34815 Spheri Valv broch _12pp - Mac Process Mac Process

34815 Spheri Valv broch _12pp - Mac Process Mac Process

34815 Spheri Valv broch _12pp - Mac Process Mac Process

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

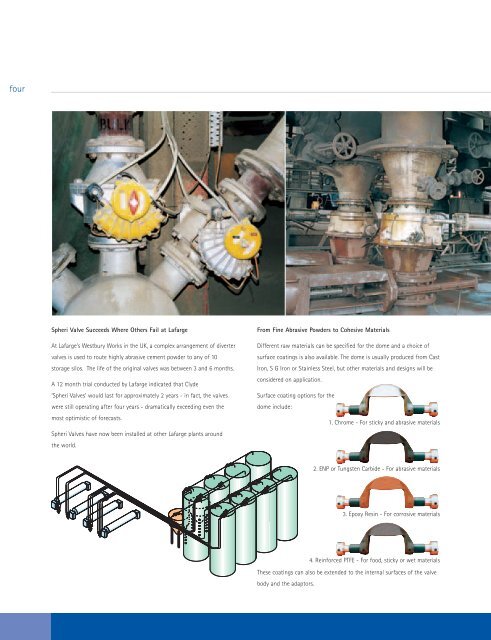

four<strong>Spheri</strong> <strong>Valv</strong>e Succeeds Where Others Fail at LafargeAt Lafarge’s Westbury Works in the UK, a complex arrangement of divertervalves is used to route highly abrasive cement powder to any of 10storage silos. The life of the original valves was between 3 and 6 months.A 12 month trial conducted by Lafarge indicated that Clyde‘<strong>Spheri</strong> <strong>Valv</strong>es’ would last for approximately 2 years - in fact, the valveswere still operating after four years - dramatically exceeding even themost optimistic of forecasts.<strong>Spheri</strong> <strong>Valv</strong>es have now been installed at other Lafarge plants aroundthe world.From Fine Abrasive Powders to Cohesive MaterialsDifferent raw materials can be specified for the dome and a choice ofsurface coatings is also available. The dome is usually produced from CastIron, S G Iron or Stainless Steel, but other materials and designs will beconsidered on application.Surface coating options for thedome include:1. Chrome - For sticky and abrasive materials2. ENP or Tungsten Carbide - For abrasive materials3. Epoxy Resin - For corrosive materials4. Reinforced PTFE - For food, sticky or wet materialsThese coatings can also be extended to the internal surfaces of the valvebody and the adaptors.