Product Features: Technical Data

Product Features: Technical Data

Product Features: Technical Data

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

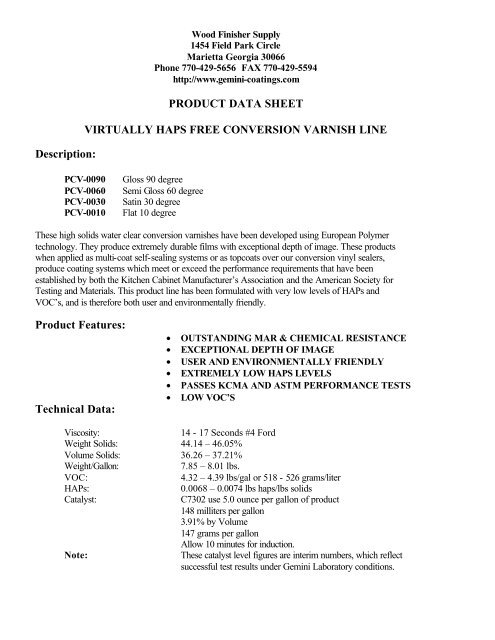

Description:Wood Finisher Supply1454 Field Park CircleMarietta Georgia 30066Phone 770-429-5656 FAX 770-429-5594http://www.gemini-coatings.comPRODUCT DATA SHEETVIRTUALLY HAPS FREE CONVERSION VARNISH LINEPCV-0090PCV-0060PCV-0030PCV-0010Gloss 90 degreeSemi Gloss 60 degreeSatin 30 degreeFlat 10 degreeThese high solids water clear conversion varnishes have been developed using European Polymertechnology. They produce extremely durable films with exceptional depth of image. These productswhen applied as multi-coat self-sealing systems or as topcoats over our conversion vinyl sealers,produce coating systems which meet or exceed the performance requirements that have beenestablished by both the Kitchen Cabinet Manufacturer’s Association and the American Society forTesting and Materials. This product line has been formulated with very low levels of HAPs andVOC’s, and is therefore both user and environmentally friendly.<strong>Product</strong> <strong>Features</strong>:<strong>Technical</strong> <strong>Data</strong>:• OUTSTANDING MAR & CHEMICAL RESISTANCE• EXCEPTIONAL DEPTH OF IMAGE• USER AND ENVIRONMENTALLY FRIENDLY• EXTREMELY LOW HAPS LEVELS• PASSES KCMA AND ASTM PERFORMANCE TESTS• LOW VOC’SViscosity:14 - 17 Seconds #4 FordWeight Solids: 44.14 – 46.05%Volume Solids: 36.26 – 37.21%Weight/Gallon:7.85 – 8.01 lbs.VOC:4.32 – 4.39 lbs/gal or 518 - 526 grams/literHAPs:0.0068 – 0.0074 lbs haps/lbs solidsCatalyst:C7302 use 5.0 ounce per gallon of product148 milliters per gallon3.91% by Volume147 grams per gallonAllow 10 minutes for induction.Note:These catalyst level figures are interim numbers, which reflectsuccessful test results under Gemini Laboratory conditions.

