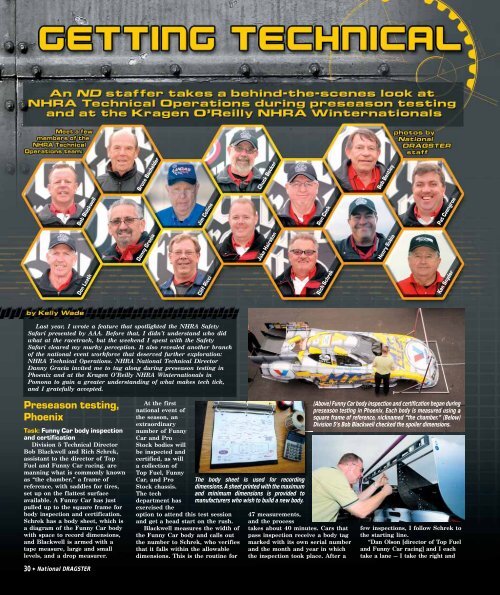

Preseason testing, Phoenix - NHRA.com

Preseason testing, Phoenix - NHRA.com

Preseason testing, Phoenix - NHRA.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ford and GM supplied accident-datarecorders, and <strong>NHRA</strong> TechnicalOperations issues them at the beginningof the season and throughout the yearfor part-time racers.Dan takes the left — and we watchthe cars as they pull up and gothrough their burnout, stage, andthen make their way downtrack,”says Schrek. “We watch for leaks,breakage, or anything else thatmight be a little off.”Schrek keeps a keen eye on eachcar and moves to the middle of thelane near the water box to monitoreach run. He and Olson are likemirror images, getting the job doneon both sides of the track.Obviously, Schrek is a fan of dragracing. He tells me that it’s going tobe interesting to watch the newlyformed Top Fuel rivalry of LarryDixon and Tony Schumacher thisseason, and when Schumacher laysdown a 3.830 pass after Dixon’s3.831, Schrek turns to me andwinks. Interesting, indeed.Technical services representativesalso performed chassis inspectionsand certifications and issued theFord Blue Box sensors (accidentdatarecorders mandated lastseason) to teams in <strong>Phoenix</strong>,knowing that anything theyac<strong>com</strong>plish before Pomona will savetime and ease the rush. Next up: thefirst stop on the <strong>NHRA</strong> Full ThrottleDrag Racing Series tour.Kragen O’Reilly<strong>NHRA</strong>Winternationals,PomonaTask: Technical inspectionI join the tech department onWednesday at Auto Club Racewayat Pomona. As Iapproach the shinyblack tech traileremblazoned with thesleek, new <strong>NHRA</strong>Full Throttle DragRacing Series logo,I am greeted bymembers of thedepartment selectedto work the event:former Division 3Technical DirectorRon Cook, Division7 Chassis InspectorCliff Ricci, eightyeartech department veteran andTexas resident Terry “TJ” Jack,longtime tech departmentemployee and track operationshandler at O’Reilly Raceway Parkat Indianapolis Bruce Bachelder,and national event new<strong>com</strong>er DonLeath, who spent two years in theDivision 7 tech departmentbefore this weekend’sopportunity.“The Pros, [Top] Alcohol, andComp cars will be teched in theirpits, but the other Sportsman[classes] are done here,” explainsRicci, who has been in thisbusiness 28 years and also worksfor Outwest Meat Co. in LasVegas. He’s no slacker, and I notethroughout the weekend thatslacking is not even on the radarfor any of these guys; even indowntime, they keep busy andtake pride in repairing scooters,affixing fresh decals to their golfcart, and assembling the new fuelcheck home base, which wasformerly the sponsor trailer.Henry Subia, who has workedevents for more than 15 yearsand is a staple at Auto ClubDragway in Fontana, Calif., isamong the inspectorsready to greet themasses, and I peg him asa jokester right from thestart when he says,“Hello, Jane, it’s nice tomeet you.” My name isn’tJane, but this game is histrademark.The drivers presenttheir <strong>com</strong>petition licensesand technical-inspectionforms. The inspectorverifies that everythingrequired is in place,including appropriateSFI tags on each driver’sgear. The tech card isstamped approved, and aweight sticker with theclass weight minimum, enginehorsepower, and cid is placed onthe vehicle’s window.The buzz in the crowd thismorning is about the inspectionof the four new Cobra JetMustangs, and Bachelder, theSuper Stock and Stock specialist,is slapping his gloved handsDivision 7’s Henry Subia begins a tech inspection bychecking the driver’s <strong>com</strong>petition license.together in anticipation as thefirst one pulls up to tech.