WebCast/OnsIte auCtIOn - Maynards Industries

WebCast/OnsIte auCtIOn - Maynards Industries

WebCast/OnsIte auCtIOn - Maynards Industries

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

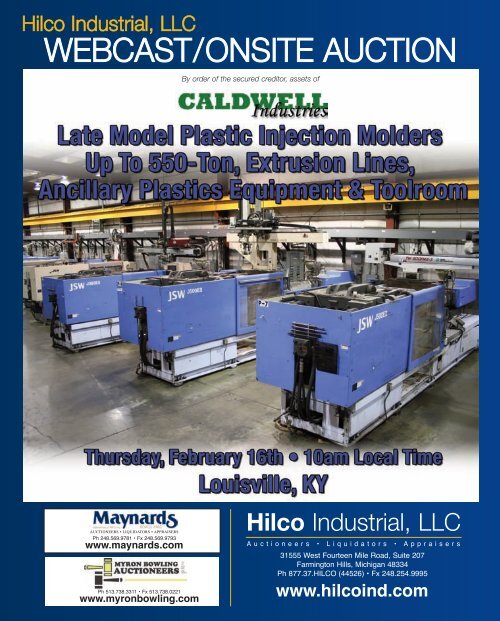

Hilco Industrial, LLC<strong>WebCast</strong>/<strong>OnsIte</strong> <strong>auCtIOn</strong>By order of the secured creditor, assets ofAuctioneers • LiquidAtors • ApprAisersPh 248.569.9781 • Fx 248.569.9793www.maynards.comPh 513.738.3311 • Fx 513.738.0221www.myronbowling.comHilco Industrial, LLCA u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s31555 West Fourteen Mile Road, Suite 207Farmington Hills, Michigan 48334Ph 877.37.HILCO (44526) • Fx 248.254.9995www.hilcoind.com

extrusIOn LInes • PLastIC InJeCtIOn mOLDIng maCHInes(17) PLASTIC INJECTION MOLDING MACHINES1 – VAN dORN dEMAg MOdEL 550HP60 PLASTIc INJEcTION MOLdINg MAcHINE, S/N 500HP60-0879(1996), LOT # 106, 550-Ton Clamp Force, 60 Oz. Shot Size, Hydraulic Clamp, Tie Bar Spacing36.5" H x 31.89" V, Daylight 11.5"-62.0", Clamp Stroke 38.0", Pathfinder 4500 MicroprocessorControl, 100-HP Main Hydraulic Pump2 – JSW MOdEL J500EII PLASTIc INJEcTION MOLdINg MAcHINES, S/Ns 298725601, 298725301,(1999), 500-Ton Clamp Force, 101.3 Cu. In. Shot Size, Toggle Clamp, Tie Bar Spacing 31.89" H x31.89" V, Mold Thickness 14.96"-29.53", Daylight Opening 61.02", Clamp Stroke 31.50", Syscom1000 Microprocessor Control1 – cINcINNATI MILAcRON MOdEL VT440-41 PLASTIc INJEcTION MOLdINg MAcHINE,S/N T39A0398039, (1998), 440-Ton Clamp Force, 41 Oz. Shot Size, Toggle Clamp, Tie Bar Spacing29" H x 29" V, CAMAC 486C Microprocessor Control1 – cINcINNATI MILAcRON MOdEL VH400-54 PLASTIc INJEcTION MOLdINg MAcHINE,S/N H04A0195057, (1995), 400-Ton Clamp Force, 54 Oz. Shot Size, Hydraulic Clamp, Tie BarSpacing 29" H x 29" V, Daylight 7.1"- 44.7", Clamp Stroke 37.0", CAMAC 486 Microprocessor Control1 – JSW MOdEL J385EII PLASTIc INJEcTION MOLdINg MAcHINE, S/N 299712107545 (2000),385 Clamp Force, Toggle Clamp, Tie Bar Spacing 28.74" H x 28.74" V, Mold Thickness 12.6"-26.38",Daylight Opening 53.94", Clamp Stroke 27.56", Syscom 1000 Microprocessor Control1 – JSW MOdEL J385E-c5 PLASTIc INJEcTION MOLdINg MAcHINE, S/N 292012017, (1992),385 Clamp Force, Toggle Clamp, Tie Bar Spacing 28.74" H x 28.74" V, Mold Thickness 12.6"-26.38",Daylight Opening 53.94", Clamp Stroke 27.56", Microprocessor Control Terminal, Machine3 – JSW MOdEL J245E-c5 PLASTIc INJEcTION MOLdINg MAcHINES, S/Ns 293008061,292008005, 293008039, (As New as 1994),245 Clamp Force, 33.87 Cu. In. Shot Size, ToggleClamp, Tie Bar Spacing 22.83" H x 22.83" V, Mold Thickness 9.06"-19.69", Daylight Opening 41.34",Clamp Stroke 21.65", Microprocessor Control Terminal1 – JSW MOdEL J200ELII PLASTIc INJEcTION MOLdINg MAcHINE, S/N 298765004, (1999),200-Ton Clamp Force, 18.3 Cu. In. Shot Size, Electric Servo Drive Clamp, Tie Bar Spacing 20.9" H x20.9" V, Mold Thickness 8.7"-19.7", Daylight