Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong><strong>Heat</strong>ing</strong> <strong>Elements</strong>Gillelejevej 30DK-3230 GraestedTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98san@san-as.com - www.san-as.comMember of the NIBE Group

2Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Member of the NIBE Group1. HEATING ELEMENTSFlat tubular heating elements13 x 5.5 mm ................................... page 416.5 x 6.5 mm .................................. page 5Round tubular heating elements14 mm ∅ ..................................... page 66.5 mm ∅ .................................... page 68.5 mm ∅ ..................................... page 8Ribbed tubular heating elements35 x 55 mm ribs ................................ page 8∅ 28 mm ribs .................................. page 9Miniature tubular heating elements3.0 x 3.0 mm .................................. page 82.2 x 4.2 mm .................................. page 83.3 mm ∅ ..................................... page 8Flexible tubular heating elements8.0, 8.2 and 8.5 mm ∅ ........................... page 11Band- and plate heating elementsBand heating elements, mica insulated .............. page 12Band heating elements, ceramic insulated ........... page 12Flat heating elements, mica insulated ............... page 12Miniature nozzle heating elements ................. page 13Nozzle heating elements .......................... page 14Embedded heating elements ..................... page 14Ceramic heating elementsRound and flat ................................. page 17Technical dataSurface load .................................... page 19Bending shapes ................................. page 20Temperature curves .............................. page 21Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 0533

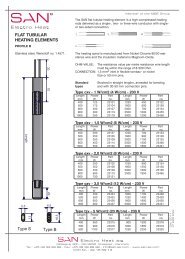

The <strong>SAN</strong> flat tubular heating element is a high-compressed heatingrods delivered as a single-, two- or three-wire conductor with singleortwo-sided connection.FLAT TUBULARHEATING ELEMENTSPROFILE BStainless steel, Werkstoff no. 1.4571.The heating spiral is manufactured from Nickel-Chrome 80/20 resistancewire and the insulation material is Magnium-Oxide.5070OHM-VALUE: The resistance value per metre resistance wire lengthmust be within the range of 8-500 Ohm.CONNECTION: 1,5 mm 2 inlet in flexible tombac- or nickellitze or 50 mm pins.StandardtypesStocked in straight lengths, annealed for bendingand with 30-50 mm connection pins.Type cxv - 1 W/cm2 (4 W/cm) - 230 VLength Power Part Length Power Partmm W no. mm W no.400 125 23101 1250 450 23122500 175 23104 1600 600 23128600 200 23107 2000 700 23134800 300 23113 2500 1000 234551000 350 23119 3000 1200 23456Type dxv - 1,5 W/cm2 (6 W/cm) - 230 VLength Power Part Length Power Partmm W no. mm W no.400 200 23137 1250 700 23123500 250 23105 1600 900 23129600 350 23108 2000 1100 23135800 450 23114 2500 1500 234601000 550 23120 3000 1800 23461Type exv - 2,0 W/cm2 (8 W/cm) - 230 VLength Power Part Length Power Partmm W no. mm W no.400 250 23102 1250 900 23124500 350 23106 1600 1250 23130600 450 23109 2000 1600 23136800 600 23115 2500 1950 234651000 750 23121Type gzv - 3,0 W/cm2 (12 W/cm) - 230 VLength Power Part Length Power Partmm W no. mm W no.400 400 23424 1000 1100 23428500 500 23425 1250 1400 23429600 650 23426 1600 1800 23430800 900 23427 2000 2250 23431Type tzv - 5 W/cm2 (20 W/cm) - 230 VLength Power Part Length Power Partmm W no. mm W no.400 650 23315 800 1500 23318500 900 23316 1000 1800 23319600 1100 23317 1250 2250 233204Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Member of the NIBE GroupType lzv - 3 W/cm2 (12 W/cm) - 3 x 400 VLength Power Part Length Power Partmm W no. mm W no.600 650 23418 1600 1800 23422800 900 23419 2000 2250 234231000 1100 23420 2500 2900 234701250 1400 23421 3000 3500 23471Type uzv - 5 W/cm2 (20 W/cm) - 3 x 400 VLength Power Part Length Power Partmm W no. mm W no.600 1100 23321 1600 3150 23325800 1500 23322 2000 4000 233261000 1800 23323 2500 4850 234751250 2250 23324 3000 6000 23476FLAT TUBULARHEATING ELEMENTSPROFILE BStainless steel, Werkstoff no. 1.4571.Also delivered with built-in thermo coupleNi/NiCr.Type tzk - 5 W/cm2 (20 W/cm) - 230 VLength Power Part Length Power Partmm W no. mm W no.400 650 23311 800 1500 23314500 900 23312 1000 1800 23301600 1100 23313 1250 2250 23302Type uzk - 5 W/cm2 (20 W/cm) - 3 x 400 VLenth Power Part Length Power Partmm W no. mm W no.600 1100 23305 1600 3150 23309800 1500 23306 2000 4000 233101000 1800 23307 2500 4860 234801250 2250 23308 3000 6000 23481The <strong>SAN</strong> flat tubular heating elements are also delivered bendedas to specification, with brazed mounting bushes with connectionboxes or other for mounting in any electrical heating aggregate.Additionally, the <strong>SAN</strong> flat tubular heating elements can be deliveredin the following sheath materials:Type SType BTUBE PROFILE +/- 0.4 mm 13 x 5.5 mm 16.5 x 6.5 mmCIRCUMFERENCE 33 mm 41 mmLENGTH max. +/- 5.0 mm 6000 mm 6000 mmWEIGHT kg/m approx. 0.35 approx. 0.45SHEATH MATERIAL:STAINLESS STEEL "V" 1.4571 1.4571ACID PROOF STEEL "C" 1.4435 1.4435MONEL 400 "L" 2.4360 2.4360INCOLOY 800 "N" 1.4876INCONEL 600 "O" 2.4816COPPER "K" 2.0090 2.0090Conductor/pinsSheath materialCeramicSEALING SET andFITTINGS for PROFILE BPlunging: power: Voltage manufacturing month and -yearSEALING SET for 5 heating elementsPart no.5 end ceramics, 1 tube of air hardening siliconerubber and 1 injection tool. 68900Tube with air hardening silicone rubber, 340 g 68911Stainless mounting fixture single 60404Stainless mounting fixture double 60405Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 0535