“I did the first LT1 Camaro in’93,” says Bachelder, who enjoysbeing front and center forhistorical moments. Later, as thefirst car to <strong>com</strong>pete in the SS/EXclass for former sport <strong>com</strong>pactentries makes its way across thescales, Bachelder happens to bethere to note the weight and nodsat me, saying with a smile,“There’s another first for me.”Before I head over to thestaging lanes for body inspectionsand certifications, a Super Stockracer requests a chassiscertification. The task is quickand easy, similar to anultrasound exam: A dab of gel isapplied to the surface of a sonicmeter that is then gently rolledacross each bar until it producesa reading. Each bar is examined,the diameter is measured, andthe welds are visually inspected.Task: Pro Stock body inspectionand certificationFunny Cars and Pro Stockersare lined up, waiting to passthrough the chamber. PatPat Cvengros, a six-year veteran in the tech department,works with Pro Stock templates to verify that the contoursof each body match those of the original. There are eightto 10 stamped templates for each body.Cvengros, who has been on stafffor six years, is working Pro Stockwith Bob Bentley, a recentlyengaged Loveland, Colo., resident,while Jake Hairston, who came to<strong>NHRA</strong> a year and a half ago andresides in nearby RanchoCucamonga, and Blackwell are onFunny Car.The processes for Pro Stockbodies are the same as for FunnyCars but with fewer dimensionsand extra steps. Each Pro Stockbody has a set of templates,created from the first body pulledfrom a mold, that are used toverify uniform contours. The crewsassist in laying the templatesacross the designated areas, andBentley runs a 1/4- or 1/8-inchblock along the gap. If the blockslides between the template andthe body, something is askew.Then an electronic gauge usedto sense microfiber chipsembedded in each body <strong>com</strong>ponentis waved over a designated areaand beeps when the chip is sensed.The gravity of these tasks seemsheavy, and enforcing the rulesdoesn’t seem very fun, but on themost basic level and with minimalexperience, I can see that when it’sfair, the game is more fun.At the end of the day, I leavethe track sunburned and hopefulthat the weather forecast for theweekend is wrong, dead wrong.Task: Pre-race and post-runinspectionRelentless rain puts a damperon the weekend, but a round ofqualifying is squeezed in, and Proracing finally <strong>com</strong>es to <strong>com</strong>pletion,with hardy Sportsman racershanging on through Wednesday.In periods of dryness, racersvisit the scales. A folding table andchairs are set up behind the scales,and the digital display is turnedtoward a steady stream of racerswanting to ensure they meet theminimum weight. Once racingbegins, the display is turnedtoward the inspector, and aftereach qualifying run, as long as theracers have bettered theirtime, they <strong>com</strong>e to weigh in.If a car misses the scale, it isnoted as “DB,” drive-by, andthe run will be thrown out.During eliminations, this is acostly mistake, and the DBturns into a DQ.Leath reads the carnumbers to Bachelder, whonotes the sticker weight andthe actual weight and readsthe latter to the driver.Seeing me scribbling in mynotebook, Bachelder warnsquietly, “The weight is a veryconfidential matter. No one ispermitted to repeat what Isay to the driver.”As the cars pull onto thescales, everyone backs away andgoes silent, with all eyes onBachelder until he quietly statesthe weight.Despite the serious nature ofthe task, the racers joke as they<strong>com</strong>e across the scales, holdingtheir bellies and claimingoverindulgence during the winter.The scale weighs in five-poundincrements, and Pro Stock racers,aiming to be as close to theminimum as possible, practicetricks to determine the true weight.After the initial weighing, thehelmet is removed and the newweight is read. Some crews havesmall weights that they add andremove from the scale until they areable to determine the exact number.At fuel check, Stock and SuperStock racers draw fuel from theirlines and <strong>com</strong>e to a trailer to haveDivision 2 Technical Servicesto page 32March 6, 2009 ✦ 31

