New Title - MAN Diesel & Turbo SE

New Title - MAN Diesel & Turbo SE

New Title - MAN Diesel & Turbo SE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

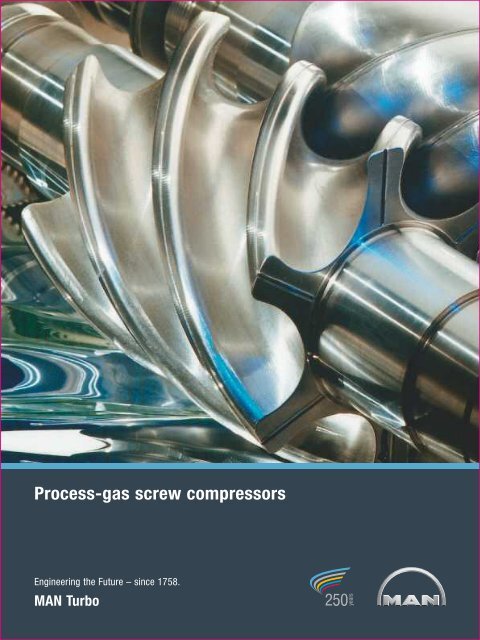

Process-gas screw compressorsEngineering the Future – since 1758.<strong>MAN</strong> <strong>Turbo</strong>

Performance characteristicsDesigned for suction volume flows of200 to 100,000 m 3 /h, suction pressuresdown to 0.1 bar (abs.) anddischarge pressures reaching above50 bar, the robust process-gasscrew compressors produced by<strong>MAN</strong> TURBO can handle highly contaminatedgases and gas mixturesthat would curtail the availability andlife expectancy of other types ofcompressors.High operational reliabilityThe operational reliability of <strong>MAN</strong>TURBO process-gas screw compressorsis based on 50 years ofexperience in screw compressordesign, and this in turn is supportedby 100 years of building a widerange of turbomachinery.Many <strong>MAN</strong> TURBO process-gasscrew compressor units have provenhigh availability factors over morethan 100,000 hours of trouble-freeoperation in unspared refinery service.QualityIntensive R & D efforts, the use ofthe most advanced manufacturingand test facilities, exchange of experiencewith plant users, close cooperationwith leading research institutes,as well as our collaborationwith international standards organisations(i.e. API 619 committee,ISO, etc.) guarantee both high technicalstandards and cost-efficiency.AdaptabilityThe adaptability of <strong>MAN</strong> TURBOprocess-gas screw compressorsis enhanced by a well-conceivedmodular design system and fieldprovenfeatures. Extensive calculationprogrammes are available forthermodynamic and mechanicaldesign, which together with modernCAD programs for design, engineeringand manufacturing ensurethat all customer requirements areconsidered in a most efficient, yettailor-made way.Application potential<strong>MAN</strong> TURBO process-gas screwcompressors are successfullyapplied to almost all branches ofindustry and for many different processes.These include mining, ironand steel mills, chemical works, thepetrochemical industry, refineriesand oilfields.For virtually every application, thescrew compressor can be adjustedto the particular requirements of theprocess for all kinds of gases andgas mixtures. As a positive displacementcompressor, the screw compressoris ideal for the compressionof light gases, and wide fluctuationsin the gas composition do not influencescrew compressor performance.Relative low tip speedsallow the compression of dust ladengases, as well as the injection ofliquids into the compression chamberfor cooling or washing.2

Product features<strong>MAN</strong> TURBO process-gas screwcompressors are designed in accordanceto API 619 and are based ona modular design system with 10different rotor diameters. Designedas single or multi-stage units, theycan be driven by electric motors orsteam turbines.Selection diagramThe selection diagram shows theCP and SKUEL compressor typesand their size as a function of suctionflow. Depending on the type ofgas compressed, pressure ratiosbetween approx. 1.3 and 6 canbe handled in a single stage, multistagearrangements or liquid injectionallow higher pressure ratios.Compared to other compressortypes used for process-gas applicationsthe process-gas screw compressorhas the following advantages:• handles gases containing dust orliquid droplets• changes in gas composition,molecular weight, and/or pressureratio have nearly no influenceon actual gas flow rate• suitable for liquid injection, forcooling or washing• operates below the first lateralcritical speed• no surging• excellent part load behaviour withspeed control (~ 50% flow and50% power at 50% speed)• no contact of lubricant withprocess gas• no wearing parts, whichrequire regular maintenance• no oscillating masses and thereforelow cost foundations• high availability up to 99%• designed for a minimum servicelife of 20 years and 3 years uninterruptedoperation.Suction volume flow (cfm)100 500 1.000 5.000 10.000 50.000CPtypeSKUELtype80100CP type for high pressuresWith 7 different rotor diametersthe CP series has 3 different length/diameter ratios, giving suctionflow rates from 200 m 3 /h up to20,000 m 3 /h.The vertically-split casing constructionallows discharge pressures inexcess of 50 bar.128160200252320321max. 16 bar230 psig408510643816100 500 1.000 5.000 10.000 50.000 100.000Suction volume flow (m 3 /h)50 bar720 psigSKUEL type for high flowsThe SKUEL series has 5 differentrotor diameters each with 2 differentlength/diameter ratios, with suctionflow rates from 4,000 m 3 /h up to100,000 m 3 /h and discharge pressuresup to 16 bar.3