Opening 37.0", Clamp Stroke 17.3", Microprocessor Control1 – cINcINNATI MILAcRON MOdEL VT-165-11 PLASTIc INJEcTION MOLdINg MAcHINE,S/N T36A0397020, (1997), 165-Ton Clamp Force, 11 Oz. Shot Size, Toggle Clamp, Tie Bar Spacing18" H x 16-1/2" V, CAMAC 486 Microprocessor Control1 – JSW MOdEL J165EII PLASTIc INJEcTION MOLdINg MAcHINE, S/N 297302513, (1997), 165-TonClamp Force, 18.3 Cu. In. Shot Size, Toggle Clamp, Tie Bar Spacing 20.08" H x 20.08" V, MoldThickness 8.66"-17.72", Daylight Opening 35.04", Clamp Stroke 17.32", Syscom Microprocessor Control1 – JSW MOdEL J85EII PLASTIc INJEcTION MOLdINg MAcHINE, S/N 296704420, (1997), 85-TonClamp Force, 9.21 Cu. In. Shot Size, Toggle Clamp, Tie Bar Spacing 14.17" H x 14.17" V, MoldThickness 7.09"-13.78", Daylight Opening 25.59", Clamp Stroke 11.81", Syscom Microprocessor Control2 – JSW MOdEL J85E-c5 PLASTIc INJEcTION MOLdINg MAcHINES, S/Ns 293019001,293767305, (1994), 85-Ton Clamp Force, 9.21 Cu. In. Shot Size, Toggle Clamp, Tie Bar Spacing14.17" H x 14.17" V, Mold Thickness 7.09"-13.78", Daylight Opening 25.59", Clamp Stroke 11.81",Microprocessor Control1 – ARBURg ALLROUNdER MOdEL 320M (750-210) PLASTIc INJEcTION MOLdINg MAcHINE,S/N 156189, (1992), Clamping Force 750 kN (84.3 Ton), 5.18 Cu. In. Shot Size, Tie Bar Spacing12" x 12", Not In ServiceFor more information, please visit us on the web at www.hilcoind.com 3

vertICaL CLamP PLastIC InJeCtIOn mOLDIng maCHInes • rObOts(5) VERTICAL CLAMP PLASTIC INJECTION MOLDING MACHINES1 – ENgEL MOdEL 2000 / 450 VHSH VERTIcAL cLAMPINg PLASTIc INJEcTION MOLdINgMAcHINE, S/N 3970-400-91, 450-Ton Clamp Force, 48.9 Oz. Shot Size, Toggle Clamp, R-L ShuttleTable, Table Size 33" x 108", Upper Platen Size 47.2 " x 47.2", Tie Bar Clearance 33.5" x 33.5", ClampStroke 27.5", 56" Maximum Daylight, 9.02"-29.02" Mold Height, Engel CC90 Microprocessor Control,*NOTE: This Machine Is Located In Grand Rapids, MI; *NOTE: Battenfield Airmould, Tu-Pac Hydraulic &Conair Vacuum Load Equipment Shown In Photo's Not Included With Machine1 – cINcINNATI MILAcRON MOdEL VEcTOR cH-150-S VERTIcAL cLAMPINg PLASTIc INJEcTIONMOLdINg MAcHINE, S/N 3958A01/94-6, 150-Ton Clamp Force, 16 Oz. Shot Size, Hydraulic Clamp,R-L Shuttle Table, Overall Table Area 16" x 121", Upper Platen Size 16" x 40", 28" Maximum Daylight,CAMAC VST Microprocessor Control, 40-HP Self-Contained Hydraulic Unit, *NOTE: This Machine IsLocated In Grand Rapids, MI; *NOTE: AEC Whitlock Vacuum Loader/Hopper Shown In Photo's NotIncluded With Machine1 – PH TRUEBLOOd MOdEL PH150A-9 VERTIcAL cLAMPINg PLASTIc INJEcTION MOLdINgMAcHINE, S/N 70012, 125-Ton Clamp Force, 8.5 Oz. Shot Size, Hydraulic Clamp, R-L Shuttle Table,Overall Table Area 14" x 45", Upper Platen Size 14" x 21", 27" Maximum Daylight, Barber ColmanMicroprocessor Control, Self-Contained Hydraulic Unit, *NOTE: This Machine Is Located In GrandRapids, MI1 – gLUcO MOdEL VS30 VERTIcAL cLAMPINg PLASTIc INJEcTION MOLdINg