Adjustable Baseplates

Adjustable Baseplates

Adjustable Baseplates

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

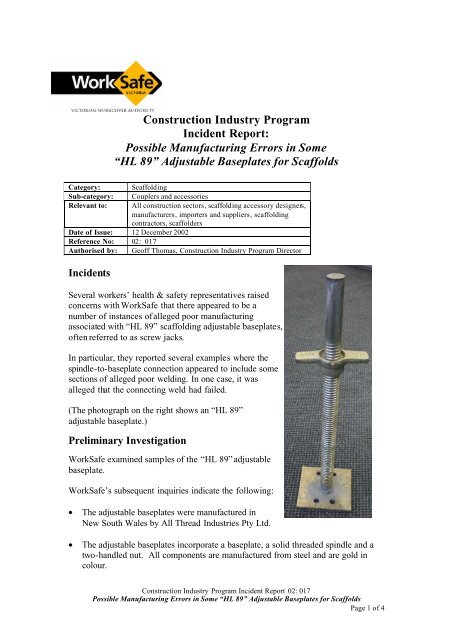

• The manufacturer had commissioned the appropriate testing on this design ofadjustable baseplate. The test report confirms that the adjustable baseplates hadsatisfied the performance testing requirements of the relevant AustralianStandard 1 .However, the test report did not reference “HL 89” or any other manufacturer’smark, meaning that there was no way of readily checking at the point of supply oron-site that the test report related to the particular products in question.• WorkSafe estimates that up to 2,000 “HL 89” adjustable baseplates may havebeen supplied by the manufacturer. It is understood that, to date, supply has beenlimited to the Victorian market.Remedial ActionVictorian suppliers of All Thread Industries adjustable baseplates have agreed tonotify all affected sites that:• The nuts on some spindles may be capable of being wound higher than 150 mmfrom the end, so that scaffolders can be alerted to ensure that they are notoverwound, and• The welding connecting the spindles to their baseplates should be visuallyinspected for faults and any items suspected of having faulty welds should beimmediately withdrawn from service and promptly returned to the supplier.The suppliers have undertaken to examine all items, once they are taken off hire, andto return any suspect items to All Thread Industries so that they can be:• Examined for welding adequacy, and/or• Provided with a mechanical means, where necessary, to permanently prevent thenut from being overwound.The manufacturer has advised that it will have the test report re-issued so that itreferences the permanent marking, HL 89, referred to above, and that it will thenprovide the re-issued test report to the suppliers of All Thread Industries adjustablebaseplates.1 The relevant Australian Standard is AS 1576.2, Scaffolding, Part 2: Couplers and Accessories.Appendix G sets out the performance test for adjustable baseplates.Construction Industry Program Incident Report 02: 017Possible Manufacturing Errors in Some “HL 89” <strong>Adjustable</strong> <strong>Baseplates</strong> for ScaffoldsPage 3 of 4

Preliminary FindingsSituations such as this may be avoided if the design, manufacturing and test reportingrequirements of the Australian Standards for scaffolding, the AS 1576 series, are fullycomplied with at all times 2 . In particular:• Clause 2.2 of AS/NZS 1576.1, Scaffolding, Part 1: General Requirements,requires the welding of steel components to comply with AS 1554.1, StructuralSteel Welding, Part 1: Welding of Steel Structures.• Clause 3.3.2 of AS 1576.2, Scaffolding, Part 2: Couplers and Accessories, statesthat, “When fully extended, a 150 mm length of the spindle shall remain in thetube and this engagement shall be mechanically ensured by a permanently fixedstop.”• Appendix G, Clause G5, of AS 1576.2 requires the test report to include, amongstother things, the manufacturer’s identification of the adjustable baseplate.The Australian Standards referred to in this incident report can be purchased on-linefrom Standards Australia at:www.standards.com.auDistributionPosted on WorkSafe web-site Construction Page: 12 December 2002E-mailed to Foundations for Safety delegates: 12 December 2002E-mailed to WorkSafe's Construction Safety Circulation Service 13 December 2002subscribers:E-mailed to interstate OHS regulatory authorities: 12 December 2002WorkSafe Construction Industry Program field staff:For on-site distributionwhere appropriateDisclaimer:This incident report contains information following WorkSafe’s inquiries into the incidents as at thedate of this report. The information contained in this report does not necessarily re flect the finaloutcome of WorkSafe’s action with respect to the incidents. WorkSafe does not warrant that theinformation in this incident report is complete or up to date and does not accept any liability to anyperson for the information contained in this incident report or as to its use.2 The AS 1576 series of Australian Standards forms part of WorkSafe’s Code of Practice for Plant,which, amongst other things, provides advice to designers, manufacturers, importers and suppliers withobligations under the Victorian Occupational Health and Safety (Plant) Regulations 1995 onrecommended ways of achieving compliance with those obligations. The Code of Practice is available,free of charge, from local WorkSafe offices or on-line at www.workcover.vic.gov.au.Construction Industry Program Incident Report 02: 017Possible Manufacturing Errors in Some “HL 89” <strong>Adjustable</strong> <strong>Baseplates</strong> for ScaffoldsPage 4 of 4