34815 Spheri Valv broch _12pp - Mac Process Mac Process

34815 Spheri Valv broch _12pp - Mac Process Mac Process

34815 Spheri Valv broch _12pp - Mac Process Mac Process

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

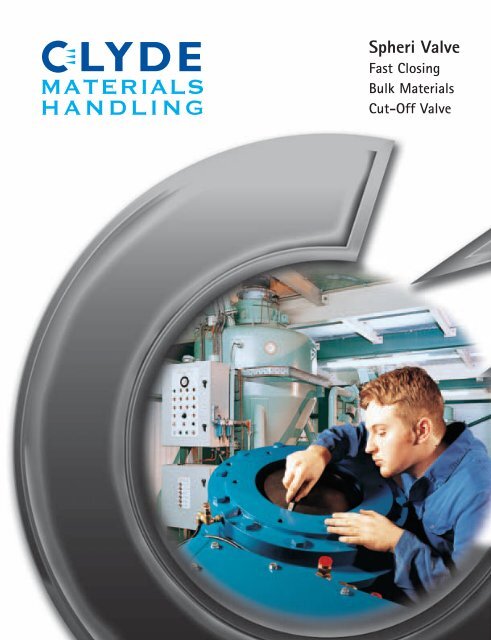

<strong>Spheri</strong> <strong>Valv</strong>eFast ClosingBulk MaterialsCut-Off <strong>Valv</strong>e

two“The most effective Bulk MaterialsHandling <strong>Valv</strong>e in the World”The seal automatically deflatesduring opening and closing,thereby avoiding contact withthe dome and eliminatingunnecessary wear.The seal automaticallyinflates only when thedome is fully closed.The <strong>Spheri</strong> <strong>Valv</strong>e has a world-widereputation for reliability. This results fromits simple robust design and only onemoving part. The same, simple designphilosophy also eases the task of routinepreventative maintenance and makes anyparts replacement a quick and simple task.

Always in ControlthreeThis highly innovative and well proven product from ClydeMaterials Handling is probably the most effective, fast closing, bulkmaterials handling valve in the world.It was developed by Clyde Materials Handling in 1974 for use within thecompany's own advanced range of pneumatic conveying systems.Soon afterwards the valve's much broader application capabilities wererealized and it was offered as a stand-alone product.To date, more than 10,000 <strong>Spheri</strong> <strong>Valv</strong>es have been sold world-wide, forapplications across a range of industries including:- minerals, power, iron,steel, food, pharmaceuticals, chemicals, and plastics.Vane Actuated <strong>Spheri</strong> <strong>Valv</strong>eUser Benefits• Full bore unobstructed material flow.• No components in material flow to wear.• Simple, fully proven design.• Can cut through moving or static columns of material.• Wide range of valve sizes: 2” (50mm) to 20” (500mm).• Forms pressure tight seal when closed.• Can cope with pressures up to 435 psi (30 bar).• Can handle material temperatures from-4°F to 900°F (-20°C to +480°C).• Long operating life.• Up to 1,000,000 cycles between major overhaulswith most materials.<strong>Spheri</strong> <strong>Valv</strong>e Switch <strong>Valv</strong>e• Low maintenance.• Ready availability of spare parts.Full Bore Material FlowTotally unrestricted full bore material flow is assured through the uniquedesign of the ‘dome’ assembly. A mere quarter turn is sufficient to movefrom the fully closed to the fully open position. This action positions thedome completely clear of the material flow path.Materials Handled• Abrasive • Toxic • Hazardous• Friable • Cohesive • Detergents• Minerals • Ores • Chemicals• Ash • Granules • Powders Cylinder Actuated <strong>Spheri</strong> <strong>Valv</strong>e