MINIATURE-TUBULARHEATING ELEMENTSSQUARE - FLAT - ROUNDPROFILE K 3 × 3 mmPROFILE F 2.2 × 4.2 mmPROFILE H 3.3 mm ØRIBBEDHEATING ELEMENTThe <strong>SAN</strong> miniature tubular heating element type KV, FV and HV aredelivered with 1000 mm PTFE-insulated flexible connection leads atone end, incl. earth connection.Sheath material: Stainless steel, Werkstoff no. 1.4571.Specific lengths can be delivered up to 3000 mm.Type KVT and HVT have a built-in thermo couple Fe/CuNi.Type FV can be delivered with a built-in thermo couple Fe/CuNi.Type Power <strong><strong>Heat</strong>ing</strong> lgth. Total lgth. W/cm 2 PartW L1 mm L2 mm no.Type KV 3x3 mm 230 VKV 18 215 300 390 6 845001KV 27 325 450 540 6 845002KV 39 470 650 740 6 845003KV 50 610 850 940 6 845004KV 63 630 1050 1140 6 845005KVT 18 215 300 390 6 845006KVT 27 325 450 540 6 845007KVT 39 470 650 740 6 845008KVT 50 610 850 940 6 845009KVT 63 630 1050 1140 6 845010Type FV 2,2x4,2 mm 230 VFV 25 195 250 340 6 845050FV 28 215 280 370 6 845052FV 33 240 335 425 5.6 845054FV 38 295 385 475 6 845056FV 46 350 460 550 5.9 845058FV 52 400 520 610 6 845060FV 60 460 600 690 6 845062FV 76 610 760 850 6.3 845064FV 90 690 900 990 6 845066Type HV 3,3 mm Ø 230 VHV 30 180 300 390 5.9 845070HV 45 270 450 540 5.8 845072HV 65 390 650 740 5.8 845074HV 85 500 850 940 5.7 845076HV 105 630 1050 1140 5.8 845078HVT 30 180 300 390 5.9 845080HVT 45 270 450 540 5.8 845082HVT 65 390 650 740 5.8 845084HVT 85 500 850 940 5.7 845086HVT 105 630 1050 1140 5.8 845088The <strong>SAN</strong> ribbed heating element type VMR has been constructed fromthe <strong>SAN</strong> tubular heating element type RC with s.s. plate ribs,35x55mm and mounted with 2 M 14 x 15 mm stainless press bushes.Type VMR230 VType Power Insertion lgth. Rib-lgth. W/cm 2 PartW L1 mm L2 mm no.VMR 34 400 290 240 3 83260VMR 56 600 290 240 5 83261VMR 36 600 390 340 3 83262VMR 59 900 390 340 5 83263VMR 38 800 490 440 3 83264VMR 512 1200 490 440 5 832658Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Member of the NIBE Group<strong>SAN</strong> heating element type RV can be delivered withmounted stainless steel ribs. This increases the surfacearea of the heating element considerably, which means amuch lower surface temperature.HEATING ELEMENTSWITH RIBSThe specific load is calculated based on the followingformula:P =P(W/cm 2 )L b x 0,267P = power in kWL b = heating zone of the heating element in cm.The surface temperature of the heating element is particularlyimportant in connection with air heating in ducts andin Ex-equipment. The relation between air velocity (m/s),temperature difference (∆t) and surface load (W/cm²) isshown on the graph.The following physical manufacturing limitations havebeen stated:d a : 8.5 mmD a : 22.5 mm or 28 mmL: min. 420 mm, max. 5700 mmL R : min. 320 mm, max. 5600 mmMA : min. 35 mm or 40 mmTemperature difference ニt between maximum tubularjacket temperature and highest air temperature tLaThe temperature on the ribs,is constantly below the temperatureof the tubular jacket,and varies a lot depending onthe height of the air velocity.Specific surface load n W/cm2at a tube diameter of 8,5 mmL u : 50 mmL 1 : min. 45 mmAir velocity W in m/sGillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 0539