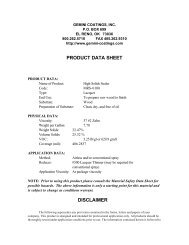

Theoretical Coverage:Dry Time:Working Pot Life:Pot Life:Package Life:These numbers may be subject to change upon further testing.592 Sq. Ft. per gallon at one mil dry film thickness25-30 minutes @ 77° F and 50% RH8-12 hoursWhen catalyzed properly & maintained in a closedvessel at standard temperature and pressure(78°F and 1 atmosphere), this product may exhibitan extended pot life of up to 3 days.1 year in a properly sealed containerThe above data is for information purpose only and actual factory batches may vary from the figures given. Tothe best of our knowledge, the above data is true and accurate at the date of issuance but is subject to changewithout prior notice.Material Preparation:All wood surfaces must be dry, clean, and free from all contaminants.Catalyzation:Catalyze only enough material to be used during the day, if you prefer to use the residual frompreviously catalyzed material, we recommend adding at least 5 parts (by volume) fresh material per 1part (by volume) of the catalyzed material. Catalyze the following morning based upon the volume offresh material added.Reduction:No reduction is required for application; however if your specific situation demands reduction, useSOL-9011, HAPs Free Lacquer Thinner or SOL-9013, Non HAPs, Non-VOC Thinner at a level not toexceed 10% (by volume) maximum. Thinning may alter the coating’s VOC content.Caution: Reduction of this product with these thinners may alter the effective pot life and the recoatparameters for this productApplication:This product may be applied as a multi-coat self-sealing system. When so applied, we recommend amaximum of 3 coats, unreduced, with a maximum wet film of 3 mils per coat. These conversionvarnishes may also be used in combination with the Gem Seal Conversion Sealer, 210-0008, or theGem Seal HAPs Compliant Precat Vinyl Sealer, 210-0001. In preparing these systems we recommend1 coat, unreduced, of vinyl sealer with a maximum wet film of 5 mils, topcoated with a maximum oftwo coats of conversion varnish, unreduced, at a maximum wet film of 3 mils per coat.<strong>Product</strong> Performance:Total dry film thickness for the complete coating system must not exceed 3 mils.

KCMA Cold Check Resistance Test:All panels passed 21 cold check cycles (cycling from 120 F degree to –5 F degree and 70% RelativeHumidity to 0% Relative Humidity)The KCMA (Kitchen Cabinet Manufacturers Association) test is conducted with the test panel in avertical position while 1-milliliter aliquots of various household chemicals are applied to the coatedsurface. All of the chemicals with the exception of mustard are allowed to remain in contact with thecoating for 24 hours. Mustard is removed from the surface after one hour.Each chemical is then evaluated for its impact upon the coated surface, which includes such parametersas loss of gloss, discoloration, blistering, and delamination. The chemicals used and their respectiveeffects upon coating are as follows:1 coat 210-0008 Precat Vinyl Sealer2 coats 550-0059 Flat Conversion VarnishKCMA Test Initial results 10-day recoveryCatsup ` no effect no changeVinegar no effect no change45% ethyl alcohol in water no effect no changeOlive Oil no effect no change2% household Ammonia no effect no changeLemon Juice no effect no changeCoffee no effect no changeWater no effect no changeMustard (one hour) slight discoloration no change1 coat 210-0001 Gem Seal HC Precat Vinyl Sealer2 coats 550-0059 Flat Conversion VarnishKCMA Test Initial results 10-day recoveryCatsup ` no effect no changeVinegar no effect no change45% ethyl alcohol in water no effect no changeOlive Oil no effect no change2% household Ammonia no effect no changeLemon Juice no effect no changeCoffee no effect no changeWater no effect no changeMustard (one hour) slight discoloration no change2 coats 550-0059 Flat Conversion VarnishKCMA Test Initial results 10-day recoveryCatsup ` no effect no change

Vinegar no effect no change45% ethyl alcohol in water no effect no changeOlive Oil no effect no change2% household Ammonia no effect no changeLemon Juice no effect no changeCoffee no effect no changeWater no effect no changeMustard (one hour) slight discoloration no change3 coats 550-0059 Flat Conversion VarnishKCMA Test Initial results 10-day recoveryCatsup ` no effect no changeVinegar no effect no change45% ethyl alcohol in water no effect no changeOlive Oil no effect no change2% household Ammonia no effect no changeLemon Juice no effect no changeCoffee no effect no changeWater no effect no changeMustard (one hour) slight discoloration no changeKCMA 24-hour Detergent Water Edge Soak TestAll panels passed with no visible effect to the coating.The ASTM (American Society for Testing Materials) test is conducted with the test panel in ahorizontal position while applying 1 milliliter of various household chemicals on the surface of thecoating. Each chemical is maintained at its respective location on the panel by the use of a watch glass.All chemicals are allowed to remain in contact with the coating surface for a period of 16 hours.Each chemical is then evaluated for its impact upon the coated surface, which includes such parametersas loss of gloss, discoloration, blistering, and delamination. The chemicals used and their respectiveeffects upon the coating are as follows:1 coat of 210-0008 Precat Vinyl Sealer2 coats of 550-0059 Flat Conversion VarnishASTM Test Initial results 10-day recoveryCatsup no effect no changeVinegar no effect no changeAlcohol 1-hour discoloration 100% recoveryOlive Oil no effect no change2% Ammonia (household) no effect no changeLemon Juice no effect no changeCoffee no effect no changeWater no effect no changeMustard (1-hour) discoloration 90% recovery