four<strong>Spheri</strong> <strong>Valv</strong>e Succeeds Where Others Fail at LafargeAt Lafarge’s Westbury Works in the UK, a complex arrangement of divertervalves is used to route highly abrasive cement powder to any of 10storage silos. The life of the original valves was between 3 and 6 months.A 12 month trial conducted by Lafarge indicated that Clyde‘<strong>Spheri</strong> <strong>Valv</strong>es’ would last for approximately 2 years - in fact, the valveswere still operating after four years - dramatically exceeding even themost optimistic of forecasts.<strong>Spheri</strong> <strong>Valv</strong>es have now been installed at other Lafarge plants aroundthe world.From Fine Abrasive Powders to Cohesive MaterialsDifferent raw materials can be specified for the dome and a choice ofsurface coatings is also available. The dome is usually produced from CastIron, S G Iron or Stainless Steel, but other materials and designs will beconsidered on application.Surface coating options for thedome include:1. Chrome - For sticky and abrasive materials2. ENP or Tungsten Carbide - For abrasive materials3. Epoxy Resin - For corrosive materials4. Reinforced PTFE - For food, sticky or wet materialsThese coatings can also be extended to the internal surfaces of the valvebody and the adaptors.

Customized Solutionsfive1From Foodstuffs to High Temperature AshSeveral inflatable seals are available, depending upon the application.The choice includes a white food quality seal as well as those speciallyformulated for high temperature or other hostile applications.34Moving and Static Column Cut OffAll <strong>Spheri</strong> <strong>Valv</strong>es are capable of handling fine grain materials and hardabrasive products.Vane Actuator models can cut through static columns of material up to1/8” particle size. They can also cut through moving columns ofpowders, pastes and granular products similar to coal above 1/8”.Cylinder Actuator models have the added capability of being able to cutthrough static columns of material above 1/8”.THIS CHART IS FOR GUIDANCE ONLY232 3/4 2 1/4Vane ActuatorModels1. Neoprene: Most materials up to 212°F (100°C)2. Silicone: Most materials up to 390°F (200°C)3. EPDM: ChemicalsPARTICLE SIZE (inches)21 1/2 11/43/43/8Cylinder ActuatorModels4. Food Quality: Hygienic applications1/81/16Fluidizable powders and soft grain materials up to 10 mesh particle size.2 3 4 6 8 10 12 16 20SPHERI VALVE SIZES (inches)