- Version 1Straight lengths, annealed.Without screw bushing.Connection equipment for M4 to bedelivered separately.- Version 2Straight lengths, annealed.With pressed or soldered 6-edgedscrew bushings.Pressed steel, galvanized.Soldered brass, galvanized.(Can also be delivered in a special versionwith CrNi steel screw bushings).Connection equipment for M4 and M14 tobe delivered separately.M4Lmax. 20 L u = not heated L u = not heatedmax. 35L 112 +26Part 4 only in soldered version6Version 1Pressed or soldered SW 19 12L RVersion 2M 1 /4x1,5- Version 3U-shape, bending with ribs.Without screw bushing.Parts as mentioned under version 1 to bedelivered separately.M4Version 3L R- Version 4U-shape, bending with ribs.With screw bushing as mentionedunder version 2.Parts as mentioned under version 2 to bedelivered separately.MA±3Version 4luDadaET- Version 5U-shape, bending without ribs.<strong><strong>Heat</strong>ing</strong> effect in bending reduced.Without screw bushing.Parts as mentioned under version 1 to bedelivered separately.- Version 6U-shape, bending without ribs.<strong><strong>Heat</strong>ing</strong> effect in bending reduced.With screw bushing as version 2.Parts as mentioned under version 2 to bedelivered separately.M4MA±3Version 5Version 6L Rmin. Ma + 152DadaSince special tools for bending of the ribbedheating elements are required, this can onlybe made at our factory.luETSpec. vlg. 50%10Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Member of the NIBE GroupThe <strong>SAN</strong> flexible tubular heating element type FRK has beendesigned from a flexible stainless steel tube. This means that theheating element is very easy to bend manually according to theexact required application - without any use of bending tools.The <strong>SAN</strong> flexible tubular heating element is delivered as to specificationin straight lengths up to 2600 mm and with a diameterof 8.0 mm, 8.2 mm or 8.5 mm.FLEXIBLE TUBULARHEATING ELEMENTSAs regards the standard type Ø 8.5 lengths from L = 500 mm/1150 W to 1500 mm/3970 W in 50 mm intervals are available.The <strong>SAN</strong> flexible tubular heating element has M 2.5 screw pinsmanufactured from stainless steel at both ends equipped withstainless discs and nuts. Can also be delivered with terminalfasteners or nickellitz insulation with glassflex or ceramic pearls.Length as to specification.Technical Data:Max. voltage : 250 VMax. current : 25 AMax. power : 15 W/cm 2Max. temperature : 700°CSheath material : Werkstoff no. 1.4541Diameter tolerance : ±0.1 mmLength tolerance : ±5% (less when requested)Output tolerance : ±10% (less when requested)Min. bending radius : R = 10 mmConnection : M 2.5 screw pin with nutType FRK230 VLength Power Part Length Power Partmm W no. mm W no.500 1150 844 800 1000 2650 844 820550 1300 844 802 1050 2800 844 822600 1450 844 804 1100 2930 844 824650 1600 844 806 1150 3060 844 826700 1750 844 808 1200 3190 844 828750 1900 844 810 1250 3320 844 830800 2050 844 812 1300 3450 844 832850 2200 844 814 1350 3580 844 834900 2350 844 816 1400 3710 844 836950 2500 844 818 1450 3840 844 8381500 3970 844 840The flexible heating element can be mounteddirectly into the slot or be hammered in with asynthetic hammer.A: Distribution beamB: Slot: B = T = heating element-Ø + 0.1 mmF: Chamfer1) Screw pin in stainless steel M 2.52) Ceramic insulator3) Sheath material stainless steel,Werkst. no. 1.4541a) Length of heating elementb) Cold end (30 mm, no bending)c) Flexible heating lengthGillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 05311