MAcHINE, S/N98670, 30-Ton Clamp Force, Shot Size NA, Hydraulic Clamp, R-L Shuttle Table, Overall Table Area 10"x 35", Upper Platen Size 16" 21", 16.5" Maximum Daylight, Allen Bradley Panel View 900 MicroprocessorControl, 15-HP Self-Contained Hydraulic Unit, *NOTE: This Machine Is Located In Grand Rapids, MI1 – AUTOJEcTOR MOdEL HA50-5 VERTIcAL cLAMPINg PLASTIc INJEcTION MOLdINg MAcHINE,S/N 44409589-0687, 30-Ton Clamp Force, 8.8 Cu. In. Shot Size, Indexing Table, Not In Service(11) ROBOTS*NOTE: Robots May Be Offered Separately From MachineThey Are Mounted On1 – WITTMANN MOdEL W633 3-AXIS ROBOT, S/N5106/084, Servo Drive Linear Slides, Stroke; X-500,Y-1600, Z-25001 – STAR AUTOMATION MOdEL TW-800FM III-3 3-AXISROBOT, S/N 80GXK16-0022, Servo Drive Linear Slides,STEC-450 Hand Held Pendant Control1 – INSOL / IcHIKOH MOdEL WB2-15115 SYNcRO-ARMdUAL HEAd 3-AXIS ROBOT, S/N M-990024, ServoDrive Linear Slides, Console Control With 5-Axis HandHeld Pendant1 – WITTMANN MOdEL W631 3-AXIS ROBOT, S/N 5157(2001), Servo Drive Linear Slides, Stroke: X-900, Y-1200,Z-2000, Hand Held Pendant Control1 – INSOL MOdEL ISP-950W SPRUE PIcKER ROBOT,S/N P000173-2, Hand Held Pendant Control1 – cONAIR HARMO MOdEL EX-450 SPRUE PIcKERROBOT, S/N 011761, Harmo PC-EIID Remote Controller1 – cONAIR HARMO MOdEL EX-350 SPRUE PIcKERROBOT, S/N 011235, No Control1 – YUSHIN MOdEL HOP-IIIM-750 SPRUE PIcKERROBOT, S/N 986395-09, Hand Pendant Controller1 – YUSHIN MOdEL HOP-III-750 SPRUE PIcKER ROBOT,S/N 976509-11, Hand Pendant Controller1 – YUSHIN MOdEL HOP-III-550 SPRUE PIcKER ROBOT,S/N NA, Hand Pendant Controller1 – cONAIR HARMO MOdEL NA SPRUE PIcKERROBOT, S/N NA, Harmo PC-RX1 Hand Pendant Control(14) VACUUM LOADERS*NOTE: Vacuum Loaders May Be Offered Separately From The Machine They AreMounted On8 – cONAIR FRANKLIN MOdEL dUST BEATER dB12 VAcUUM LOAdERS, WithLoader Control, Collector Hopper4 – cONAIR FRANKLIN MOdEL dUST BEATER VAcUUM LOAdERS, WithLoader Control, Collector Hopper1 – BUdgET MOLdER MOdEL NA VAcUUM LOAdER, S/N NA, With CollectorHopper, Separator Magnet1 – cONAIR FRANKLIN MOdEL 7000600401 VAcUUM LOAdER, S/N B47420(22) TEMPERATURE CONTROL UNITS*NOTE: Temperature Control Units May Be Offered Separately From The MachineThey Are Connected To8 – cONAIR TEMPRO MOdEL MIcRO TRAc 2 THERMOLATOR TEMPERATUREcONTROL UNITS6 – THERMAL cARE MOdEL RA122004 TEMPERATURE cONTROL UNITS2 – BUdZAR MOdEL BWA-1WT-12-2-50-dS-460 TEMPERATURE cONTROLUNITS, S/Ns 200711-13148, 200608-11359-24- THERMAL cARE MOdEL Rd090804 TEMPERATURE cONTROL UNITS2 – THERMAL cARE MOdEL RA0920042 TEMPERATURE cONTROL UNITSQuantity Of Temperature Control Units Including: Conair, Thermal Care, Budzar,Additional Units, Stored4to schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