sixSelection GuideSVDS <strong>Spheri</strong> <strong>Valv</strong>eBASE BULKHEADInlet side pressure tight up to 7psigOutlet side pressure tight up to 100psigSVDT <strong>Spheri</strong> <strong>Valv</strong>eTOP INLET ADAPTORInlet and outlet sidespressure tight up to 100psigSVDB <strong>Spheri</strong> <strong>Valv</strong>eBOTTOM OUTLET ADAPTORInlet side pressure tight up to 7psigOutlet side pressure tight up to 100psigSVDI <strong>Spheri</strong> <strong>Valv</strong>eIN-LINE STYLEInlet and outlet sidespressure tight up to 100psigSVS <strong>Spheri</strong> <strong>Valv</strong>eASA BULKHEADInlet side pressure tight up to 7psigOutlet side pressure tight up to 100psigSVT <strong>Spheri</strong> <strong>Valv</strong>eASA TOP INLET ADAPTORInlet and outlet sidespressure tight up to 100psigVALVESIZES(inches)PHO PHV PHO PHV PHO PHV PHO PHV PHO PHV PHO PHV-4°F to 212°F 212°F to 390°F -4°F to 212°F 212°F to 390°F -4°F to 212°F 212°F to 390°F -4°F to 212°F 212°F to 390°F -4°F to 212°F 212°F to 390°F -4°F to 212°F 212°F to 390°F(-20°C to 100°C) (100°C to 200°C) (-20°C to 100°C) (100°C to 200°C) (-20°C to 100°C) (100°C to 200°C) (-20°C to 100°C) (100°C to 200°C) (-20°C to 100°C) (100°C to 200°C) (-20°C to 100°C) (100°C to 200°C)Vane Actuator Models2 SVD 2 IOVO SVD 2 IVVO3 SVD 3 IOVO SVD 3 IVVO4 SVD 4 SOVO SVD 4 SVVO SVD 4 TOVO SVD 4 TVVO SVD 4 BOVO SVD 4 BVVO SVD 4 IOVO SVD 4 IVVO SV 4 SOVO SV 4 SVVO SV 4 TOVO SV 4 TVVO6 SVD 6 SOVO SVD 6 SVVO SVD 6 TOVO SVD 6 TVVO SVD 6 BOVO SVD 6 BVVO SVD 6 IOVO SVD 6 IVVO SV 6 SOVO SV 6 SVVO SV 6 TOVO SV 6 TVVO8 SVD 8 SOVO SVD 8 SVVO SVD 8 TOVO SVD 8 TVVO SVD 8 BOVO SVD 8 BVVO SVD 8 IOVO SVD 8 IVVO SV 8 SOVO SV 8 SVVO SV 8 TOVO SV 8 TVVO10 SVD 10 SOVO SVD 10 SVVO SVD 10 TOVO SVD 10 TVVO SVD 10 BOVO SVD 10 BVVO SVD 10 IOVO SVD 10 IVVO SV 10 SOVO SV 10 SVVO SV 10 TOVO SV 10 TVVO12 SVD 12 SOVO SVD 12 SVVO SVD 12 TOVO SVD 12 TVVO SVD 12 BOVO SVD 12 BVVO SVD 12 IOVO SVD 12 IVVO SV 12 SOVO SV 12 SVVO SV 12 TOVO SV 12 TVVOVALVESIZES(inches)Cylinder Actuator Models8 SVD 8 SOCO SVD 8 SVCO SVD 8 TOCO SVD 8 TVCO SVD 8 BOCO SVD 8 BVCO SVD 8 IOCO SVD 8 IVCO SV 8 SOCO SV 8 SVCO SV 8 TOCO SV 8 TVCO10 SVD 10 SOCO SVD 10 SVCO SVD 10 TOCO SVD 10 TVCO SVD 10 BOCO SVD 10 BVCO SVD 10 IOCO SVD 10 IVCO SV 10 SOCO SV 10 SVCO SV 10 TOCO SV 10 TVCO12 SVD 12 SOCO SVD 12 SVCO SVD 12 TOCO SVD 12 TVCO SVD 12 BOCO SVD 12 BVCO SVD 12 IOCO SVD 12 IVCO SV 12 SOCO SV 12 SVCO SV 12 TOCO SV 12 TVCO16 SVD 16 SOCO SVD 16 SVCO SVD 16 TOCO SVD 16 TVCO SVD 16 BOCO SVD 16 BVCO SVD 16 IOCO SVD 16 IVCO SV 16 SOCO SV 16 SVCO SV 16 TOCO SV 16 TVCO20 SVD 20 SOCO SVD 20 SVCO SVD 20 TOCO SVD 20 TVCO SVD 20 BOCO SVD 20 BVCO SVD 20 IOCO SVD 20 IVCO SV 20 SOCO SV 20 SVCO SV 20 TOCO SV 20 TVCOWater Cooled OptionsWater cooling is recommended for applicationsinvolving temperatures in excess of 400°F.Water cooled <strong>Valv</strong>es are available in threeoptions in selective sizes throughout the range:* PH1 Water cooled top plate only* PH2 As PH1 but including a watercooled Dome* PH3 As PH2 but including a watercooled bodyModel Code ReferencesSVDorSVSPHERI VALVE4 SIZE (inches)SOVOCONFIGURATIONS = Standard Bulkhead T = Top InletB = Bottom Outlet I = InlineTEMPERATURE0 = -4°F to 212°F V = 212°F to 390°FACTUATOR TYPEV = VaneC = CylinderSPECIAL FEATURESO = No Special FeaturesS = Special Features RequiredTemperature RatingsTEMPERATURE (°F)90066054039521015STANDARDVALVESOptional Special FeaturesThe following special features are not offered asstandard on models PH1, PH2 and PH3:* Proximity Switch* Seal Pressure Switch* Solenoid <strong>Valv</strong>e and Timer* Quick Exhaust <strong>Valv</strong>eWATER COOLEDVALVESPH3*PH2*PH1*PHVPHO