For heating of moulds, tools, nozzles and machines <strong>SAN</strong> manufacturesvarious types of band- and plate heating elements.BAND- and PLATEHEATING ELEMENTSThese heating elements, mica- or ceramically insulated, are manufacturedas to specification in all shapes.The heating elements can be delivered with different kinds of connection,holes for temperature sensors, parts for assembling etc. Seebelow and next page.Voltage : As to specificationPower : As to specification. Max. 8 W/cm 2Materials : Band heating elements: Aluminium plated steelDIN 1624/1544 or stainless steelPlate heating elements: Galv. steel, stainless steelor nickled steel.Resistance wire: NiCr 80/20.For further information: Please contact our sales department.Mounting Tips:There must not be any air wells between the nozzle and the heatingelement, and over width heating elements are not allowed.After the initial heating period, the fixing screws must be tightened.Bending of the wires should be avoided where they are leading out of theheating element.Band heating elements mica-insulated:Dimension limits: Ø min.: 70 mm, width 25 mmMax. surface temperature : 350°CMax. power : 3,2 W/cm 2Band heating elements ceramic insulated:Dimension limits: Ø min.: 65 mm, width 35 mmMax. surface temperature : 650°CMax. power : 8 W/cm 2Plate heating elements mica-insulated:Dimension limits: Min. length x width 50x30 mmMax. surface temperature : 350°CMax. power: >3 W/cm 2 no guarantee12Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Member of the NIBE GroupQuantity:Dimensions(mm): ∅Voltage:Watt:LengthOrdering specificationfor band-/nozzle heatersPlease use this form when ordering nozzleheating elements.∅LA contact fittingtype KOB cable fittingtype KAC nozzle jacket w/cable indicatedD Holder forthermo sensorE HoleF Positioning offixturePlease indicate cable output direction using an arrowas well as length of cable.Please statethreadPlease statediameterThe <strong>SAN</strong> MINIATURE-nozzle heating elements have been designedfrom a stainless tubular heating element 1.3x2.3 mm, cylinder woundand sheathed by a stainless steel jacket.Max. temperature : 750。CMax. load : 15 W/cm 2Connection : 1000 mm teflon insulatedVoltage : 230 V.MINIATURE-NOZZLE HEATINGELEMENTS 230 VOLT∅ 19.05 mm (3/4”) ∅ 22,0 mm (7/8”)Width Power Part Width Power Partmm W no. mm W no.25.4 125 845500 30.5 125 84551025.4 250 845502 30.5 250 84551230.5 125 84550430.5 250 845506Other services according to requirement.Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 05313