Dryers • HOPPers • granuLatOrs • bLenDIng statIOnDRYERS / HOPPERS1 – NOVATEc dRYER / HOPPER cOMBO, With Model MDM-50 Dryer, S/N10-121-0221, 200-Lb. Capacity Drying Hopper, Conair Dust BeaterVacuum Loader, Portable Base1 – NOVATEc dRYER / HOPPER cOMBO, With Model MD-50 Dryer, S/N10A1732-0520, 200-Lb. Capacity Drying Hopper, Novatec VacuumLoader, Portable Base1 – cONAIR dRYER / HOPPER cOMBO, With Model SC60 Dryer, S/N99776, Model CH24-8 Drying Hopper, S/N 93106, Portable Base1 – dRYER / HOPPER cOMBO, With Conair Franklin Model CD-100 Dryer,S/N 9D0807, Thoreson McCosh 360-Lb. Capacity Drying Hopper, S/N303977, Conair Franklin Dust Beater Vacuum Loader, Portable Base1 – cONAIR dRYER / HOPPER cOMBO, With Model SC-30 SmallCarousel Dryer, S/N 80110, Model CH16-6 Drying Hopper, S/N 71617,Conair Dust Beater Vacuum Loader, Portable Base1 – cONAIR dRYER / HOPPER cOMBO, With Model Compu-Dry CD-30Dryer, S/N D50735, Drying Hopper, Stationary StandDRYERS4 – cONAIR FRANKLIN MOdEL cS 201 dRYERS, S/Ns D41722, D41721,2D0496, D31255, Portable1 – cONAIR FRANKLIN MOdEL cS 101 dRYER, S/N D51338, Portable1 – cONAIR FRANKLIN MOdEL cd 200 dRYER, S/N 9D1256, Portable1 – cONAIR FRANKLIN MOdEL cd 100 dRYER, S/N 0D0500, PortableDRYING HOPPERS1 – cONAIR FRANKLIN MOdEL 1805390400 dRYINg HOPPER, S/N NA,Est. 400-Lb., Stationary4 – cONAIR FRANKLIN MOdEL 1805390300 dRYINg HOPPERS, S/NsD41633, 201994, D044xx, 2D1772, Est. 300-Lb., With Conair DustBeater Vacuum Loader, (3) Portable, (1) Stationary1 – cONAIR FRANKLIN MOdEL 1805390200 dRYINg HOPPER, S/ND44010, Est. 200-Lb., With Conair Dust Beater Vacuum Loader, Portable1 – cONAIR FRANKLIN MOdEL cH24-18 dRYINg HOPPER, S/N 192198,With Vacuum Loader, StationaryOVER 15 GRANULATORS4 – NELMOR MOdEL g1012M1 gRANULATORS, S/Ns 84-11-21617,76-12-9733, 70-02-3338, 68-06-1721, 7.5-HP, Top Load, Portable1 – NELMOR MOdEL g810M1 gRANULATOR, S/N 80-01-1520, 5-HP, Portable1 – NELMOR MOdEL cF819 gRANULATOR, S/N 390.109, 5.5 KW, Portable1 – cUMBERLANd MOdEL 14x16 gRANULATOR, S/N 21230-6494, HP NA,Portable1 – cUMBERLANd MOdEL SIZE 10x12 gRANULATOR, S/N 25086-6554,20-HP, Stationary1 – cUMBERLANd MOdEL SIZE 4gRAN 3KN gRANULATOR, S/N 221370-754-R, HP NA, Top Load, Portable2 – RAPId MOdEL 912c gRANULATORS, S/Ns 305334, 305359, 7.5-HP, TopLoad, Portable1 – POLYMER MOdEL 912SPL gRANULATOR, S/N 3000791N, 7.5-HP, Top &Side Load, Portable1 – IMS MOdEL LP120Sc gRANULATOR, S/N LP120SC-0260,7.5-HP, Portable1 – cONAIR MOdEL Jc814 gRANULATOR, S/N 67319, 5-HP, Portable1 – cONAIR MARTIN MOdEL cP611 gRANULATOR, S/N 240498, 3-HP, TopLoad, Portable1 – BELOIT MOdEL M-88 gRANULATOR, S/N 7376-H/C-6099, PortableQuantity of Granulators Stored, Some Not In Service, Including: Nelmor, Conair,Rapid, Polymer, & OthersBLENDING STATION1 – cONAIR cONOMIX MOdEL cMX2 BLENdINg STATION, S/N 9A0248, With(2) Additive Hoppers, Each With Una Dyn Vacuum Loaders & Screw AugerDischarge, (1) Blending Auger, Stationary Steel Stand With Conomix MainControl, Central Auger Control, Vacuum Loader ControlsHOT RUNNER TEMPERATURE CONTROLLERS1 – dME MOdEL MPP126 24-ZONE HOT RUNNER TEMPERTAUREcONTROLLER, (2) 12 Zone Units, S/Ns 1C41230, 1C412291 – INcOE 15-ZONE HOT RUNNER TEMPERATURE cONTROLLERAdditional DME & INCOE Hot Runners, Some IncompleteFor more information, please visit us on the web at www.hilcoind.com 5

