novatec PREMIUM II - Frenzelit Sealing Systems, Inc.

novatec PREMIUM II - Frenzelit Sealing Systems, Inc.

novatec PREMIUM II - Frenzelit Sealing Systems, Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong>The standard gasket forindustrial applications.GASKETSTECHNICAL TEXTILESEXPANSION JOINTSINSULATIONNEW MATERIALS

Your wish …• Higher safety standards• Higher temperature resistance• Higher media resistance• All-purpose products• Maximum design reliability• Optimised adaptability• Better handling properties… is our command.• <strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> isthe standard gasket.• <strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> covers 80%of all industrial applications.Typical applications for <strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong>• All-purpose use in many areas of industryin general and the chemical industry in particular• Oils and greases, acids and alkalis, solvents,refrigerants, water, steam• Compliance with the German pollution regulations e.g. TA Luftin these areas:- Petrochemicals- Gerneral industry- Chemical industry- Plant engineering

Optimum benefitsthanks to a unique material compositionMedia-resistant at high temperatures<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> is the second generation of the proven<strong>novatec</strong>® <strong>PREMIUM</strong> range. The graphite – Kevlar® materialcombination guarantees an efficiency level that exceedsall standard fibre gaskets on the market. The large proportionof graphite combined with the small proportion ofbonding agent provides resistance to about 80% of all themedia used commonly for general industrial applicationsas well as in the chemical industry particularly.Excellent pressure resistance<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> has long-term resistance propertiesand guarantees constant reliability throughout the maintenancecycle. Pressure resistance is higher than with allconventional high-pressure gaskets. The long useful lifeextended maintenance intervals and can therefore berelied on to cut costs.Optimised adaptabilityDue to its material structure, <strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong>compensates for flange unevenness and roughness thatare found in old systems in particular.Unique release propertiesThe special process used to apply the release coatingincorporated in the blue colour makes the coatingconsiderably more effective than conventional fibregaskets, while the solvent-free formulation means itcontributes actively to protection of the environment.Tool-friendly processing<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> is simple and excellent to processbecause of the large proportion of graphite it contains.Better handling propertiesSince they are very flexible, even sheets 3.0 mm thick canbe shipped inexpensively in tubes. <strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong>proves to be extremely rugged when handled improperlyduring transport and installation.Single-piece gaskets of all sizes and thicknesses<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> is available in large formats and allnormal thicknesses. Special dimensions can be producedin a single piece without any complicated processingoperations.Kevlar® is a trademark registered by DuPont.

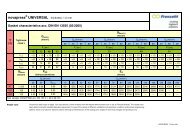

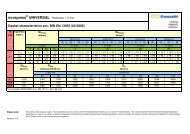

Technical informationabout <strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong>Specific leakage rateLeakage rate under the influence of temperatureSurface pressure (N/mm 2 ) Surface pressure (N/mm 2 )10090807060504030L 0,11010.1RT201000.010.001100°C200°C0 10 20 30 40 50 60 70 80 90 10010 15 20 25 30 35 40 45Internal pressure (bar)<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> remains well below the leakagelimits specified by DIN 3535.Leakage category: L = 0.1 mg/(s·m) · test gas: nitrogen · thickness: 2.0 mmLong-term creep relaxationLeakage rate (mg/(s·m))<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> is designed for minimum leakage.Microporosity under the influence of temperature and surfacepressure is reduced and the gasket material istransformed into a closed, homogeneous structure. Leakageat 200 °C is lower than the detection limit in mass flow ratemeasurement of 0.001 mg/(s•m).Surface pressure: σ = 30 N/mm 2 · specimen dimensions: 90 x 50 x 2 mmtest medium: N 2Deformation under temperature 2.0 mm50504846404442304020383610323000,1 1 10 16 100 1000 100000 10 20 30 40 50 40° 60° 80° 100° 120° 140° 160° 180° 200° 220° 240° 260° 280° 300°Time (hours)Change in thickness (%)N/mm 2at room temperatureInternal pressure (bar)Temperature (°C)at 50 N/mm 2 surface pressure<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> has very high long-term pressureresistance properties and thus provides constant reliabilitythroughout the maintenance cycle.Gasket dimensions: 75 x 55 x 1.5 mm · surface pressure: 48 - 50 N/mm 2test temperature: 300 °C · stiffness C: 840 kN/mmThe thickness of <strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> decreases to aparticularly small extent under the influence oftemperature. At 300 °C, thickness is only 5 % lower than atroom temperature.Recommendations for use according to the pressure and temperaturePressure (bar)120100806040200Water/steam Other media* The temperature and pressure recommendations in the graphs apply togaskets with a thickness of 2.0 mm and smooth flanges. Higher stresses are120possible when thinner gaskets are used!Saturated steam curve0 50 100 150 200 250Temperature (°C)Pressure (bar)100806040200-100 -50 0 50 100 150 200 250 300Temperature (°C)*Example for the most common other media. Exact data for specificindividual cases are available in the <strong>Frenzelit</strong> novaDISC programme orcontact our application engineering specialists.Warranty exclusionIn view of the variety of different installation and operation conditions andapplication and process engineering options, the information given in thisprospectus can only provide approximate guidance.There is as a result no basis for warranty claims.

