Download the Complete Catalog in One PDF - Ramset

Download the Complete Catalog in One PDF - Ramset

Download the Complete Catalog in One PDF - Ramset

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Powder Tra<strong>in</strong><strong>in</strong>g Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4Buy American Act ....................................5Into To Gas Technology ....................................6Suggested Specifications ..................................7Fasteners – How They Work ................................8LEED Credits ...................................10Toubleshoot<strong>in</strong>g ...................................11Tool Selection Guide ...................................12Powder Fastener & Load Selection Chart ....................14Gas Fasten<strong>in</strong>g SystemsT3MAG ................................... 16TrakFast ................................... 17T3SS ................................... 18GypFastG2 ................................... 19Powder Fasten<strong>in</strong>g SystemsR25 ................................... 20XT540 ................................... 21SA270 ................................... 22Cobra ................................... 22Viper ................................... 23D45A ................................... 24D60 ................................... 24721 ................................... 25MasterShot ................................... 25T3Cup ................................... 26Extension Poles ................................. 27Tool Accessories (Batteries, Fuel Cells, Chargers, etc). .... 28FastenersGas Tool Fasteners (T3MAG, TrakFast)................. 29GypFast Tool Fasteners. ........................... 31Gas Tool Fasteners (T3ss).......................... 32Powder Fasteners. ............................... 34Powder Loads ...................................38Performance/Submittal ..................................39J Master Tool ...................................49XBA / CB CBD ...................................50Conduit / Cable Support ..................................51Strut Clamps ...................................52Beam/Purl<strong>in</strong> ...................................53Metal Stud Support ...................................55Rod Hangers ...................................57Acoustical ...................................57Harware Accessories ...................................57Low-Voltage ...................................58Part Number Reference ..................................59WoodSAMMYS for Wood. .............................. 62Sammy Swivelhead for Wood....................... 62Sidew<strong>in</strong>ders for Wood............................. 63SteelSAMMYS for Steel ............................... 64Sammy Swivelhead for Steel. ...................... 64Sidew<strong>in</strong>ders for Steel. ............................ 65SAMMY XPress.................................. 65SAMMT XPress It Installation Tool ................... 65ConcreteSAMMYS for Concrete ............................ 66Sammy Swivelhead for Concrete. ................... 66Swivelhead for Concrete........................... 66Concrete / Wood Installation Kit ..................... 67Approvals ...................................68CONCRETE ANCHORING SYSTEMSElectrical Contractor Applications ..........................70Mechanical Contractor Applications ........................71Trubolt Wedge Anchors ..................................72LDT Anchors ...................................80Multi-Set II Drop In Anchors ..............................86Dynabolt Sleeve Anchors .................................91Stud Anchors ...................................95Redi-Drive Anchors ...................................97Tapcon ..................................101EZ Ancor ..................................104Poly-Set Anchors ..................................1053

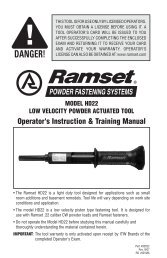

POWDER TRAININGAND CERTIFICATION<strong>Ramset</strong> has designed and eng<strong>in</strong>eered <strong>the</strong> right powderactuated tool for your applications. To ensure you use apowder actuated tool correctly, please take <strong>the</strong> time toreview <strong>the</strong> Operator's Safety and Operat<strong>in</strong>g InstructionManual packaged with each tool. These manuals are alsoavailable for download on <strong>the</strong> <strong>Ramset</strong> website.To assure safety on <strong>the</strong> jobsite, OSHA and ANSI requirethat all powder actuated tool users become tra<strong>in</strong>ed andcertified for <strong>the</strong> particular tool be<strong>in</strong>g used. <strong>One</strong> way<strong>Ramset</strong> enables you to receive this tra<strong>in</strong><strong>in</strong>g is throughour website tra<strong>in</strong><strong>in</strong>g program. This <strong>in</strong>novative approachto education comb<strong>in</strong>es <strong>in</strong>teractive web-based tra<strong>in</strong><strong>in</strong>gtechniques and onl<strong>in</strong>e test<strong>in</strong>g with immediate feedback toprovide you a rich learn<strong>in</strong>g environment.The course consists of approximately 30 pages of usage,safety and troubleshoot<strong>in</strong>g material.Upon completion of this brief course you will have <strong>the</strong>opportunity to take an onl<strong>in</strong>e exam. Instructions for tak<strong>in</strong>g<strong>the</strong>se exams are provided at <strong>the</strong> end of <strong>the</strong> course.With successful completion of <strong>the</strong> exam, you have <strong>the</strong>opportunity to pr<strong>in</strong>t a certification card.As an <strong>in</strong>dustry leader <strong>in</strong> powder actuated fasten<strong>in</strong>gsystems. <strong>Ramset</strong> cont<strong>in</strong>ues to provide <strong>the</strong> most effectiveand comprehensive <strong>in</strong>structor and operator tra<strong>in</strong><strong>in</strong>gprograms available.Visit www.ramset.comwww.ramset.com4

Dedicated to American Made ProductsThe American Recovery and Re<strong>in</strong>vestment Act of 2009 requires that all constructionmaterials for federal, state and local stimulus projects must be manufactured <strong>in</strong> <strong>the</strong>United States.<strong>Ramset</strong> is unique <strong>in</strong> <strong>the</strong> world of construction tools, fasteners and sealant manufactur<strong>in</strong>g.Overall, 98% of <strong>Ramset</strong> fasteners and accessories are made <strong>in</strong> <strong>the</strong> USA.Unlike our competitors you know you are buy<strong>in</strong>g American made products and support<strong>in</strong>g<strong>the</strong> American economy and workers when you buy <strong>Ramset</strong>. <strong>Ramset</strong>’s parent company,Ill<strong>in</strong>ois Tool Works (NYSE: ITW) employees more than 25,000 Americans.Manufacturer Tools Fasteners<strong>Ramset</strong> Tools:TrakFast Glendale Heights, IL Paris, KYGypFast Glendale Heights, IL Paris, KYT3SS Glendale Heights, IL Paris, KYT3Mag Glendale Heights, IL Paris, KYD45A Glendale Heights, IL Paris, KYBUY AMERICAN ACTSEC. 1605—Use of American iron,SEC. 1605steel, and manufactured goods.(3) <strong>in</strong>clusion of iron, steel, and(a) None of <strong>the</strong> funds appropriated manufactured goods produced <strong>in</strong>or o<strong>the</strong>rwise made available by <strong>the</strong> United States will <strong>in</strong>crease <strong>the</strong>this Act may be used for a project cost of <strong>the</strong> overall project by morefor <strong>the</strong> construction, alteration, than 25 percent.ma<strong>in</strong>tenance, or repair of a public(c) If <strong>the</strong> head of a Federal departmentor agency determ<strong>in</strong>es that itbuild<strong>in</strong>g or public work unless allof <strong>the</strong> iron, steel, and manufacturedgoods used <strong>in</strong> <strong>the</strong> project areis necessary to waive <strong>the</strong> applicationof subsection (a) based on aproduced <strong>in</strong> <strong>the</strong> United States.f<strong>in</strong>d<strong>in</strong>g under subsection (b), <strong>the</strong>(b) Subsection (a) shall not apply head of <strong>the</strong> department or agency<strong>in</strong> any case or category of cases shall publish <strong>in</strong> <strong>the</strong> Federal Registera detailed written justification<strong>in</strong> which <strong>the</strong> head of <strong>the</strong> Federaldepartment or agency <strong>in</strong>volved as to why <strong>the</strong> provision is be<strong>in</strong>gf<strong>in</strong>ds that—waived.(1) apply<strong>in</strong>g subsection (a) would (d) This section shall be applied <strong>in</strong>be <strong>in</strong>consistent with <strong>the</strong> public a manner consistent with United<strong>in</strong>terest;States obligations under <strong>in</strong>ternationalagreements.(2) iron, steel, and <strong>the</strong> relevantmanufactured goods are notproduced <strong>in</strong> <strong>the</strong> United States <strong>in</strong>sufficient and reasonably availablequantities and of a satisfactoryquality; or*Excerpted from HR 1, “American Recoveryand Re<strong>in</strong>vestment Act of 2009",Division A, Title XVI, Section 1605<strong>Ramset</strong> Manufactur<strong>in</strong>g:Powder Loads Manufactur<strong>in</strong>gGas Fuel Cells ProductionSealant Manufactur<strong>in</strong>gSpr<strong>in</strong>g Steel Manufactur<strong>in</strong>gWedge Anchors and LDT Anchors Manufactur<strong>in</strong>gTapcon Manufactur<strong>in</strong>gEZ Anchor Manufactur<strong>in</strong>gOxford, MSPontotoc, MSRockland, MAAddison, ILMichigan City, INItasca, ILElk Grove Village, IL10/12The follow<strong>in</strong>g is a sampl<strong>in</strong>g of government projects that haveutilized <strong>the</strong> Buy American Act us<strong>in</strong>g <strong>Ramset</strong> products:• Aberdeen Prov<strong>in</strong>g Grounds Project C4 (9 build<strong>in</strong>gs)• Fort Belvoir Hospital (6 build<strong>in</strong>gs)• Fort Bragg• Fort Detrick Department of Army Vacancies Serviced• Fort Meade (6 build<strong>in</strong>gs)• National Maritime Intelligent Center• Norfolk Naval Basewww.ramset.com5

