Pre-Start-up Checklist - Dunham-Bush Americas

Pre-Start-up Checklist - Dunham-Bush Americas

Pre-Start-up Checklist - Dunham-Bush Americas

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

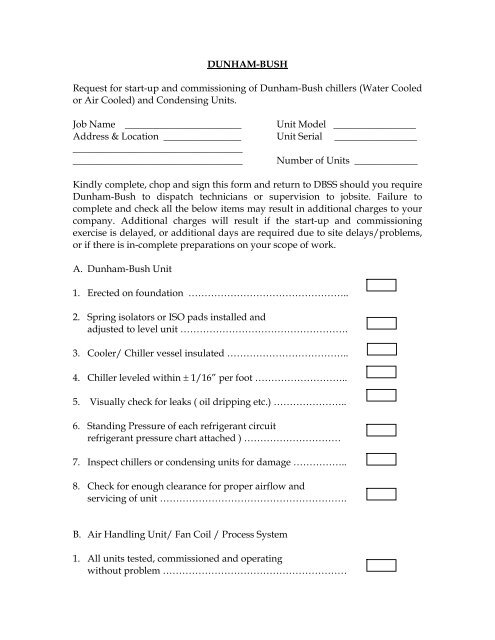

DUNHAM-BUSHRequest for start-<strong>up</strong> and commissioning of <strong>Dunham</strong>-<strong>Bush</strong> chillers (Water Cooledor Air Cooled) and Condensing Units.Job Name ________________________ Unit Model _________________Address & Location ________________ Unit Serial _______________________________________________________________________________________ Number of Units _____________Kindly complete, chop and sign this form and return to DBSS should you require<strong>Dunham</strong>-<strong>Bush</strong> to dispatch technicians or s<strong>up</strong>ervision to jobsite. Failure tocomplete and check all the below items may result in additional charges to yourcompany. Additional charges will result if the start-<strong>up</strong> and commissioningexercise is delayed, or additional days are required due to site delays/problems,or if there is in-complete preparations on your scope of work.A. <strong>Dunham</strong>-<strong>Bush</strong> Unit1. Erected on foundation …………………………………………..2. Spring isolators or ISO pads installed andadjusted to level unit …………………………………………….3. Cooler/ Chiller vessel insulated ………………………………..4. Chiller leveled within 1/16” per foot ………………………..5. Visually check for leaks ( oil dripping etc.) …………………..6. Standing <strong>Pre</strong>ssure of each refrigerant circuitrefrigerant pressure chart attached ) …………………………7. Inspect chillers or condensing units for damage ……………..8. Check for enough clearance for proper airflow andservicing of unit ………………………………………………….B. Air Handling Unit/ Fan Coil / Process System1. All units tested, commissioned and operatingwithout problem …………………………………………………

2. All process system ready and completed forOperation …………………………………………………………C. Piping1. Cleaned , flushed and pressure tested for leaks ………………2. Properly s<strong>up</strong>ported – vibration eliminatorsinstalled ……………………………………………………… …..3. Air vents, thermometers and pressure gaugesinstalled ………………………………………………………….4. All water balancing and isolating valvesinstalled and tested ………………………………………………5. All chilled and condenser water flow switchesinstalled, tested and calibrated …………………………………6. All modulating valves and flow controls checkedand calibrated ……………………………………………………7. All modulating valves and flows set at design flowrequirement ………………………………………………………8. Water piping system properly purged of air andno air lock in system ……………………………………………..D. Units with Cooling Tower1. Cleaned, tested and operational ……………………………….2. Tower fan tested and balanced ………………………………..3. Tower water flow balanced ……………………………………4. Water treatment services performed, auto chemicalFeed has flow interlock …………………………………………

Charging at job site………………………………………………2. Entire system properly dehydrated – must holdvacuum at 800-1,000 microns for a minimum ofeight (8) hours with vacuum pump secured ………………….3. All fan cycling, damper control systems checkedand operational …………………………………………………..4. All control wiring installed ……………………………………..H. Remote Evaporator Systems1. Liquid line solenoid interlocked with <strong>Dunham</strong>-<strong>Bush</strong>Unit control panel ………………………………………………..2. Entire system properly dehydrated – must holdvacuum at 800-1,000 microns for a minimum ofeight (8) hours with vacuum pump secured ………………….3. All thermal expansion valves properly sized andProperly installed ……………………………………………….4. All refrigerant piping installed in accordanceWith standard good practice and design criteria……………..5. All terminal equipment properly sized andproperly installed ………………………………………………..6. All automatic control devices checked andoperational ………………………………………………………..I. Conditions1. Essential electrical power isavailable …………………………………………………………..2. Essential water s<strong>up</strong>ply for city usage andconditions is available …………………………………………..3. Full load available for proper test and balance of<strong>Dunham</strong>-<strong>Bush</strong> equipment ………………………………………

Services To Be Rendered<strong>Dunham</strong>-<strong>Bush</strong> engineers, s<strong>up</strong>ervisors, technicians and service representative willcheck, test, start-<strong>up</strong> and commission the chiller and condensing units inaccordance to standard <strong>Dunham</strong>-<strong>Bush</strong> procedures and re-commendation andstandard commercial good practices.<strong>Dunham</strong>-<strong>Bush</strong> Rendered Services Above Do Not Include Any Responsibility ForThe Following:-1. Installation and operating of the temperature control system external to thechillers or condensing units – Other wise agreed <strong>up</strong>on by both parties prior toperformance of works.a. Balancing of the air distributor side of this system.b. Balancing of the water side of the system other than the chillers orcondensing units.c. Balancing of refrigerant systems.2. Electrical wiring performed by others.We (the dealer/contractor) ______________________________________requestThe present of <strong>Dunham</strong>-<strong>Bush</strong> personnel at the job site on or about___________________ (date) to check, test start-<strong>up</strong> and commission theequipment/system as required.On receipt of this form, <strong>Dunham</strong>-<strong>Bush</strong> will schedule their service personnelto this job within seven to fourteen days (7-14 days) of the requested date.It is understood that <strong>Dunham</strong>-<strong>Bush</strong> personnel will be at site to perform start<strong>up</strong>and commissioning exercise for a period not exceeding ______________normal working days.We the undersigned agree that we will pay a free for such time that is spenton this over the specific normal working days agreed <strong>up</strong>on, due to delays andin-complete preparations on our part and scope of works/responsibilities. Tocover this contingency, our contingency Purchase Order No. _____________be issued with the assurance that if no addition time is required, thispurchase order will be cancelled.

An overtime charge will be rendered for work executed on Saturday, Sundayand Public Holidays.Dealer / Contractor _______________________________________________________Address _____________________________Signed by _______________________________________________________________________________Company StampFull Name____________________Position inCompany ____________________________________________________________