Material dataMaterial profile• Very compact gasket material, pressureresistant,temperature-resistant andwith good forming properties• The main components are graphiteand aramide fibres, bonded with NBR.• State-of-the-art composite materialthat combines the advantages ofgraphite and aramide.Blow-out test passed easilyProof of the blow-out resistance of thegasket system is required in addition toleakage testing. According to VDI 2200(draft 06/2005), the gasket has to beable to withstand 1.5 times nominalpressure at very reduced surface pressurelevels. The gasket is fitted in a DIN flangeDN40/PN40 at 30N/mm 2 .After storage of the flange system at200 °C for 24 hours, nitrogen is appliedgradually at a pressure of up to a maximumof 60 bar. Pressure would dropvery rapidly if the gasket failed.The gasket is then tested at twoconsiderably reduced surface pressurelevels. If the test is passed at 10 N/mm 2 , afurther reduction is made to 7.5 N/mm 2 .Even in the most critical case of anextremely low surface pressure level of7.5 N/mm 2 and maximum pressure of 60bar, <strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> demonstratesits impressive blow-out resistance in linewith the German pollution regulations –without internal edging. We can providea certificate confirming this on request.General dataBindersNBRApprovals DVGW, KTW, WRAS, W 270, VP 401,BAM (max. 110 °C/130 bar), TA Luft, SVGWColourroyal blueAnti-stick coatingboth sides A 310 standardTolerances in thickness according to DIN 28 091-1Physical properties Standard Unity Value*Gasket thickness 2.0 mmIdentification DIN 28 091-2 FA - A 1 - ODensity DIN 28 090-2 [g/cm 3 ] 1.70Tensile strength DIN 52 910longitudinal [N/mm 2 ] 18transverse [N/mm 2 ] 14Residual stress σ dE/16 DIN 52 913175 °C [N/mm 2 ] 37300 °C [N/mm 2 ] 30Compressibility ASTM F 36 J [%] 7Recovery ASTM F 36 J [%] 60Cold compressibility ε KSW DIN 28 090-2 [%] 6Cold recovery ε KRW DIN 28 090-2 [%] 3Hot creep ε WSW/200 DIN 28 090-2 [%] 6Hot recovery ε WRW/200 DIN 28 090-2 [%] 2Recovery R DIN 28 090-2 [mm] 0.04Specific leakage rate DIN 3535-6 [mg/(s·m)] ≤ 0.1Specific leakage rate λ 2,0 DIN 28 090-2 [mg/(s·m)] ≤ 0.1Fluid resistance ASTM F 146ASTM IRM903 5h/150 °CWeight change [%] ≤ 10Thickness increase [%] ≤ 5ASTM Fuel B 5h/23 °CWeight change [%] ≤ 10Thickness increase [%] ≤ 5Chloride content FZT PV-001-133 [ppm] ≤ 50* Mode (typical value)Internal pressure (bar)60504030201000 5 10 15 20 25Time (min)Product data• Dimensions in mm: 1500 x 1500Thicknesses in mm: 0.5/0.8• Dimensions in mm: 2000 x 1500Thicknesses in mm: 1.0/1.5/2.0/3.0• Further dimensions andthicknesses are availableon requestDo you have any questions about your application?The gasket information service will help you:gaskets@frenzelit.de

Good for people and the environment.<strong>Frenzelit</strong> has obtained certification that the company complies with the requirementsof both ISO/TS 16949 and ISO 14001. This means complete transparency in ISO/TS 16949Quality managementall areas and a high degree of security for our customers.Environmental managementISO 14001German fugitive emission regulations with clear instructionsThe air pollution regulations that have applied in Germany since October2002 define and specify the commitments for operators of industrialequipment that requires approval.Clear rules are made there for flange connections. In this context, technicallytight flange connections have to be used in accordance with VDI 2440(issue 11/2000).<strong>novatec</strong>® <strong>PREMIUM</strong> <strong>II</strong> has been tested extensively at a temperature of 250 °Cat MPA Stuttgart and has been classified as a high-quality gasket inaccordance with the VDI directive 2440 for the German pollution regulations.The leakage rate of 2.3 · 10 -5 mbar · l/(s·m) is therefore substantially lowerthan the maximum acceptable limit of 10 -4 mbar · l/(s·m), which is measuredwith the help of a helium mass spectrometer at a surface pressure level of30 N/mm 2 and with pressure of 1 bar.FL/4/12.08/03/FL All previous versions of this prospectus cease to apply. Subject to technical amendment.GASKETSTECHNICAL TEXTILESEXPANSION JOINTSINSULATIONNEW MATERIALS<strong>Frenzelit</strong>-Werke GmbH & Co. KGP.O.Box 11 40 · 95456 Bad Berneck · GermanyPhone: +49 9273 72-0 · Fax: +49 9273 72-221info@frenzelit.de · www.frenzelit.com