<strong>in</strong>tro to gas technologyITW saw a challenge: how to create a portable tool that delivered<strong>the</strong> power of pneumatic tools without <strong>the</strong> hoses and compressors. In1991, ITW Paslode conquered <strong>the</strong> challenge with <strong>the</strong> revolution of gaspoweredtechnology. The cordless Impulse F<strong>in</strong>ish Nailer delivered <strong>the</strong>power of pneumatic tools without clutter<strong>in</strong>g job sites.With <strong>the</strong> thought of Driv<strong>in</strong>g Jobsite Speed while creat<strong>in</strong>g a safer workenvironment, ITW <strong>Ramset</strong> built upon <strong>the</strong> Paslode technology and <strong>in</strong>1992 <strong>in</strong>troduced <strong>the</strong> TrakFast to <strong>the</strong> drywall trade. It forever changed<strong>the</strong> way <strong>the</strong> world worked. In 2003, ITW <strong>Ramset</strong> followed up on <strong>the</strong>success of <strong>the</strong> TrakFast with <strong>the</strong> T3SS which is sett<strong>in</strong>g <strong>the</strong> standardfor electrical and mechanical contractors.Gas significantly lowers cost-<strong>in</strong>-place, reduces stress on <strong>the</strong> employee,and it's much quieter to use than drill<strong>in</strong>g or powder actuated tools(PATs), so you can work <strong>in</strong> occupied build<strong>in</strong>gs. There are times whenyou need <strong>the</strong> power and accuracy of our PATs—like <strong>the</strong> speed of ourD45A disc tool, or <strong>the</strong> work horse, nearly ma<strong>in</strong>tenance-free 721 s<strong>in</strong>gleshot PAT. But constant use of <strong>the</strong>se tools can be noisy and overly jarr<strong>in</strong>gon <strong>the</strong> body.• No Licens<strong>in</strong>g Required• Fast and Easy to Use• Quiet—No Recoil• No Cords or Hoses• Long Fuel Cell & Battery LifeDrywall Electrical MechanicalWhen <strong>the</strong> conditions are right, gas is <strong>the</strong> right choice.Problem:“My guys work on block all day long—from electricalboxes to furr<strong>in</strong>g. I've tried powder tools and <strong>the</strong>yblow holes <strong>in</strong> block. What makes <strong>the</strong> <strong>Ramset</strong>technology different?"Solution:<strong>Ramset</strong> technology has patentedoverdrive technology built <strong>in</strong> toevery gas-powered tool. The tool works under<strong>the</strong> same pr<strong>in</strong>cipal as a combustion eng<strong>in</strong>e. Alittle gas, a little spark and a powerful shot,without <strong>the</strong> recoil associated with powder.The <strong>in</strong>dustry transitions to gas technologyProblem:“I don’t want to have to re-license my guys towork with gas technology"Solution:S<strong>in</strong>ce <strong>the</strong>re are no loads, <strong>the</strong>re's no licens<strong>in</strong>g needed.In fact, Union Tra<strong>in</strong>ers have begun <strong>in</strong>clud<strong>in</strong>g <strong>the</strong> <strong>Ramset</strong>Gas Tools <strong>in</strong> tra<strong>in</strong><strong>in</strong>g classes, and students can't believehow easy <strong>the</strong> tools are to work with.In addition, <strong>the</strong> gas powered tools are totallyportable and can be used for almost all yourjobs—without <strong>the</strong> worry of hav<strong>in</strong>g unspent loadson your jobsite.The Inside StorySPARK PLUGSteelPowderAlwaysThe patented <strong>Ramset</strong> technology deliversprecisely balanced power elim<strong>in</strong>at<strong>in</strong>g <strong>the</strong>damage caused by overdrive <strong>in</strong> PATs.FUEL PORTHigh PSI concreteMedium PSI concreteLow PSI concretePan deckGrout filled blocksubstrate materialGas PreferredGasdaily shot frequencyLow Medium High Very highHow it works: As <strong>the</strong> nosepiece is depressed,a rechargeable battery turns on <strong>the</strong> fanmotor. In less than a second: a preciseamount of fuel is <strong>in</strong>jected <strong>in</strong>to <strong>the</strong> combustionchamber. When <strong>the</strong> trigger is pulled, aspark creates an explosion that drives <strong>the</strong>piston <strong>in</strong>to <strong>the</strong> fastener, and <strong>the</strong> fastener<strong>in</strong> <strong>the</strong> work surface. The action creates avacuum that pulls <strong>the</strong> piston back to <strong>the</strong>start position.In fact <strong>the</strong> technology is so precise it won'tblow through a pop can.FAN MOTORCOMBUSTIONCHAMBERPISTONASSEMBLYCYLINDER6 www.ramset.com

SUGGESTED SPECIFICATIONS<strong>Ramset</strong> provides <strong>the</strong> architect andeng<strong>in</strong>eer <strong>the</strong> follow<strong>in</strong>g suggestedlanguage and helpful <strong>in</strong>formation for<strong>the</strong> purpose of fasten<strong>in</strong>g specifications.Plywood to Metal Fram<strong>in</strong>gor TrussPart Number PLY138Fasteners used shall have a 0.100nom<strong>in</strong>al shank diameter with helical knurland a length of 1-3/8-<strong>in</strong>ches.Track or Clip to Steel BeamPart Number 1503K (pg.35)Fasteners used shall have a 0.300head with a 0.145 knurled shankdiameter and a length of 1/2-<strong>in</strong>ches.Part Number TE12 (pg.37)Fasteners used shall have a 0.320 headwith a 0.157 knurled shank diameterand a length of .545 <strong>in</strong>ches.Part Number TE100 (pg.37)Fasteners shall be designated “TrueEmbedment” type with a 0.320 headwith a 0.157 shank and length of 1.0625provid<strong>in</strong>g m<strong>in</strong>imum of 1” of embedment<strong>in</strong> up to 14ga track. Fastener shall have<strong>the</strong> embedment depth of 1” stampedon head.Interior Partition Track toConcretePart Number T3034B (pg.29)Fasteners shall be designated T3 Typewith a 0.125 nom<strong>in</strong>al shank diameterand a length of 3/4 <strong>in</strong>ch.Exterior Sheath<strong>in</strong>gto Metal StudPart Number GF112 (pg.31)Fasteners designated“GYPFAST" and have ahelical knurled shankwith a 1-1/2" LengthExterior PerimeterTrack to ConcretePart Number 1510SD (pg.35)Fasteners used shall havea 0.145 nom<strong>in</strong>al shankdiameter and a lengthof 1-1/4 <strong>in</strong>ches. Thefastener shall have apre-assembled 7/8-<strong>in</strong>chwasher.Part Number SP114 (pg.36)Fasteners used shall bedesignated PowerPo<strong>in</strong>ttype with a 0.150/.180 steppedshank and a length of 1-1/4<strong>in</strong>ches.For assistance with specifications and/or substitutions, contact Technical Service at 800-726-7386.www.ramset.com7

Fasteners – how <strong>the</strong>y workSelect<strong>in</strong>g <strong>the</strong> correct fastener lengthSelect<strong>in</strong>g <strong>the</strong> correct fastener lengthHigh quality fasteners provide consistent andreliable performance <strong>in</strong> concrete, block, masonry,and steel applications. Choos<strong>in</strong>g <strong>the</strong> correct fastenerfor <strong>the</strong> job will assure professional results.A Determ<strong>in</strong>e thickness of material be<strong>in</strong>g attached.b Fastener must be long enough to driveapproximately 1" <strong>in</strong>to concrete, cement block orpenetrate thickness of steel.Power level guide for loadsAll loads are color coded and load levelnumbered. As <strong>the</strong> number <strong>in</strong>creases, <strong>the</strong>power level <strong>in</strong>creases.Always start with <strong>the</strong> lightest load. If <strong>the</strong>fastener does not set completely, use <strong>the</strong>next higher load and repeat <strong>the</strong> process.2 ...Brown3 ...Green4 ...Yellow5 ...RedLeastPowerfulMostPowerfulTypical USESWOOD attachmentMATERIAL*Concrete base materialCommonly UsedFastenerCommonly UsedLoad2 x 4 1516SDC (2-1/2") Yellow #4Commonly UsedFastener1514SD (2")SP178 (1-7/8")Structural steel baseCommonly UsedLoadRed #5Red #53/4" Plywood for furr<strong>in</strong>g strip 1512 (1-1/2") Yellow #4 1510 (1-1/4") Yellow #41/4" - 1/2" 1510 (1-1/4") Green #3 SP34 (3/4") Yellow #4* Use Ramguard P<strong>in</strong> for treated lumber.THIN GAGE STEEL Concrete base material Structural steel baseCommonly UsedFastenerCommonly UsedLoadCommonly UsedFastenerCommonly UsedLoadElectrical Junction Boxes M100BB (1") Green #3 SP58TH (5/8") Yellow #4Shelf Brackets M100BB (1") Green #3 SP34 (3/4") Yellow #4Interior Drywall Track 1506B (3/4") Brown #2 SP12 (1/2") Yellow #4Perimeter Track 1510 (1-1/4") Yellow #4 SP12 (1/2") Yellow #4NOTE: This chart is presented as a guide only. Start with <strong>the</strong> lightest load. If <strong>the</strong> fastener does not set completely, use <strong>the</strong> next higher load and repeat <strong>the</strong> process.Product suggestions may not be suitable for all types of base materials. Contact Technical Services if you have fur<strong>the</strong>r questions.8 www.ramset.com

Fasteners – how <strong>the</strong>y workDescriptionFasten<strong>in</strong>g to concreteAs <strong>the</strong> fastener enters <strong>the</strong> concrete, extreme pressures and heat are created.This creates a bond that provides high load<strong>in</strong>g strength <strong>in</strong> concrete snuglyand provides tool protection.Fasten<strong>in</strong>g to steelThe resilience of steel provides a clamp<strong>in</strong>g effect to <strong>the</strong>fastener. This comb<strong>in</strong>ed with <strong>the</strong> tremendous heat that iscreated, provides a weld<strong>in</strong>g and clamp<strong>in</strong>g effect to givemaximum hold<strong>in</strong>g power.Fasten<strong>in</strong>g placement and penetrationThe follow<strong>in</strong>g represents <strong>the</strong> m<strong>in</strong>imum edge and spac<strong>in</strong>g requirements, plus base material thickness requirements:Concrete1. Edge distance. Do not fasten closer than 3 <strong>in</strong>ches from <strong>the</strong> edge of concrete. If <strong>the</strong>concrete cracks, <strong>the</strong> fastener may not hold and may allow <strong>the</strong> fastener to ricochet,caus<strong>in</strong>g serious <strong>in</strong>jury or death to <strong>the</strong> operator or bystanders.2. Recommended m<strong>in</strong>imum fastener spac<strong>in</strong>g. Sett<strong>in</strong>g fasteners too close toge<strong>the</strong>rcan cause <strong>the</strong> concrete to crack. The recommended MINIMUM DISTANCE betweenfasten<strong>in</strong>g is three (3) <strong>in</strong>ches. Never attempt a fastener application too close to ano<strong>the</strong>rpreviously <strong>in</strong>serted fastener to prevent <strong>the</strong> second fastener from ricochet<strong>in</strong>g off <strong>the</strong>previously <strong>in</strong>stalled fastener. A ricochet can result <strong>in</strong> serious <strong>in</strong>jury or death to <strong>the</strong>operator or bystanders.3. Concrete thickness. It is important that <strong>the</strong> concrete be at least three (3) times asthick as <strong>the</strong> fastener penetration. If <strong>the</strong> concrete is too th<strong>in</strong>, <strong>the</strong> compressive forcesform<strong>in</strong>g at <strong>the</strong> fastener’s po<strong>in</strong>t can cause <strong>the</strong> free face of <strong>the</strong> concrete to break away.This creates a dangerous condition from fly<strong>in</strong>g concrete and/or <strong>the</strong> fastener and alsoresults <strong>in</strong> a reduction of fastener hold<strong>in</strong>g power.Steel1. Edge distance. The recommended edge distance for afastener to <strong>the</strong> edge of steel is 1/2 <strong>in</strong>ch. Never fire <strong>the</strong>tool with<strong>in</strong> 1/2 <strong>in</strong>ch of <strong>the</strong> edge of a steel base materialbecause <strong>the</strong> steel may bend or break off, allow<strong>in</strong>g <strong>the</strong>fastener to ricochet, caus<strong>in</strong>g serious <strong>in</strong>jury or death to <strong>the</strong>operator or bystanders.2. Recommended m<strong>in</strong>imum fastener spac<strong>in</strong>g. Therecommended m<strong>in</strong>imum distance between fasten<strong>in</strong>g is1 <strong>in</strong>ch. Never attempt a fasten<strong>in</strong>g application too close toano<strong>the</strong>r previously <strong>in</strong>serted fastener to prevent <strong>the</strong> second fastener from ricochet<strong>in</strong>goff <strong>the</strong> previously <strong>in</strong>stalled fastener. A ricochet can result <strong>in</strong> serious <strong>in</strong>jury or death to<strong>the</strong> operator or bystanders.3. Steel thickness. Do not fasten <strong>in</strong>to steel base material th<strong>in</strong>ner than <strong>the</strong> fastener shankdiameter. Hold<strong>in</strong>g power will be reduced and <strong>the</strong> fastener may be over-driven, creat<strong>in</strong>ga dangerous situation to <strong>the</strong> operator or bystanders due to a free-fly<strong>in</strong>g fastener.How to select a powder actuated fastener• Drive p<strong>in</strong>s are used to directly fasten an object (permanent <strong>in</strong>stallation).• Threaded studs are used where <strong>the</strong> object fastened is to be removed or where shimm<strong>in</strong>g is required. The follow<strong>in</strong>g shows how to determ<strong>in</strong>e shankand thread length. Required penetration is determ<strong>in</strong>ed by load requirement (illustrated <strong>in</strong> <strong>the</strong> follow<strong>in</strong>g examples).<strong>Ramset</strong> fasteners may be specified by <strong>the</strong>ir type or catalog number to satisfy fasten<strong>in</strong>g requirements.Permanent InstallationTo ConcreteRemovable InstallationTo ConcreteThread Thickness Allowance*Length = of Material + For Nut(A) (M) & WasherM<strong>in</strong>imum Thickness RequiredShank = of Material + PenetrationLength (M) (P)To SteelM<strong>in</strong>imum Thickness Thickness 1/4 M<strong>in</strong>.Shank = of Material + of Steel + Po<strong>in</strong>tLength (M) (T) AllowanceTo SteelShank Length = 1"*Allowance for thickness of nut & washer = threadsize (i.e. allow 1/4" for 1/4-20 thread, etc.)Thread Thickness Allowance*Length = of Material + For Nut(A) (M) & WasherShank Length = 1/2"www.ramset.com9