The <strong>SAN</strong>-nozzle heating elements are completely resistive to all outer mediassuch as melted plastics, oil, water, gas, etc. The high specific Watt load providesa fast and reliable optaining of the required working temperature.NOZZLEHEATING ELEMENTS<strong>SAN</strong> offers the following 3 types:Type DG: Jacket material : brassMax. operating temp.Max. surface load :280°C3.5 W/cm 2Type DGS: Jacket material : stainless steelMax. operating temp.Max. surface load :350°C6.5 W/cm 2Type DGM: Jacket material : stainless steelMax. operating temp.Max. surface load :600°C10 W/cm 2Other technical data:Voltage : 230 VConnection cable :Length tolerance : + 2 mmHigh voltage test : 2000 VAccessories:3-wire conductor nickellitz with heat resistant insulationand metal braided cover.L = 1000 mm45° axial connection is standardThe nozzle heating elements can be delivered with built-in thermo couple.Special version:The nozzle heating elements can be delivered in special versions, e.g.:• equipped with holes or cuttings• connection cable with various plugsStandardAlternativeAAlternativeBAlternativeCAlternativeS14Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Type DGWidth Power Part Width Power Partmm W no. mm W no.∅ 25 mm∅ 50 mm20 70 844577 20 120 84464030 85 844578 25 150 844641∅ 30 mm 30 180 84464220 70 844580 34 200 84464325 90 844581 38 225 84464430 100 844582 ∅ 55 mm∅ 35 mm 20 150 84465020 85 844600 25 160 84465125 100 844601 30 200 84465230 130 844602 34 225 84465334 140 844603 ∅ 60 mm38 150 844604 20 140 844660∅ 40 mm 25 180 84466120 100 844610 30 225 84466225 120 844611 34 250 84466330 140 844612 38 280 84466434 150 844613 ∅ 70 mm38 180 844614 20 160 84467048 225 844616 25 200 844672∅ 45 mm 30 250 84467320 100 844630 34 280 84467425 140 844631 38 300 84467530 150 844632 ∅ 100 mm34 180 844633 25 280 84467838 200 844634 38 400 84468060 700 844682Member of the NIBE GroupNOZZLEHEATING ELEMENTSDiametres up to 200 mm and other widths can be delivered.Type DGS∅ 32 mm∅ 60 mm30 180 844700 22 275 84473055 300 844704 30 430 844734∅ 40 mm 38 450 84474022 180 844708 48 550 84474430 250 844712 ∅ 70 mm48 375 844716 22 300 844750∅ 45 mm 30 400 84475422 200 844720 38 500 84476038 325 844724 48 650 844764∅ 100 mm22 400 84477038 700 844774Diametres up to 135 mm and other widths can be delivered.Type DGM(not stocked)∅ 30 mm∅ 50 mm25 300 845100 25 375 84514038 350 845104 38 600 84514450 475 845108 60 600 845148∅ 40 mm 75 1100 84515025 300 845120 ∅ 60 mm38 450 845124 25 475 84516060 700 845128 38 725 845164∅ 45 mm 60 600 84516825 350 845130 75 800 84517038 500 84513460 800 845138Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 05315