seCOnDary equIPment • DIe CuttIng Press • tOOLrOOmSECONDARY EQUIPMENT2 – BRANSON MOdEL cV-12 ORBITAL WELdERS, S/Ns02R493591, 97R308678 (As New as 2002), Hydraulic,Programmable Control, Working Bed Area 19" x 19",12" Maximum Daylight1 – BRANSON MOdEL 9101W ULTRASONIc WELdER,S/N VE30074C1 – cUSTOM BUILT FOAM STRIP SPLITTER, ProgrammableKeypad1 – SHARP cELL cUTTER, Custom1 – HOLLINgER MOdEL KPSM-H-11 EXTRUSION SHARPcELL MANUAL WELdER, S/N 8028 (2003), Digital ElectricHeater Controls1 – SYN-TEc MOdEL OMEgA-8100 EXTRUSION SHARPcELL AUTO WELdER, S/N W-004 (2004)1 – LASER MIKE MOdEL 700 IN-LINE MEASUREMENTgAUgE, S/N 5-1117, With Model 182 Dual AxisProgrammable Control1 – VERSA cOMBINATION PULLER / cUTTER, With VersaFeed Model C-22 2" x 12" Belt Puller, S/N 22724, RotaryKnife Cutter With 45-Degree Angle Adjustment, LengthRun-Out Meters, Commander SE Variable Drive Control1 – cONVEYORIZEd WATER BATH TABLE, Stainless SteelTank Size 10" x 12" x 20' Long, 6" Wide Plastic MeshConveyor Belt With Variable Speed Drive, Water Spray Pump1 – WATER BATH TABLE, Stainless Steel Tank Size 14" x 8" x9' Long, Not In ServiceDIE CUTTING PRESS1 – ATOM MOdEL HSP-588/3 HYdRAULIc dIE cUTTINgPRESS, S/N 10021961-5 (2004), Working Bed Area 63-1/2"LR x 19-1/2" FB, Die Platen Size 19-1/4" x 19-1/4", PowerR-L Die Head Adjustment, With Model AL-81 Backgauge,S/N 100199882004TOOLROOM / MAINTENANCE EQUIPMENT1 – LEAdWELL MOdEL McV-610AP cNc VERTIcAL MAcHININg cENTER, S/N L19306026, Fanuc SeriesO-M Control, Table Size 15-1/2" x 30-1/2", 40-Taper, 20-Position ATC, Coolant1 – SHARP MOdEL HMV-3 VERTIcAL MILLINg MAcHINE, S/N 70401056, 3-HP, Variable Speeds 60-4500RPM, 10" x 51" Table With Power Feed, Kurt Power Drawbar, Newall DRO1 – BRIdgEPORT VERTIcAL MILLINg MAcHINE, S/N BR-266337, 2-HP, Variable Speeds 60-4200 RPM,9" x 42" Table, 4" Column Riser, Kurt Power Drawbar, Newall DRO2 – TRI-ONIcS VERTIcAL MILLINg MAcHINES, S/Ns 0235, 0194, 3-HP, Variable Speeds 60-4200, 9" x 49"Table, 1 with Newall DRO1 – SHARP MOdEL Rd 820 RAdIAL dRILL, S/N 13136, 3' Arm x 8" Column, (6) Spindle Speeds 88-1500 RPM,Plain Box Table, Coolant1 – TOOLMEX MOdEL TUM-35 ENgINE LATHE, S/N 3687, 14" Swing x 42" Centers, Spindle Speeds 28-2500RPM, Threading, Taper Attachment, 1-7/16" Hole Thru Spindle, Coolant, Newall Topaz DRO1 – OKAMOTO MOdEL Acc-1224ST HYdRAULIc SURFAcE gRINdER, S/N 83444, 12" x 24" ElectromagneticChuck, External Coolant System With Paper Media Filtration2 – OKAMOTO MOdEL LINEAR 618 HANd FEEd SURFAcE gRINdERS, S/Ns 4895, 4577U, 6" x 18"Permanent Magnetic Chuck, Coolant, Newall DRO1 – OKAMOTO MOdEL PFg-618 HANd FEEd SURFAcE gRINdER, S/N 8567U, 6" x 18" Permanent MagneticChuck, Coolant, AcuRite DRO1 – cLAUSINg MOdEL cS-618c HANd FEEd SURFAcE gRINdER, S/N 02C-5870, 