What is LEED?<strong>Ramset</strong> LEED Credit MR 5.1LEED CreditsThe purpose of Leadership <strong>in</strong> Energy and Environmental Design (LEED) is to construct build<strong>in</strong>gs <strong>in</strong> an energyefficient manner and reduce <strong>the</strong> build<strong>in</strong>gs’ energy consumption. As a result, <strong>the</strong>se build<strong>in</strong>gs can help conservenon-renewable energy resources; decrease dependence on foreign oil; and lower greenhouse gas emissions.MR 5.1 was developed with <strong>the</strong> <strong>in</strong>tent to <strong>in</strong>crease demand for build<strong>in</strong>g materials and products that are extracted andmanufactured with<strong>in</strong> <strong>the</strong> region, <strong>the</strong>reby support<strong>in</strong>g <strong>the</strong> use of <strong>in</strong>digenous resources and reduc<strong>in</strong>g <strong>the</strong> environmentalimpact result<strong>in</strong>g from transportation.<strong>Ramset</strong>’s p<strong>in</strong>s, sealants, spr<strong>in</strong>g steel products, electrical accessories and anchors may meet <strong>the</strong> requirements for LEEDMR 5.1 if your project falls with<strong>in</strong> 500 miles of ourmanufactur<strong>in</strong>g facilities.How to calculate LEED MR 5.1LEED MR Credit 5.1 is calculated on a 500 mile radius from/todistribution po<strong>in</strong>ts. Use Google Maps to calculate <strong>the</strong> distance toyour project from:Addison, IL (60101) Spr<strong>in</strong>g SteelElk Grove Village, IL (60007) EZ AnchorItasca, IL (60143)Tapcon/GypFast & FastenersMichigan City, IN (46360)Wedge AnchorsLDT AnchorsRockland, MA (02370)SealantLocation Zip Code ProductAddison, IL 60101 Spr<strong>in</strong>g SteelElk Grove Village, IL 60007 EZ AnchorItasca, IL 60143 Tapcon/GypFast & FastenersMichigan City, IN 46360 Wedge & LDT AnchorsParis, KY 40361 Powder & Gas FastenersParis, KY (40361)Powder & Gas FastenersRecycl<strong>in</strong>g<strong>Ramset</strong> Recycles<strong>Ramset</strong> has always recognized <strong>the</strong> value of utiliz<strong>in</strong>g recycled materialswhere available.The raw material sourced for <strong>the</strong> manufacture of <strong>Ramset</strong> p<strong>in</strong>s conta<strong>in</strong>sapproximately 10-20% mill scrap when it is converted to wire material. The plasticand cas<strong>in</strong>g material <strong>in</strong> our loads typically consists of 10% recycled material.Our packag<strong>in</strong>g also conta<strong>in</strong>s post-consumer recycled material. The paper board(<strong>in</strong>ner cartons) conta<strong>in</strong>ers are typically made from 40% recycled material;corrugated cartons typically conta<strong>in</strong> 30-35% recycled material.<strong>Ramset</strong> has also <strong>in</strong>stituted a recycl<strong>in</strong>g program at its Glendale Heights facility for<strong>the</strong> batteries used <strong>in</strong> its gas powered tools.10 www.ramset.com

Selection GuideTooL DESCRIPTIoN TYPICAL build<strong>in</strong>g trade*T3MAGn 45-P<strong>in</strong> Magaz<strong>in</strong>en <strong>One</strong> Step Fuel Injection & Ejectn Fully Automaticn 2 Year Warranty or 50,000 shotsn Length: 18-1/2"n Height: 15"n Weight: 9.2 lbs.n Maximum P<strong>in</strong> Length: 1"Walls & Ceil<strong>in</strong>gsGas Powered ToolsTRAKFAST TF1200n 42 P<strong>in</strong> Magaz<strong>in</strong>en Fully Automaticn 2 Year WarrantyT3SSn S<strong>in</strong>gle Shot Gas Tooln <strong>One</strong> Step Fuel Injection & Ejectn 2 Year Warrantyn Length: 17.5"n Height: 15-1/2"n Weight: 7.9 lbs.n Maximum P<strong>in</strong> Length: 1-1/2"n Length: 13-1/2"n Height: 15"n Weight: 7.0 lbs.n Maximum P<strong>in</strong> Length: 1-1/2"Walls & Ceil<strong>in</strong>gsElectrical/MechanicalGYPFAST G2n 150 P<strong>in</strong> Coiln Fully Automaticn 2 Year Warranty or 50,000 shotsn Length: 15"n Height: 15.25"n Weight: 7.6 lbs. (with battery)n Maximum P<strong>in</strong> Length: 2-1/2"Exterior sheath<strong>in</strong>g.22 cal s<strong>in</strong>gle shot721n S<strong>in</strong>gle Shotn 3 Year WarrantyMasterShotn S<strong>in</strong>gle Shotn 90 Day Year Warrantyn Length: 13-1/2"n Weight: 4.3 lbs.n Muzzle Bush<strong>in</strong>g O.D.: 5/8"n Maximum P<strong>in</strong> Length: 1-1/2"n Length: 15"n Weight: 4.4 lbs.n Muzzle Bush<strong>in</strong>g O.D.: 3/4"n Maximum P<strong>in</strong> Length: 3"Walls & Ceil<strong>in</strong>gsWood fram<strong>in</strong>g*Build<strong>in</strong>g trade shown as suggestions. Tools are not limited to <strong>the</strong>se trades.12 www.ramset.com

selection GuideTooL DESCRIPTIoN TYPICAL build<strong>in</strong>g trade*.25 cal stripR25n Semi-Automaticn 1 Year Warrantyn Length: 11.6'"n Weight: 4.3 lbs.n Muzzle Bush<strong>in</strong>g O.D.: 3/4"n Maximum P<strong>in</strong> Length: 1-1/2"Walls & Ceil<strong>in</strong>gs.25 cal disc toolsD45An Automatic Piston Returnn 3 Year WarrantyD60n Semi-Automaticn Power Adjustablen 3 Year Warrantyn Length: 15"n Weight: 4.5 lbs.n Muzzle Bush<strong>in</strong>g O.D.: 5/8"n Maximum P<strong>in</strong> Length: 2"n Length: 12-1/2"n Weight: 4.9 lbs.n Muzzle Bush<strong>in</strong>g O.D.: 3/4"n Maximum P<strong>in</strong> Length: 2-3/8"(2-1/2" w/Washer)Walls & Ceil<strong>in</strong>gsElectrical/MechanicalXT540n Automatic Piston Returnn Power Adjustn 3 Year Warrantyn Length: 19'"n Weight: 5.5 lbs.n Muzzle Bush<strong>in</strong>g O.D.: 7/8"n Maximum P<strong>in</strong> Length: 3"Walls & Ceil<strong>in</strong>gs.27 cal strip toolsSA270n Semi-Automaticn Power Adjustn 3 Year WarrantyCOBRAn Semi-Automaticn Economicaln 1 Year Warrantyn Length: 15.3'"n Weight: 5.45 lbs.n Muzzle Bush<strong>in</strong>g O.D.: 5/8"n Maximum P<strong>in</strong> Length: 3"n Length: 13-1/4'"n Weight: 4.5 lbs.n Muzzle Bush<strong>in</strong>g O.D.: 9/16"n Maximum P<strong>in</strong> Length: 2-1/2"(3" w/Washer)Wood fram<strong>in</strong>gWood fram<strong>in</strong>gVIPER IVn Automatic Piston Returnn Designed Specifically forOverhead Applicationsn 3 Year Warrantyn Length: 17'"n Weight: 4.5 lbs.n Maximum P<strong>in</strong> Length: 1-1/2"Acoustical/overhead*Build<strong>in</strong>g trade shown as suggestions. Tools are not limited to <strong>the</strong>se trades.www.ramset.com13

