novaform GB - Frenzelit Sealing Systems, Inc.

novaform GB - Frenzelit Sealing Systems, Inc.

novaform GB - Frenzelit Sealing Systems, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

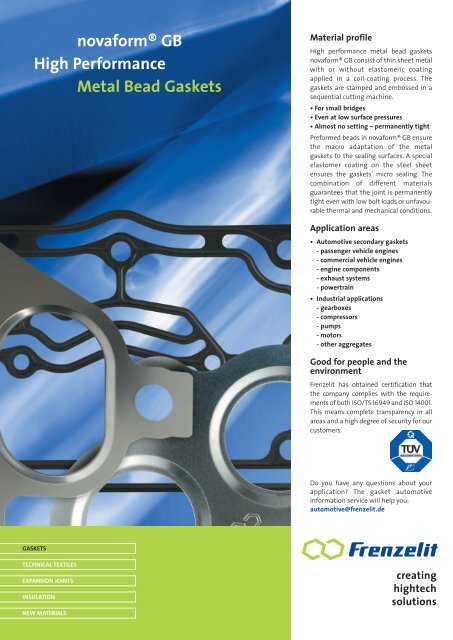

<strong>novaform</strong>® <strong>GB</strong>High PerformanceMetal Bead GasketsMaterial profileHigh performance metal bead gaskets<strong>novaform</strong>® <strong>GB</strong> consist of thin sheet metalwith or without elastomeric coatingapplied in a coil-coating process. Thegaskets are stamped and embossed in asequential cutting machine.• For small bridges• Even at low surface pressures• Almost no setting – permanently tightPreformed beads in <strong>novaform</strong>® <strong>GB</strong> ensurethe macro adaptation of the metalgaskets to the sealing surfaces. A specialelastomer coating on the steel sheetensures the gaskets' micro sealing. Thecombination of different materialsguarantees that the joint is permanentlytight even with low bolt loads or unfavourablethermal and mechanical conditions.Application areas• Automotive secondary gaskets- passenger vehicle engines- commercial vehicle engines- engine components- exhaust systems- powertrain• Industrial applications- gearboxes- compressors- pumps- motors- other aggregatesGood for people and theenvironment<strong>Frenzelit</strong> has obtained certification thatthe company complies with the requirementsof both ISO/TS 16949 and ISO 14001.This means complete transparency in allareas and a high degree of security for ourcustomers.Do you have any questions about yourapplication? The gasket automotiveinformation service will help you:automotive@frenzelit.deGASKETSTECHNICAL TEXTILESEXPANSION JOINTSINSULATIONNEW MATERIALS

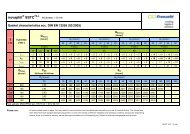

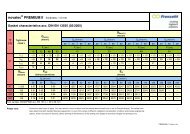

Technical information about <strong>novaform</strong>® <strong>GB</strong>DesignThe material consists of a steel sheet and an elastomercoating on both sides.Example<strong>novaform</strong>® <strong>GB</strong>S – bs NBR TYP 25/XXGeneral dataColourblackMaterial no 1.0330Anti-stick coatingstandard PTFE based coating on both sidesPhysical properties Standard Unit Value*Gasket thickness 0.33 mmThickness of base material [mm] 0.25Thickness tolerance B acc. DIN EN 10 140<strong>novaform</strong>® <strong>GB</strong>S-bs NBR TYP 25 / 50total thickness of coating [mm] 0.060 ± 0.010total thickness [mm] 0.37<strong>novaform</strong>® <strong>GB</strong>S-bs NBR TYP 25 / 35total thickness of coating [mm] 0.042 ± 0.007total thickness [mm] 0.33<strong>novaform</strong>® <strong>GB</strong>S-bs NBR TYP 25 / 25total thickness of coating [mm] 0.032 ± 0.007total thickness [mm] 0.31Tensile strength EN 10002 T1 [N/mm 2 ] 565 ± 75Temperature resistance <strong>Frenzelit</strong> 0110019 [°C] -25/+160(following the automotive specification)Chemical resistance ASTM F 146Engine Oil SAE 10 W 40 5 h / 150 °CChange in thickness [%] 1*Change in weight [%] 1*ASTM Fuel B 5 h / 23 °CChange in thickness [%] 10*Change in weight [%] 2*Water / Glycol (50:50) 5 h / 100 °CChange in thickness [%] 7*Change in weight [%] 2** Mode (typical value)Design possibilitiesBase materialMaterials Base materials Thicknesses<strong>novaform</strong>® <strong>GB</strong>S carbon steel 0.25 mm<strong>novaform</strong>® <strong>GB</strong>C stainless steel, rolled 0.20/0.25/0.30 mmto higher tensile strengthFurther base materials and thicknesses are available on request.CoatingsCoatingsMaterial profileThicknesses of coatingNBR 25 / 35 / 50 µm black, optional with greencovering colourFPM 20 / 30 µm with blue covering colouron one sideHTC 10 / 20 µm high-temperaturecoatingFurther thicknesses of coating and materials are available on request.• Cold rolled strip DC 01 C490 to DIN EN 10140, steel thickness0.25 mm• Steel sheet with highly oil and fuel resistant NBR coatingas well as anti-stick coating• To be used as cut gaskets and/or gaskets with beads• Available with half or full beads with a typical height of100 to 400 µm and a width of 1.5 to 2.5 mmEngineering and Service<strong>Frenzelit</strong> is specialised in manufacturing gaskets tospecification. With state-of-the-art technical systems athand, e.g. various CAD systems and a FEM simulation software,the required products can be adjusted to the exactrequirements of the applications in question. Prototypes fortesting purposes are manufactured in small lot sizes and atshort notice. In this way we are able to develop the bestpossible solutions for all kinds of flat gasket applications forand together with our customers.FL/3/09.06/01/FLAll previous versions of this prospectus cease to apply. Subject to technical amendment.GASKETSTECHNICAL TEXTILESEXPANSION JOINTSINSULATIONNEW MATERIALS<strong>Frenzelit</strong>-Werke GmbH & Co. KGP.O. Box 11 40 · 95456 Bad Berneck · GermanyPhone: +49 9273 72-0 · Fax: +49 9273 72-221info@frenzelit.de · www.frenzelit.com