from page 31(Above) A DC meter is connected to atemperature meter to provide two readingsfor Stock and Super Stock fuel. Thereadings are recorded on a spreadsheetand <strong>com</strong>pared to the baseline providedby the supplier. (Left) Ken Snyder checksmethanol fuel using a density meter.Representative Ken Snyder take aresistance reading. The racersstate their car number and type offuel, and Snyder determines thetemperature and takes a readingwith a DC meter, checking thetemperature and fuel <strong>com</strong>binationagainst a spreadsheet to find theacceptable range in which thereading should fall. Snyder makesa note, thanks each driver, anddumps the fuel into a jug to beproperly disposed of later.When Pro Stock cars arrive,Hairston passes a cup to the firstperson who extends his hand. Theteams quickly remove the frontend, and fuel is drawn from theline.Top Alcohol Dragster and TopAlcohol Funny Car fuel checks arealso done here but with densitymeters, one for methanol and onefor nitro. Gracia and ChuckBecker, a member of the Division5 certification team, use densitymeters to fuel check Funny Carsand Top Fuelers at the top end.The handheld meters feature alever-controlled pump and factorin temperature, and theydetermine nitro percentage orspecific gravity for methanol,which requires another step: Asmall sample is mixed withdistilled water in a glass vial andshaken. If the concoction turnsmilky, it indicates the presence ofan unknown hydrocarbon andconstitutes failure.In a small office in the trailer,a machine that looks like a minifridgeis attached to a <strong>com</strong>puter.Hairston explains that this is theGC meter, which breaks downparticles in fuel samples for amore in-depth reading.The GC meter is operated bySoutheast Division TechnicalDirector Jim Collins, who keeps awatchful eye on Top AlcoholDragsters and Top Alcohol FunnyCars as they make their runs,ensuring that blower straps arefastened tight and nothing isleaking or loose.Everyone is busy. Betweensessions, Becker makes his waythrough the fuel pits, addressingany concerns and performingrandom checks on things like boreand stroke dimensions, rear-end32 ✦ National DRAGSTERBlackwell, left, and Bruce Bachelder work the scales. Blackwell calls out the carnumber to Bachelder, who finds the car on a spreadsheet, then notes the weight, alongwith the minimum weight for the class, which is displayed on a window sticker.

Snyder, left, and Jim Collins are mainstaysin the fuel-check trailer and also cover<strong>NHRA</strong> Jr. Drag Racing League events.ratio, and wing angles and height.Everyone has an assignment beforethe weekend begins and knowswhich classes they’ll be responsiblefor. Most, like Becker and Collins,have a specialty, but a few, asGracia tells me, are able to doeverything.“It’s such a specialty job,” saysGracia. “It’s hard to find qualifiedpeople who want to do it becausewe put in long hours and we workso hard.”Task: Tear down a Pro StockengineRicci is working the scales whena Comp racer goes too quick andreceives a Competition IndexControl (CIC) penalty. He preparesa certification form H.“We treat a CIC as we would anational record,” says Ricci. “We fillout this form certifying his fuel andweight and attach the time slip, sealtheir motor [with Torque Seal, ananti-sabotage inspector’s lacquer],then later do a teardown.”Later, I’m at the scales withCook and Leath when the time slipis spit out declaring GregAnderson’s new Pro Stock nationale.t. record. I hope to observe bothteardowns, but when the Compracer pulls in at the same time asBlackwell is leaving for Anderson’spit, I can’t pass up the chance towatch the teardown of an enginethat just set a national record.We are wel<strong>com</strong>ed into the KBRacing pit, and Blackwell sets upDuring an engine teardown, as shown in this Sportsmanteardown, thorough weights and measurements are taken,including bore and stroke.shop, calibrating a small scale andlaying out his tools. Andersonbegins disassembling the engine,and parts are presented forverification. Among other things,the material of a pushrod isauthenticated, a lifter is weighed,and digital calipers are used todetermine bore and stroke.“Bore and stroke measurementsnever leave their pit areas,” saysBlackwell. “We write them on ascrap of paper and hand it to thedriver after we’ve got ourcalculation.”The entire process is verythorough, though relatively quick,and the findings of the teardownare placed in a sealed envelope. Noone will see theresults unless therecord iscontested.EpilogueAlthough it maynot have been theideal raceweekend, thedowntimepresentedopportunities topick up a fewthings I mighthave otherwisemissed.I spent time with <strong>NHRA</strong> SeniorDirector-National TechnicalOperations Don Taylor and newlyappointed <strong>NHRA</strong> Vice President-Technical Operations Glen Gray(who, it should be noted, madesure we were all fed on race day).I observed a Pro StockMotorcycle inspection andcertification when FredCamarena brought over hisSuzuki. The procedure for themotorcycles is similar to the ProStock cars, except the chamber issmaller and fork degrees aremeasured.I learned a little more abouteveryone: Cook’s first nationalevent was the 1977 U.S.Nationals, and Bentley has aknack for refurbishing.Bachelder’s wife, Barbara, hasworked in the credential trailerfor many years, and whenBachelder speaks of theirgrandkids, his eyes light up evenmore than when he teched theCobra Jet.As the weekend draws to aclose, I am able to conclude that<strong>NHRA</strong> Technical Operationscontains a fine group ofindividuals and that each one is<strong>com</strong>mitted to his position and themission.“We just want to be fair to theracer,” says Snyder. NDMarch 6, 2009 ✦ 33