download - Utility Contractor Online

download - Utility Contractor Online

download - Utility Contractor Online

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

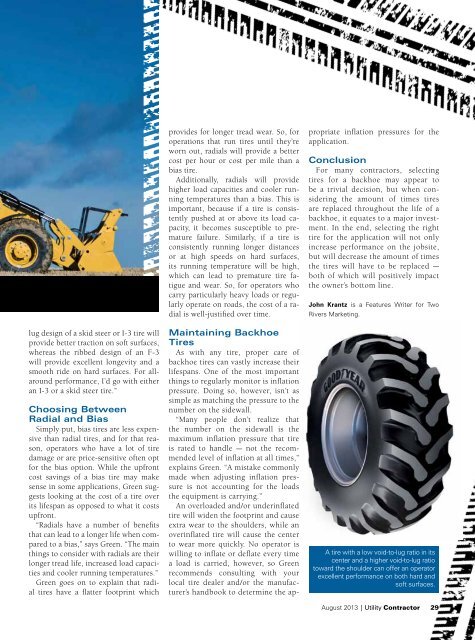

lug design of a skid steer or I-3 tire willprovide better traction on soft surfaces,whereas the ribbed design of an F-3will provide excellent longevity and asmooth ride on hard surfaces. For allaroundperformance, I’d go with eitheran I-3 or a skid steer tire.”Choosing BetweenRadial and BiasSimply put, bias tires are less expensivethan radial tires, and for that reason,operators who have a lot of tiredamage or are price-sensitive often optfor the bias option. While the upfrontcost savings of a bias tire may makesense in some applications, Green suggestslooking at the cost of a tire overits lifespan as opposed to what it costsupfront.“Radials have a number of benefitsthat can lead to a longer life when comparedto a bias,” says Green. “The mainthings to consider with radials are theirlonger tread life, increased load capacitiesand cooler running temperatures.”Green goes on to explain that radialtires have a flatter footprint whichprovides for longer tread wear. So, foroperations that run tires until they’reworn out, radials will provide a bettercost per hour or cost per mile than abias tire.Additionally, radials will providehigher load capacities and cooler runningtemperatures than a bias. This isimportant, because if a tire is consistentlypushed at or above its load capacity,it becomes susceptible to prematurefailure. Similarly, if a tire isconsistently running longer distancesor at high speeds on hard surfaces,its running temperature will be high,which can lead to premature tire fatigueand wear. So, for operators whocarry particularly heavy loads or regularlyoperate on roads, the cost of a radialis well-justified over time.Maintaining BackhoeTiresAs with any tire, proper care ofbackhoe tires can vastly increase theirlifespans. One of the most importantthings to regularly monitor is inflationpressure. Doing so, however, isn’t assimple as matching the pressure to thenumber on the sidewall.“Many people don’t realize thatthe number on the sidewall is themaximum inflation pressure that tireis rated to handle — not the recommendedlevel of inflation at all times,”explains Green. “A mistake commonlymade when adjusting inflation pressureis not accounting for the loadsthe equipment is carrying.”An overloaded and/or underinflatedtire will widen the footprint and causeextra wear to the shoulders, while anoverinflated tire will cause the centerto wear more quickly. No operator iswilling to inflate or deflate every timea load is carried, however, so Greenrecommends consulting with yourlocal tire dealer and/or the manufacturer’shandbook to determine the appropriateinflation pressures for theapplication.ConclusionFor many contractors, selectingtires for a backhoe may appear tobe a trivial decision, but when consideringthe amount of times tiresare replaced throughout the life of abackhoe, it equates to a major investment.In the end, selecting the righttire for the application will not onlyincrease performance on the jobsite,but will decrease the amount of timesthe tires will have to be replaced —both of which will positively impactthe owner’s bottom line.John Krantz is a Features Writer for TwoRivers Marketing.A tire with a low void-to-lug ratio in itscenter and a higher void-to-lug ratiotoward the shoulder can offer an operatorexcellent performance on both hard andsoft surfaces.August 2013 | <strong>Utility</strong> <strong>Contractor</strong> 29