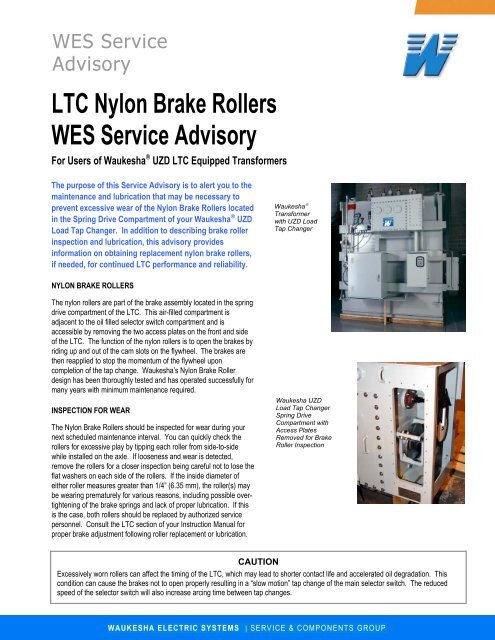

LTC Nylon Brake Rollers WES Service Advisory - SPX Transformer ...

LTC Nylon Brake Rollers WES Service Advisory - SPX Transformer ...

LTC Nylon Brake Rollers WES Service Advisory - SPX Transformer ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

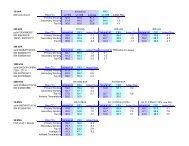

A5. Reassemble the rollers onto the lubricated axle usingboth flat washers and the cotter pin (see Figure 2).Refer to your Instruction Manual to check for properbrake operation in both directions.A6. Make adjustments to the brake spring tension asneeded to stop flywheel rotation between the indicatormarks on the flywheel that are appropriate to thedirection of travel. Spring tension setting should not beless than 35 mm as measured between flat washers(see Figure 1). Note: Over-tightening may causeaccelerated wear of the nylon brake rollers.A7. If the flywheel rotation cannot be stopped between theappropriate indicator marks with a brake spring lengthof 35 mm or greater, complete brake replacement maybe required. Contact Larry Kriege at <strong>WES</strong> <strong>Transformer</strong><strong>Service</strong> (800-835-2732 ext. 1507) for additionalinformation.This completes the inspection and lubrication processfor existing brake rollers. Proceed to Step B1 for nylon brakeroller replacement.NYLON BRAKE ROLLER REPLACEMENTB1. Use angled pliers to remove the cotter pin from theshaft. Remove and discard the used cotter pin andoutside washer.B2. Use a small pry bar to separate the brake shoe from theflywheel. Use care not to damage the brake pad orflywheel.B3. Remove and discard the existing roller and insidewasher.B4. Wipe the axle shaft clean and check for burrs.B5. Install the replacement roller by assembling the insidewasher, roller, outside washer and cotter pin supplied inthe <strong>Brake</strong> Roller Replacement Kit, either: HVS Part Number: 1030-043K-V1 Waukesha Part Number: 550012R1473B6. Lubrication of the replacement brake roller axles is notrequired since the new rollers have lubricantimpregnated,bronze inserts.B7. Make adjustments to the brake spring tension as neededto stop the flywheel rotation between the indicator markson the flywheel that are appropriate to the direction oftravel. Spring tension setting should not be less than 35mm as measured between flat washers (see Figure 1).Note: Over-tightening may cause accelerated wear of thenylon brake rollers.If the flywheel rotation cannot be stopped between the appropriateindicator marks with a brake spring length of 35 mm or greater,complete brake replacement may be required.KIT ORDERING AND CONTACT INFORMATIONIf you need replacement Waukesha UZD <strong>LTC</strong> <strong>Nylon</strong> <strong>Brake</strong> <strong>Rollers</strong>please contact High Voltage Supply at 800-338-5526 and ask forthe Sales department. Request HVS Part Number 1030-043K-V1.You will need to request one <strong>Brake</strong> Roller Replacement Kit perUZD <strong>LTC</strong>. These kits will be supplied to you at no charge.If you have questions or require additional information, pleasecontact Larry Kriege at <strong>WES</strong> <strong>Transformer</strong> <strong>Service</strong> at 800-835-2732ext. 1507.At Waukesha Electric Systems, your satisfaction is our mostimportant goal.<strong>Nylon</strong> <strong>Brake</strong> Roller assembly forWaukesha ® UZD Load Tap Changer

400 S. Prairie Ave.Waukesha, WI 53186800-835-2732www.wesservice.com©2003 Waukesha Electric Systems, Inc.SRV-SA-0312WAUKESHA ELECTRIC SYSTEMS | SERVICE & COMPONENTS GROUP