Member of the NIBE GroupThe <strong>SAN</strong> ceramic heating elements are manufactured to specificationand are used especially for designs where an easy dismountingof the entire plant or part of it is needed, and at thesame time emptying of tanks, pressure vessels and others areto be avoided.The <strong>SAN</strong> round ceramic heating elements are available in variousdiametres and lengths and are mounted mostly in tubewells in the plants, which are to be heated.CERAMICHEATING ELEMENTSROUND and FLATThe <strong>SAN</strong> flat ceramic heating elements are also available in variouswidths and lengths and are most often used for surfaceheating in order to obtain an even heat distribution.headround steatiteend discApart from that, the <strong>SAN</strong> ceramic heating elements are alsoadvantagely used in many constructions, e.g. furnaces in whicha high operating temperature up to 900。C is required.The below table can be used for most heating tasks.L KL VL = n 50LOAD TABLEflat steatiteAIR OIL WATER(stationary) (stationary) andcirculating1.5 W/cm 2 2 W/cm 2 OIL 3 W/cm 2Diametremm W per m W per m W per m10 475 650 95015 700 950 140017 800 1100 160022 1050 1400 210026 1250 1650 245029 1400 1800 270032 1500 2000 300036 1700 2250 340040 1900 2500 380045 2150 2850 425058 2750 3650 5500L KL = n 100L VWidth mmFlat ceramic heating elements48 725 950 145054 800 1100 162558 875 1175 1750Ceramic heating elements built in tubes onflanges for tank heating.REMEMBER VOLT and WATT - DIAMETER - TOTALwhen ordering: LENGTH (L) - COLD END(L k ) -CONNECTION TYPE.VERTICAL OR HORIZONTAL MOUNTINGGillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 05317

CERAMICHEATING ELEMENTS<strong>SAN</strong> offers a minor standard stock programme of ceramic heating elementsfor horizontal mounting and with 50 mm cold end. Otherlengths and power are available upon request.Type Power Max. PartkW L mm no.∅ 29 mm ceramic 230 Vf/A5 0.5 450 83038f/A10 1.0 850 83039f/A15 1.5 1225 83040f/A20 2.0 1650 83041400 Vf/A5/4 0.5 450 83037f/A10/4 1.0 850 83042f/A15/4 1.5 1225 83043f/A20/4 2.0 1650 83044f/A30/4 3.0 1650 830453 x 400 Vf/A40/4 4.0 1650 83046∅ 45 mm ceramic 230 V 1 W/cm 2f/SR 3-1 0.35 250 84300-31f/SR 7-1 0.70 500 84300-71f/SR 10-1 1.00 750 84300-101f/SR 14-1 1.40 1000 84300-141f/SR 17-1 1.75 1250 84300-171f/SR 21-1 2.10 1500 84300-2113 x 400 V 3 W/cm 2f/SR 11-3* 1.10 250 84300-113f/SR 22-3* 2.20 500 84300-223f/SR 33-3 3.30 750 84300-333f/SR 44-3 4.40 1000 84300-443f/SR 55-3 5.50 1250 84300-553f/SR 66-3 6.60 1500 84300-6633 x 400 V 5 W/cm 2f/SR 18-5 1.75 250 84300-185f/SR 35-5 3.50 500 84300-355f/SR 52-5 5.25 750 84300-525f/SR 70-5 7.00 1000 84300-705f/SR 87-5 8.75 1250 84300-875f/SR 105-5 10.50 1500 84300-1055* Only for 230 V18Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Member of the NIBE GroupSURFACELOADThe lifetime of a tubular heating element is mainly determinedby the operating temperature of the resistance wire. The temperatureof the resistance wire is directly dependant of the surfaceload (Watt per cm 2 ) of the tubular heating element.Stationary airThe graph fig. 1 shows the surface temperature of the tubularheating elements in various medias. The stated values areapproximate values, dependant of flow and pressure.OilAir at 10m/sWaterFIG. 1W/cm 2The graph fig. 2 shows the approximate temperature of tubularheating elements mounted in air stream as function of the velocityat constant surface loads.The ambient temperature is 20。C.Additional temperature graphs on page 27.FIG. 2m/sec.In the scheme fig. 3 a guiding load of tubular heatingelements used in various medias is stated.In medias with high heat transmission, the surface load can beincreased considerably in relation to load in air.In corrossive medias, where special tubular jacket material isrequired, the tubular heating elements can be supplied in acidproof steel, Monel 400, Incoloy 800, Inconel 600 and Titaniumas well as PTFE-coated. Also quartz tubular heating elementsare available.In medias, where special care should be taken against danger offire, Ex-danger and others, the surface load must be particularlylow.Our sales department is at your service as regards dimensioningof your special electrical heating assignment.Temp. Recom-Media range mended°C W/cm 2Alcalic baths 100 4-6Ammonia and sal ammoniacbaths 100 2-3Phosphating baths 90 2-4Oil, viscous 100 1-1.5Oil, fluid 50 2.5-3same 100 2-2.5same 250 1.5-2same 350 1-1.5Water, stationary 100 6-10Water in movement 100 10-15Water soluble acids and salts 100 1-2Wax and paint 60 0.5Laid down in rails 200 3-6Embedded in metal 4-6same, but with adjustment 8-10FIG. 3Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 05319

