Feature Story - Utility Contractor Magazine

Feature Story - Utility Contractor Magazine

Feature Story - Utility Contractor Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

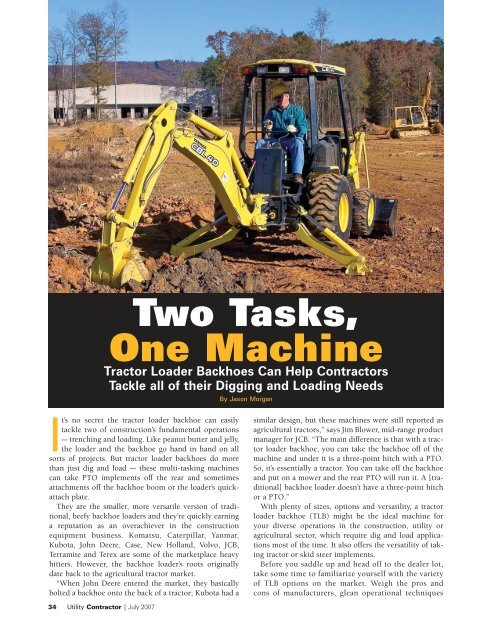

Two Tasks,One MachineTractor Loader Backhoes Can Help <strong>Contractor</strong>sTackle all of their Digging and Loading NeedsBy Jason MorganIt’s no secret the tractor loader backhoe can easilytackle two of construction’s fundamental operations— trenching and loading. Like peanut butter and jelly,the loader and the backhoe go hand in hand on allsorts of projects. But tractor loader backhoes do morethan just dig and load — these multi-tasking machinescan take PTO implements off the rear and sometimesattachments off the backhoe boom or the loader’s quickattachplate.They are the smaller, more versatile version of traditional,beefy backhoe loaders and they’re quickly earninga reputation as an overachiever in the constructionequipment business. Komatsu, Caterpillar, Yanmar,Kubota, John Deere, Case, New Holland, Volvo, JCB,Terramite and Terex are some of the marketplace heavyhitters. However, the backhoe loader’s roots originallydate back to the agricultural tractor market.“When John Deere entered the market, they basicallybolted a backhoe onto the back of a tractor; Kubota had asimilar design, but these machines were still reported asagricultural tractors,” says Jim Blower, mid-range productmanager for JCB. “The main difference is that with a tractorloader backhoe, you can take the backhoe off of themachine and under it is a three-point hitch with a PTO.So, it’s essentially a tractor. You can take off the backhoeand put on a mower and the rear PTO will run it. A [traditional]backhoe loader doesn’t have a three-point hitchor a PTO.”With plenty of sizes, options and versatility, a tractorloader backhoe (TLB) might be the ideal machine foryour diverse operations in the construction, utility oragricultural sector, which require dig and load applicationsmost of the time. It also offers the versatility of takingtractor or skid steer implements.Before you saddle up and head off to the dealer lot,take some time to familiarize yourself with the varietyof TLB options on the market. Weigh the pros andcons of manufacturers, glean operational techniques34 <strong>Utility</strong> <strong>Contractor</strong> | July 2007