The <strong>MAN</strong> TURBO modular systemThe modular design system isemployed for all key process-gasscrew compressor components, i.e.covering the rotor profile, shafts,bearings and seals allowing flexibleadaptation of the compressor to theapplication under consideration,while retaining its optimum designfeatures.Process-gas screw compressor stage,SKUEL type3SKUEL horizontalsectional view1 casing2 male rotor3 female rotor4 synchronising gear5 bearings6 shaft sealings4 5 6 12 6 54

CP verticalsectional viewProcess-gas screw compressorstage, CP type5

Assembly of process-gas screwcompressor stage type SKUEL643ComponentsCasingOnly cast casings are used for <strong>MAN</strong>TURBO process-gas screw compressors.The bearing housings arean integral part of the compressorcasing. The standard nozzle arrangementwith top suction and bottomdischarge allows liquid injection dueto the free draining arrangement.Single wall construction is used toavoid the use of cooling jackets.Depending on the type of gas tobe compressed, casings can besupplied in nodular cast iron, castcarbon steel or cast stainless steel.Manufacturing a compressor casing6

CP type variation of L/DSKUEL643 type during assemblyRotorsAll <strong>MAN</strong> TURBO process-gas screwcompressors are equipped withsingle piece forged rotors with anasymmetric rotor profile, to assurethe highest efficiency when handlinga wide variety of gases and gas mixtures.No internal rotor cooling isrequired due to advanced designand manufacturing methods.The synchronising gear, located atthe non-driven end of the rotor pair,assures contact-free operation of therotors whilst maintaining their smallclearances.A variety of rotor materials from carbonto stainless steel is available toresist any corrosive and/or erosivecomponents within the gas mixture.Rotors of a <strong>MAN</strong> TURBO process-gasscrew compressor7

BearingsBecause of high rotational speedsand bearing loads, process-gasscrew compressors are equippedwith hydrodynamic journal bearingsand tapered land thrust bearings.Forced feed lubrication of thesebearings provides an unlimited lifetime.Tilting pad thrust bearings canbe provided, if specially required.Combined journal and thrust bearings ofmale and female rotorMulti-face thrust ring (tapered-landbearing) as part of <strong>MAN</strong> TURBOmodular system8

Liquid systemsDry systemsLabyrinthFloating ringsMechanical contact sealPossible shaft sealing systemsCarbon ringsCarbon ringsDry gas sealShaft sealingsThe compression chamber of theprocess-gas screw compressor isseparated from atmosphere by shaftseals; these are installed at eachshaft end of the compressor rotors.To adapt the process-gas screwcompressor to different applicationsa wide variety of shaft sealingsystems are available. Divided intodry and liquid sealing systems, theexamples show the most commonlyused shaft sealing arrangements. Forspecific processes a number of otheroptions have been developed.9

Single and multi stage process-gas screw compressor unitsSingle stage units are best suited forpressure ratios up to 6. For pressureratios exceeding the limits of a singlestage compressor, units can be builtwith 2 or 3 stages, which are usuallydriven through a common gearbox.Any combination of compressortypes SKUEL and CP can bearranged into a multi stage unit.Package designEach process-gas screw compressorunit is tailor-made to meet therequirements of a specific application.State-of-the-art 3D design programmesare used to optimizethe overall compressor arrangement.2-stage process-gas screw compressorunit with a wing pinion speed increasinggear allowing the speed of each compressorstage to be optimizedView at a process-gas screw compressor module for an offshore application3D computer modell10

