End Rounding Punch End Flattening Punch End Rounding Die

End Rounding Punch End Flattening Punch End Rounding Die

End Rounding Punch End Flattening Punch End Rounding Die

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

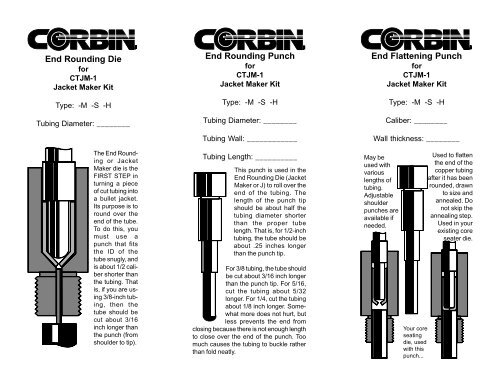

<strong>End</strong> <strong>Rounding</strong> <strong>Die</strong>forCTJM-1Jacket Maker KitType: -M -S -HTubing Diameter: ________The <strong>End</strong> <strong>Rounding</strong>or JacketMaker die is theFIRST STEP inturning a pieceof cut tubing intoa bullet jacket.Its purpose is toround over theend of the tube.To do this, youmust use apunch that fitsthe ID of thetube snugly, andis about 1/2 calibershorter thanthe tubing. Thatis, if you are using3/8-inch tubing,then thetube should becut about 3/16inch longer thanthe punch (fromshoulder to tip).<strong>End</strong> <strong>Rounding</strong> <strong>Punch</strong>forCTJM-1Jacket Maker KitType: -M -S -HTubing Diameter: ________Tubing Wall: ____________Tubing Length: __________This punch is used in the<strong>End</strong> <strong>Rounding</strong> <strong>Die</strong> (JacketMaker or J) to roll over theend of the tubing. Thelength of the punch tipshould be about half thetubing diameter shorterthan the proper tubelength. That is, for 1/2-inchtubing, the tube should beabout .25 inches longerthan the punch tip.For 3/8 tubing, the tube shouldbe cut about 3/16 inch longerthan the punch tip. For 5/16,cut the tubing about 5/32longer. For 1/4, cut the tubingabout 1/8 inch longer. Somewhatmore does not hurt, butless prevents the end fromclosing because there is not enough lengthto close over the end of the punch. Toomuch causes the tubing to buckle ratherthan fold neatly.<strong>End</strong> <strong>Flattening</strong> <strong>Punch</strong>forCTJM-1Jacket Maker KitType: -M -S -HCaliber: ________Wall thickness: ________May beused withvariouslengths oftubing.Adjustableshoulderpunches areavailable ifneeded.Your coreseatingdie, usedwith thispunch...Used to flattenthe end of thecopper tubingafter it has beenrounded, drawnto size andannealed. Donot skip theannealing step.Used in yourexisting coreseater die.

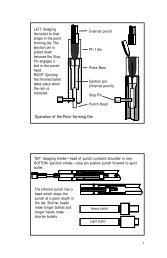

123456789012345123456789012345123456789012345123456789012345How to make a copper tubing bullet...Tools required: CTJM-1 tubing jacket maker,plus a bullet swaging die set (FJFB-3, RBTO-4)Step 1.Round theend in theJM die.123456789012345123456789012345123456789012345123456789012345123456789012345123456789012345123456789012345123456789012345123456789012345Step2.Anneal thetubing!Step 4.Form BT-shape inBT-1 die for RBTbullets, or flattenthe end in CS-1die for flat basebullets.Step 5.Seat Core inCS-2 for flatbase bullets.Alternate Step 5.Seat Core in BT-2die for RBTbullets.Step 6.Form theogive.Tubelength is1/4-inchmore thanpunch tip.123456789012345123456789012345123456789012345123456789012345123456789012345123456789012345123456789012345123456789012345Annealing the tubing can bedone by heating briefly to red(950-1200 degrees F.) with apropane torch, heat treatmentfurnace, or othermeans. If the tubing is alreadyannealed when youbuy it, this step is not required.Straight lengths ofhard drawn tubing must beannealed!Step 3.Draw thetube tosize.<strong>Punch</strong> for RBT bulletsis shaped like aboattail bullet, andforces the jacket totake on the BT shape(the rebate is formedin the next die, BT-2,during core seating).Use RBTpunch onlyfor RBTbullets; useflat punchfor flat-basebullets.JThe Jacket Reducing <strong>Die</strong>is used to bring the standardtubing diameter (from1/2-inch to 1/4-inch range)to the size that will fit intothe core seating or firstboattail forming die (just afew thousandths under finishedbullet size). It is notneeded for .50 BMG using1/2-inch tubing.<strong>Punch</strong> for the flatbase bullet is flat onthe end, and fitsinside the tubing afterdrawing (the similarlooking end roundingpunch fits into thetubing beforedrawing).BT-1orCS-1BT-2PF-1Type -H dies and punchesare illustrated. The sameoperation holds for type -Mand -S sets.Jacket-maker die is also calledthe “end rounding” die, becauseit rounds the end of the tubing,providing that the tubing is at least1/4-inch longer than the punch tip.JRD-1Depending on whether you use a flat base or rebated boattail (RBT) design,you will use an “end flattening” punch to finish closing the end of thetube and /or to shape the boattail angle. The lead core is then insertedand swaged with a shorter core seating punch, either in the same coreseat die (flat base) or in the BT-2 forming die (RBT base).