Download the Bottle, Drum & Tank Washing brochure in SI/Metric ...

Download the Bottle, Drum & Tank Washing brochure in SI/Metric ...

Download the Bottle, Drum & Tank Washing brochure in SI/Metric ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HydroWhirl ® S<strong>Tank</strong> <strong>Wash<strong>in</strong>g</strong> - Slotted Spray NozzleDE<strong>SI</strong>GN FEATURES• Cleans more quickly, and uses lesswater and lower pressure than statictank washers• Surface f<strong>in</strong>ish of 0.8 microns R a or better:ideal for sanitary applications• Laser-welded design for durability• Sta<strong>in</strong>less steel construction - corrosionresistantmaterial• Three connections: threaded, clip-on,and welded• Made from FDA approved materials foruse <strong>in</strong> Clean-In-Place (CIP) applications.SPRAY CHARACTERISTICS• Self-clean<strong>in</strong>g bear<strong>in</strong>gs• Vigorous mov<strong>in</strong>g spray action• Spray Angles: 360°, 90° Up, 90° Down,180° Up, 180° Down, 270° Up, 270° DownFlow rates: 4.39 – 338 l/m<strong>in</strong>All 360° HydroWhirl S nozzlesare available with ATEX approvalfor Zone 0.STANDARD CONNECTION <strong>SI</strong>ZESAdditional connnection sizes available on requestConnectionTypeHWS20-3HWS20-4HWS20HWS30-5HWS30-6HWS30HWS40-7.5Nozzle NumberHWS40-8HWS40-9HWS40HWS40HF-11Pipe Clip On -- -- -- -- -- 3/8” -- -- -- 3/4” -- 3/4” -- 1-1/2”Tube Clip On -- -- -- -- -- 3/4” -- -- -- 1” -- 1” -- 2”Pipe Weld On -- -- 1/4” -- -- 3/8”, 1/2” -- -- -- 3/4”, 1 -- 3/4”, 1 -- 1-1/2”, 2”Tube Weld On -- -- 1/2” -- -- 3/4” -- -- -- 1” -- 1” -- 2”FNPT/FBSP 1/8” 1/8” 1/8” 3/8” 3/8” 1/4” 3/4” 3/4” 3/4” 3/4” 3/4” 3/4” 1-1/2” 1-1/2”DIN Clip On(mm)-- -- 8 -- -- 15 -- -- -- 20, 25 -- 20, 25 -- 40, 50DIN Weld On(mm)HWS40HFHWS50-16-- -- 8, 10 -- -- 15 -- -- -- 15, 20, 25 -- 15, 20, 25 -- 40, 50HydroWhirl ® S Flow Rates and DimensionsHWS50FemalePipeSizeNozzleNumber0.5barLITERS PER MINUTE @BAR0.7bar1bar2bar3bar4barDimensions (mm)A B CMass(g)CoverageDiameter(m)@2.75 barB1/8"HWS-20-3 4.39 4.79 5.40 7.05 8.19 9.11HWS-20-4 7.41 8.10 9.20 12.2 14.2 15.9HWS-20 10.8 12.0 13.9 20.2 25.3 29.13/8” HWS-30-5 7.71 8.80 10.4 15.3 18.9 21.9HWS-30-6 19.5 21.0 23.4 29.8 34.2 37.616.6 42.7 69.1 24.91.51.827.9 59.4 83.3 93.0 2.4A1/4" HWS-30 19.1 21.7 25.7 37.0 45.4 53.1HWS-40-7.5 18.8 21.3 25.1 35.7 43.8 50.73/4"HWS-40-8 21.5 24.3 28.6 40.6 49.6 57.2HWS-40-9 26.6 30.2 35.7 51.5 63.0 72.738.9 92.7 108 306 3.4HWS-40 30.2 34.6 41.2 59.9 71.8 82.5HWS-40HF-11 40.9 46.4 54.5 77.3 95.0 109HWS-40HF 50.4 57.3 67.5 97.0 116 13238.9 92.7 108 302 4.0C1 1/2" HWS-50-16 81.6 92.0 108 154 188 218HWS-50 125 142 167 238 293 338Standard Materials: nozzle: 316L; ball bear<strong>in</strong>gs: 316 sta<strong>in</strong>less steel69.1 154.9 180 1524 5.5Awww.BETE.com

