NSC94-EPA-Z-008-004

NSC94-EPA-Z-008-004

NSC94-EPA-Z-008-004

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

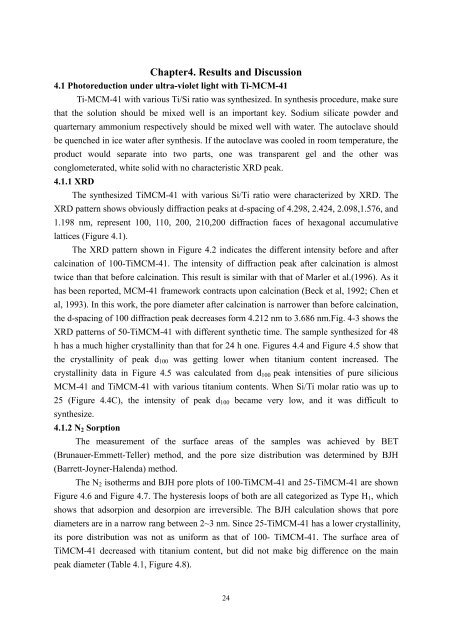

Chapter4. Results and Discussion4.1 Photoreduction under ultra-violet light with Ti-MCM-41Ti-MCM-41 with various Ti/Si ratio was synthesized. In synthesis procedure, make surethat the solution should be mixed well is an important key. Sodium silicate powder andquarternary ammonium respectively should be mixed well with water. The autoclave shouldbe quenched in ice water after synthesis. If the autoclave was cooled in room temperature, theproduct would separate into two parts, one was transparent gel and the other wasconglometerated, white solid with no characteristic XRD peak.4.1.1 XRDThe synthesized TiMCM-41 with various Si/Ti ratio were characterized by XRD. TheXRD pattern shows obviously diffraction peaks at d-spacing of 4.298, 2.424, 2.098,1.576, and1.198 nm, represent 100, 110, 200, 210,200 diffraction faces of hexagonal accumulativelattices (Figure 4.1).The XRD pattern shown in Figure 4.2 indicates the different intensity before and aftercalcination of 100-TiMCM-41. The intensity of diffraction peak after calcination is almosttwice than that before calcination. This result is similar with that of Marler et al.(1996). As ithas been reported, MCM-41 framework contracts upon calcination (Beck et al, 1992; Chen etal, 1993). In this work, the pore diameter after calcination is narrower than before calcination,the d-spacing of 100 diffraction peak decreases form 4.212 nm to 3.686 nm.Fig. 4-3 shows theXRD patterns of 50-TiMCM-41 with different synthetic time. The sample synthesized for 48h has a much higher crystallinity than that for 24 h one. Figures 4.4 and Figure 4.5 show thatthe crystallinity of peak d 100 was getting lower when titanium content increased. Thecrystallinity data in Figure 4.5 was calculated from d 100 peak intensities of pure siliciousMCM-41 and TiMCM-41 with various titanium contents. When Si/Ti molar ratio was up to25 (Figure 4.4C), the intensity of peak d 100 became very low, and it was difficult tosynthesize.4.1.2 N 2 SorptionThe measurement of the surface areas of the samples was achieved by BET(Brunauer-Emmett-Teller) method, and the pore size distribution was determined by BJH(Barrett-Joyner-Halenda) method.The N 2 isotherms and BJH pore plots of 100-TiMCM-41 and 25-TiMCM-41 are shownFigure 4.6 and Figure 4.7. The hysteresis loops of both are all categorized as Type H 1 , whichshows that adsorpion and desorpion are irreversible. The BJH calculation shows that porediameters are in a narrow rang between 2~3 nm. Since 25-TiMCM-41 has a lower crystallinity,its pore distribution was not as uniform as that of 100- TiMCM-41. The surface area ofTiMCM-41 decreased with titanium content, but did not make big difference on the mainpeak diameter (Table 4.1, Figure 4.8).24