TO THIS BASE MaterialCONCRETESTEEL BEAM - 3/16" to 1/2" THICKFasten This MaterialINTERIOR NON-LOADBEARING DRYWALL TRACK25 - 20 GAGEEXTERIOR PERIMETERDRYWALL TRACK18 -12 GAGECLIPS or BRACKETS forSTEEL FRAMINGFASTENERLENGTH(<strong>in</strong>ches)3/4GASTOOLTF1200T3MAG1-1/4 N.R.1-1/4 N.R.2 x 4 , 2 x 6 LUMBER 2-1/2 N.R.1/2" PLYWOOD 1-1/4 N.R.POWDERTOOLR25POWDER LOAD#3 GRN .25cal STRIPFASTENERLENGTH(<strong>in</strong>ches)GASTOOLPOWDERTOOLPOWDER LOADD45A #2 BRN .25cal DISC TF1200 D45A #4 YEL .25cal DISC1/2721 #2 BRN .22cal SINGLE T3MAG 721 #4 YEL .22cal SINGLER25#4 YEL .25cal STRIPSA270 #3 GRN .27cal STRIP SA270 #4 YEL .27cal STRIPSA270#4 YEL .27cal STRIPSA270#4 YEL .27cal STRIPXT540 #4 YEL .27cal STRIP XT540 #4 YEL .27cal STRIP1/2 N.R.D45A #4 YEL .25cal DISC D45A #4 YEL .25cal DISCCOBRA #4 YEL .27cal STRIP COBRA #4 YEL .27cal STRIPSA270#4 YEL .27cal STRIPSA270#4 YEL .27cal STRIPXT540 #4 YEL .27cal STRIP XT540 #4 YEL .27cal STRIP1/2 N.R.D45A #4 YEL .25cal DISC D45A #4 YEL .25cal DISCCOBRA #4 YEL .27cal STRIP COBRA #4 YEL .27cal STRIPSA270#4 YEL .27cal STRIPSA270#4 YEL .27cal STRIPXT540 #4 YEL .27cal STRIP XT540 #4 YEL .27cal STRIP1-7/8 N.R.COBRA #5 RED .27cal STRIP COBRA #5 RED .27cal STRIPMasterShot #4 YEL .22cal SINGLE MasterShot #4 YEL .25cal DISCSA270#4 YEL .27cal STRIPSA270#4 YEL .27cal STRIPCOBRA #4 YEL .27cal STRIP COBRA #4 YEL .27cal STRIPD45A #4 YEL .25cal DISC1 N.R.D45A #4 YEL .25cal DISCXT540 #4 YEL .27cal STRIP XT540 #4 YEL .27cal STRIP3/4" PLYWOOD1 x 4, 1 x 6 WOOD1-1/2 N.R.SA270 #4 YEL .27cal STRIPSA270 #4 YEL .27cal STRIPCOBRA #4 YEL .27cal STRIP COBRA #4 YEL .27cal STRIP1-1/4 N.R.D45A #4 YEL .25cal DISC D45A #4 YEL .25cal DISCXT540 #4 YEL .27cal STRIP XT540 #4 YEL .27cal STRIP1/2" or 5/8" GYPSUMSHEATHING- N.R. N.R. - N.R. N.R.NOTES:1) This chart is presented as a guide only. Start with <strong>the</strong> lightest load available. If <strong>the</strong> fastener does not completely set, use <strong>the</strong> next higher load and repeat <strong>the</strong> process.2) Product suggestions may not be suitable for all types of base materials.3) N.R. is Not Recommended14 www.ramset.com

POWDER FASTENER &LOAD SELECTION CHARTCONCRETE BLOCK MORTAR JOINT (horizontal only) LIGHT GAGE STEEL 18-12gageFASTENERLENGTH(<strong>in</strong>ches)GASTOOLPOWDERTOOLPOWDER LOADFASTENERLENGTH(<strong>in</strong>ches)GASTOOLPOWDERTOOLPOWDER LOADFASTENERLENGTH(<strong>in</strong>ches)GASTOOLPOWDERTOOLPOWDERLOADR25#3 GRN .25cal STRIPR25#3 GRN .25cal STRIP1TF1200T3MAGD45A #2 BRN .25cal DISC TF1200 D45A #2 BRN .25cal DISC1721 #2 BRN .22cal SINGLE T3MAG 721 #2 BRN .22cal SINGLE- N.R. N.R.SA270 #2 BRN .27cal STRIP COBRA #3 GRN .27cal STRIPSA270#3 GRN .27cal STRIPSA270#3 GRN .27cal STRIP1TF1200T3MAGCOBRA #3 GRN .27cal STRIP TF1200 COBRA #3 GRN .27cal STRIP1D45A #2 BRN .25cal DISC T3MAG D45A #2 BRN .25cal DISC- N.R. N.R.R25 #3 GRN .25cal STRIP R25 #3 GRN .25cal STRIPSA270#3 GRN .27cal STRIPSA270#3 GRN .27cal STRIP1TF1200T3MAGXT540 #3 GRN .27cal STRIP TF1200 COBRA #3 GRN .27cal STRIP1D45A #2 BRN .25cal DISC T3MAG D45A #2 BRN .25cal DISC- N.R. N.R.721 #3 GRN .22cal SINGLE R25 #3 GRN .25cal STRIPSA270#4 YEL .27cal STRIPSA270#4 YEL .27cal STRIP2-1/2 N.R.XT540 #3 GRN .27cal STRIP XT540 #3 GRN .27cal STRIP2-1/2 N.R.COBRA #4 YEL .27cal STRIP COBRA #4 YEL .27cal STRIP- N.R. N.R.MasterShot #4 YEL .22cal SINGLE MasterShot #4 YEL .22cal SINGLESA270#3 GRN .27cal STRIPSA270#3 GRN .27cal STRIP1-1/2 TF1200COBRA #3 GRN .27cal STRIP COBRA #3 GRN .27cal STRIPD45A #3 GRN .25cal DISC1-1/2 TF1200D45A #3 GRN .25cal DISC1-1/2TF1200G2N.R.MasterShot #3 GRN .22cal SINGLE MasterShot #3 GRN .22cal SINGLESA270#3 GRN .27cal STRIPSA270#3 GRN .27cal STRIP2 N.R.COBRA #3 GRN .27cal STRIP COBRA #3 GRN .27cal STRIP2 N.R.D45A #3 GRN .25cal DISC D45A #3 GRN .25cal DISC1-1/2TF1200G2N.R.XT540 #4 YEL .27cal STRIP MasterShot #3 GRN .22cal SINGLE- N.R. N.R. - N.R. N.R. 1-1/2 G2 N.R.www.ramset.com15

GAS TECHNOLOGYT3MAG• Gas Technology• 45-P<strong>in</strong> Magaz<strong>in</strong>e• <strong>One</strong> Step Fuel Injection• 6 months or 10,000 shotson wearable parts• Length: 18-1/2"• Height: 15"• Weight: 9.2 lbs.• P<strong>in</strong> Guide O.D.: .590• Maximum P<strong>in</strong> Length: 1"ADVANTAGESMost common fastenersPIN #DESCRIPTIONT30121/2" steel p<strong>in</strong> with T3 fuel cellT3012S 1/2" premium steel p<strong>in</strong> with fuel cellT3034B 3/4" concrete p<strong>in</strong> with T3 fuel cellT3034S 3/4" step shank p<strong>in</strong> with T3 fuel cellT31001" concrete p<strong>in</strong> with T3 fuel cellFasteners on page 29.• Higher stick rate• 25% more power• Easy push down force• Deep leg track capacity• 45-p<strong>in</strong> magaz<strong>in</strong>e capabilityFEATURES• Fitted dust shieldT3MAG Increase Your Range withOverhead PowerThe Power of <strong>the</strong> T3MAG allows you toconsistently shoot where no o<strong>the</strong>r gas tool hasgone before. The .125 diameter p<strong>in</strong> is specificallyeng<strong>in</strong>eered to work <strong>in</strong> <strong>the</strong> toughest concrete andsteel where o<strong>the</strong>r p<strong>in</strong>s cannot perform. The newT3MAG system delivers power that rivals o<strong>the</strong>rgas and powder systems.• Battery charger provides constant charg<strong>in</strong>g even withlow voltage drops• 2 Year Warranty or 50,000 shots(6 months on wearable parts or 10,000 shots)• No License RequiredFuel cell and batteryT3 fuel cellPart No. T3FUELReplaces conventionalpowder loads and drivesmore than 1000 p<strong>in</strong>sFuel <strong>in</strong>jection meansno additional steps ofprepar<strong>in</strong>g a fuel cell.Click <strong>the</strong> fuel cell <strong>in</strong> placeand <strong>the</strong> tool is ready to go.Easy battery load<strong>in</strong>g. Battery restposition allows you to turn off <strong>the</strong>tool without fully remov<strong>in</strong>g <strong>the</strong>battery.Settl<strong>in</strong>g aggregate is<strong>the</strong> biggest reason foroverhead p<strong>in</strong> failure.With <strong>the</strong> T3’s 1/2 steel p<strong>in</strong>you can even shoot <strong>in</strong>to <strong>the</strong>web of steel.Part No. B0092The 6-volt Ni-Cd battery can drive morethan 3000 shots per chargeAPPLICATIONSThe T3 has enough power to fasten <strong>in</strong>to hard concrete and steel andstill will not blow through hollow block.Will not spall hollow block like powderactuated.Perfect for hat channel applications.16 www.ramset.com

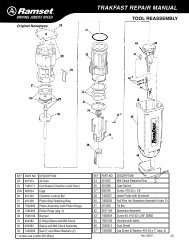

GAS TECHNOLOGYTRAKFAST TF1200• Gas Technology• Fully Automatic• 1-1/2" P<strong>in</strong> Capacity• 42 P<strong>in</strong> Magaz<strong>in</strong>e CapacityADVANTAGES• SPEED: Three to five times faster thanpowder tools. 42-p<strong>in</strong> magaz<strong>in</strong>e reducesload time.• Length: 17.5"• Height: 15"• EASY TO USE: Tool automatically resetspiston. No recoil, tool absorbs shockresult<strong>in</strong>g <strong>in</strong> less operator fatigue.• Weight: 8.3 lbs.• Maximum Capacity:42 p<strong>in</strong>s• NO LICENSING REQUIRED: Unlike powderactuatedtools, no licens<strong>in</strong>g is required.FEATURES• Maximum cycles/second: 2• Fuel cell: 1000 shots• Battery (charged):3000 shots• NO CHANGING LOADS: TrakFast uses afuel cell, not a load. No need to <strong>in</strong>ventorydifferent colored loads• NARROW NOSE & PROFILE: Allows toolto reach <strong>in</strong>side deep leg track (1-5/8"wide x 2" high).• 2 Year Warranty (6 months on wearableparts).Still <strong>the</strong> most revolutionary fasten<strong>in</strong>g system <strong>in</strong> <strong>the</strong>construction <strong>in</strong>dustry!S<strong>in</strong>ce its <strong>in</strong>troduction <strong>in</strong> 1991, TrakFast has been <strong>the</strong> tool of choice for both <strong>in</strong>terior andexterior contractors. The TrakFast Automatic Fasten<strong>in</strong>g System fastens all types of track,from standard track to hat channel, deep leg, Z, and J channel. Contractors cont<strong>in</strong>ue toreport tremendous sav<strong>in</strong>gs when us<strong>in</strong>g TrakFast for high production fasten<strong>in</strong>g. They havelearned that TrakFast’s actual cost <strong>in</strong> place beats all o<strong>the</strong>r systems. The <strong>in</strong>creased speedand productivity of TrakFast allows <strong>the</strong> contractor to bid more competitively, complete <strong>the</strong>job sooner and move on to <strong>the</strong> next job. Anyone can use TrakFast—just load <strong>the</strong> p<strong>in</strong>s andfire. It’s that easy!TrakFast ICC ESR-2579 is <strong>the</strong> only approval thatallows you to fasten <strong>in</strong>to any location on a hollowblock wall and won’t blow away block like apowder tool.Most common fastenersPIN #P<strong>in</strong> length Most common<strong>in</strong>. (MM) APPLICATIonFPP012S 1/2 12.7 Track to steelFPP034B 3/4 19.1 Track to concreteFasteners on page 29.APPLICATIONSTrakFast’s power comes from<strong>the</strong> battery and fuel cellThe 6-volt rechargeable Ni-CD batterycan drive approximately 3000 shotsper charge. The clean burn<strong>in</strong>g fuel cellcan drive over 1000 p<strong>in</strong>s and keeps<strong>the</strong> tool cleaner than powderactuated tools.Fasten<strong>in</strong>g System ProductivityIn <strong>the</strong> time it takes youto drive two p<strong>in</strong>s witha powder tool, you candrive up to 10 p<strong>in</strong>swith TrakFast!Track to steelLath attachment—us<strong>in</strong>gone-<strong>in</strong>ch TrakFast discs andmagnetic probe adapterFurr<strong>in</strong>g attachment—perfectfasten<strong>in</strong>g every time <strong>in</strong> softand hard base materialsPlywood attachment—us<strong>in</strong>g TrakFast plywood tosteel p<strong>in</strong>Track to concretewww.ramset.com17