HydroWhirl Poseidon ®spray nozzles for quick,efficient tank clean<strong>in</strong>gThe HydroWhirl Poseidon tankwash<strong>in</strong>g nozzle directs<strong>the</strong> clean<strong>in</strong>g water through a rotat<strong>in</strong>g head at <strong>the</strong> tip of<strong>the</strong> spray assembly. This produces a slowmov<strong>in</strong>g, highimpactspray action aga<strong>in</strong>st <strong>in</strong>ternal surfaces of <strong>the</strong> tank.The HydroWhirl Poseidon nozzle head uses impact andrepetition to quickly break up and wash away contam<strong>in</strong>ation.The comb<strong>in</strong>ation of <strong>the</strong> spray pattern and slowrotation of <strong>the</strong> HydroWhirl Poseidon tankwash<strong>in</strong>g nozzleis especially effective at remov<strong>in</strong>g scum r<strong>in</strong>gs ortougher, stuckon material.Advantages of <strong>the</strong> HydroWhirl®Poseidon® rotary tank-wash<strong>in</strong>g nozzle:• Cleans more quickly and uses less water and lowerpressure than static tank washers• Complete 360° omnidirectional coverage• Slow rotation speed provides higher impact and moreefficient clean<strong>in</strong>g.• Durable PTFE nozzle construction withstands extremechemical and elevated temperature environments.• Simple <strong>in</strong>ternal design allows reliable flowthroughoperation• Design validated by lab test<strong>in</strong>g to 93°C (200°F)• Ma<strong>in</strong>tenancefriendly design allows disassembly,<strong>in</strong>spection, and reassembly with basic hand tools.• Made from FDAapproved materials for use <strong>in</strong> Clean<strong>in</strong>Place(CIP) applicationsThe HydroWhirl Poseidon tank-wash<strong>in</strong>gnozzle has been carefully designed forlong service lifeThe HydroWhirl Poseidon tank wash<strong>in</strong>gnozzle is an outstand<strong>in</strong>g comb<strong>in</strong>ationof design, quality, and performance.The HydroWhirl Poseidon tank wash<strong>in</strong>gnozzle is ideal for anyone who needsa polymer nozzle for reliable, efficientclean<strong>in</strong>g of tanks and o<strong>the</strong>r <strong>in</strong>terior spaces.Comprehensive Quality Control:• Material traceability controlled throughout production• BETE product quality is ma<strong>in</strong>ta<strong>in</strong>ed us<strong>in</strong>g a qualitysystem registered to ISO 90012008Design flexibility:• Available with pipe, tube, or DIN clipon connections.Threaded connections available upon request.• Flow range: 58.3 to 333 L/m<strong>in</strong>

HydroWhirl ® Orbitortank clean<strong>in</strong>g mach<strong>in</strong>e is idealfor high impact clean<strong>in</strong>gThe HydroWhirl ® Orbitor is a versatile tank clean<strong>in</strong>gmach<strong>in</strong>e designed to meet <strong>the</strong> high standards required<strong>in</strong> <strong>the</strong> food, brew<strong>in</strong>g, beverage, dairy, andchemical <strong>in</strong>dustries comb<strong>in</strong><strong>in</strong>g high performanceclean<strong>in</strong>g efficiency with extended operat<strong>in</strong>g life andreduced life cycle costs.Advantages of <strong>the</strong> HydroWhirl Orbitor tankclean<strong>in</strong>g mach<strong>in</strong>e.• The HydroWhirl Orbitor can be stripped,ma<strong>in</strong>ta<strong>in</strong>ed, and rebuilt <strong>in</strong> less than 15 m<strong>in</strong>utes.• The HydroWhirl Orbitor is self clean<strong>in</strong>g andself lubricated.• Enhanced external clean<strong>in</strong>g with dedicated nozzlesthat clean <strong>the</strong> external surfaces of <strong>the</strong> mach<strong>in</strong>e andits mount<strong>in</strong>g pipe.• Designed for use where high impact clean<strong>in</strong>gis required.• The HydroWhirl Orbitor is ideal for use <strong>in</strong> largertanks and where <strong>the</strong> product is difficult to clean.• Designed with m<strong>in</strong>imum mov<strong>in</strong>g parts to ensureextended operat<strong>in</strong>g life and reduced down time.Available Versions:• 2 or 4 nozzle mach<strong>in</strong>es• Variable cycle times• Male or Female connections• 360º wash pattern• 180º down wash pattern• 180º up wash patternTypical HydroWhirl Orbitor Applications:Typically used where high imp<strong>in</strong>gement clean<strong>in</strong>g isrequired and where <strong>the</strong> most efficient use of utilities<strong>in</strong> necessary.BREWINGBright beer tanks, coppers, malt<strong>in</strong>gsCOATINGS AND PAINTSStorage silos, process vessels, mixersFOOD AND DAIRYRaw milk storage, spray driers, process vessels,storage silosCHEMICALProcess vessels, mixers, storage silosBEVERAGEProcess vessels, storage silosKey Features and Benefits:• Designed to meet hygienic standards• Optimum consumption of water, chemicals, and time= reduced operat<strong>in</strong>g costs• M<strong>in</strong>imum mov<strong>in</strong>g parts = reduced lifecycle costs• Self clean<strong>in</strong>g; self lubricat<strong>in</strong>g = no process contam<strong>in</strong>ation• High impact jets; orbital wash pattern = high efficiencyclean<strong>in</strong>g process• Compact design = will fit through small accessflanges• 2 or 4 nozzle configuration = wash pattern variableup to super <strong>in</strong>tense• External Surface F<strong>in</strong>ish: 0.5 microns Ra or betterAll HydroWhirl Orbitor tank clean<strong>in</strong>g mach<strong>in</strong>es areavailable with ATEX approval for Zone 0.

