Download file (1.8Mb) - MAN Diesel & Turbo SE

Download file (1.8Mb) - MAN Diesel & Turbo SE

Download file (1.8Mb) - MAN Diesel & Turbo SE

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

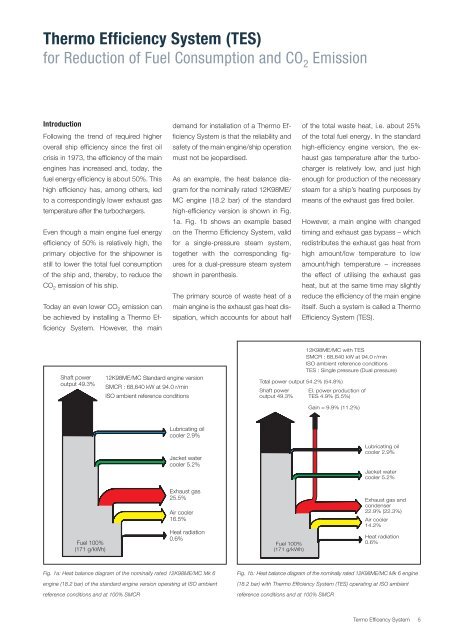

Thermo Efficiency System (TES)for Reduction of Fuel Consumption and CO 2 EmissionIntroductionFollowing the trend of required higheroverall ship efficiency since the first oilcrisis in 1973, the efficiency of the mainengines has increased and, today, thefuel energy efficiency is about 50%. Thishigh efficiency has, among others, ledto a correspondingly lower exhaust gastemperature after the turbochargers.Even though a main engine fuel energyefficiency of 50% is relatively high, theprimary objective for the shipowner isstill to lower the total fuel consumptionof the ship and, thereby, to reduce theCO 2 emission of his ship.Today an even lower CO 2 emission canbe achieved by installing a Thermo Efficiency System. However, the maindemand for installation of a Thermo Efficiency System is that the reliability andsafety of the main engine/ship operationmust not be jeopardised.As an example, the heat balance diagram for the nominally rated 12K98ME/MC engine (18.2 bar) of the standardhighefficiency version is shown in Fig.1a. Fig. 1b shows an example basedon the Thermo Efficiency System, validfor a singlepressure steam system,together with the corresponding figures for a dualpressure steam systemshown in parenthesis.The primary source of waste heat of amain engine is the exhaust gas heat dissipation, which accounts for about halfof the total waste heat, i.e. about 25%of the total fuel energy. In the standardhighefficiency engine version, the exhaust gas temperature after the turbocharger is relatively low, and just highenough for production of the necessarysteam for a ship’s heating purposes bymeans of the exhaust gas fired boiler.However, a main engine with changedtiming and exhaust gas bypass – whichredistributes the exhaust gas heat fromhigh amount/low temperature to lowamount/high temperature – increasesthe effect of utilising the exhaust gasheat, but at the same time may slightlyreduce the efficiency of the main engineitself. Such a system is called a ThermoEfficiency System (TES).Shaft poweroutput 49.3%12K98ME/MC Standard engine versionSMCR : 68,640 kW at 94.0 r/minISO ambient reference conditionsTotal power output 54.2% (54.8%)Shaft poweroutput 49.3%12K98ME/MC with TESSMCR : 68,640 kW at 94.0 r/minISO ambient reference conditionsTES : Single pressure (Dual pressure)El. power production ofTES 4.9% (5.5%)Gain = 9.9% (11.2%)Lubricating oilcooler 2.9%Jacket watercooler 5.2%Lubricating oilcooler 2.9%Jacket watercooler 5.2%Fuel 100%(171 g/kWh)Exhaust gas25.5%Air cooler16.5%Heat radiation0.6%Fuel 100%(171 g/kWh)Exhaust gas andcondenser22.9% (22.3%)Air cooler14.2%Heat radiation0.6%Fig. 1a: Heat balance diagram of the nominally rated 12K98ME/MC Mk 6engine (18.2 bar) of the standard engine version operating at ISO ambientreference conditions and at 100% SMCR<strong>MAN</strong> B&W <strong>Diesel</strong>Fig. 1b: Heat balance diagram of the nominally rated 12K98ME/MC Mk 6 engine(18.2 bar) with Thermo Efficiency System (TES) operating at ISO ambientreference conditions and at 100% SMCRTermo Efficency System5