VW252-65 ABC Auto Test Report to GMN8423 Type II ... - Darcoid

VW252-65 ABC Auto Test Report to GMN8423 Type II ... - Darcoid

VW252-65 ABC Auto Test Report to GMN8423 Type II ... - Darcoid

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

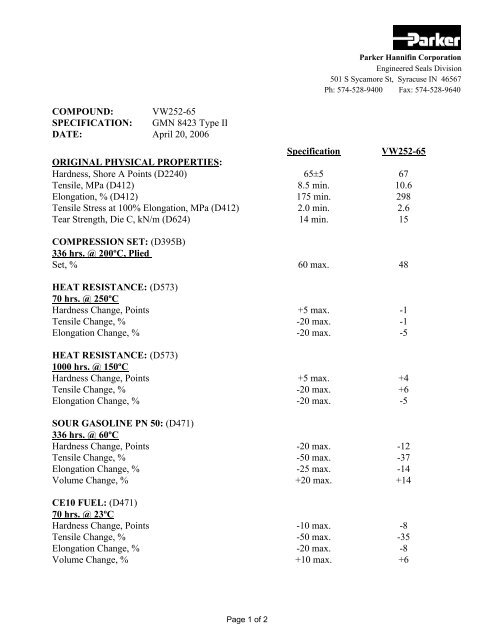

COMPOUND: <strong>VW252</strong>-<strong>65</strong>SPECIFICATION: GMN 8423 <strong>Type</strong> <strong>II</strong>DATE: April 20, 2006Parker Hannifin CorporationEngineered Seals Division501 S Sycamore St, Syracuse IN 4<strong>65</strong>67Ph: 574-528-9400 Fax: 574-528-9640Specification <strong>VW252</strong>-<strong>65</strong>ORIGINAL PHYSICAL PROPERTIES:Hardness, Shore A Points (D2240) <strong>65</strong>±5 67Tensile, MPa (D412) 8.5 min. 10.6Elongation, % (D412) 175 min. 298Tensile Stress at 100% Elongation, MPa (D412) 2.0 min. 2.6Tear Strength, Die C, kN/m (D624) 14 min. 15COMPRESSION SET: (D395B)336 hrs. @ 200ºC, PliedSet, % 60 max. 48HEAT RESISTANCE: (D573)70 hrs. @ 250ºCHardness Change, Points +5 max. -1Tensile Change, % -20 max. -1Elongation Change, % -20 max. -5HEAT RESISTANCE: (D573)1000 hrs. @ 150ºCHardness Change, Points +5 max. +4Tensile Change, % -20 max. +6Elongation Change, % -20 max. -5SOUR GASOLINE PN 50: (D471)336 hrs. @ 60ºCHardness Change, Points -20 max. -12Tensile Change, % -50 max. -37Elongation Change, % -25 max. -14Volume Change, % +20 max. +14CE10 FUEL: (D471)70 hrs. @ 23ºCHardness Change, Points -10 max. -8Tensile Change, % -50 max. -35Elongation Change, % -20 max. -8Volume Change, % +10 max. +6Page 1 of 2

Parker Hannifin CorporationEngineered Seals Division501 S Sycamore St, Syracuse IN 4<strong>65</strong>67Ph: 574-528-9400 Fax: 574-528-9640COMPOUND: <strong>VW252</strong>-<strong>65</strong>SPECIFICATION: GMN 8423 <strong>Type</strong> <strong>II</strong>DATE: April 20, 2006Specification<strong>VW252</strong>-<strong>65</strong>TF2W FUEL: (D471)1000 hrs. @ 60ºCHardness Change, Points -20 max. -16Tensile Change, % -60 max. -45Elongation Change, % -25 max. -10Volume Change, % +25 max. +20LOW-TEMPERATURE RESISTANCE: (D1329)Temperature of Retraction, TR-10, ºC -5 max. -7PERMEATION CONSTANT: (Thwing-Albert Cup Method)CE10 Fuel @ 40ºC(g*mm)/(m 2 *day) 40 max. 34COMPRESSION STRESS RELAXATION:(Modified Wykeham Farrance Jig, 0.25 in x 0.51 in Solid But<strong>to</strong>n)1008 hrs. @ 150ºC Dry AirInitial Retained Force, % 25 min. 28Relaxed Retained Force, % 35 min. 52Page 2 of 2