Case Study 117 â Tutto Piccolo, Alcoy, Spain - Sdi Group UK

Case Study 117 â Tutto Piccolo, Alcoy, Spain - Sdi Group UK

Case Study 117 â Tutto Piccolo, Alcoy, Spain - Sdi Group UK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

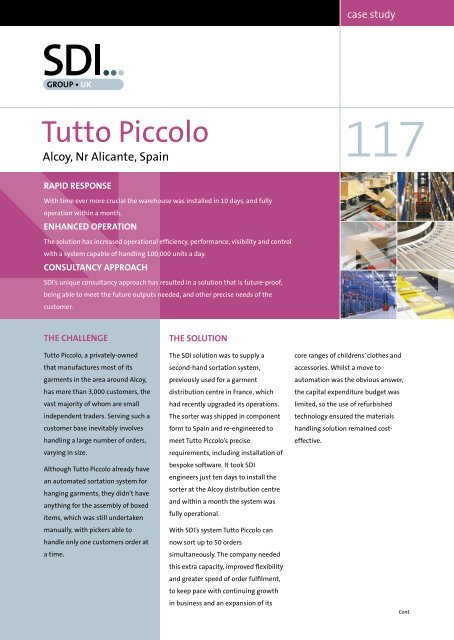

case study<strong>Tutto</strong> <strong>Piccolo</strong><strong>117</strong><strong>Alcoy</strong>, Nr Alicante, <strong>Spain</strong>RAPID RESPONSEWith time ever more crucial the warehouse was installed in 10 days, and fullyoperation within a month.ENHANCED OPERATIONThe solution has increased operational efficiency, performance, visibility and controlwith a system capable of handling 100,000 units a day.CONSULTANCY APPROACHSDI’s unique consultancy approach has resulted in a solution that is future-proof,being able to meet the future outputs needed, and other precise needs of thecustomer.THE CHALLENGE<strong>Tutto</strong> <strong>Piccolo</strong>, a privately-ownedthat manufactures most of itsgarments in the area around <strong>Alcoy</strong>,has more than 3,000 customers, thevast majority of whom are smallindependent traders. Serving such acustomer base inevitably involveshandling a large number of orders,varying in size.Although <strong>Tutto</strong> <strong>Piccolo</strong> already havean automated sortation system forhanging garments, they didn’t haveanything for the assembly of boxeditems, which was still undertakenmanually, with pickers able tohandle only one customers order ata time.THE SOLUTIONThe SDI solution was to supply asecond-hand sortation system,previously used for a garmentdistribution centre in France, whichhad recently upgraded its operations.The sorter was shipped in componentform to <strong>Spain</strong> and re-engineered tomeet <strong>Tutto</strong> <strong>Piccolo</strong>’s preciserequirements, including installation ofbespoke software. It took SDIengineers just ten days to install thesorter at the <strong>Alcoy</strong> distribution centreand within a month the system wasfully operational.With SDI’s system <strong>Tutto</strong> <strong>Piccolo</strong> cannow sort up to 50 orderssimultaneously. The company neededthis extra capacity, improved flexibilityand greater speed of order fulfilment,to keep pace with continuing growthin business and an expansion of itscore ranges of childrens’ clothes andaccessories. Whilst a move toautomation was the obvious answer,the capital expenditure budget waslimited, so the use of refurbishedtechnology ensured the materialshandling solution remained costeffective.Cont.

THE SYSTEMThe SDI system comprises of a 25m-longoblong rotating carousel equipped withsteel trays. Arranged around the carouselare 50-drop zones, which are allocated,as required to individual customers.Items are picked into boxes, fromgarments hanging on rails – in someinstances using the hanging garmentsorter – or from ready-packedconsignments. These boxes are thentransferred to the sorter and loaded ontoany of three induct stations, where thebar codes on the boxes are read by anautomatic in-line scanner.Communicating with SDI’s WarehouseSortation System (WSS) the cartons arethen loaded one by one into individualtrays.As the goods pass round the system theWWS send signals to the sorter’s PLC toactivate solenoids that tilt the trays asthey pass over the required dropstations,which are allocated in eachsorting wave to specific customers. Theaccumulated boxes are then transferredby conveyor from the sorter to thedispatch area for onward delivery.<strong>Tutto</strong> <strong>Piccolo</strong> is currently sorting 40,000items per day on the SDI system. At peakperiods, during major promotions forexample, the company expects thesystem to be handling up to 100,000units per day.“With our oldmanual system wecould only pickgoods for onecustomer at a time,but the SDI machinecan now sort for 50customers in onepass. This has greatlyspeeded up the orderassembly operation,and has given usmuch improvedflexibility. We candeliver to customersas and when theydemand, and mostorders are deliveredwithin less than 48hours.”Rafael Mataix Molto -Director and co-founder of <strong>Tutto</strong> <strong>Piccolo</strong>“When looking for asortation system weconducted a surveyof the industry inEurope, and foundthat SDI had all theexperience andexpertise we required.Although our budgetwas limited, this wasn’ta problem for SDI, therefurbished sortationsystem was theperfect solution.”Rafael Mataix Molto -Director and co-founder of <strong>Tutto</strong> <strong>Piccolo</strong>ABOUT SDI GROUPSDI group is an innovative providerof systems and solutions to theretail, wholesale, fulfilment ande-commerce industries for allaspects of distribution centrematerials handling.As both consultants and systemintegrators, the company providesclients with a total logistics solutionpackage, which includes materialshandling consulting, as well asdesign, engineering, fabrication,installation and integrationservices.Tel: +44 (0)1788 574666Web: www.sdigroupuk.com Email: sales@sdigroupuk.comSDI <strong>Group</strong> <strong>UK</strong>, 20 Somers Road, Somers Road Industrial Estate, Rugby, Warwickshire CV22 7DH <strong>UK</strong>A member of the SDI <strong>Group</strong>