When you climb into a tractor loader backhoe and swing the seat around to the backhoe position, take specialnotice of the boom. There are two types of boom configurations for TLBs today — curved and straight.aimed at improving efficiency and safety and find aversatile loader backhoe that can handle the complexityof projects that make your business so diverse andrewarding.Boom, Boom, BoomIf your piece of equipment is an extension of your owntwo hands, and the TLB’s loader is your right hand andthe backhoe is your left, you might be able to get awaywith calling yourself ambidextrous. The loader and thebackhoe are a great starting point for measuring yourmachine needs. We suggest climbing into the TLB andswinging the seat around to the backhoe position, takingspecial notice of the boom. There are two types of boomconfigurations for TLBs today — curved and straight.While John Deere, Caterpillar, New Holland, IngersollRand and Yanmar are set up on the curved boom end ofthe camp, Komatsu, JCB, Kubota and Terramite utilizestraight boom designs. In a nutshell, the argument is usuallythat curved booms might provide improved visibilityand easier truck loading. On the other hand, straightbooms utilize fewer welded plates to gain strength andtend to be less expensive machines.The curved boom craze began when backhoes startedto mirror the design of hydraulic excavators that employa curved design for added visibility beneath their booms.However, a TLB with a 10-ft dig depth isn’t going to bemoving mountains, so the curved vs. straight boomargument comes down to a matter of philosophy andpersonal opinion.“We could argue the pros and cons of straight andcurved booms all day. It basically came from manufacturerswho made big excavators. Big excavators have curvedbooms,” says Blower. “CAT came from making big excavatorsand they brought that design to the smallermachines. All JCB’s backhoes have straight boom.”As your eye travels down the length of the boom,you may find that the TLB has the option of a sideshiftingboom system, as opposed to a center-mountedboom, which is the standard in North America.A side-shifting boom is a backhoe boom that is set onrails, on which the boom can slide to the left or rightremotely. It’s a popular European technology. With theside-shifting mounting system, operators can pullthe TLB next to a house or wall, slide the boom overand dig right up against the obstruction. Just note thatside-shifting booms are fairly rare machines, but a fewmanufacturers, such as JCB, still manufacture smallside-shift machines.“Yanmar had such a system on its compact excavatorsin the 1960s, but with the advent of house swing andboom swing on excavators, side-shifting on excavators isno longer needed,” says Bill Gearhart, assistant marketingand product manager for Yanmar ConstructionEquipment. “Also, the cost of a side-shift backhoe isusually much higher than a center pivot backhoe.”Although uncommon, side-shifting backhoes can beuseful when traversing the jobsite. If you happen tobe operating a side-shifting backhoe and you’re workingon a cramped jobsite, slide the backhoe to one sideof the machine and then pivot the boom inward towardthe machine. By pulling the boom parallel to the backof the TLB, you minimize the boom’s overhang and theresult is a smoother, more compact ride.July 2007 | <strong>Utility</strong> <strong>Contractor</strong> 35

With spiky teeth and the load capacity of a construction-grade icecream scoop, the TLB's heavy-duty bucket is primed for someserious trenching action.Buckets of OptionsJust past the boom, something catches your eye.With spikey teeth and the load capacity of a construction-gradeice cream scoop, the TLB’s heavy-dutybucket is primed for some serious trenching action.Like their compact excavator brethren, TLB bucketscome in an array of sizes and options.“The bucket on a TLB is similar to, but different from,the one found on a compact excavator. Usually, the backhoeloader bucket is a heavy-duty design due to higherdigging forces. Of course, this depends greatly on who isdefining a compact excavator,” says Jeff Aubrey, backhoeloader product manager for Komatsu. “Eight-ton compactexcavators can use buckets much like those foundon tractor loader backhoes.”On a TLB the most common size bucket is a 12-in.But 8-, 18- and 24-in. buckets are also available so you canoutfit your backhoe for any job, big or small. Like compactexcavators, most TLBs feature a quick attachmentsystem as standard equipment, for swapping a heavy-dutybucket for a rock bucket, and many manufacturers offerauxiliary boom hydraulics for powering more demandingattachments such as hydraulic breakers, hydraulic thumbsand tilting buckets. But the majority of the time, you’regoing to have the standard heavy-duty bucket equippedand you’re going to be boom-deep into a trench.“When digging a trench, peel — don’t scoop. Use thedipper to strip layers of soil from the trench. This is36 <strong>Utility</strong> <strong>Contractor</strong> | July 2007faster and neater,” says Aubrey.“When repositioning the unit toextend the trench, lift the stabilizersand the loader bucket off the ground.Then lift and push with the backhoeto move the entire machine forward.There is no need to engage the transmissionor turn the seat. The operatorcan then use the backhoe tostraighten the machine on the trenchline.”Before you starting trenching, allTLB manufacturers agree that safetyshould be at the top of the list when itcomes to operation. As with any pieceof equipment, always be sure to readthe owner’s manual before hoppingonto the operator’s seat and wear yourseat belt when you are at the reins.Then phone your one-call servicesbefore moving a muscle.“Check with the utility companies tosee if there are any buried utilities inthe area where the operator will be digging,”says Curt Unger, general salesmanager for Yanmar ConstructionEquipment. “Never swing any loadabove another worker’s head. This isespecially true if you are swinging overa trench where someone is working.Be aware of the outriggers and watch them to be sure theydon’t cause a cave in into the trench.”Carrying the LoadAfter exploring the backhoe portion of your TLB, it’stime to concentrate on the bucket. There’s probably ahuge pile of dirt beside your trench after you tested yourdigging skills. At this point, a skid steer loader wouldcome by to collect the spoils. But you and your TLB arebig boys and you can clean up your own mess. Just returnyour backhoe to the full and up-right position, swingyour seat around and hit the material loading warpath.While the skid steer loader will fit in tighter work areas,the TLB can move more material faster on open range jobsites.The popular 24-in. bucket and simple load and drivecontrols make quick work of any loading job. The jobdetermining the size of the attachment or bucket is fairlystandard procedure in the attachment game. If you’reworking a construction site, oftentimes the building codeswill determine what bucket size the operator should use.For instance, if building footers need to be 18 in. wide, an18-in. bucket would be a perfect match. There are 12- and16-in. buckets that are also commonplace on a TLB, alongwith 4-in-1 buckets and grapple bucketsBasically, the loader bucket is controlled with one lever.Pull the lever back to raise the bucket, push it forward tolower it, left to curl the bucket and right to dump the contents(controls may vary). Depending on the manufactur-

