Gas Assist Brochure - BAUER Compressors

Gas Assist Brochure - BAUER Compressors

Gas Assist Brochure - BAUER Compressors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SYSTEMS SERVICE TRAINING WORLDWIDEGAS ASSIST SOLUTIONSFrom the Injection Molding Experts

<strong>BAUER</strong> PLASTICS TECHNOLOGY GROUP36830 Metro Court, Suite ASterling Heights, MI 48312TEL. +1 (586) 264-0360FAX +1 (586) 264-0361info@bauerptg.comwww.bauerptg.com12.07.BCIsubject to alteration without notice or obligation

CONTENTSSYSTEMSTurnkey SystemsMISSION STATEMENTTo be the global leader by supplyingthe best quality product whilecontinuously improving throughinnovation.2

SERVICETRAININGWORLDWIDEContentsAPPLICATIONS / 0104 FAQsGAS ASSIST / 0206 OverviewCOMPRESSION / 0308 Nitrogen controllers10 Nitrogen generation12 <strong>Compressors</strong> and boostersSTORAGE / 0414 High pressureACCESSORIES / 0516 From the sourceCOMPANY / 0618 Commitment to qualityINNOVATION / 0720 Compressor technology<strong>BAUER</strong> GROUP / 0822 Worldwide3

APPLICATIONSSYSTEMSFAQsAPPLICATIONSAUTOMOTIVE CONSUMER MEDICAL4

SERVICETRAININGWORLDWIDEWhat is gas assist injectionmolding?The most effective method of applyingpressure to an injection moldedpart during cooling.<strong>Gas</strong> assist injection molding is a lowpressure process which reduces theclamp tonnage required for molding.<strong>Gas</strong>eous nitrogen is applied internally,either directly into thicker sections ofthe part or via a network of gas channels.Through proper design, thislower gas pressure is applied evenlythroughout the part and sustainedduring the entire cooling phase, therebyeliminating potential defects.Packing force must be applied andmaintained to an injection molded partas it cools. Conventional moldingoften results in relatively high pressurewithin the mold cavity, which cancause flash, premature tool wear, sinkmarks and shrink.What can gas assist do for me?<strong>Gas</strong> assist injection molding willlower your production costs.There are many benefits associatedwith the gas assist process.Clamp Tonnage ReductionSignificant cost savings can be realizedvia reduced clamp tonnage; in somecases, gas assist can lower theserequirements by 30% to 70%. Evenwith a full resin shot gas is able to penetrate,if only to take up volumetricshrinkage within the cavity. As a result,tools that would normally run in 1500ton presses can be placed in smallerpresses. The reduction in machinerycost, potential energy savings, andincreased flexibility to quote jobsbeyond current tonnage capacity canmake any project interesting.Cycle Time ReductionNitrogen extends the flow of resin as ittravels through the part, completing fillwhile displacing resin from thick areasof the part. With less material in thickareas, cooling time and cycle time arereduced; cycle times for some thickwalled parts have been reduced morethan 50%. With thin wall parts, cycletimes can be reduced by replacing thepack and hold phase of the processwith gas pressure, allowing for screwrecovery immediately after injection.Resin SavingsWith today’s resin pricing, part weightreduction is important to molders.Handles and similarly thick-sectionedparts are ideal candidates for gas assistand offer potential for significantweight reductions, but resin savingsare also possible in thin walled parts.In many parts nominal wall thicknesscan be reduced when using gas assist,increasing part strength. With propertool design, gas assist will also allowyou to reduce scrap rates.Improved Part Quality<strong>Gas</strong> assist technology can improve thequality of products having certaindimensional and appearance requirements.Recent trends have reducednominal wall thickness and increasedboss and mounting configurations,which can result in added stresses,shrinkage, surface defects and imperfections.Thin walled parts with heavybosses are also susceptible to sink.When properly applied, gas assist caneliminate these quality concerns.Design Freedom<strong>Gas</strong> assist offers certain freedoms todesigners that are unachievable withconventional methods. Heavy wall sectionscan intersect thinner ones, ribsand bosses can be designed thickerthan the nominal wall without fear ofsinks, mechanical tool movementsused for coring can be eliminated, andparts can be designed with thick sectionsthat will become hollow. Whenthe runner system is designed withinthe part, gas assist can potentiallyeliminate the added expense and complications(weld lines) associated withhot manifold systems.ELECTRONICS5

GAS ASSISTSYSTEMSAOverviewAA1Process Consultation- Part design and mold filling analysis- Mold trials and process demonstrations- Project evaluation and tool layout assistanceBCABCDESource of nitrogen in the form of nitrogenbottles, fluid tank or nitrogen generatorHigh pressure compressor unit and suitably sized andrated storage facility for the compression and storageof nitrogen at elevated pressuresHigh pressure stainless steel lines to transport the nitrogenNitrogen control unit that generates a pressure/time profile toaccurately and repeatedly dispense the nitrogen2 Compression- Up to 400 bar and 45 Nm3/hrGA SERIES and BK SERIES BOOSTERS- Up to 6000 psig and 27 scfm<strong>Gas</strong> injectors and injection nozzles to deliver nitrogen into the plastic parts- Complete unit with N2 purification and storageB3 InjectionGAS INJECTORS- For molding machines of 20 tons or larger- 5 1/2 inch length and 13/4-8 thread size- Simple disassembly for easy maintenance6

SERVICETRAININGWORLDWIDEDEDD6Supportand Service- Installation / start-up services- Maintenance / repair services- Operational / process trainingCVent Control Valve ®EUniversal Self ActuatingShut-Off NozzleTool Face Mounted<strong>Gas</strong> <strong>Assist</strong> Injector Pins5 OptimizationVENT CONTROL VALVE ®- Latest advance in high pressure regulator protection- For use with any gas assist control unit- 4 1/2 inch length4 ControlNCM-1 and NCU-V2- Control units for gas injection technology- Up to 5000 psig (345 bar)- Up to 4 independently controlled channels (NCU-V2 only)7

COMPRESSIONSYSTEMSNitrogen controllersPRODUCTSNCU NCM MNR-00258

SERVICETRAININGWORLDWIDEEXCELLENCEInjection molding is a study in precision,a symphony of numerousprocesses working simultaneously tocreate a single part. If even one of theprocesses is even the slightest bit off,the part can be compromised. This isparticularly true with gas assist injectionmolding, where the timing of gasinjection can make the differencebetween a Class A part and scrap.Given the ever-rising costs of energyand raw materials, you need the assurancethat your gas assist controls canperform consistently and accurately,time and time again.<strong>BAUER</strong> understands that reliability andoptimal performance are extremelycritical for these applications. That’swhy we’ve worked for many years todevelop the very best high pressuregas assist injection molding solutionsin the world. Our systems are designedfor designing gas assist profiles thatare easy to configure, repeatable, andreliableWhen you need control of your gasassist process, <strong>BAUER</strong> PlasticsTechnology Group is there.MFC9

COMPRESSIONSYSTEMSNitrogen generationPRODUCTSSNGII (to 6000 psi) SNGII-LP (to 150 psi) NGM10

SERVICETRAININGWORLDWIDEWHY BUY NITROGEN WHENYOU CAN MAKE YOUR OWN?Nitrogen is a versatile and crucial componentof any gas assist operation.When it isn’t available at the pressures,capacities, and purities you need, itcan create high scrap counts and evenbring your processing operations to astandstill. Even when it is available,poor quality gas can result inunplanned maintenance issues andunnecessary downtime. Given theever-rising costs and increased safetyrequirements for manufacturing operations,you need the assurance thatyour nitrogen systems can performconsistently and accurately, time andtime again.<strong>BAUER</strong> understands that reliability andoptimal performance are extremelycritical for these applications. That’swhy we’ve worked for many years todevelop the very best high pressuregas assist injection molding solutionsin the world. Our systems are designedto safely deliver consistent purity athigher capacities than ever before. Itbegs the question: Why buy nitrogen,when you can make your own?When you need nitrogen, <strong>BAUER</strong>Plastics Technology Group is there.Technical DataModel Product flow at Product flow at Product flow at99.5% purity 99.0% purity 98.0% purityscfm 1) l/min scfm 1) l/min scfm 1) l/min5000 psig (345 bar)SNGII-15305 4 113 5.5 156 7.5 212SNGII-20410 7 198 11 311 14 396SNGII-30615 13 368 18 510 26 736SNGII-40815 25 708 26 736 27 7656000 psig (414 bar)SNGII-15376 10 254 10 254 10 254SNGII-40820 25 708 25 708 25 7081) Capacity (FGD) is referenced to standard conditions. Tolerance +/- 5%.Dimensions and weight are approximate and are dependent upon model and drive.CUSTOM DESIGN11

COMPRESSIONSYSTEMS<strong>Compressors</strong> and boostersPRODUCTSMINI VERTICUS MAXI VERTICUS VERTECON12

SERVICETRAININGWORLDWIDECOST EFFECTIVEFor many molders, purchasing nitrogenis a part of the day-to-day operations.For those who use this nitrogenin support of the gas assist process,returning bottles with substantiallyunused gas is wasteful and a drain onthe bottom line. Given the ever-risingcosts of merchant-supplied gas, youneed the assurance that you can atleast use what you purchase. With ourhigh pressure compressors and boostersyou can, time and time again.<strong>BAUER</strong> understands that reliability andoptimal performance are extremelycritical for these applications. That’swhy we’ve worked for many years todevelop the very best high pressuregas assist injection molding solutionsin the world. Our systems are designedto completely empty your merchantgas bottles and recompress the gas toa higher pressure, giving you full valuefor your purchased gas.When you need efficiency and optimumperformance, <strong>BAUER</strong> PlasticsTechnology Group is there.CUSTOM PACKAGES13

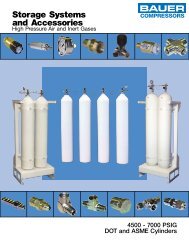

STORAGESYSTEMSHigh pressurePRODUCTSUN/ISO ASME LOW PRESSURE STORAGE14

SERVICETRAININGWORLDWIDEENERGY IN RESERVEWhen an application requires storage,either in the form of a single cylinderor multiple cylinders, arranged eitherfor bulk or in banks for cascading, aproperly sized storage system offersmany benefits to the compressedair/gas system. The main purpose ofstorage is to serve as a reservoir tohandle constant, sudden or unusuallyhigh demands for air/gas that canexceed the capacity of the compressor.Storage protects the compressor fromthe direct demand of the system aswell as serving to dampen or eliminatepressure pulsations to the system.Each high pressure application must becarefully reviewed to determine thebest type and size of storage to use.The cost of equipment as well as operationaland maintenance costs can bereduced by properly matching thecompressor to the storage system.<strong>BAUER</strong> recommends that the compressordoes not start more than 4 timesper hour to avoid short-cycling of thecompressor. Short-cycling can be detrimentalto the compressor, motor,compressor control system and to thehigh pressure system. Our Storage<strong>Brochure</strong> will serve as a guide toselecting the best storage system solutionfor your application.The volume of storage required for aspecific application depends upon:A. Consumption rate of the systemB. Capacity of the compressor/boosterC. Deadband of the final pressure sensorSTORAGE SIZINGBulk storage for limiting the number ofcompressor starts to 4 times per hourcan be calculated by the following formula:VR = 58 x (QC / Δ P)Where:- VR = Volume of storage, cubic feetwater volume- QC = Capacity of compressor,standard cubic feet per minute (scfm)- ΔP= Approximate deadband of finalpressure sensor, pounds per squareinch differential (psid).Multiple cylinders and banks can beused for applications that require alarge volume of storage. Contact<strong>BAUER</strong> for sizing storage with multiplebanks for cascading.TECHNICAL DATA<strong>BAUER</strong> is knowledgeable in the applicationof storage to medium and highpressure applications. We offer cylindersfor storage to meet the coderequirements of either the AmericanSociety of Mechanical Engineers(ASME) or the United Nations (UN)Model Regulations (ISO 9809-PART 2).Refer to the Storage brochure for technicaldata when storing inert gases.The table provides a summarization oftechnical data for cylinders offered by<strong>BAUER</strong> when storing air.SYSTEMAll UN cylinders are shipped with aprotective cap for the cylinder valve.Valve caps are shipped installed onloose cylinders and shipped loose withracked assemblies. The mandatoryretest period for these UN cylinders isevery ten (10) years. Under no circumstancesare these cylinders to be filledto a pressure exceeding the markedservice pressure at 70 ºF.Model Weight *lbs kgUN 4500 455 206UN 5000 475 215UN 6000 525 238ASME 935 424*2-cylinder rack with bottles.CUSTOM PACKAGES UN/ISO ASME15

ACCESSORIESSYSTEMSFrom the sourceQUALITY U.S. Patent # 6,904,925INJECTION NOZZLE INJECTION PINS VENT CONTROL VALVE16

SERVICETRAININGWORLDWIDEQUALITYIt’s the little things that matter mostwith injection molding. Small pieces,such as slides or ejectors, play big rolesin the molding process and are crucialto the finished product. The same principleapplies to gas assist, where thelittle things such as injectors help toprecisely target the injection point ofnitrogen to deliver the very bestresults. Given the ever-increasingneeds for efficiency and reliability, youneed the assurance that the littlethings will work as consistently as thebig things.<strong>BAUER</strong> understands that reliability andoptimal performance are extremelycritical for these applications. That’swhy we’ve worked for many years todevelop the very best high pressuregas assist injection molding solutionsin the world. Our accessories are application-testedand designed for simpleinstallation and maintenance. We’re soconfident about our capabilities thatwe’ve even written a book on theprocess – feel free to contact us andtake advantage of our industry-leadingexpertise!When you need knowledge and support,<strong>BAUER</strong> Plastics Technology Groupis there.INJ-0001 (3/16” <strong>Gas</strong> Injector Pin)#8-32 THREAD.125” .090” 5/32 HEX.187”.320” .630”.062”INJ-0016 (1/4” <strong>Gas</strong> Injector Pin)1/4 - 28 THREAD.150” 7/32 HEX.250”.320” .645”MANUAL17