6" x 18" PermanentMagnetic Chuck1 – cHEVALIER MOdEL Ed-252 RAM TYPE EdM, S/N 0022272, CD-Bipulse 50 Amp Power Supply, 23-1/2" x11-3/4" T-Slotted Work Table With 6" x 12" Permanent Magnetic Chuck, 31" x 20" x 12" Deep Work Tank,System 3R Rotary Chuck, Anilam Wizard 900E DRO, Self-Contained Dielectric Fluid System1 – EXcELLO RAM TYPE EdM, Model & S/N NA, 7-1/2" x 15" T-Slotted Work Table With 6" x 10" PermanentMagnetic Chuck, Work Tank Size 21" x 13" x 12", Excello 25 Amp Power Supply, System 3R Work Chuck,Anilam MiniWizard DRO, Self-Contained Dielectric Fluid System1 – dOALL MOdEL c-916S HORIZONTAL METAL cUTTINg BANdSAW, S/N 503-95670, Coolant,Power Clamping1 – gROB MOdEL 4V-18 VERTIcAL BANdSAW, S/N 3803, 18" Throat, Power Table Feed, Blade Welder1 – MILLER MOdEL SYNcROWAVE 350 cONSTANT cURRENT Ac/dc WELdINg POWEER SUPPLY,S/N KC256001, With Coolmate 4 Water Cooling System, Tig Leads1 – MILLER MOdEL SYNcROWAVE 250 cONSTANT cURRENT Ac/dc WELdINg POWEER SUPPLY,S/N KD408913, With Radiator 1A Water Cooling System, Tig Leads1 – THERMAL SYSTEMS MOdEL TS20220U ELEcTRIc OVEN, S/N 9403, Upper & Lower Chambers, ChamberSize 20"L x 12"W x 11"H, Digital Temperature Controls1 – PEXTO MOdEL 137g 36" FOOT OPERATEd SHEAR, S/N 4x41, Air Conversion1 – WESTHOFF MOdEL WM100-1 PREcISION HORIZONTAL dRILLINg MAcHINE, S/N 9412181 – KUHLMANN SINgLE LIP TOOL gRINdER, S/N NA1 – cYcLONE ABRASIVE dRY BLAST cABINET, S/N NA, 24" x 36"1 – AAF SYNdER gENERAL dUST cOLLEcTOR, (Outside)Quantity Of Toolroom Accessories Including: Double End Grinders, Drill Press, Workbenches, Kurt 6" & 8" MachineVises, 40-Taper Toolholders, Shop Cabinets, Die Lift Tables, Etc.6to schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

aIr COmPressOrs • Water system • materIaL HanDLIng • InsPeCtIOnAIR COMPRESSORS & DRYERS1 – INgERSOLL RANd MOdEL IRN25H-cc 25-HP ROTARY ScREW AIRcOMPRESSOR, S/N BN0347U07228, 94 CFM, 150 PSIG, Air Cooled,Enclosure Panels1 – INgERSOLL RANd MOdEL SSR-EP25 25-HP ROTARY ScREW AIRcOMPRESSOR, S/N JX1345U00049, 97 CFM, 125 PSIG, Air Cooled,Enclosure Panels1 – HANKISON MOdEL HPRP125MX-115 REFRIgERATEd cOMPRESSEdAIR dRYER, S/N RH0B3125A01A2NH07136, Rated 125 SCFM @ 100PSI @ 100-Deg. F1 – HANKISON MOdEL HPRP100-115 REFRIgERATEd cOMPRESSEdAIR dRYER, S/N H100A1150002045, Rated 100 SCFM @ 100 PSI @100-Deg. F1 – SILVAN INdUSTRIES 240 gALLON VERTIcAL cOMPRESSEdREcEIVER TANKPROCESS COOLING WATER SYSTEM1 – THERMAL cARE MOdEL PT1300 PROcESS cOOLINg WATERREcIRcULATION SYSTEM, S/N 46730010002, (2) 20-HP ProcessPumps, (1) 7-1/2 HP Recirculation Pump, 60"x72"x72"H Carbon SteelHolding Tank, Steel Platform Base1 – APPLIcATION ENgINEERINg MOdEL gLAcIER SERIES NXgW25PORTABLE PROcESS WATER cHILLER, S/N 30H0432, 25-HPCompressor Pump, 7-1/2 HP Process Pump, 2-HP Recirculation Pump1 – THERMAL cARE MOdEL AccUcHILLER SERIES AQOW1004PORTABLE PROcESS WATER cHILLER, S/N 46710010002, 10-HPCompressor, 3-HP Process Pump1 – POLY HOLdINg TANK, Approx. 