er and options, there might be a second lever that operatesauxiliary hydraulics for a grapple or 4-in-1 bucket.If your loader duties call for moving material that isless pliable, such as a crates of bricks or stacks of lumber,more than likely, your backhoe loader is equipped with aquick attachment system that will let you swap yourbucket for a set of pallet forks. Typically, these quickattachsystems are compatible with skid steer attachments,but you’ll want to be careful as to which attachmentsyou slap on your TLB.“There are a couple things to look out for when equippinga skid steer attachment to a tractor. You have to considerwhat you are working with, how dense and howheavy it is. Determine the material’s weight by cubic footand then compare that number to what your tractor canhandle,” says Blower. “Sometimes operators will be movinglight material and they’ll put on a larger bucket. Thenthey’ll move heavy material with that same bucket withouteven thinking about it. It tends to happen more oftenin the north when operators move snow. They thinksnow is light, which it is when it falls from the sky, butwhen it sits around and freezes, it gets extremely heavy.”Although it isn’t really fair to compare the skid steer’ssupreme versatility with a TLB, these loader backhoes dohave tool carrying advantages.“With a TLB the operator sits up higher, so he has bettervisibility. The two machines [TLB and skid steer] arealso built differently. A skid steer loader is built on a rigid,one-piece frame with a small wheelbase and small tires. It gives a rougherride than a TLB,” says Unger.“Conventional steering wheels alsomake the TLB more popular in therental yards because many people arenot familiar with skid steer controls.”then use both the lift and bucket functions to fill thebucket. Finish, don’t start, with the bucket curl to get themaximum payload.”As the backhoe outriggers sink into the ground likelanding alien spacecraft from planet productivity and thebucket tears into the ground, it’s just a matter of timebefore you oscillate your seat and take hold of the loadercontrols to move the backhoe’s spoils. Just don’t get tooexcited when you are getting your work done in recordtime and forget about safety, proper machine operationsand the machine’s limitations. Although you may feel bigand mighty atop your TLB, remember that the TLB is stilla compact machine.“Don’t overwork the machine. These are still compactmachines with limitations. If you spend all day, every daydigging 10-ft trenches with a 10-ft machine, you mayneed a larger machine,” says Blower. “While 10-ftmachines can dig a trench that deep, that’s the maximum.10-ft machines were designed to dig 5- or 6-ft trenchesand then move on to a new operation.”A safe operator who is conscious of the machine’s limitationswill be a productive operator. Although thesehighly productive machines are ready to tackle two of themost common jobsite chores, keep in mind that the TLBisn’t a magic wand. But that might not stop the crew fromcalling you Merlin after you’ve dug a trench and made thedirt pile “magically disappear” in no time.Jason Morgan is assistant editor of <strong>Utility</strong> <strong>Contractor</strong>.Safety ChecksSafety should be in the forefront ofevery equipment operator’s mind.Aside from reading the owner’s manual,the operator needs to be aware of allpersonnel in his work area and wherethey are at all times. The machines cancover a lot of ground and handle ahuge work load quickly, but you don’twant to be too eager to swing aroundto the loader controls and get movingbefore you survey the area to makesure you aren’t going to mow downany of your working buddies.Check and double check the areawhen operating a TLB on any jobsite.When you’re faced with a mountainof material to load and move,“use the proper gear so you don’t spinthe tires or tax the engine excessivelyand stay in control,” says Aubrey.“Enter a pile with the bucket level,July 2007 | <strong>Utility</strong> <strong>Contractor</strong> 37