BENDING SHAPESA1 2 3 4 5BCDEFGHIJK20Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Member of the NIBE GroupSurface temperature for <strong>SAN</strong> tubular heating elements, naturalconvection, with chrome nickel steel jacket at various air velocitiesand ambient temperatures.The curves are only guiding, as the surface temperaturedepends on e.g. the dimension between the heating elements,air distribution etc.TEMPERATURE CURVES°C Surface temperatureMax for CN heating pipesAMBIENTTEMPERATURE20°CMax for steel heating pipesSpecific surface load w/cm 2°C Surface temperatureMax for CN heating pipesAMBIENTTEMPERATURE150°CMax for steel heating pipesSpecific surface load w/cm 2Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 05321

TEMPERATURE CURVESAMBIENTTEMPERATURE°C Surface temperatureMax for CN heating pipes250°CMax for steel heating pipesSpecific surface load w/cm 2AMBIENTTEMPERATURE°C Surface temperatureMax for CN heating pipes350°CMax for steel heating pipesSpecific surface load w/cm 222Gillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 053

Member of the NIBE GroupGillelejevej 30 - DK-3230 Graested - DenmarkTel.: +45 48 39 88 88 - Fax: +45 48 39 88 98 - san@san-as.com - www.san-as.comCVR No.: 42 16 59 13 - A/S reg. No.: 53 05323

Gillelejevej 30DK-3230 GraestedTel: +45 48 39 88 88 - Fax: +45 48 39 88 98san@san-as.com - www.san-as.comMember of the NIBE Group• Process <strong><strong>Heat</strong>ing</strong>• <strong><strong>Heat</strong>ing</strong> <strong>Elements</strong>• <strong><strong>Heat</strong>ing</strong> Cables• Ribbed Tube Furnaces• Immersion <strong>Heat</strong>ers• Church <strong><strong>Heat</strong>ing</strong>• Frost Protection• Ex-Material• Oil Radiators• Drum <strong>Heat</strong>ers• <strong><strong>Heat</strong>ing</strong> Mats• Flow <strong>Heat</strong>ers• Air Duct <strong>Heat</strong>ers• High-voltage• Resistors• Controllers• Graested, Denmark• Hereford, England• Frankfurt, GermanyShanghai, China •• Johannesburg, South AftricaWith more than 50 years of experience <strong>SAN</strong> <strong>Electro</strong> <strong>Heat</strong>’smost valuable asset is special knowhow about design, productdevelopment and manufacturing of professional electricalheating equipment for industrial use.The company is geared to deliver 100% customized products,and thus functions both as a catalyst for a developmentproject and as supplier of the final product. At the same timewe insure and maintain the required quality level, mechanicaland electrical dimensioning, approvals and documentation.