GAS TECHNOLOGYT3SS• Gas Technology• S<strong>in</strong>gle P<strong>in</strong> Gas Tool• Fuel Injection• Cross Over Technology• 2 Year Warranty(6 months on wearableparts)• Length:13-1/2"• Height: 15"• Weight: 7.0 lbs.• P<strong>in</strong> Guide O.D.: 1/2"Standard, 7/8" Magnetic• Maximum P<strong>in</strong> Length:1-1/2"ADVANTAGES• Sets <strong>the</strong> standard for s<strong>in</strong>gle-shotapplications• 5 times faster than traditional drill andanchor methods• Replaces <strong>the</strong> need for tools like <strong>the</strong> DX35• Reduced operator fatigue• Reduced <strong>in</strong>stallation costs—up to 75%• Quiet enough to work <strong>in</strong> tenant occupiedbuild<strong>in</strong>gs• Removable rear foot• Interchange noseVERSATILE, fastens to solid concrete,hollow block, pan deck and steel.APPLICATIONSFEATURESCross<strong>in</strong>g over from powder to gas<strong>Ramset</strong> is serious when it comes to driv<strong>in</strong>g job speed bycreat<strong>in</strong>g <strong>the</strong> T3SS—<strong>the</strong> s<strong>in</strong>gle shot tool that will help movecontractors from powder to gas.The T3SS provides <strong>the</strong> benefits of shoot<strong>in</strong>g a gas tool,<strong>in</strong>clud<strong>in</strong>g reduced <strong>in</strong>stallation time and operator fatigue for<strong>the</strong> contractor who normally shoots a muzzle loadedpowder tool.No more f<strong>in</strong>es for unspent loadson <strong>the</strong> jobsite.To make <strong>the</strong> T3SS <strong>the</strong> most versatile gas tool <strong>in</strong> <strong>the</strong> <strong>in</strong>dustry,Users can change out nosepieces to accommodate any fasten<strong>in</strong>g need. From metal-to-concrete, hardconcrete or steel, pan deck, block and just about surface you can th<strong>in</strong>k of <strong>the</strong> T3SS works for you.Fastener and magnetic nosepieceThe optional <strong>in</strong>terchangeable nosepiece (Part NumberM150200) is able to shoot a variety of M series fasteners.Fuel cell and batteryT3 fuel cellPart No. T3FUELReplaces conventional powderloads and drives more than1000 p<strong>in</strong>s12HSMP034 clip assemblyused to secure conduitM034 fastener used to hangHVAC Duct StrapM100 fastener usedto attach a junctionboxEasy battery load<strong>in</strong>g.Battery rest positionallows you to turn off<strong>the</strong> tool without fullyremov<strong>in</strong>g <strong>the</strong> battery.T3 CupMost common fastenersPIN #Description12HSMP034 1/2" <strong>One</strong> hole strap with 3/4" p<strong>in</strong>MP034TH 3/4" Plated p<strong>in</strong> with top hatM1001" P<strong>in</strong> with gold domed washer14THRHMP034 1/4" Threaded rod hangerFasteners on page 32.Fuel <strong>in</strong>jection meansno additional steps of prepar<strong>in</strong>ga fuel cell. Click <strong>the</strong> fuel cell <strong>in</strong>place and <strong>the</strong> tool is ready to go.Part No. B0092The 6-volt Ni-Cd battery can drivemore than 3000 shots per charge18 www.ramset.com

GAS TECHNOLOGYGYPFAST G2• Part No.: GYPFAST• Fully Automatic• 2-1/2" P<strong>in</strong> Capacity• Length: 15"ADVANTAGES• Height: 15.25"• Weight: 7.6lbs.with battery• Lengths: 1-1/2", 2" and2-1/2"• Diameter: .140" Nom<strong>in</strong>al• Head Style: 5/16" dia.bugle head• F<strong>in</strong>ish: Climacoat Long LifePolymer• Exterior Gypsum sheath<strong>in</strong>g to steel fram<strong>in</strong>g• Plywood and OSB sheath<strong>in</strong>g/floor<strong>in</strong>g• Fiber cement panel attachment• Block<strong>in</strong>gFEATURES• Fully automatic system with 150 nailcapacity is 3-5 times faster than screw<strong>in</strong>g.• Fast set-up and tear down – <strong>in</strong>sert battery,fuel cell and nail coil – elim<strong>in</strong>ates need forextension cord, hoses and compressors.• Exterior walls• W<strong>in</strong>dows/door bucks• Specialty exterior sheath<strong>in</strong>g attachment• Woven wire mesh or expanded metal lathto steel fram<strong>in</strong>g• Long life Climacoat f<strong>in</strong>ish is 10 timesmore corrosion resistant than electro-z<strong>in</strong>cplat<strong>in</strong>g.• Woven wire mesh or expanded metal lathto steel fram<strong>in</strong>gFully Automatic Cordless Gas Fasten<strong>in</strong>gSystem for Attach<strong>in</strong>g Exterior Sheath<strong>in</strong>g toLight Gauge Steel Fram<strong>in</strong>gFuel cellPart No. TFUELBatteryPart No. B0092Magnetic Nose ProbePart No. 2761910• Aggressive, patented nail shank designprovides high pullout performance.• 2 year warranty• Contoured bugle head style provides highpullover (w<strong>in</strong>d) resistance.Most common fastenersFasteners on page 31..140" dia. knurled shankPIN # 5/16" dia. bugle head Master carton Application<strong>in</strong>. (MM)GF100 1 25.4 4,800 nails/ctn (48 - 100Metal to Metal Attachmentct. coils) 5 fuel cellsGF112 1-1/2 38.1 6,000 nails/ctn (40- 150ct. coils) 6 fuel cellsGF200 2 50.8 4,800 nails/ctn (32 - 150ct. coils) 5 fuel cellsGF212 2-1/2 63.5 2,700 nails/ctn (18 - 150ct. coils) 3 fuel cellsS<strong>in</strong>gle Layer of Exterior Sheath<strong>in</strong>g, WoodFurr<strong>in</strong>g and Block<strong>in</strong>gDouble Layer of Exterior GypsumSheath<strong>in</strong>g, Wood Furr<strong>in</strong>g and Block<strong>in</strong>gMulti-Layers of Sheath<strong>in</strong>g, Wood Block<strong>in</strong>g,and Dimensional LumberAPPLICATIONSPlated 1" Lath<strong>in</strong>g DiscPart No. LD100Plated 1-1/4" Lath<strong>in</strong>gDisc Part No. LD114Exterior Gypsum sheath<strong>in</strong>g to steel fram<strong>in</strong>g, Plywood and OSB sheath<strong>in</strong>g/floor<strong>in</strong>g, Fiber cementpanel attachment, Block<strong>in</strong>g Exterior walls, W<strong>in</strong>dows/door bucks, Specialty exterior sheath<strong>in</strong>gattachment, Woven wire mesh or expanded metal lath to steel fram<strong>in</strong>g.OSB and plywood to iSPAN joistswww.ramset.com19

Powder fasten<strong>in</strong>gOver a half century of leadership <strong>in</strong> powder actuated tools and fastenersThe first powder actuated tools (PATs) were used for repair<strong>in</strong>g damaged shiphulls dur<strong>in</strong>g World War I. This application cont<strong>in</strong>ued through World War II, when<strong>the</strong> son of <strong>the</strong> orig<strong>in</strong>al <strong>in</strong>ventor, Stanley Temple, developed and implemented <strong>the</strong>technology for commercial use. In 1947, <strong>the</strong> "Tempotool" was <strong>in</strong>troduced to <strong>the</strong>construction <strong>in</strong>dustry.<strong>Ramset</strong> Fasteners was founded <strong>in</strong> 1948 to handle distribution and sales for<strong>the</strong> construction trades. In 1949, <strong>Ramset</strong>’s accredited Operator Program wasofficially launched. Today this highly successful tra<strong>in</strong><strong>in</strong>g program has <strong>in</strong>structedover 1,000,000 trades people <strong>in</strong> <strong>the</strong> safe use of PATs.Onl<strong>in</strong>e Powder Tra<strong>in</strong><strong>in</strong>g and CertificationOnly properly tra<strong>in</strong>ed and licensed operators are described <strong>in</strong> ANSI Standard A10.3 and/or local regulations may operate powder actuated tools. ITW <strong>Ramset</strong>distributors offer complete tra<strong>in</strong><strong>in</strong>g programs for end users. Contact your local<strong>Ramset</strong> distributor for complete details.<strong>Ramset</strong> has designed and eng<strong>in</strong>eered <strong>the</strong> right powder actuated tool (PAT)for your applications. To ensure you use a PAT correctly, please take <strong>the</strong> timeto review <strong>the</strong> Operator’s Safety and Operat<strong>in</strong>g Instruction Manual packagedwith each tool. These manuals are also available for download on <strong>the</strong><strong>Ramset</strong> website.To ensure safety on <strong>the</strong> jobsite, OSHA and ANSI require that all PAT users becometra<strong>in</strong>ed and certified for <strong>the</strong> particular tool be<strong>in</strong>g used. <strong>One</strong> way <strong>Ramset</strong> enablesyou to receive this tra<strong>in</strong><strong>in</strong>g is through our website tra<strong>in</strong><strong>in</strong>g program. This <strong>in</strong>novativeapproach to education comb<strong>in</strong>es <strong>in</strong>teractive web-based tra<strong>in</strong><strong>in</strong>g techniques andonl<strong>in</strong>e test<strong>in</strong>g with immediate feedback to provide you a rich learn<strong>in</strong>g environment.The course consists of approximately 30 pages of usage, safety and troubleshoot<strong>in</strong>gmaterial.Upon completion of this brief course you can take an onl<strong>in</strong>e exam. Withsuccessful completion of <strong>the</strong> exam, you can pr<strong>in</strong>t a certification card.As an <strong>in</strong>dustry leader <strong>in</strong> powder actuated fasten<strong>in</strong>g systems, <strong>Ramset</strong>cont<strong>in</strong>ues to provide <strong>the</strong> most effective and comprehensive <strong>in</strong>structor andoperator tra<strong>in</strong><strong>in</strong>g programs available.Today, <strong>Ramset</strong> cont<strong>in</strong>ues to br<strong>in</strong>g <strong>the</strong> <strong>in</strong>dustry <strong>the</strong> products, service and<strong>in</strong>novation that <strong>the</strong>y have come to expect from <strong>the</strong> leader <strong>in</strong> powder fasten<strong>in</strong>g.All geared to help contractors do <strong>the</strong>ir job faster, more safely and moreproductively.www.ramset.comR25• .25 Caliber Strip Tool• Semi-Automatic• .25 Caliber Strip Loads:3 (Green), 4 (Yellow), 5 (Red)• Weight: 4.3 lbs.ADVANTAGES• Rugged metal hous<strong>in</strong>g• Rubber cushion grip• Length: 11.6"• Maximum P<strong>in</strong> Length: 1-1/2"• 1 Year Warranty• Popular drywall track tool• 1 Year WarrantyMost common fastenersPIN #Shank LengthIN. (MM)Most common application1506B 3/4 19.0 Track to concreteSP58TH 5/8 15.9 Track to steelFasteners start on page 34.COMMON REPLACEMENT PARTS• SC325207A Piston Assembly• SC301011A Shear Clip (Pkg of 3)• SC306010 Fastener Guide• SC326009 Front Barrel/Baseplate20 www.ramset.com