Key ComponentsTop Adaptor(optional)sevenTop PlateVane ActuatorLimit SwitchInsert RingInflatable SealSealRetaining RingGasketPneumaticCylinderActuator<strong>Valv</strong>e BodyCylinder GuardVane Actuator OptionDomeLimit SwitchTorque ArmCylinder GuardCylinder Actuator OptionBottom Adaptor(optional)* Seal protection ringfor abrasive products* Choice of four Pneumatic Seals,depending on application* Choice of materials andsurface finishes for Dome* High pressure up to435 psi (30 bar)* ‘<strong>Valv</strong>e open’ proximityswitch availableChoice of ‘vane’ or ‘cylinder’actuator for different applications* Stainless steel‘food quality’* SPECIAL FEATURE NOTOFFERED AS STANDARDPlease consult ClydeMaterials HandlingOnly one moving part withinmain valve bodyFlanges drilled to ASA 150lb* Other specifications available

Other Bulk Materials Handling <strong>Valv</strong>esDump <strong>Valv</strong>es and Terminal BoxesThese form the termination of the pneumatic conveying transfer pipeand secure entry of the material into the chosen reception hopper.Dump <strong>Valv</strong>es are used where a number of hoppers positioned in seriesrequire selective feeding. They have two operating conditions, ‘straightthrough’ and ‘dump.’ In the straight through condition, a self-inflatingeasily replaceable seal closes off the respective hopper inlet, allowingthe material to be conveyed ‘straight through’ to the next availablereception point.Terminal Boxes are used at the end of a series of Dump <strong>Valv</strong>es or wherethere is only a single reception point within the pneumatic conveying system.Their deflector plate, which deflects the conveyed material through 90°,is readily accessible for inspection or replacement.A common mounting arrangement enables Dump <strong>Valv</strong>es and TerminalBoxes to be easily interchanged and both are available to suit a rangeof pipe diameters from 2”-14”.Plate & Tube <strong>Valv</strong>esPlate and Tube <strong>Valv</strong>es are used to divert the material flow from a singlesource to either of two different destinations. A number of these valvesplaced in series within the transfer pipe can be used to direct the flowto many different destinations. In all cases, valve operation can beindependent or form part of an automated PLC controlled routing system.Both valve types are suitable for use with a wide range offree-flowing materials typically found within minerals and otherprocess industries.Clyde Materials Handling Inc, 1002 Ford Circle, Unit A, Milford, OH 45150, USATel: +1 (513) 576-9200 Fax: +1 (513) 576-9300 Toll-Free: +1 (888) 422-5933Email: gcooper@clydematerials.com Website: www.clydematerials.comClyde Materials Handling Ltd, Shaw Lane Industrial Estate, Doncaster, South Yorkshire, DN2 4SE, EnglandTel: +44 (0)1302 321313 Fax: +44 (0)1302 554400Email: solutions@clydematerials.co.ukClyde Materials Handling Technology (Beijing) Co. Ltd. Rm 302, Tower A, He Qiao Building, No.8 Guanghua Road, Beijing 100026, ChinaTel: +86-10-65815602 Fax: +86-10-65815603Email: davidxu@clyde.sina.netClyde Materials Handling Sistemas do Brasil Ltda. Rua Alcides Ricardini Neves, n.° 12, Cj. 410, São Paulo-SP, CEP: 04575-050, BrazilTel: +55 (0) 11 5505-6244 Fax: +55 (0) 11 5505-8073e-mail: danderson@clydematerials.com.brJ<strong>34815</strong> 04/04