Control and safety equipmentThe demands for control and protectionsystems of modern process-gasscrew compressor units in terms ofquality and flexibility are steadilyincreasing.Individually designed control systemsare provided to comply with therequirements of the process andprovide all functions from start-upto emergency shutdown.Oil supply systemsProcess-gas screw compressor unitsare equipped with oil supplysystems designed by <strong>MAN</strong> TURBO.Normally oil systems are integratedinto the compressor package, howeverseparate consoles in accordancewith API Standard 614 orother customer specifications canbe provided if required.Acoustic treatmentSpecial attention has to be paid tothe acoustic treatment of a screwcompressor unit.To fulfil environmental regulations,<strong>MAN</strong> TURBO process-gas screwcompressor units are equipped withspecially designed noise protectionequipment, i. e. silencer systems inthe connecting pipework, noiseenclosures, etc.Typical control panel for a <strong>MAN</strong> TURBOprocess-gas screw compressor unitSeparate oil supply consoledesigned to API 614Acoustic enclosure of a process-gasscrew compressor unitGear boxThe speed increasing gear box, usedfor single or multi stage compressordesigns, is designed by <strong>MAN</strong>TURBO in accordance to therelevant international standards,i. e. AGMA, API 613, etc.View of gearbox internals11

Some examples of referencesOil and gas productionand gas production• CP200• 4,000 m 3 /h associated gas• 5 to 20 barRefinery• SKUEL321/CP128• 8,200 m 3 /h flaregas• 1 to 16 barButadiene extractionButadiene • SKUEL321 and CP128• 7,200 and 1,900 m 3 /h butadiene• 1.2 to 6 barStyrene monomer productionmonomer production• SKUEL643• 56,000 m 3 /h offgas• 0.3 to 1.6 bar12

Hydrogen purificationHydrogen (PSA)• SKUEL408• 14,000 m 3 /h PSA waste gas• 2.5 to 8 barPower generationgeneration (fuel gas)• 3 x CP100• 1,000 m 3 /h fuelgas• 15.3 to 28 barSoda ash productionSoda ash • 3 x SKUEL408• 13,000 m 3 /h lime kiln gas• 0.9 to 3.8 barSteel productionSteel production (coke oven gas)• 2 x SKUEL643/SKUEL408• 41,000 m 3 /h coke oven gas• 1 to 11 bar13

Core competencies and capabilities of <strong>MAN</strong> TURBO<strong>MAN</strong> TURBO offers the most comprehensiveturbomachinery productrange in the world. Incorporating200 years of technological achievementsby four Original EquipmentManufacturers (OEM), we supplystate-of-the-art products and servicesfor every industrial process.Tailor-made solutions by <strong>MAN</strong>TURBO are based on an uniquespectrum of compressors and turbines– from single machines tototal train capability.Product line• compressors (axial, centrifugal,pipeline, gear type, isotherm,process-gas screw)• vacuum blowers• process-gas expanders• gas turbines• steam turbines• turbolog ® control and monitoringsystem• after sales service.Using four large state-of-the-artproduction sites and test facilitieswhich include a type 1 – test stand,<strong>MAN</strong> TURBO provides cost-effectiveand efficient solutions worldwide.14

Core competencies• design and engineering• research and development• manufacturing• testing• installation, commissioning andservice support• quality assurance.15

<strong>MAN</strong> <strong>Turbo</strong> AGSteinbrinkstrasse 146145 Oberhausen / GermanyPhone +49. 208. 6 92-01Fax +49. 208. 6 92-20 19www.manturbo.com<strong>MAN</strong> <strong>Turbo</strong> AGEgellsstrasse 2113507 Berlin / GermanyPhone +49. 30. 44 04 02-0Fax +49. 30. 44 04 02-20 00<strong>MAN</strong> <strong>Turbo</strong> AGHermann-Blohm-Strasse 520457 Hamburg / GermanyPhone +49. 40. 3 70 82-0Fax +49. 40. 3 70 82-19 90<strong>MAN</strong> <strong>Turbo</strong> AG SchweizHardstrasse 3198005 Zürich / SwitzerlandPhone +41. 44. 278-22 11Fax +41. 44. 278-29 89<strong>MAN</strong> <strong>Turbo</strong> S.r.l. De PrettoVia A. Fogazzaro 536015 Schio (VI) / ItalyPhone +39. 0445. 6 91-5 11Fax +39. 0445. 5 11-1 38In the interests of technical progress,subject to change without notice.Printed in Germany.June 2008<strong>Turbo</strong> 946 e 0608 1,0 ba