500 Gallon With Rack2 – THERMAL cARE WATER cOOLINg TOWERS1 – MARLEY WATER cOOLINg TOWERCRANES1 – KONE cRANES TOP RIdINg SINgLE gIRdER BRIdgE cRANE, S/N 5860030, 10-TonCapacity, Estimated 45' Span, XL-400 Bottom Running Electric Cable Hoist, 2-Speed Hoist,2-Speed Bridge & Trolley, 6-Way Power Pendant Control, With Estimated 295' Runway Beams1 – 360-dEgREE FLOOR STANdINg JIB cRANE, 10' Height x 10' Reach, With Budgit 2-TonElectric Chain HoistMATERIAL HANDLING1 – NOVATEc MOdEL McS-132 BULK MATERIAL cONVEYINg SYSTEM, S/N 12-326-0647,32-Station Control Panel, 5-HP Vacuum Pump Unit, Disconnected – Not In Use18 – MAc MOdEL RB350 PORTABLE MATERIAL dISTRIBUTION HOPPERS, Est. 350-Lb. Capacity5 – VAcU-BIN MOdEL 500 PORTABLE MATERIAL dISTRIBUTION HOPPERS, Est. 500-Lb. Capacity1 – HYTROL MOTORIZEd HORIZONTAL BELT cONVEYOR, 36" Wide x 34' Long, Not In UseQuantity Of Aluminum Conveying Pipe, Disconnected, Stored and Assorted Motorized Belt ConveyorsFORKLIFTS1 – NISSAN MOdEL cPH02A202V 3850-LB. cAPAcITY FORKLIFT, S/N CPH02-920701, LPG,Solid Tires, 169" Lift, Side Shift, 42" Forks1 – MITSUBISHI MOdEL Fgc20 3700-LB. cAPAcITY FORKLIFT, S/N AF82B-00232, LPG, SolidTires, 189" Lift, Side Shift, 42" Forks1 – TOYOTA MOdEL 5FBE15 1500-LB. cAPAcITY FORKLIFT, S/N 34572, Electric, Sit DownRider, 3- Wheel Chassis, 189" Lift, Side Shift, 42" Forks, 36 Volt1 – YALE MOdEL VE30S090 3000-LB. cAPAcITY WALK BEHINd ELEcTRIc FORKLIFT,S/N S277322, 163" Maximum Lift, Straddle Legs, Reach ForksWAREHOUSE1 – LANTEcH MOdEL Q300 SEMI-AUTOMATIc PALLET SHRINK WRAP MAcHINE, S/N QM0137831 – WEIgH-TRONIX MOdEL dSL-4848-05 ELEcTRONIc PLATFORM ScALE, S/N 38687, 5000-Lb. Capacity, 48" x 48" Platform, With Setra Super Count Electronic Counting Scale / Readout1 – PALLET JAcKS, MATERIAL cARTS1 – cARdINAL PALLET RAcKINg, Adjustable, Tear-Drop Style, 20' High Uprights, 42" Deep,9' Wide Cross Beams, Wire Mesh Deck Shelf Inlays, 3-Tier Cross Beams, (98 Sections Total),(11 Rows With 8 Sections, 5 Units With 2 Sections)Quantity of Adjustable Pallet Racking Including Interlake, Cardinal, & Other Mfg'rs, AssortedTRUCKS1 – 2005 INTERNATIONAL MOdEL 4300 SBA 4X2 SINgLE AXLE BOX VAN TRUcK, VIN:1HTMMAAL45H695440, DT466 Diesel, 6-Speed, Air Brakes, With Supreme 25' Aluminum VanBody, Roll-Up Door, Equalizer Systems Electric / Hydraulic Lift & Level System1 – 1996 cHEVROLET MOdEL 3500 cHEYENNE FLATBEd TRUcK, VIN:1GBJC34R3TE230469, V8 Gas, Automatic, Dual Rear Wheels, 12' Steel Deck FlatbedQUALITY CONTROL / INSPECTION1 – MIcRO VU MOdEL M436 VIdEO MEASURINg MAcHINE, S/N 4G10, Control Desk WithComputer System & Joystick Pendant1 – TENSI TEcH MOdEL SSM-AJ-2000 TENSILE TESTER, S/N 1027061 – RAY-RAN MELT FLOW INdEXER, S/N RR01005/3031 – AccUPRO ROcKWELL HARdNESS TESTER, S/N 1815Quantity Of Misc. Gauges & Inspection Room EquipmentOFFICESQuantity Of Computer Equipment & Office Furniture, Including Servers, PC's, Laptops, Monitors,Printers, Office Suites, Conference Room Table & Chair Sets, Cubicle Stations, Receptionist Station,General Office FurnitureFor more information, please visit us on the web at www.hilcoind.com 7