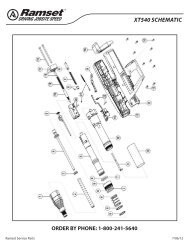

.27 caliber strip TOOLSXT540The most powerful tool <strong>in</strong> its classThe <strong>Ramset</strong> XT540 was specifically designed for <strong>the</strong> commercial framer for heavy-duty <strong>in</strong>terior& exterior applications. The XT540's comb<strong>in</strong>ation of high power and durability make it perfect for<strong>the</strong>se applications:• Driv<strong>in</strong>g 1-1/4” embedment for perimeter track• Fasten<strong>in</strong>g track & clips to structural steel• Track to hard concrete• Excellent compliment to your <strong>Ramset</strong> TrakFast programFeatures• .27 Caliber Strip Tool• Automatic Piston Return• Power Adjust• 3" P<strong>in</strong> Capacity• 3 Year Warranty• Length: 19"• .27 Caliber Strip Loads: • Muzzle Bush<strong>in</strong>g O.D.: 7/8"3 (Green), 4 (Yellow), 5 (Red)• Weight: 7.25 lbs.Durable, Reliable, Powerful, AutomaticADVANTAGES• Very Powerful• Spr<strong>in</strong>g return front end—no manual resett<strong>in</strong>g of <strong>the</strong> piston• Power adjust—dial down 2 full load levels• Rugged soft grip handle• Trigger lock & hand guard to <strong>in</strong>crease safety• Low recoil• Ergonomically balanced• Works with Magnetic Muzzle (Part# 100227)& Lath<strong>in</strong>g DiscsMost common fastenersPIN #Shank LengthIN.(MM)Most common applicationSP58TH 5/8 15.9 Track to steelSP34 3/4 19.1 Track to concreteM100BB 1 25.4 Track to concreteSP114 1-1/4 31.8 Track to concreteWorks with TE (True Embedment) P<strong>in</strong>sFasteners start on page 34.COMMON REPLACEMENT PARTS• PA37037 Piston• 100167 Piston Return Spr<strong>in</strong>g#XTMAGwww.ramset.com21

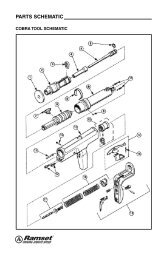

.27 caliber strip TOOLSSA270• .27 Caliber Strip Tool• Semi-Automatic• Power Adjust• .27 caliber 10-shot striploads: 3 (Green),4 (Yellow), 5 (Red)• Weight: 5.45 lbs.• Length: 15.3"• Muzzle Bush<strong>in</strong>g O.D.: 5/8"• Maximum P<strong>in</strong> Length:3" straight p<strong>in</strong>• 3 Year WarrantyADVANTAGES• Very Powerful• Excellent balance—easy to use all day long• Rubber grip on front barrel—elim<strong>in</strong>ates p<strong>in</strong>ched f<strong>in</strong>gers and hands• Twist lock front end—easy to clean• Rugged polyamide hous<strong>in</strong>g—reduces heattransfer and maximizes operator comfort• Soft, recoil-absorb<strong>in</strong>g handle—for <strong>in</strong>creased operator comfortMost common fastenersPIN #Shank LengthIN. (MM)Most common application1516SDC (washered) 2-1/2 63.5 2" x 4" to concrete1524SDP(washered) 3 76.2 2" x 4" to concreteSP58TH 5/8 15.9 Track to steelFasteners start on page 34.COMMON REPLACEMENT PARTS• 27833 Piston with R<strong>in</strong>gCobra• .27 Caliber Strip Tool• Semi-Automatic• Economical• .27 caliber 10-shot striploads: 3 (Green), 4 (Yellow),5 (Red)• Weight: 4.5 lbs.• Length: 13-1/4"• Muzzle Bush<strong>in</strong>g O.D.: 9/16"• Maximum P<strong>in</strong> Length:2-1/2" (3" w/washer)ADVANTAGES• Semi-automatic .27-caliber tool —uses strip loads• Padded recoil-absorb<strong>in</strong>g handle—for greater operator comfort• Fastens up to 3" standard <strong>Ramset</strong> drivep<strong>in</strong>s and threaded studs—ideal forgeneral construction applications• Full one-year warrantyMost common fastenersPIN #Shank LengthIN. (MM)Most common application1524SDP (washered) 3 76.2 2" x 4" concrete1524SDC (washered) 2-1/2 63.5 2" x 4" concrete1506B 3/4 19.1 Drywall track to concreteFasteners start on page 34.COMMON REPLACEMENT PARTS• SC301200A Piston and R<strong>in</strong>g• SC301012 Pawl (stop)22 www.ramset.com

.27 caliber strip TOOLSViper IV• .27 Caliber Strip Tool• Semi-Automatic• Designed Specifically forOverhead ApplicationsADVANTAGES• 3 Year Warranty• Automatic load advance: Load is advancedconsistently each time <strong>the</strong> Viper is fired.• Automatic Piston return: No time spentmanually resett<strong>in</strong>g or cycl<strong>in</strong>g <strong>the</strong> tool. Allowsyou to work faster.• Overdrive Protection: Heavy duty buffersystem prevents front end damage causedby piston overdrive —especially throughsprayed-on <strong>in</strong>sulation.• Open Front-end design: <strong>Complete</strong>lyredesigned open-ended muzzle keeps yourtool cleaner longer.• .27 caliber 10-shot striploads: 3 (Green), 4 (Yellow),5 (Red)• Weight: 4.9 lbs.• Length: 17.25"• Maximum P<strong>in</strong> Length:1-1/2"• Simplified Barrel Retention Collar: No toolsare required for assembly or disassembly.• Stable Steel Collar: The Viper screwssecurely <strong>in</strong>to <strong>the</strong> end of <strong>the</strong> extensionpole with <strong>the</strong> steel collar ensur<strong>in</strong>g a moredurable and rigid connection.• Uses exist<strong>in</strong>g Viper pole system: Works with<strong>the</strong> exist<strong>in</strong>g family of durable <strong>Ramset</strong> poles.FASTENERSTOOL/POLE CONNECTIONThe new poles have an <strong>in</strong>ternal rod, whenactivated by push<strong>in</strong>g on <strong>the</strong> pole sleevetriggers <strong>the</strong> new Viper.PARTNUMBERDESCRIPTIONV4-3 3' PoleV4-6 6' PoleV4-8 8' PoleV4-EXT3' Extension (no trigger)*Telescop<strong>in</strong>g poles are NOT available for <strong>the</strong> VIPER4.Most common fastenersShank LengthPIN #<strong>in</strong>. (MM)Most commonAPPLICATIon14TRHSS10 1 25.4 Threaded Rod HangerSDC125 1-1/4 31.8 Ceil<strong>in</strong>g ClipSPC114 1-1/4 31.8 Ceil<strong>in</strong>g ClipFasteners start on page 34.COMMON REPLACEMENT PARTS• MVP500AP Advance Lever Assembly• MVP140 Piston• electrical p<strong>in</strong>/clip assembliesPreassembled P<strong>in</strong> & Clips for some of <strong>the</strong> mostcommon electrical applications <strong>in</strong>crease jobsite speedfor <strong>the</strong> electrician.• standard p<strong>in</strong>/clip assembliesSDC Fasteners are designed with special dimples on<strong>the</strong> angle clips which act as a shim and assure a snugfit between <strong>the</strong> structural member and <strong>the</strong> clip.• PowerPo<strong>in</strong>t ® P<strong>in</strong>/clip assembliesSPC Fasteners are assembled with <strong>the</strong> patentedtechnology of PowerPo<strong>in</strong>t p<strong>in</strong>s for penetration <strong>in</strong> hardconcrete and steel. The uniform shape and f<strong>in</strong>ish of <strong>the</strong>eng<strong>in</strong>eered tip results <strong>in</strong> more consistent performance<strong>in</strong> your toughest situations.The Viper screws solidlyonto a pole for high reachand secure operation forceil<strong>in</strong>g applications.The Viper was eng<strong>in</strong>eeredspecifically for overheadapplications.www.ramset.com23

.25 caliber disc TOOLSD45A• .25 Caliber Disc Tool• Semi-Automatic• Automatic Piston Return• .25 caliber 10-shot discloads: 2 (Brown), 3 (Green),4 (Yellow), 5 (Red)• Weight: 4.5 lbs.• Length: 15"• Muzzle Bush<strong>in</strong>g O.D.: 5/8"• Maximum P<strong>in</strong> Length:2" (2-1/2" w/washer)• 3 Year WarrantyADVANTAGES• Most durable, powerful powder tool—designed for high production use <strong>in</strong>steel and concrete• Heavy-duty buffer system—preventsfront-end tool damage for longer tool life• 33% faster than semi-automatic tools—saves time and labor costs• <strong>Ramset</strong> Disc Technology—loads onlyadvance after fir<strong>in</strong>g—elim<strong>in</strong>ates 10-20%of load waste3/8" Muzzle Bush<strong>in</strong>gavailable for limitedapplicationsPart Number32330038MMost common fastenersPIN #Shank LengthIN. (MM)Most common applicationSP58TH 5/8 15.9 Track to steelSP12 1/2 12.7 Track to hard steel1506B 3/4 19.1 Track to concreteFasteners on pages 35 and 36.COMMON REPLACEMENT PARTS• 323110 Muzzle Bush<strong>in</strong>g Shroud• 30645 PistonD60• .25 Caliber Disc Tool• Semi-Automatic• Power Adjustable• 3 Year Warranty• .25 caliber 10-shot discloads: 2 (Brown), 3 (Green),4 (Yellow)• Weight: 4.9 lbs.• Length: 12-1/2"• Muzzle Bush<strong>in</strong>g O.D.: 3/4"• Maximum P<strong>in</strong> Length:2-3/8" (2-1/2" w/washer)ADVANTAGES• Quick power adjustment—gives eightlevels of power with only one load levelfor a variety of applications• Rugged polyamide hous<strong>in</strong>g—reducesheat transfer and maximizes operatorcomfort• Soft, recoil-absorb<strong>in</strong>g handle—for<strong>in</strong>creased operator comfort• <strong>Ramset</strong> Disc Technology—loads onlyadvance after fir<strong>in</strong>g—elim<strong>in</strong>ates 10-20%of load wasteMost common fastenersPIN #Shank Length Thread LengthIN. (MM) IN. MMMost common applicationM100BB 1 25.4 Sheet metal to concrete1643W 1 25.4 3/4 19.1 Electrical box to concreteFasteners start on page 34.COMMON REPLACEMENT PARTS• 30691 Piston• 135220 Pawl Assmebly24 www.ramset.com