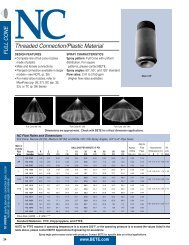

TW<strong>Tank</strong> <strong>Wash<strong>in</strong>g</strong>DE<strong>SI</strong>GN FEATURES• Clog-resistant spiral design• Energy efficient• Compact design; fits small open<strong>in</strong>gsSPRAY CHARACTERISTICS• Easy to ma<strong>in</strong>ta<strong>in</strong>• Unique patterns that spray <strong>in</strong> oppos<strong>in</strong>gdirectionsFlow rates: 11.4 to 260 l/m<strong>in</strong>BTW 20 TW 1TW 12-TW 20 (180°)TW 12-TW 20 (270°)60°TW 1Dimensions are approximate. Check with BETE for critical dimension applications.Pipe Nozzle Scrubb<strong>in</strong>g R<strong>in</strong>s<strong>in</strong>gSize Number Diameter (mm) Diameter (mm)TW12 380 760TW14 460 12003/8TW16 610 1500TW20 910 21001 TW1 2400 6100Dimensions are approximate. Check with BETE for critical dimension applications.Approx. (mm)Male Available LITERS PER MINUTE Free Metal Only WeightPipe Nozzle Spray K 0.7 1 2 3 4 5 Orifice Pass. Dim. (mm) (g)Size Number Angles Factor bar bar bar bar bar bar Dia Dia. A B C MetalTW12 180°, 270° 13.7 11.4 13.7 19.3 23.7 27.3 30.64.83 3.30TW14 180°, 270° 18.5 15.4 18.5 26.1 32.0 36.9 41.35.59 3.303/873.0 17.5 49.6TW16 180°, 270° 24.2 20.2 24.2 34.2 41.8 48.3 54.06.35 3.30TW20 180°, 270° 37.6 31.5 37.6 53.2 65.1 75.2 84.17.87 3.301 TW1 270° 116 97.2 116 164 201 232 26014.2 5.08 146.1 298Flow Rate ( l ⁄ m<strong>in</strong> ) = K √ barbarStandard Materials: Brass, 316 Sta<strong>in</strong>less Steel.Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.www.BETE.com

CLUMP<strong>Tank</strong> <strong>Wash<strong>in</strong>g</strong> NozzlesDE<strong>SI</strong>GN FEATURES• Each nozzle <strong>in</strong> <strong>the</strong> stationary cluster isa BETE clog-resistant full cone nozzleof <strong>the</strong> MaxiPass ® series• Can be supplied with various o<strong>the</strong>rBETE nozzles for any desiredapplication• Female connectionSPRAY CHARACTERISTICS• Spherical omnidirectionalcoverage• Six nozzles arranged <strong>in</strong> clusterto project spray <strong>in</strong> all directionsFlow rates: 28.1 to 290 l/m<strong>in</strong>(Special flow rates available)MetalCLUMP Coverage ChartWhen spray<strong>in</strong>g at 3 barFemalePipe Nozzle Scrubb<strong>in</strong>g R<strong>in</strong>s<strong>in</strong>gSize Number Diameter (mm) Diameter (mm)CLUMP125 1200 24003/4" CLUMP156 1200 3700CLUMP187 1800 4300CLUMP187 1800 43001" CLUMP218 2400 4300CLUMP250 3000 4900CLUMP Flow Rates and DimensionsSpherical, 360° Spray Angle, 3/4" and 1" Pipe Size, BSP or NPTTypical CLUMP <strong>in</strong>stallationLITERS PER MINUTE @ BARM<strong>in</strong>imumFemale Entrance WeightPipe Nozzle K 0.7 1 2 3 4 5 Open<strong>in</strong>g (mm) (kg)Size Number Factor bar bar bar bar bar bar A Metal Plas.CLUMP125 33.2 28.1 33.2 46.0 55.6 63.7 70.83/4"CLUMP156 52.7 44.6 52.7 73.2 88.2 101 112 120 1.29 0.22CLUMP187 76.2 65.7 76.2 106 128 146 163CLUMP187 76.2 65.7 76.2 106 128 146 1631" CLUMP218 121 103 121 168 203 232 258 146 2.34 0.40CLUMP250 136 115 136 188 228 261 290Flow Rate (l/m<strong>in</strong>) = K (bar) 0.47Dimensions are approximate. Check with BETE for critical dimension applications.Standard Materials: 316 Sta<strong>in</strong>less Steel. O<strong>the</strong>r materials available on request. 3/4" CLUMP not available <strong>in</strong> PTFE.Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.www.BETE.com

BETE Fog Nozzle,Inc.50 Greenfield St.Greenfield, MA 01301T (413) 7720846F (413) 7726729www.BETE.com©2013 BETE Fog Nozzle, Inc. All rights reserved.TW 0213 <strong>SI</strong>/<strong>Metric</strong>