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong (Greater China) •Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Singapore • Thailand • Toronto • Villahermosa (MX)Hilco Industrial, LLCA u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r sHeadquarters31555 W. Fourteen Mile Road, Suite 207Farmington Hills, MI 48334Ph: 877-37-HILCO (44526)Fx: 248.254.9995www.hilcoind.comPresortedFirst Class MailU.S. PostagePAIdDetroit, Mich.Permit No. 2655Forwarding Service RequestedHILCO <strong>WebCast</strong>/<strong>OnsIte</strong> <strong>auCtIOn</strong>By order of the secured creditor, assets ofHILCO Industrial, LLC is a division of Hilco trading, LLC • Headquarters 5 revere Drive, ste. 206 • northbrook, IL 60062 • all rights reservedPrinted in usa • CaLD0037 • Kentucky auctioneer & License: Myron C. Bowling, License #RP 7079 • IL License #444.000215Please visit our website at www.hilcoind.com to review our complete terms and conditions.Terms of SaleAn 18% buyer's premium will be charged on all assets. Thebuyer’s premium will be reduced to 15% for paymentsmade by cash, company check or wire transfer. Everythingwill be sold to the highest bidder for cash, in accordancewith the Auctioneer’s customary “Terms of Sale”, copies ofwhich will be posted on the premises of the sale and subjectto additional terms announced the day of sale. All itemswill be sold “as is, where-is” without any warranties,expressed or implied. Although obtained from sourcesdeemed reliable, the Auctioneer makes no warranty orguarantee to the accuracy of the information herein contained.Bidders are encouraged to thoroughly inspect theitems on which they intend to bid prior to sale. Absolutelyno items will be removed until the day after the conclusionof the sale and payment is made in full. Subject to additions,deletions and prior sale.Payment: ALL PURchASES MUST BE PAID IN FULL ONThE DAy OF ThE AUcTION. If you intend to pay by wiretransfer, we will accept payment the day after the saleONLy IF a deposit of 25% of total purchases is made onthe day of the sale. contact our office for wire transferinstructions. Only cash, wire transfer or certified check,payable to hilco Industrial, LLc will be accepted. companychecks payable to hilco Industrial, LLc will be acceptedonly if accompanied by a bank letter of guarantee, (seesample letter below). All sales are subject to sales tax.Purchasers claiming exemptions from taxes must provideproof satisfactory to the Auctioneer of their entitlement toclaim such exemptions.Sample Bank Letter(Bank Name) unconditionally guarantees payment tohilco Industrial, LLc from (company Name). Thisguarantee will be valid for purchases made at theAuction of caldwell <strong>Industries</strong> on February 16, 2012.FollowUs on: