LOckerbaskets® - Equipment World Inc.

LOckerbaskets® - Equipment World Inc.

LOckerbaskets® - Equipment World Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

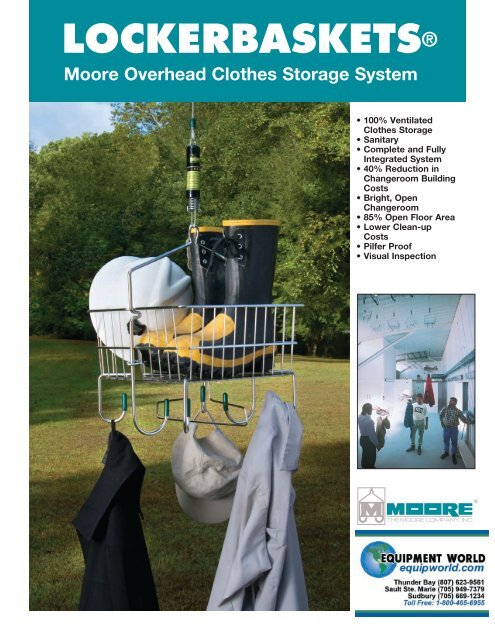

LOckerbaskets ®Moore Overhead Clothes Storage System• 100% VentilatedClothes Storage• Sanitary• Complete and FullyIntegrated System• 40% Reduction inChangeroom BuildingCosts• Bright, OpenChangeroom• 85% Open Floor Area• Lower Clean-upCosts• Pilfer Proof• Visual InspectionThe Moore Company, <strong>Inc</strong>.P.O. Box 3570Charleston, WV 25337Phone: 304-344-8024Fax: 304-344-8025www.moorecompany.com

Chain Hoisting andLocking AssemblyEach complete LOCKERBASKET® is furnished with 9’-0” ofMoore MCO-100 Machine Link Chain and a Locking Plate andswivel sub assembly. This housing assembly is connected tothe Moore Polycore cable and is used to raise and lower theLOCKERBASKET®. The wide-profiled surface of the chainprovides for a comfortable, secure handgrip for operatingLOCKERBASKETS®. A Locking Bolt is designed to fit through theLocking Plate when the basket has been raised and secured inplace with a padlock.A Fully Integrated SystemThe Moore overhead LOCKERBASKET® storage system isshipped complete with necessary pulley support channels,standard operating equipment, bench, bench support systemand LOCKERBASKETS®. This integrated system is easily andeconomically installed in industrial buildings. By utilizing thecomplete, integrated system approach, savings of up to 40% arerealized in labor, material and floor area.100% Ventilated Clothes Stor ageThe Moore LOCKERBASKET® System stores employee clothingand personal effects safely and securely overhead in a corridor ofmoving air, inhibiting growth of odor causing bacteria and promotingquicker aeration of clothing. LOCKERBASKETS® are designedto allow clothing to hang full length to maximize garment surfaceexposure.LOCKERBASKETS® eliminate employee complaints and unrestcaused by odors and the discomfort from damp clothing stored inconfined lockers.Moorframe ® Prepunched ChannelsMOORFRAME® is a high strength (50,000 psi yield point), cold rolledgalvanized steel channel that is prepunched for easy installationof pulleys and locking assembly. MOORFRAME® is designed tosupport the Moore LOCKERBASKET® System overhead on clearspans up to 10’-0”. This flexibility makes it possible to be usedequally well in steel, concrete or wooden structures; and in bothflat roof and rigid frame design. MOORFRAME® engineering andframing attachmentdetails are completely covered in our installation instructions.Moore Operating <strong>Equipment</strong>Double Swivel Eye Cable PulleysTwo (2) Moore double swivel eye cable groove pulleys are suppliedper LOCKERBASKET®. The Moore pulley is designed with a 4 3/8”sheave, injected molded from the dimensionally stable and selflubricatingDelrin plastic. The sheave is designed to properly cradlethe polycore cable to give it a silent, smooth action. The housing isfabricated from 16-gauge stainless steel with a light chrome finish.The double swivel eye prevents the pulley from binding regardless ofthe roof pitch or direction the MOORFRAME® runs.Moore Polycore CableMoore standard operating equipment is shipped complete with16’-0” of Moore Polycore cable per LOCKERASKET®for operating over pulleys. The 1/8” Moore cable ismanufactured from high quality preformed galvanizedsteel wire, stranded around a polycore fiber. This uniqueconstruction absorbs the high concentration of internalstresses which are formed by the LOCKERBASKET®hoisting action. The cable is designed for 280 poundsworking load limit (maximum break strength of 1,400pounds) and is shipped with cable fittings.Self VentilatingLockerbasketsThe ideal Clothes Storage Unit – theclothing is suspended full length belowthe basket exposing it to circulatingfresh air. Clothing hangs below thebasket allowing the unit to be near level.LOCKERBASKETS® are furnished withsix hooks and come complete with guide bolts, vinyl cushiontipped clothes hooks and a coat hanger. Hook bales are positionedunder the basket to maximize storage area. The entire unit is epoxycoated after fabrication.Locking Rail andBench Support UnitsPrefabricated locking rail bench support units are available insingle or double bench styles and are designed to accommodateMOORFRAME® locking rail and Moore ALUMIBENCH®. Lockingrail support posts are fabricated from 2”x2” tube steel, capped,drilled and threaded to receive a locking rail anchor bolt.Bench support pedestals are fabricated from 3” x ¼” steel andprepunched for quick assembly. Individual pedestals are alsoavailable for use with Alumibench® where bench will be installedin a free standing configuration. All pedestals are provided with two(2) hold down clips for attaching Alumibench®. All parts are hotdipped galvanized for superior rust protection.Moore Alumibench ®Fabricated from heavy extruded striated aluminum, in satinanodized finish, ALUMIBENCH® is 9-1/2” wide x 1-3/4” deepwith integral reinforcing ribs. It is designed to span 6’-0” betweensupports with carry capacity of 200 pounds per lineal foot.Furnished in standard 12’-0”lengths. Complete with aluminum capsfor ends of bench rows, sections may be joined at pedestals togive long continuous runs. The ALUMIBENCH® provides warm,comfortable changeroom seating.Saving Space — Enhancing SecurityLOCKERBASKETS® store clothes overhead out of reach of pryinghands, enhancing security for employees’ personal belongings. Theuse of open changeroom construction eliminates hidden aisles,discourages forced entry into individual LOCKERBASKETS® andthe storing and dispersing of contraband on company property.The fully integrated operatingassembly of the Moore chain, lockingplate and polycore cable providessafe and secure clothes storagesystem for your employees.

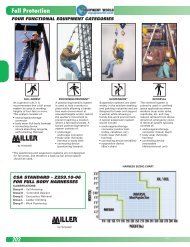

4270 mm MINIMUMCEILING HEIGHT (14’ 0”)4880 mm PREFERREDCEILING HEIGHT (16’ 0”)(5’ 0”)1520 mm(4’ 7 1/2”)1960 mm(1’ 5”)430 mmTypical Elevationand Floor PlanROOF LOAD:Roof structure must be designed bya design professional to withstandan 10 psf uniform load causedby loaded LOCKERBASKET® inaddition to roof loads determinedfrom appropriate building codesand local conditions. The designprofessional must also separatelyconsider the point loads causedby the reaction of the collector rail.Each LOCKERBASKET® load mustbe limited to 30 pounds.ROOF LOAD:Add 4.54 kg per0.0929 m2(10 lbs. per SF) forOverhead Storage SystemBOTTOM OF ROOFSUPPORT FRAMINGSUPPORT RAIL610 mm(2’0”)610 mmCOLLECTORRAILMOORE SWIVELPULLEYMOOREPOLYCORECABLELOCKING BOLTNUMBER PLATEMS-10 CHAINHOISTING ASSEMBLYMOORE ALUMIBENCHFIN. FLOORDOUBLE PEDESTAL LOCKINGRAIL SUPPORT UNIT1220 mm(4’ 0”)3660 mm(6’ 0”)3660 mm(6’ 0”)610 mm(2’ 0”) (No aisle)1220 mm(4’ 0”) (w/Aisle)3660 mm(6’ 0”)102 mm(0’ 4”)TYPICALLAYOUT5490 MM (18’ 0”) 305 mm(1’ 0”)Technical SupportThe Moore Company, <strong>Inc</strong>. provides preliminary layout assistance,estimating or other technical information for the Owner and its DesignProfessionals. For product information, specification assistance oranswers to your questions, please contact The Moore Company.FAX 304-344-8025 or by email agalan@moorecompany.comLOCKERBASKET®, operating equipment and accessories areprotected by patents and Trade Marks in the United States and manyforeign countries.The Moore Company, <strong>Inc</strong>. reserves the right to make design andproduct changes or to withdraw any design or product without notice.Current literature may be found on our website.The Moore Company, <strong>Inc</strong>.P.O. Box 3570Charleston, WV 25337Phone: 304-344-8024Fax: 304-344-8025Distributors in Principal Citieswww.moorecompany.com© 2008 The Moore Company, <strong>Inc</strong>.