1 coat of 210-0001 Gem Seal HC Precat Vinyl Sealer2 coats of 550-0059 Flat Conversion VarnishASTM Test Initial results 10-day recoveryCatsup no effect no changeVinegar no effect no changeAlcohol 1-hour discoloration 100% recoveryOlive Oil no effect no change2% Ammonia (household) no effect no changeLemon Juice no effect no changeCoffee no effect no changeWater no effect no changeMustard (1-hour) discoloration 90% recovery2 coats of 550-0059 Flat Conversion VarnishASTM Test Initial results 10-day recoveryCatsup no effect no changeVinegar no effect no changeAlcohol 1-hour discoloration 100% recoveryOlive Oil no effect no change2% Ammonia (household) no effect no changeLemon Juice no effect no changeCoffee no effect no changeWater no effect no changeMustard (1-hour) discoloration no change3 coats of 550-0059 Flat Conversion VarnishASTM Test Initial results 10-day recoveryCatsup no effect no changeVinegar no effect no changeAlcohol 1-hour discoloration 100% recoveryOlive Oil no effect no change2% Ammonia (household) no effect no changeLemon Juice no effect no changeCoffee no effect no changeWater no effect no changeMustard (1-hour) discoloration no changeClean Up:Use SOL-9011, Non HAPs Thinner or SOL-9013, Non HAPs/Non VOC thinner to clean up allequipment. Dispose of dirty solvent and cleaning rags in a safe and approved manner. Solvent orlacquer soaked rags should be stored in water filled, closed containers prior to disposal.

DISCLAIMERThe following supercedes any provision contained in the forms, letters and papers of yourcompany. This product is designed and intended for professional application only. All products shouldbe thoroughly tested under application conditions prior to use. The information contained herein isbelieved to be reliable. HOWEVER, GEMINI MAKES NO WARRANTY CONCERNING THISPRODUCT, WHETHER EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OFMERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.UNDER NO CIRCUMSTANCES SHALL GEMINI BE LIABLE FOR SPECIAL,INCIDENTAL, CONSEQUENTIAL, OR ANY OTHER DAMAGES FROM ALLEGEDNEGLIGENCE, BREACH OF WARRANTY, STRICT LIABILITY, OR ANY OTHER LEGALTHEORY, ARISING OUT OF THE USE OR HANDLING OF THIS PRODUCT. THE SOLEREMEDY OF THE BUYER AND THE SOLE LIABILITY OF GEMINI FOR ANY CLAIMSSHALL BE LIMITED TO THE BUYER’S PURCHASE PRICE OF THE PRODUCT WHICHIS THE SUBJECT OF THE CLAIM OR THE AMOUNT ACTUALLY PAID FOR SUCHPRODUCT, WHICHEVER IS LESS.TECHNICAL ADVICE FURNISHED BY GEMINI SHALL NOT CONSTITUTE ANEXPRESS WARRANTY, WHICH IS EXPRESSLY DISCLAIMED. ALL TECHNICALADVICE GIVEN IS ACCEPTED AT THE RISK OF THE BUYER.CAUTION: DANGER! FLAMMABLE! VAPORS MAY CAUSE FLASH FIRE. VAPOR HARMFUL.HARMFUL OR FATAL IF SWALLOWED. INJURIOUS TO EYES. KEEP OUT OF THE REACH OFCHILDREN! BEFORE using this product it is essential that the “Material Safety <strong>Data</strong> Sheet” describing theproduct as well as the “<strong>Product</strong> Label” be reviewed. If your company does not have such information or has anyquestions, contact the manufacturer.Issued: 3/25/04Updated: 3/31/04This <strong>Product</strong> <strong>Data</strong> Sheet supercedes all previous data sheets.