.22 caliber s<strong>in</strong>gle shot721MASTERSHOT• .22 Caliber S<strong>in</strong>gle Shot Tool• S<strong>in</strong>gle Shot• 3 Year WarrantyADVANTAGES• Rugged metal hous<strong>in</strong>g—holds up for years• Low recoil—reduces operator fatigue onlarge jobs• Simple to clean—saves on labor costs• Rubber cushion grip—for maximumoperator comfort• .22 caliber, s<strong>in</strong>gle-shotloads: 2 (Brown), 3 (Green),4 (Yellow)• Weight: 4.3 lbs.• Length: 13-1/2"• Muzzle Bush<strong>in</strong>g O.D.: 5/8"• Maximum P<strong>in</strong> Length:1-1/2"• Only two mov<strong>in</strong>g parts to clean—easyma<strong>in</strong>tenance; saves time• Narrow 5/8" muzzle bush<strong>in</strong>g—for easyaccess <strong>in</strong> tight fasten<strong>in</strong>g areas• Automatic cartridge ejection system—<strong>in</strong>creases operator speed and productivityMost common fastenersPIN #Shank LengthIN. (MM)Most common application1506B 3/4 19.1 Track to concreteM100BB 1 25.4 Track to concreteSP58TH 5/8 15.9 Track to steelFasteners start on page 34.common replacement parts• 33657 Piston R<strong>in</strong>g Assembly• 12258 Barrel Extension• .22 S<strong>in</strong>gle Shot Tool• Trigger Operated PowderActuate Tool• 90 Day WarrantyADVANTAGES• Designed for frequent use provid<strong>in</strong>gprofessional fasten<strong>in</strong>g results <strong>in</strong> avariety of concrete, masonry or steelapplications• The MasterShot is a traditional triggeroperated tool• Ergonomic design for operator comfort• Uses standard .22 calibers<strong>in</strong>gle shot powder loads:2 (Brown), 3 (Green),4 (Yellow)• Weight: 4.4 lbs.• Length: 15"• Muzzle Bush<strong>in</strong>g O.D.: 3/4"• Maximum P<strong>in</strong> Length: 3"• Positive barrel and load retention preventsbarrel from open<strong>in</strong>g freely, allow<strong>in</strong>g easyhorizontal and overhead fasten<strong>in</strong>g• Powder load automatically ejects aftereach use• Heavy-duty construction2" x 4" to concrete slabTrack to floorMost common fastenersPIN #Shank LengthIN. (MM)Most common application1524SDP (washered) 3 76.2 2" x 4" to concrete1516SDC (washered) 2-1/2 63.5 2" x 4" to concrete1506B 3/4 19.1 Drywall to concreteFasteners start on page 34.www.ramset.com25

t3ss pole toolT3 CUPADVANTAGES• Faster way to put <strong>the</strong> T3ss on a pole• Works with <strong>the</strong> T3ss Gas Tool and updatedViper 4 Poles• No hose clamps required: Simple toassemble• 1 Year warranty on nom<strong>in</strong>al wear and tear• Sturdy designExtend Your Reach!New ergonomic design balances <strong>the</strong> tool directly over <strong>the</strong> pole for a lightweight feeleasy to assembleLog on to www.ramset.com for a video on attach<strong>in</strong>g <strong>the</strong> pole tool to <strong>the</strong> T3SSUses NEW Viper pole system:Works with four newly designed <strong>Ramset</strong>® poles for greater ease and accuracy.V4-EXTTOOL/POLE CONNECTIONThe new poles have an <strong>in</strong>ternal rod, whenactivated by push<strong>in</strong>g on <strong>the</strong> pole sleevetriggers <strong>the</strong> new Viper.PARTNUMBERDESCRIPTIONV4-3 3' PoleV4-6 6' PoleV4-8 8' PoleV4-EXT3' Extension (no trigger)26 www.ramset.com

Tool accessoriesTool Clean<strong>in</strong>g Kitn Wood Handle Wire Brushn Round Wire Brushes:Small, medium, largen Package of 10 Scrubs:Hand and tool cleanersPart No. TFUELFuel Cell–TrackFast (TF1100, TF1200)Gypfast, G2 Qty: 12Part No. T3FUELFuel Cell–T3SS & T3MAGQty: 12 (6–2 packs)Part No. PATCKClean<strong>in</strong>g KitQty: 1Part No. 7505012Battery–TF1100Qty: 1Part No. B0092Battery–T3SS & T3MAGQty: 1Part No. 405176Battery–GYPFASTQty: 1Part No. B0022Battery Charger–TF1100, T3SS & T3MAGQty: 1Part No. 7505142Battery Charger–T2 & R150, E150 & M150Qty: 1Part No. LD100Plated 1" Lath<strong>in</strong>g Disc 22gQty: 1,000 per boxWorks with all magnetic probesPart No. LD114Plated 1-1/4" Lath<strong>in</strong>g Disc(GYPFAST)Qty: 1,000 per boxPart No. 100227Magnetic Muzzle for XT540Qty: 1Part No. 100018Disc Hold<strong>in</strong>g Probe(for TF1100 <strong>One</strong> Piece Nose)Qty: 1Part No. 10041LADisc Hold<strong>in</strong>g Probe(for TF1200 Probe)Qty: 1Part No. M150200Magnetic nose Piece(for R150 and T3SS)Qty: 1Part No. B0237Disc Probe(T3MAG)Qty: 1Part No. 2761910Gas Mag Probe(GYPFAST)Qty: 1Part No. 100342G2 Lath ProbeQty: 128 www.ramset.com

GAS TOOL FASTENERS<strong>Ramset</strong> Collated Gas Tool Fasteners are specifically eng<strong>in</strong>eered for optimalperformance <strong>in</strong> <strong>Ramset</strong> Gas Power Tools us<strong>in</strong>g fastener magaz<strong>in</strong>es.Selection chartT3mag fuel/p<strong>in</strong> pack1000 PINS AND 1 FUEL CELL PER BOX Larger .125 shank diameter offers improved success rate (15 p<strong>in</strong> strip)PART NUMBER PIN LENGTH DESCRIPTIONIN. (MM)T3012 1/2 (12.7) 1/2" steel p<strong>in</strong> with T3 fuel cellT3012S 1/2 (12.7) 1/2" premium steel p<strong>in</strong> with T3 fuel cellT3034B 3/4 (19.1) 3/4" concrete p<strong>in</strong> with T3 fuel cellT3034S* 3/4 (19.1) 3/4" step shank p<strong>in</strong> with T3 fuel cellT3100 1 (25.4) 1" concrete p<strong>in</strong> with T3 fuel cellShank diameter = .125 *Shank diameter= .104/.125Head diameter = .250TrakFast standardfuel/p<strong>in</strong> pack1000 PINS AND 1 FUEL CELL PER BOX For high volume, repetitive fasten<strong>in</strong>gs to concrete and steel such as drywall track to concretePART NUMBER PIN LENGTH DESCRIPTIONIN. (MM)FPP012 1/2 (12.7) 1/2" Plated steel p<strong>in</strong>FPP012S* 1/2 (12.7) 1/2" Premium Plated step shank p<strong>in</strong>FPP034B 3/4 (19.1) 3/4" Black p<strong>in</strong>FPP034S* 3/4 (19.1) 3/4" Premium Plated step shank p<strong>in</strong>FPP100 1 (25.4) 1" Plated p<strong>in</strong>FPP114 1-1/4 (31.8) 1-1/4" Plated P<strong>in</strong>Shank diameter = .109Head diameter = .250* Shank diameter = .104/.118* Head diameter = .250TrakFast breakawayStrip fuel/p<strong>in</strong> pack1000 PINS AND 1 FUEL CELL PER BOXCollation designed to breakaway on impact. For high volume, repetitive fasten<strong>in</strong>gs to concrete suchas wood furr<strong>in</strong>g to concretePART NUMBER PIN LENGTH DESCRIPTIONIN. (MM)FPP034T 3/4 (19.1) 3/4" Plated p<strong>in</strong>FPP100T 1 (25.4) 1" Plated p<strong>in</strong>FPP114T 1-1/4 (31.8) 1-1/4" Plated P<strong>in</strong>FPP112T 1-1/2 (38.1) 1-1/2" Plated P<strong>in</strong>Shank diameter = .109Head diameter = .250Sold <strong>in</strong> master cartons of 5000 m<strong>in</strong>imum. Cartons cannot be split.www.ramset.com29

GAS TOOL FASTENERSPLY138 Trakfast Plywood P<strong>in</strong>for attach<strong>in</strong>g plywoodto metal studs• Fastener Length: 1-3/8"• Shank Diameter: .100 dia. (before knurl)• Head Diameter: .250• Helical Knurled Shank• Mechanical Z<strong>in</strong>c Plated• Can Be Used With:Wood Sheath<strong>in</strong>gs: 3/8", 1/2", 5/8", 3/4"Steel Stud Gauges: 16, 18, 201000 p<strong>in</strong>s and 1 fuel cell per boxAdvantagesvs screws• 3 - 5 times faster than screw <strong>in</strong>stallation. Noworry<strong>in</strong>g about electrical cords.Strip• Collation strip breaks away upon impact,allow<strong>in</strong>g <strong>the</strong> head of <strong>the</strong> p<strong>in</strong> to recess <strong>in</strong>to <strong>the</strong>wood for a nice, clean look• 10-p<strong>in</strong> strips transfer easily from <strong>the</strong> operator’spouch to <strong>the</strong> TrakFast tool, elim<strong>in</strong>at<strong>in</strong>g wastevs air systems• No set-up and tear down time. No hassl<strong>in</strong>g withcompressors or hoses.p<strong>in</strong>s• Hardened steel p<strong>in</strong> ensures a clean penetrationof <strong>the</strong> fastener — no dimpl<strong>in</strong>g of <strong>the</strong> stud• Knurled helical shank gives <strong>the</strong> fastener superiorhold<strong>in</strong>g values• Z<strong>in</strong>c plated for corrosion resistance30 www.ramset.com