COMPANYSYSTEMSCommitment to qualityCAD DESIGN LASER CUTTING ROBOTIC BRAKE18

SERVICETRAININGWORLDWIDEEXPERIENCE FOR YOUR BENEFIT<strong>BAUER</strong> compressor systems are fieldprovenin a multitude of diverse plasticsprocessing applications worldwide.More than 60 years of combinedexperience, research and developmentare in place to find the very best solutionsto your plastics processingrequirements. We are world renownedfor reliability and durability, and <strong>BAUER</strong>as a company is recognized as a leadinginnovator in the design and manufactureof high pressure compressorsolutions.<strong>BAUER</strong> is especially capable of workingwith clients on a worldwide basisbecause of our vast network of salesand service centers around the globe.<strong>BAUER</strong>’S U.S. operations include a115,000 sq ft manufacturing facility inNorfolk, VA and branch offices inMichigan, California and Florida.DEDICATION TO YOU<strong>BAUER</strong> is committed to the philosophythat customer satisfaction is achievedthrough a strategy of continuousimprovement using in-house researchand development, engineering, manufacturingand support services. OurISO 9001 registered quality managementsystem is testament to our commitmentto quality and customer satisfaction.CUSTOMER SATISFACTION<strong>BAUER</strong> begins with expert system evaluationand continues with the design,installation, training and support servicesto ensure the highest quality andoptimum performance of the product.<strong>BAUER</strong> Block Manufacturing Geretsried, Germany<strong>BAUER</strong> COMPRESSORS INC. Norfolk, Virginia USAROBOTIC WELDINGQUALITY<strong>BAUER</strong> UNIVERSITY TRAINING19

INOVATIONSYSTEMSCompressor technologyCOMPRESSORS AND BOOSTERSBooster 15.x 22.x 23.x20

SERVICETRAININGWORLDWIDE<strong>BAUER</strong> ADVANTAGES...Wide range of capacity and pressure inboth compressor and booster configurationallows tailoring a solution tomeet specific requirements.Proven air-cooled design is economical,reliable and environmentallyfriendly. An external power source isnot required and no coolant.Large surface area and fine ribbing oncylinders provides efficient heat dissipationfor lower operating temperatures.Aftercooler provides low dischargetemperature. Supplemental cooling atthe outlet is not required.Pressurized lubrication ensures reliablelubrication of all internal componentsfor extended compressor life. Oil filterprotects the lubrication system.Roller or needle bearing used at eachbearing surface for reduced frictionand optimum mechanical efficiency.Compressor runs cooler, oil life isextended and maintenance is reduced.Heavy-duty roller bearings to supportthe crankshaft. 30,000 hours designlife.Aluminum alloy crankcase usedthrough 30 hp enables compactdimensions because of rapid heat dissipation.Cast iron crankcase used on40 hp and greater to support greaterforces. High capacity cooling fan(s)provide efficient cooling.Encapsulated crankcase to protect theenvironment from oil laden mist.High efficiency intake filter to protectthe compressor from damaging particles.Safety valve after each stage of compressionto protect the compressorfrom overpressure and to safeguardthe operator. <strong>Gas</strong> compressors andboosters also include a safety valve atthe inlet.Balanced flywheel and counterbalancedcrankshaft results in nearlyvibration-free operation. <strong>BAUER</strong> compressorsand boosters do not requirespecial foundations which reducesinstallation cost.Readily accessible valves do not requiredisassembly of compressor piping foreasy accessibility and reduced maintenancecost and downtime.Corrosion resistant materials used forcoolers, separators and valves forlonger life and reduced maintenance.Genuine spare parts at affordableprices.Operation and maintenance manualwith illustrated parts lists....FOR YOUR BENEFIT25.x and 28.x21

<strong>BAUER</strong> GROUPSYSTEMSWorldwide<strong>BAUER</strong> OFFICESPTG DISTRIBUTORS22

SERVICETRAININGWORLDWIDE23