canopen up the plant for higher productionlevels. Keep the burnerstuned up. Do any little thing youcan to save on energy. Believeme: All of those thermal thingswill end up paying for themselves.It might take one year or it mighttake ten years—but all that stuffpays for itself eventually.HOT-MIX: Is that it?BOSSIER: Make sure you trainyour people. A lot of operatorsmay know what buttons to push,but they may not really knowwhat they are doing. They needthat training. So you should takeadvantage of <strong>Astec</strong>’s operatortrainingprograms. We’re fixingto get a big dose of that trainingourselves this winter. We’ve asked<strong>Astec</strong> to just train the britchesoff of us!HOT-MIX: It sounds like you havea lot of confidence in <strong>Astec</strong>...BOSSIER: I’m just a dyed-in-thewool<strong>Astec</strong> fan. I have had theirequipment for almost 20 years,now. I just can’t imagine havinganother kind of hot-mix plant. Iobviously have a lot of confidencein <strong>Astec</strong>. They are really a firstclassoperation! ▼▲▼FOR INFORMATIONcontact Diane Hunt at423-867-4210fax: 423-867-3570e-mail: dhunt@astecinc.comHOT-MIX MAGAZINE 26 VOLUME 5, NUMBER 3