T3SS Electrical accessoriesGas tool fasteners(Pre-assembled, S<strong>in</strong>gle-Shot)The fasteners are designed for use <strong>in</strong> <strong>Ramset</strong> S<strong>in</strong>gle-Shot Gas Tools (R150, T3SS)Selection chartThreaded rod hangerU LFor suspended ceil<strong>in</strong>gs, pip<strong>in</strong>g and o<strong>the</strong>r items us<strong>in</strong>g 1/4" or 3/8"threaded rod. Fastener is pre-assembled to a 16 gage threaded rodhanger. 100 per jar.PARTDESCRIPTIONNUMBER14TRHMP0341/4" Rod hanger with 3/4" plated p<strong>in</strong>38TRHMP034Shank diameter = .104/.125 Head diameter = .3003/8" Rod hanger with 3/4" plated p<strong>in</strong>Available <strong>in</strong>convenient jars!<strong>One</strong> hole strapUsed to attach EMT conduit or armored cable to concrete. Fastener preassembledto a 16 gage conduit strap. 100 per jar, 3/8" 200 per jar.PARTDESCRIPTIONNUMBERConduit clamp38HSMP034*3/8" Hole strap with 3/4" plated p<strong>in</strong>U L12HSMP0341/2" Hole strap with 3/4" plated p<strong>in</strong>34HSMP0343/4" Hole strap with 3/4" plated p<strong>in</strong>10HSMP0341" Hole strap with 3/4" plated p<strong>in</strong>Shank diameter = .104/.125 Head diameter = .300 *38HSMP034 = 18 gage, 200 per jarU LUsed to attach conduit to concrete. P<strong>in</strong> pre-assembled to an 18 gageconduit strap. 1/2" 50 per jar and 3/4" 25 per jar.PARTDESCRIPTIONNUMBER12CCMP034L1/2" Conduit clamp with 3/4" plated p<strong>in</strong>34CCMP034L3/4" Conduit clamp with 3/4" plated p<strong>in</strong>Shank diameter = .104/.125 Head diameter = .300The new durable plastic conta<strong>in</strong>ersmean less waste on <strong>the</strong> jobsite, or<strong>in</strong> <strong>the</strong> back of a truck. Their widemouthdesign makes it easy to grabwhat you need.Ceil<strong>in</strong>g Clip AssemblyPre-assembled Ceil<strong>in</strong>g Clip. Plated 14 gage clip. 100 per jar.PARTNUMBERDESCRIPTION34CLIP3/4" wide angle clip w/ 3/4" length p<strong>in</strong>Shank diameter = .104/.125 Head diameter = .300Each T3ss gas accessory and p<strong>in</strong>label provides vital hold<strong>in</strong>g value<strong>in</strong>formation—tak<strong>in</strong>g away <strong>the</strong>guess work.32 www.ramset.com

GAS TOOL FASTENERS(Pre-assembled, S<strong>in</strong>gle-Shot)Selection chartTie strap holderUsed to <strong>in</strong>stall temporary light<strong>in</strong>g and secure low voltage cable to concrete, uses a standard cable tie up to 3/8" <strong>in</strong>width. Fastener is pre-assembled to a 22 gage tie strap holder. 50 per jar.PARTNUMBERTSHMP034Shank diameter = .104/.125 Head diameter = .300DESCRIPTIONTie strap holder with 3/4" plated p<strong>in</strong>Mechanical p<strong>in</strong>with washerMUST USE WITH MAGNETIC WORKCONTACT ELEMENT (M150200)Used for <strong>the</strong> attachment of light gage metal to concrete and steel such as HVAC duct strap to concrete. Plated p<strong>in</strong>pre-assembled to a 1/2" domed washer. 200 per jar, 1" 100 per jar.PARTNUMBERM012M034M034BBM100DESCRIPTION1/2" Plated step p<strong>in</strong> with dome washer3/4" Plated p<strong>in</strong> with domed washer3/4" Premium step p<strong>in</strong> with domed washer1" Plated p<strong>in</strong> with domed washerShank diameter = .125, Step P<strong>in</strong> .104/.118 Head diameter = .300 (M012 = .250)*Will fit R150 & T3SS with optional work contact element, P/N: M1502001/4-20 threaded studNOT MADE IN USAUsed to attach electrical components to concrete where removability of <strong>the</strong> component is required. Plated threadedstud. 200 per jar.PARTNUMBERDESCRIPTIONSHANK LENGTH14STUD 1/2" 5/8"Shank diameter = .125TOP HAT PINUsed for general purpose fasten<strong>in</strong>g to concrete.Plated p<strong>in</strong> with top hat. 200 per jar.PARTNUMBERMPO34THShank diameter = .125 Head diameter = .300DESCRIPTION3/4" Plated p<strong>in</strong> with top hatBridle r<strong>in</strong>gPre-Assembled 2" Bridle R<strong>in</strong>g supports low voltage, data com, signal, and control cables50 per box.PARTDESCRIPTIONNUMBERBR22" Bridal r<strong>in</strong>gShank diameter = .125www.ramset.com33

Powder fastenersThese Mechanical/Electrical Assemblies are designedto be used <strong>in</strong> ei<strong>the</strong>r Gas or Powder Actuated Tools.The unique fastener design <strong>in</strong>creases fasten<strong>in</strong>gsuccess rate while provid<strong>in</strong>g outstand<strong>in</strong>g performance.Selection chartHybrid p<strong>in</strong>For general purpose attachments to concrete.PowerPo<strong>in</strong>t step shank p<strong>in</strong> pre-assembled to 1/2" washer. 500 per jar.PARTNUMBERDESCRIPTIONALL POWDER TOOLSM100BB 1" PowerPo<strong>in</strong>t step shank p<strong>in</strong> with 1/2" domed washer & flute •Shank diameter = .125/.150 Head diameter = .300<strong>One</strong> holeconduit strapUsed to attach EMT conduit or armored cable to concrete.PowerPo<strong>in</strong>t fastener pre-assembled to a 16 gage conduit strap. 100 per box.PARTNUMBERDESCRIPTIONALL POWDER TOOLS38HSSS10 3/8" Hole strap with w/1 premium p<strong>in</strong> •12HSSS10 1/2" Hole strap with w/1 premium p<strong>in</strong> •34HSSS10 3/4" Hole strap with w/1 premium p<strong>in</strong> •10HSSS10 1" Hole strap with w/1-1/4" premium p<strong>in</strong> •Shank diameter = .125/.150 Head diameter = .30038HSSS10 = 18 gageThreadedrod hangerU LFor suspended ceil<strong>in</strong>gs, pip<strong>in</strong>g, and o<strong>the</strong>r items us<strong>in</strong>g 1/4" or 3/8" threaded rod.PowerPo<strong>in</strong>t fastener pre-assembled to a 16 gage threaded rod hanger. 100 per box.PARTNUMBERDESCRIPTIONALL POWDER TOOLS14TRHSS10 1/4" Rod hanger w/1" premium p<strong>in</strong> •38TRHSS10 3/8" Rod hanger w/1" premium p<strong>in</strong> •Shank diameter = .125/.150 Head diameter = .30034 www.ramset.com

POWDER FASTENERSWe ma<strong>in</strong>ta<strong>in</strong> only <strong>the</strong> highest standards <strong>in</strong> <strong>the</strong> materials, production techniques andquality control measures used to manufacture our fasteners, assur<strong>in</strong>g consistent,optimum quality <strong>in</strong> every fastener.FASTENER TERMINOLOGY SUFFIXK = Knurled X = Collated C = 100 countB = Black SD = Washer M = 1000 countE = RamguardTH = Top HatAdvantagesITW <strong>Ramset</strong> powder actuated fasteners are specifically fabricated to meet <strong>the</strong>exact<strong>in</strong>g requirements of toughness and durability that enable <strong>the</strong>m to penetratedense concrete and structural quality steel. All <strong>Ramset</strong> fasteners with .300 head willfit <strong>in</strong>to tools with 8mm barrels.Selection chartBlack track p<strong>in</strong>s Designed for use <strong>in</strong> concrete and structural steel applications. Available <strong>in</strong> 1000-pack per box.PART SHANK LENGTH 721/ ROCKET D60/ SA270 XT540 COBRA MASTERSHOT/NUMBER IN. (MM) R25D45ARS221506B 3/4 (19.1) • • • • • • •Shank diameter = .145 Head diameter = .300plated p<strong>in</strong>s Designed for use <strong>in</strong> concrete and structural steel applications. 100 per box.PART SHANK LENGTH 721/ ROCKET D60/ SA270 XT540 COBRA MASTERSHOT/NUMBER IN. (MM) R25D45ARS221503K 1/2 Knurled (12.7) • • • • • • •1506 3/4 (19.1) • • • • • • •1508 1 (25.4) • • • • • • •1510 1-1/4 (31.8) • • • • • • •1512 1-1/2 (38.1) • • • • • • •1514 2 (50.8) • • • • • •1516 2-1/2 (63.5) • • • •1524 3 (76.2) • • •Shank diameter = .145 Head diameter = .300washered p<strong>in</strong>sWasher <strong>in</strong>creases bear<strong>in</strong>g surface aga<strong>in</strong>st <strong>the</strong> material to be fastened.100 per box. 16 gage metal washer. 7/8" diameter washer after 16 gage.PART SHANK LENGTH 721/ ROCKET D60/ SA270 XT540 COBRA MASTERSHOT/NUMBER IN. (MM) R25D45ARS221506SD 3/4 (19.1) • • • • • • •1508SD 1 (25.4) • • • • • • •1510SD 1-1/4 (31.8) • • • • • • •1512SD 1-1/2 (38.1) • • • • • • •1514SD 2 (50.8) • • • • • • •1516SDC 2-1/2 (63.5) • • • • • •1524SDP* 3 (76.2) • • • •*Square washer <strong>in</strong>dicates 3" p<strong>in</strong> has been <strong>in</strong>stalled Shank diameter = .145 Head diameter = .300www.ramset.com35

POWDER FASTENERSPowerPo<strong>in</strong>t p<strong>in</strong>spowerpo<strong>in</strong>tstep shank p<strong>in</strong>sUsed for fasten<strong>in</strong>g <strong>in</strong>to harder steel and concrete. Premium steel and hard concrete p<strong>in</strong>. 100 per box.PARTNUMBERSHANK LENGTH 721/IN. (MM) R25ROCKET D60/D45ASelection chartSA270 XT540 COBRA MASTERSHOT/RS22SP12 1/2 (12.7) • • • • • • •SP58 5/8 (15.9) • • • • • • •SP34 3/4 (19.1) • • • • • • •Shank diameter = .150 Head diameter = .300Used for fasten<strong>in</strong>g <strong>in</strong>to harder steel and concrete. Premium steel and hard concrete p<strong>in</strong>.P<strong>in</strong> for fasten<strong>in</strong>g <strong>in</strong>to harder steel and concrete. 100 per box. (M100BB 500 per jar)PART SHANK LENGTH 721/ ROCKET D60/ SA270 XT540 COBRA MASTERSHOT/NUMBER IN. (MM) R25D45ARS22M100BB 1 (25.4) • • • • • • •SP100 1 (25.4) • • • • • • •SP114 1-1/4 (31.8) • • • • • • •SP178 1-7/8 (47.6) • • • • • •Shank diameter = .150/.180 Head diameter = .300M100BB shank diameter = .125/.150 with 1/2" washerRamguard p<strong>in</strong>sCoated to improve corrosion resistance <strong>in</strong> treated lumber and o<strong>the</strong>r applications.100 per box. Recommended for threaded lumber applications.PARTNUMBERSHANK LENGTH 721/IN. (MM) R25AUTOFAST D60/D45A ROCKET/SA270XT540 COBRA MASTERSHOT/RS221516SDE 2-1/2 (63.5) • • • • •1524SDE* 3 (76.2) • • • • • •Shank diameter = .145 (SP178E = .150/.180)Head diameter = .300 *Square washer <strong>in</strong>dicates 3" p<strong>in</strong> has been <strong>in</strong>stalled* 1500 Series Coated with RamGuard* SP Series Coated with Triple Z<strong>in</strong>c36 www.ramset.com